– 9 –

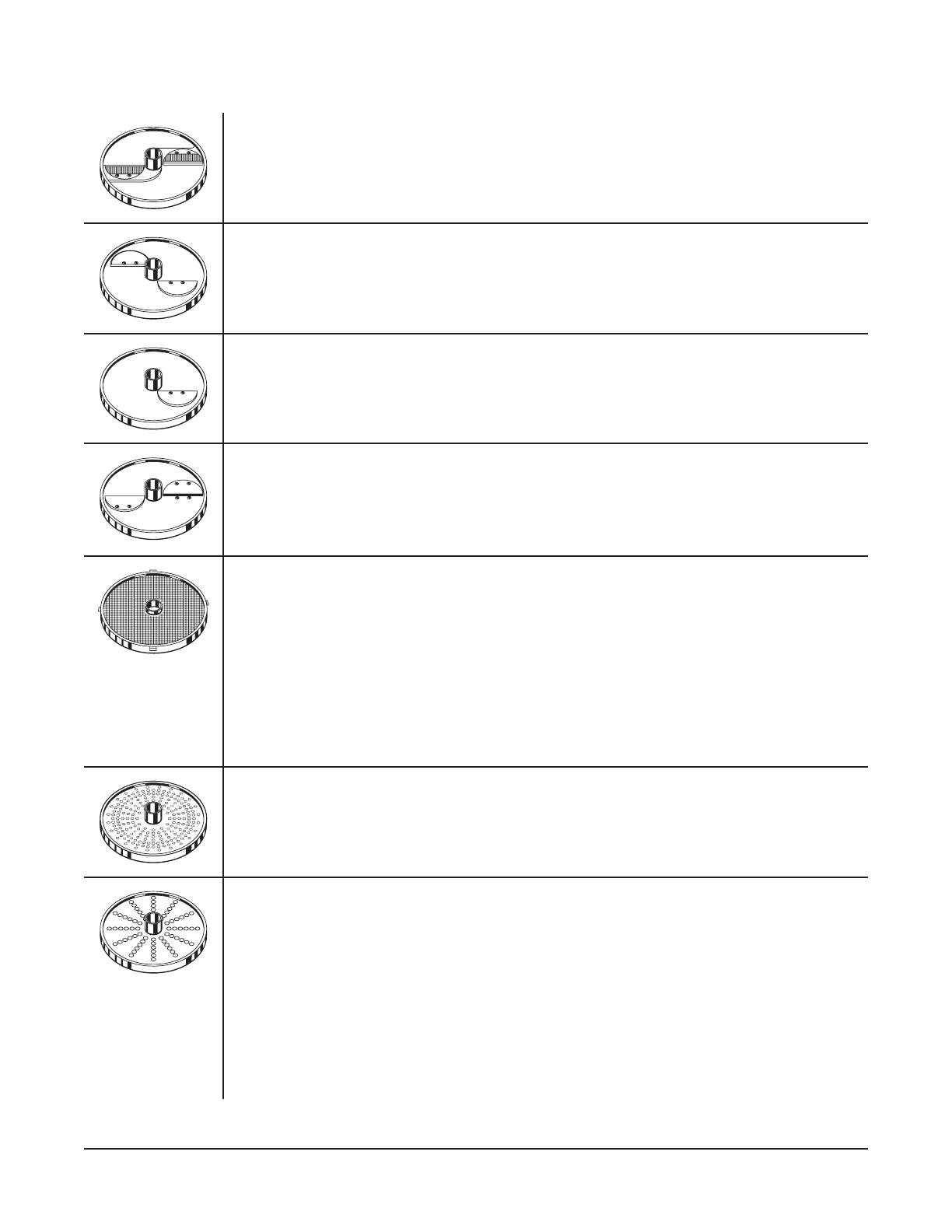

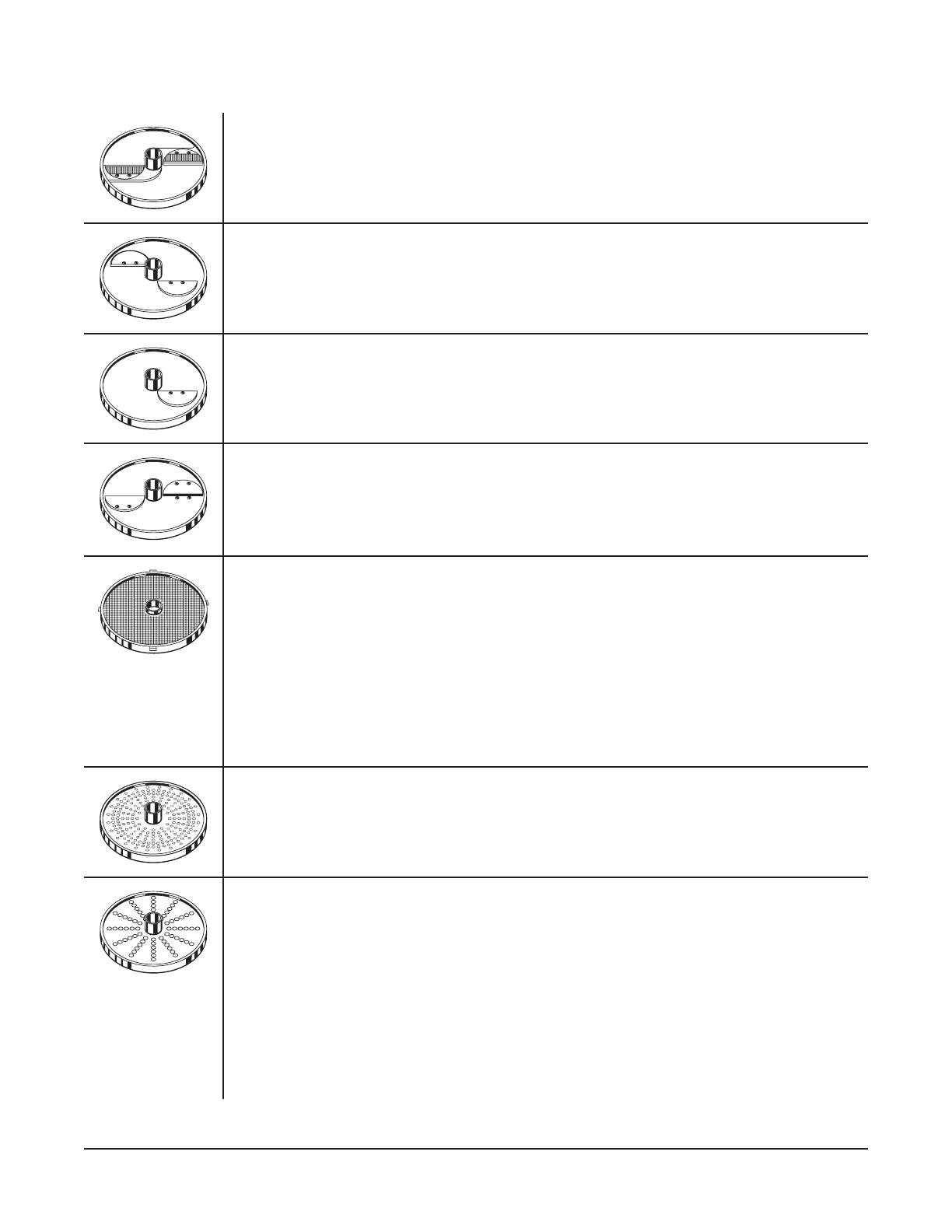

CUTTING TOOL GUIDE

Crimping Slicer — 3/16" (4.5 MM)

For ripple slicing of root vegetables.

Fine Slicer (2 Blade) — 1/16" (1.5 MM)

For slicing rm or fragile products. Also for use with 9/32" dicing plate. Makes very thin slices of

pepperoni, mushrooms, cabbage, potatoes, cucumbers and radishes.

Fine Slicer (1 Blade) — 5/32" (4 MM), 9/16" (14 MM), 1/8" (3 MM), 7/32" (6 MM), 3/8" (10 MM)

Use is same as 2-blade ne slicer. Also slices soft and/or juicy products such as tomato,

lemon and banana. Shreds lettuce. Dices in combination with 5/32" dicing grid. Chops onion in

combination with 3/8" dicing grid.

Julienne Cutter —

3/32" (2 MM) — Makes various salad toppings.

3/16" (4.5 MM) — Makes shoestring French fries.

5/16" (8 MM) — Makes French fries.

Dicing Grid — Dices in combination with dicing cutter or ne cut slicer. The dicer grid dimension

must be equal to, or larger than, the slicer dimension.

9/32" (7.5 MM) (use with 7/32" or smaller Slicer) — For thin diced vegetables (carrots,

celery, onions, potatoes and vegetables for soup).

3/8" (10 MM) (use with 3/8" or smaller Slicer) — Good for dicing rm chilled tomatoes.

3/4" (20 MM) (use only with 9/16" Slicer) — Prepares tomatoes, potatoes for home fries

or potato salad and dices apples or melon.

5/8" (15 MM) (use with 3/8" or smaller Slicer) — Dices tomatoes, apples, melon and other

fruits for salads, pies or other uses.

Grater — Fine

Makes grated Parmesan or Romano cheese (hard cheese only).

Shredder — Shredder plates are used to process cheese for toppings and salad bar items,

cabbage for coleslaw, potatoes for hash browns or potato pancakes.

1/16" (1.5 MM) — Makes extra ne shredded cheese for sandwich topping or other uses.

3/32" (2 MM) — Makes ne breadcrumbs and cracker crumbs for use in cooking. Use when

machine and product are dry.

1/8" (3 MM) — Medium shredder for various uses.

3/16" (4.5 MM) — Makes pizza toppings and salad bar items.

5/16" (8 MM) — Shreds cabbage and soft pizza cheese.

7/32" (6 MM) — Shreds carrot, dry bread, almonds, nuts, and soft pizza cheese.

A wall rack is available to hang the cutting tools for easy access of the operator and to protect sharpness of the blades.