Model Ultrefiner II - FMV - BNFP, Ultrefiner II - FMV - BNFV, Ultrefiner II - FMV - CHFP and Ultrefiner II - FMV -

CHFV are tested and certified by NSF International against NSF/ANSI standard 42, 58 and 401 for the reduction of claims

specified on the performance data sheet. Refer to the manufacturer’s Performance Data Sheet for the specific reduction

claims.

www.rainsoft.com

Part No.: 16778

Rev: P 02/2021

CUS

Not approved for use in California. Please request California-specific product literature from your local RainSoft Dealer.

Model Ultrefiner II - FMV - BNFP, Ultrefiner II - FMV - BNFV, Ultrefiner II - FMV - CHFP and Ultrefiner II - FMV -

CHFV are tested and certified by NSF International against to CSA B483.1 Standard.

Rainsoft Division of Aquion, Inc

101 S. Gary Ave

Roselle, Illinois 60172

1.847.437.9400 or 1.800.860.7638

www.rainsoft.com

This product is manufactured in an ISO 9001:2015 certified facility.

NSF/ANSI Standard 58 certified to reduce cysts such as Cryptosporidium and Giardia by mechanical means

EPA EST NO: 002623-IL-003

2

Table of Contents

Product Information .................................................................................... 3

Product Certification Information ............................................................ 4

Components Requiring Periodic Replacement ........................................ 4

Operational Specifications .......................................................................... 5

Items Required for Installation .................................................................. 6

Installation Location .................................................................................... 6

Installation Instructions ........................................................................ 7-11

System Start Up .................................................................................... 12-13

Routine System Maintenance.................................................................... 13

Periodic System Maintenance .................................................................. 13

How to Change the Filters ........................................................................ 14

RainSoft Replacement Part Numbers ...................................................... 14

Exploded View and Parts List.............................................................. 15-16

Troubleshooting Guide .............................................................................. 18

Performance Data Sheet ...................................................................... 19-22

Warranty Information................................................................................ 23

Installer Specification Sheet ...................................................................... 25

Congratulations on your purchase of one of the finest Drinking Water Systems available to homeowners.

This Owner’s Manual is designed to assist with the operation, maintenance, and installation of the Ultrefiner II System.

It is our sincere hope that this manual is clear, concise, and helpful to you as a new owner.

Questions? If you have any questions regarding the installation, operation or servicing of this system, please contact

your local RainSoft Dealer. Your RainSoft Dealer will be familiar with your particular situation, your water conditions,

etc. and should be able to address your concerns promptly and efficiently.

Product Information

Your RainSoft Ultrefiner II system provides several stages of treatment

to provide you with the best possible drinking water.

The components of the system are:

Pre-Filter

The pre-filter is a combination carbon/sediment filter. It removes most

suspended solids 10 microns or larger in size and also reduces incoming

chlorine levels.

Ultrefiner II Membrane Cartridge

The membrane cartridge consists of a semi-permeable membrane

wound in a spiral to fit a large membrane area into a compact diameter.

This membrane filters on a molecular level and reduces dissolved inor-

ganic solids in the water such as lead, chromium and copper. It will also

reduce cysts, such as cryptosporidium, which have been known to cause

outbreaks of gastrointestinal illness. Since the filtration process is so

fine, the system continuously flushes water across the surface of the

membrane while producing drinking water. The incoming water stream

is split, with some water passing through the membrane as treated water

while the water that flushes the membrane to keep it clean flows to the

drain.

Air Pressured Storage Tank

Since the water passes through the membrane too slowly to satisfy your

instantaneous demand for water, the system includes a storage tank.

This storage tank contains a rubber bladder and is similar to the tank on

a well system, but smaller. Water passing through the membrane

(“permeate”) is sent to one side of the bladder, while the other side is

pressurized with air (about 8 psi when empty of water). As the tank fills

with water, the air is compressed, providing the pressure needed to

dispense the water when your drinking water faucet is opened. A

hydraulic shutoff valve built into the filter housing assembly automati-

cally turns off flow through the system when the tank is full, and turns

the water back on as the tank is emptied.

Post-Filter

When the water leaves the storage tank on its way to the faucet, it passes

through a carbon block post-filter. This filter is specially formulated to

reduce volatile organic compounds (i.e. VOC’s), Chloramine and

Chlorine. See the performance data sheet for the specific VOC’s this

system is rated to reduce. VOCs include compounds such as benzene,

lindane, and trihalomethanes. The post-filter also serves as a "polishing

filter," the final step in removing any tastes or odors.

Putting it all together, your RainSoft Ultrefiner II system gives you

multiple lines of defense to protect the drinking water your family relies

on.

3

INLET

UNTREATED

WATER TO

SYSTEM

DRAIN TO

AIRGAP

OUTLET

TREATED

WATER TO

FAUCET

WATER

STORAGE TANK

POST-FILTER MEMBRANE PRE-FILTER

Figure 1

COUNTER

MOUNTED

FAUCET

5-10 psi AIR CHARGE

INLET TO SYSTEM

DRAIN TO AIRGAP

STORAGE TANK

POST−FILTER MEMBRANE PRE−FILTER

Figure 2

POST-FILTER MEMBRANE PRE-FILTER

UNTREATE

D WATER

IN

DRAIN

WATER OUT

PERMEATE WATER TO

STORAGE TANK

TREATED

WATER TO

FAUCET

4

Product Certification Information

Models Ultrefiner II - FMV - BNFP, Ultrefiner II - FMV - BNFV,

Ultrefiner II - FMV - CHFP and Ultrefiner II - FMV - CHFV conform to

NSF/ANSI 58, 42 and 401 for the specific performance claims as verified

and substantiated by test data. See performance data sheets for

specific reduction claims.

Models Ultrefiner II - FMV - BNFP, Ultrefiner II - FMV - BNFV,

Ultrefiner II - FMV - CHFP and Ultrefiner II - FMV - CHFV conform to

NSF/ANSI 58 for VOC reduction. See performance data sheets for

individual contaminants and reduction performance.

Models ULTREFINER II-FMV-BNFP, ULTREFINER II-FMV-BNFV,

ULTREFINER II-FMV-CHFP and ULTREFINER II-FMV-CHFV are

tested and certified by NSF International to CSA B483.1 Standard.

The compounds certified under NSF/ANSI 401 have been deemed as

“incidental contaminants/emerging compounds”. Incidental contami-

nants are those compounds that have been detected in drinking water

supplies at trace levels. While occurring at only trace levels, these

compounds can affect the public acceptance/perception of drinking water

quality.

CALIFORNIA RESIDENTS: Water treatment devices sold to retail

consumers in California, accompanied by certain health claims, must be

registered by California State Water Resources Control Board. The

product accompanied by this manual is not certified in the State of

California for the purpose of making health claims. Please ask your dealer

about California certified models.

Components Requiring Periodic

Replacement

Pre-filter

The pre-filter reduces chlorine and removes most particles and sediment

as small as 10 microns in size from the water supply. The pre-filter requires

periodic replacement every 12 months after installation. Your water

quality and water usage may affect this replacement schedule. Please refer

to the chart on page 14 for replacement part numbers.

Ultrefiner II Membrane Cartridge

The Ultrefiner II membrane cartridge is a spiral wound, semi-permeable

membrane that requires periodic replacement approximately every 24 to

36 months after installation. Your water quality and water usage may affect

this replacement schedule. A water test for TDS reduction is the best indi-

cator of membrane performance. Please refer to the chart on page 14 for

replacement part numbers.

Post-filter

The post-filter will remove unwanted tastes and odors from the water. The

post-filter requires periodic replacement every 12 months after installation

to maintain VOC and Chloramine reduction. Your water quality and

water usage may affect this replacement schedule. Please refer to the chart

on page 14 for replacement part numbers.

!

Important Note: This Ultrefiner II System

contains replaceable treatment components,

critical for the effective reduction of total

dissolved solids (TDS). The product water

should be tested periodically to verify that the

system is performing properly. See your local

RainSoft Dealer for details.

*

Operational Specifications

Working Pressure

40 psi _100 psi (275 kPa _689 kPa)

Operating Temperatures

50°F _100°F (10°C _38°C)

pH Range

2 _11

Maximum TDS Level

1400 parts per million (PPM)

Maximum Turbidity Influent Level

11 NTU (nephelometric turbidity units)

Maximum Hardness Level

5 grains per gallon (85ppm)

Capacity for VOC , Chloramine and Chlorine Reduction

225 gallons (850 liters)

Approximate Flow Rate @ 60psi:

0.94 gpm

Data Chart

Additional Specifications

• The inlet water should be free from iron, manganese, and sulfur.

• This system has been tested for the treatment of water containing

pentavalent arsenic (also known as AS (V), As (+5), or arsenate) at

concentrations of 0.30 mg/L or less. This system reduces pentavalent

arsenic, but may not remove other forms of arsenic. This system is to be

used on water containing a detectable free chlorine residual or on water

supplies that have been demonstrated to contain only pentavalent

arsenic. Treatment with chloramine (combined chlorine) is not suffi-

cient to ensure complete conversion of trivalent arsenic to pentavalent

arsenic. Please see the Arsenic Facts section of the performance data

sheets for further information.

• Do not use this product with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before or after the

system. Systems certified for cyst reduction may be used on disinfected

waters that may contain filterable cysts.

• This system must be installed in accordance with all applicable state

and local laws and regulations.

• This system must be installed in an area not affected by extreme heat,

cold or the elements. The selected installation area must be adequate for

easy service of all parts.

• This system is designed to treat cold water only. The installation must

be on a cold water supply.

5

!

Important Note:

If the hardness is greater than 5 grains, the

system will still perform properly, but the

longevity of the membrane may be affected.

The efficiency and recovery ratings are verified

by testing in accordance with NSF/ANSI Standard

58.

Efficiency rating means the percentage of the

influent water to the system that is available to

the user as reverse osmosis treated water under

operating conditions that approximate typical

daily usage.

Recovery rating means the percentage of the

influent water to the membrane portion of the

system that is available to the user as reverse

osmosis treated water when the system is oper-

ated without a storage tank or when the storage

tank is bypassed.

Model Faucet Model Daily

Production Rates

Efficiency

Rating*

Recovery

Rating*

ULTREFINER II -FMV

BNFP

24.22 gpd / (91.67

L/day) 27.16% 44.42%

BNFV

CHFP

CHFV

6

Items Required for Installation

Tools:

Drill, drill bits, Screwdriver, tube cutter, adjustable wrench, Phillips Offset

Screwdriver, and vinyl gloves .

Parts not included in package:

Inlet shut off valve, PTFE Thread Sealant Tape, 1/4 inch O.D. tubing,

additional 3/8 inch O.D. tubing and mounting screws.

Installation Location

For your convenience, the Ultrefiner II bracket assembly is designed to be

mounted on either side of the cabinet, with the tubing ports pointing to

the back.

Kitchen Sink Installation

• Systems being mounted under a kitchen sink require an air gap faucet.

See figure 3.

Wall Mount or Other

• Systems being mounted in different location than under a kitchen sink

can use a non air gap faucet with the drain line connecting to a separate

air gap device.

!

Important Notes:

The tubing used for installation must be of

food grade type. John Guest or Parker brand

tubing is recommended for their compatibility

with the fittings on your system.

STORAGE TANK

REVERSE OSMOSIS

MOUNTED

UNDER SINK

INLET VALVE

CONNECTED TO

COLD WATER LINE

Figure 3

1/2 " DRAIN LINE

FLOOR DRAIN

GAP−A−FLOW AIR GA

"Mr. Drain"

AIR GAP

STAND PIPE

FOR

WASHER,

DRAIN

STACK

AIR GAP - floor drain AIR GAP - Mr. Drain AIR GAP - Wall Mount

FAUCET WITH

AIR GAP

DRAIN

CONNECTION

FROM AIR GAP

FAUCET

ALL TUBING RUNS TO

BACK OF CABINET

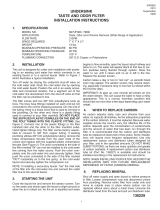

Installation Instructions

1. Install the Filters and Membrane Cartridge

• Wearing sterile gloves, remove the two filters and membrane from the

sterile packaging and place them in the appropriate housings.

• Secure filter housings by hand tightening Counter Clockwise (looking

from the top) to Ultrefiner II bracket(see figure 5).

7

Helpful Tip: Be careful not to contaminate the

filters and membrane by touching non-sterile

objects.

INSERT FILTE

R

ENSURE O−RING IS SEATED

IN FILTER HOUSING

CORRECTLY

HAND TIGHTEN

FILTER HOUSING

ONTO THE BRACKET

PLUG FILTERS INTO THE

BRACKET ASSEMBLY

INSURE FILTER HOUSING

HAS O−RING IN PLACE

PRE-FILTER

CARBON BLOCK

REVERSE OSMOSIS

MEMBRANE

POST-FILTER

CARBON BLOCK

WHITE

CAP

BLACK

CAP

Figure 4

Figure 5

2. Mount the System

Use screws (not supplied) to secure the Ultrefiner II bracket assembly to

the planned location.

8

10.0 in (25.4 cm)

4.7 in (11.9 cm) without cover

5.0 in (12.7 cm) with cover

7.0 in (17.8 cm) Mimimum required

from mounted wall for cover on / off

15.1 in (38.4 cm)

12.3 in (31.3 cm)

12.5 in (31.8 cm) with Cover

10.0 IN (25.4 CM)

3.5 IN (8.9CM) MINIMUM

DISTANCE REQUIRED ABOVE THE

ULTREFINER II UNIT

13.0 IN (33.0 CM) MINIMUM

DISTANCE REQUIRED BELOW

THE MOUNTING HOLES

USING PHILIPS OFFSET

SCREWDRIVER

TO SECURE THE ULTREFINER II

Helpful Tip: The proper drill bit should be

selected according to the type of material at the

desired installation location.

Figure 6

Figure 7

3. Push-IN Tubing Connections:

For all tubing connections on the system, follow these steps to be sure that

the tube is properly installed in the fitting:

•Slightly lubricate the tube with silicone before pushing into the fitting.

•It is important that the tube be fully inserted to the proper depth. You

may measure from the end of the tube & use a marker to put a line as a

guide.

•See figure 8 for proper installation practice & depth on each connection.

!

Important Note: Ultrefiner II tank port and

outlet port use double o-rings. If you see a leak

from one of these ports, remove the tube and

look into the port to see that both o-rings are

properly aligned, leaving a clear path for the

tubing. If one of the o-rings is moved out of posi-

tion, it may block tube insertion. Please push it

back into position before inserting the tube.

9

4. Install the Faucet

• Select a location for the faucet to be mounted.

• Drill a hole according to the manufacturer’s recommendations.

• Mount the faucet per instructions.

• If using faucet air gap, press drain line tubing onto faucet.

• Use 3/8 inch tubing (not supplied) to connect the faucet to the system

outlet. Make sure the flow restrictor is installed in the 3/8 inch tubing

(not supplied) connected to the outlet of the Ultrefiner II system.

5. Install the Inlet Shut Off Valve (Not Supplied)

• Turn off the cold water supply and open the cold water faucet to relieve

any line pressure;

• Install an inlet shut off valve (not supplied) between the existing shut

off valve and the kitchen faucet, in a way that conforms to state and

local plumbing codes;

• Use 1/4 inch tubing (not supplied) to connect the inlet shut off valve to

the system inlet.

6. Install the Storage Tank

• Before installation of the storage tank, unscrew the cap on the air valve

(located on the bottom of the tank) and check the air charge in the tank

to ensure that it has 5-7 psi of pressure;

• Select a location for the storage tank. The storage tank can be installed

vertically or horizontally;

• Wrap PTFE Thread Sealant Tape (not supplied) around the threads

of storage tank ;

• Install the shut off valve (supplied) onto the storage tank. The shut off

valve must be in the open position;

• Use the 3/8 inch x 4 foot tubing (supplied) to connect the storage tank

shut off valve to the tank port on the Ultrefiner II Bracket. Additional

tubing may be required pending tank location to location of

Ultrefiner-II Bracket.

Helpful Tip: If the desired installation location is

in the basement, the storage tank can be

mounted in between the floor joists. The closer

the storage tank is to the Ultrefiner II bracket

assembly, the greater the flow of water.

The storage tank can be installed vertically or

horizontally.

!

Important Note: The inlet shut off valve must

have a 1/4 inch tube connection.

PUSH TUBE STRAIGHT PUSH TUBE STRAIGHT

PAST O−RING TILL PAST O−RING TILL

TUBE STOPSTUBE STOPS

TUBE CORRECTLY TUBE CORRECTLY

LOCATED LOCATED

IN SECURED IN SECURED

POSITIONPOSITION

PUSH IN COLLET PUSH IN COLLET

TO RELEASE TUBETO RELEASE TUBE

A

Helpful Tip: To secure the connection, wet the

end of the tubing and press the tubing firmly into

cartridge.

Figure 8

TUBING CONNECTION PORT TUBE INSERTION DISTANCE(A)

UF II INLET - 1/4" TUBE 3/4"

UF II DRAIN - 1/4" TUBE 3/4"

UFII TANK - 3/8" TUBE -DOUBLE O-RING 1"

UF II OUTLET - 3/8" TUBE -DOUBLE O-RING 15/16"

STORAGE TANK JG - 3/8" TUBE 3/4"

FAUCET FITTING - 3/8" TUBE 3/4"

Helpful Tip: Although the tanks are shipped with

a 5-7 psi pre-charge, environmental conditions

such as temperature and altitude can have an

effect on the pressure inside the tank and may

need to be adjusted.

Depending on location, additional air can be

added to help deliver water to locations further

away from the system.

Adding air to the tank beyond the 7 psi charge

will decrease the volume of water that the tank

can hold. It is recommended not to exceed 15psi.

For installations where the reverse osmosis water

is being fed to ice makers and refrigerators with

indoor water dispensers that require higher pres-

sures for proper function, the addition of a vari-

able speed delivery pump is recommended.

7.Connect the Drain Outlet

Use 1/4 inch tubing (not supplied) to connect the drain outlet to the

appropriate drain connection.

8. Secure the Connections

Attach the red locking clips (supplied) to the connection fittings.

10

USE RELEASEABLE

STRAPS TO BAND

TOGETHER TUBING

USE RELEASABLE

STRAP TO BAND

TUBING TOGETHER

Figure 10

Wrap PTFE Thread

Sealant Tape Around

3/8-NPT Tank Thread

Figure 9

!

Important Note: The drain connection must

conform to state and local plumbing codes.

If the system is mounted under a kitchen sink,

an air gap faucet will be required. If the

system is mounted in a different location, a

non-air gap faucet may be used, along with a

separate air gap device on the drain line.

9. After SYSTEM START UP

Because the Ultrefiner II bracket assembly and cover are reversible, the

cover is designed with removable side panels for tube routing. Choose

the correct side panel to remove based on the installation.

• Remove the side panel by cutting with knife or clippers.

• Place cover onto Ultrefiner II and ensure tubing is correctly secure to

the one side of the Ultrefiner II bracket assembly.

11

Figure 11

REMOVE PANEL USING KNIFE OR CLIPPERS

12

System Start Up

1. Turn on the Water Supply

Allow the system to start filling with water.

2. Fast Flush the System

Open the Ultrefiner II faucet and turn the drain barrel to the fast flush

(“F” on the drain barrel)position (see figure 12).

3. Reposition the Drain Barrel

Once the air has been purged from the system, position the drain

barrel in #2 service position(see figure 13). The storage tank will

continue to fill with water.

The drain barrel must always be positioned with the arrow pointing at

numbers 1 – 4 or “F.” In each location, a hole of fixed size is positioned

internally over the drain connection, controlling the flow rate for that

setting. Do not position the drain barrel between settings, as this does

not provide any fine tuning and may even block drain flow by putting an

internal seal directly over the drain connection.

Position “0” shuts off drain flow. The system should never be left in

position “0,” as this will cause the membrane to foul. This position is

provided only as a diagnostic tool.

4. Check for Leaks

If a leak is present, make the necessary repairs.

5. Fill the System

When the water stops flowing to the drain, the system should be fully

pressurized and the storage tank should be filled with water.

6. Drain the Storage Tank

Open the Ultrefiner II faucet and drain all the water from the storage

tank.

!

Important Note: It is common to experience

cloudy water, cloudy or hazy ice cubes and/or

air bubbles when the system is new or after the

filters/cartridges have been changed. This is

simply due to air trapped in the system which

will soon dissipate.

Helpful Tips: Maintaining a fresh water supply

in the storage tank will promote better opera-

tion of the membrane cartridge.

When you go on vacation, close the cold water

inlet valve. When you return from vacation,

open the cold water inlet valve, drain the

storage tank and fast flush the system.

!

Important Note: This procedure will flush any

remaining residue from the storage tank.

!

Important Note: The 24 hour flush will ensure

the proper rinsing of the Ultrefiner II

Membrane.

Figure 12

Figure 13

Helpful Tips: In both the fast flush and # 2 posi-

tion, the ears of the drain barrel are aligned with

the mounting screws. To make it easier to iden-

tify positions, there is a raised rib at the “F” posi-

tion. (See Figure 13)

!

Important Note: NSF certified performance data,

as shown on the Performance Data Sheet, is

based on operation at Drain Setting # 2.

Certification results do not apply to other

settings.

13

7. Complete the Installation

• If a 24 hour-flush pre-installation is not performed by your local

dealer, it is important to open the faucet and let the system run to

drain or 24 hours first.

• After the 24 hour water flush , close the Ultrefiner II faucet and allow

the storage tank to fill with water. When the storage tank is full, the

system will be ready for operation.

Routine System Maintenance

If the incoming water to your Ultrefiner II system is very poor (for

example: high hardness, high dissolved solids, high iron), you can help

maintain the system's operation by periodically performing this

flushing procedure:

Drain Your Storage Tank

Open the Ultrefiner II faucet and let the water run until the flow turns

into small drips. Close the Ultrefiner II faucet. The Drain flow will

continue to run until your tank has been refilled.

Flush the Membrane And Drain Line

While refilling your storage tank, turn the Drain Dial to the F position.

(See Figure 12 on Page 11.) This will increase the volume of drain

water flushing through the membrane. Once your tank has refilled

(typically 2 -3 hours), the Drain flow will shut off. You should then

turn the Drain Dial back to its previous setting.

Periodic System Maintenance and

Testing of Your Water

Nitrate Reduction

If you are relying on this system for nitrate reduction, we recommend

testing your water periodically (2 times a year minimum) with a

nitrate test kit (supplied) to ensure that the system is performing

properly.

Additional nitrate test kits (part number 12061) can be purchased

from your local RainSoft Dealer.

VOC/Chloramine Reduction

If you are relying on this system for VOC/ Chloramine reduction, we

recommend testing your water periodically (2 times a year minimum)

to ensure that the system is performing properly. Your local RainSoft

Dealer can arrange this testing for a nominal fee.

Cyst Reduction

If you are relying on this system for cyst reduction, we recommend

testing your water periodically (2 times a year minimum) to ensure

that the system is performing properly. Your local RainSoft Dealer can

arrange this testing for a nominal fee.

Other Health Reduction Claims

If you are relying on this system for any other health claims, please

refer to the performance data sheets on pages 17 thru 19. See your

local RainSoft Dealer for additional information.

!

Important Notes: Nitrate reduction units are

acceptable for treatment of influent

concentrations of no more than 27 ppm nitrate

and 3 ppm nitrite in combination (measures as

“N”) and are certified for nitrate/nitrite reduction

only for water supplies with a pressure of 40 psi

or greater.

14

Helpful Tips: To avoid contamination, we

recommend the use of sterile gloves while

changing the system components.

When changing the membrane cartridge,

verify that the rubber brine seal and O-rings

are secure and in place. Always lubricate the o-

rings with a NON-PETROLEUM based lubricant

to ensure the longevity of the o-rings. Never

over-tighten the housing to the cap _HAND

TIGHT ONLY!

!

Important Note: It is important to maintain

the quality of your system by using only

genuine RainSoft replacement filters and

cartridges. Other “made-to-fit” alternative

filters and cartridges claim to perform the

same duties as the original RainSoft parts, but

these items are not approved for use in your

system! “Made-to-fit” alternative filters and

cartridges will increase the probability of

leaks, putting your entire system at risk! Also,

many aftermarket replacement filters are not

tested for safe contact with drinking water.

When “made-to-fit” alternative filters and

cartridges are placed into your RainSoft

Ultrefiner II Premium Drinking Water System,

the product warranty will become null and

void and the system will lose its NSF certifica-

tion. To guarantee proper operation and certi-

fication of your RainSoft Ultrefiner II Premium

Drinking Water System, please use genuine

RainSoft parts.

How to Change the Filters

1. Turn off the cold water supply to the Ultrefiner II system.

2. Close the storage tank shut-off valve and then open the Ultrefiner II

faucet.

3. Place a drip pan or bucket if necessary to catch the water from the

filter canisters to prevent spillage.

4. To replace the filters, use a Slim Line Spanner Wrench (not supplied)

to unscrew the filter housings from the cap (see figures 14).

5. Replace the filters and reassemble (see helpful hints).

6. Once assembled, turn the drain barrel to F position. (see figure 12 on

page 11).

7. Turn on the inlet water to the Ultrefiner II system.

8. Open the storage tank valve and Ultrefiner II faucet. Allow the water

system to flush for 15 minutes.

9. Turn the Drain Barrel back to predetermined number setting

and turn off the faucet and allow a minimum of 2 hours for the tank

to fill up. If you have replaced the membrane, please open the faucet

after 2 hours to drain the first tank of water. This will properly flush

the membrane.

RainSoft Filter and Membrane

Replacements

The following RainSoft replacement parts are available through your

local RainSoft Dealer:

If you are unable to order replacement parts from your local RainSoft

Dealer, please contact RainSoft at 1-800-860-7638 for assistance.

Model Pre-filter Membrane

Cartridge Post-filter

ULTREFINER II-FMV 51635 51637 51636

Figure 14

!

Important Note: When Unscrewing Filter

Housings use of Slim Line Spanner Wrench is

required. Unscrewing filter housings with use

of other unapproved tools can damage the

filter housings and void warranty.

!

Important Note: It is recommended that the

sump o-rings be replaced on each filter change

to insure proper compression of the o-ring,

failure to do so may result in over tightening of

the sump to create a seal and can cause undue

stress on the sump and cap that can lead to

cracking of these components under pressure.

15

3

11

12

8

4

5

9

10

21

10

10

64

5

15

16

17

18

27

28

26

22

31

9

2

20

19

6

9

14

1

7

13

29

24

25

23

30

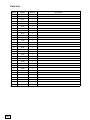

Ultrefiner II System Exploded View and Parts List

16

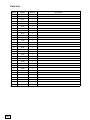

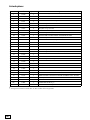

Parts List

Item # PART # Quantity Description

1 51570 1 UF II UNIBODY 1/4 DRAIN & 3/8 TANK ASSEMBLY

2 51571 1 UF II SUMP CAP 1/4 INLET PRE ASSEMBLY

3 51572 1 UF II SUMP CAP 3/8 OUTLET POST ASSEMBLY

4 51561 2 UF II WASHER UNIBODY

5 19914 2 O-RING -013

6 19621 2 3/8 O-RING

7 71497 4 SCREW #10-16 x 1in (15-222)

8 51567 6 SCREW 8-16 X 3/4 SS PAN HEAD

9 12994 3 237 O-RING -9516

10 51605 3 UF II SUMP, SLIM LINE GRAY SPECKLES

11 12632 1 029 O-RING

12 17360 1 UNIBODY DRAIN SHUT OFF CARTRIDGE

13 19899 1 UF II SHUT-OFF CAP

14 19897 1 UF II DRAIN BARREL

15 10102 1 DRAIN VALVE RETAINER

16 51630 1 O-RING 2MM X 16MM EPR 70 D

17 17958 1 015 O-RING

18 19898 1 UF II DRAIN BARREL FACE SEAL

19 71961 1 RESTRICTOR BALL

20 51562 1 O-RING 008

21 51560 1 UF II CHECK BALL PLUG

22* 51631 1 BEADED TIE RELEASEABLE BLACK

23 51741 1 UF II COVER 3 UP ASSEMBLY SILVER

24 17034 1 3/8 TUBE x 1/4” NPT BALL VALVE

25 51640 1 UF II STORAGE TANK ASSEMBLY

26 51635 1 REPLACEMENT UF II PRE CARBON FILTER / BLACK

27 51636 1 REPLACEMENT UF II POST CARBON FILTER VOC / WHITE

28 51637 1 REPLACEMENT UF II 50 GPD MEMBRANE

29 * 51614 1 UF II 1.0 GPM FLOW CONTROL

30 * 19005 3 LOCKING CLIP 3/8in

31 * 19006 2 LOCKING CLIP 1/4in

* You can find item #22, 29, 30 and 31 in the warranty package.

17

Hole Dimension

with use of air gap

Min Ø

15

16

"

Max Ø 1

"

1

2

Air Gap OUT

3

8

" Tube

to Drain Connection

Air Gap IN

1

4

" Tube to UF II

Drain Connection

Product Water

IN with

3

8

" Tube

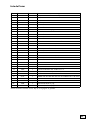

Item # QTY Aquion Part Description

1 1

51609 CONTEMP PLUS B-NICKEL FAUCET ASSY

( INCLUDES ITEM # 2)

51624 CONTEMP PLUS CHROME FAUCET ASSY

( INCLUDES ITEM # 2)

51616 CONTEMPORARY FAUCET B-NICKEL ASSY

( INCLUDES ITEM # 2)

51603 CONTEMPORARY FAUCET CHROME ASSY

( INCLUDES ITEM # 2)

2 1 51617 FAUCET FITTING 3/8 X 7/16-24 UNS O-RING *

* This item is included in the faucet assembly, but may be purchased separately.

18

Troubleshooting Guide

Symptom Cause Solution

No Water Running

from Outlet

1. Water Supply Is Turned Off. 1. Turn on the Water.

2. Water Supply Is Blocked 2. Clear Blockage. If this does not work

Blockage could be internal to the Ultrefiner II

or external with the water line. Contact your

Rainsoft Dealer for issues with the Ultrefiner

3. Membrane cartridge is Fouled 3. Replace Membrane - Contact your Rainsoft

Dealer for New Membrane.

4. Incoming water line is crimped or

pinched off.

4. Check incoming line and verify no crimps in

line. Remove any pinch points.

Extremely low Water

pressure from outlet

or faucet.

1. Storage Tank is not collecting water. 1. Ensure Storage Tank Ball Valve is turned to

the Open position.

2.Water Line from Storage tank or from

Outlet to Faucet is crimped.

2. Remove Crimp from line and verify no line

damage.

3. Storage Tank air pressure has leaked

or has lost pressure.

3. Recharge Air Valve using Bike pump to 8 psi.

If water pressure is restored, contact Rainsoft

Dealer to explain issue. New Storage tank may

be required.

4. Water passage inside Ultrefiner II

Unit has blockage.

4. Contact your Rainsoft Dealer for required

service.

Drain Water not shut-

ting off after 2 to 3

hours of running.

1. Faucet or other connection on system

outlet (such as ice maker) is not shut off

and is not allowing enough back pres-

sure to shut off the diaphragm .

1. Ensure all outlet connections are closed

completely.

2. Drain shutoff cartridge has failed. 2. Contact your Rainsoft Dealer for required

service.

3. Check Ball is leaking. 3. Contact your Rainsoft Dealer for required

service.

If the troubleshooting guide did not resolve the symptom, please contact your local RainSoft Dealer for service. If

you cannot locate your local RainSoft Dealer, please contact RainSoft Customer Service at 1-800-860-7638 or log

onto www.rainsoft.com for the name and location of your nearest Dealer.

• AUTOMATIC DRAIN SHUT-OFF VALVE • pH RANGE: 2 - 11

• MANUAL FAST FLUSH VALVE • REPLACEMENT FILTERS:

• DAILY PRODUCTION RATE = 24.22 GPD DESCRIPTION ITEM#

• EFFICIENCY RATING3= 27.16% PRE FILTER 51635

• RECOVERY RATING4= 44.42% MEMBRANE 51637

• MAX TDS LEVEL (PPM) = 1400 POST VOC FILTER 51636

• CAPACITY FOR VOC REDUCTION: 225 GALLONS

• CAPACITY FOR CHLORAMINE, CHLORINE, TASTE & ODOR: 225 GALLONS

• OPERATING PSI OF SUPPLY: 40 - 100 PSI (275 - 689 kPa)

• OPERATING TEMPERATURE: 50 - 100oF (10 - 38oC)

• FLOWRATE FOR POST FILTER: 1.0 GPM

PERFORMANCE DATA SHEET - page 1 of 4

Ultrefiner II - FMV

PREMIUM DRINKING WATER SYSTEM

THE UNIT SHOULD BE INSTALLED IN AN AREA NOT AFFECTED BY

EXTREME HEAT, COLD, OR THE ELEMENTS. THIS SYSTEM MUST BE

INSTALLED IN ACCORDANCE WITH ALL APPLICABLE STATE AND LOCAL

LAWS AND REGULATIONS.

DO NOT USE WITH WATER THAT IS MICROBIOLOGICALLY UNSAFE OR

OF UNKNOWN QUALITY WITHOUT ADEQUATE DISINFECTION BEFORE

OR AFTER THE SYSTEM. SYSTEMS CERTIFIED FOR CYST REDUCTION

MAY BE USED ON DISINFECTED WATER THAT MAY CONTAIN FILTER-

ABLE CYSTS. THE SYSTEM CONTAINS REPLACEMENT COMPONENTS

CRITICAL FOR EFFECTIVE REDUCTION OF contaminant. THE WATER

SHOULD BE TESTED PERIODICALLY (2 TIMES A YEAR MINIMUM) TO

VERIFY THAT THE SYSTEM IS PERFORMING SATISFACTORILY.

REPLACE ULTREFINER II - FMV MEMBRANE CARTRIDGE 24 TO 36

MONTHS AFTER INSTALLATION, DEPENDING ON WATER CONDITIONS.

A WATER TEST FOR TDS REDUCTION IS THE BEST INDICATOR OF

MEMBRANE PERFORMANCE. REPLACE THE PREFILTER AND POST FIL-

TER CARTRIDGES 12 MONTHS AFTER INSTALLATION OR SOONER

DEPENDING ON WATER CONDITIONS.

THE INLET FEED WATER SHOULD BE FREE FROM IRON, MANGANESE,

SULFUR.

NSF CERTIFIED PERFORMANCE DATA, AS SHOWN ON THE

PERFORMANCE DATA SHEET, IS BASED ON OPERATION AT DRAIN

SETTING # 2. CERTIFICATION RESULTS DO NOT APPLY TO OTHER

SETTINGS.

WHILE TESTING WAS PERFORMED UNDER STANDARD LABORATORY

CONDITIONS, ACTUAL PERFORMANCE MAY VARY DUE TO LOCAL

WATER CONDITIONS.

SEE WARRANTY CARD FOR SPECIFIC WARRANTY INFORMATION

NOT APPROVED FOR USE IN CALIFORNIA. PLEASE REQUEST

CALIFORNIA-SPECIFIC LITERATURE FROM YOUR LOCAL RAIN-

SOFT DEALER.

IMPORTANT NOTICE:

READ THIS PERFORMANCE DATA SHEET AND COMPARE

THE CAPABILITIES OF THIS UNIT WITH YOUR ACTUAL

WATER TREATMENT NEEDS. IT IS RECOMMENDED THAT

BEFORE PURCHASING A WATER TREATMENT UNIT, YOU

HAVE YOUR WATER SUPPLY TESTED TO DETERMINE

YOUR ACTUAL WATER TREATMENT NEEDS.

CUS

Model ULTREFINER II - FMV - BNFP, ULTRE-

FINER II - FMV - BNFV, ULTREFINER II - FMV -

CHFP and ULTREFINER II - FMV - CHFV are

tested and certified by NSF International

against NSF/ANSI 42, 58 & 401 for the reduc-

tion of claims specified on the performance

data sheet

This system has been tested according to NSF/ANSI 58 for reduction of the

substances listed below. The concentration of the indicated substances in

water entering the system was reduced to a concentration less than or

equal to the permissible limit for water leaving the system, as specified in

NSF/ANSI 58.

Model ULTREFINER II - FMV - BNFP, ULTRE-

FINER II - FMV - BNFV, ULTREFINER II - FMV

- CHFP and ULTREFINER II - FMV - CHFV are

tested and certified by NSF International to

CSA B483.1 standard.

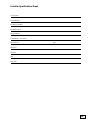

LIST OF contaminant

CONTAMINANT

AVERAGE

INFLUENT

CONCENTRATION

(mg/L)

AVERAGE

EFFLUENT

CONCENTRATION

(mg/L)

AVERAGE

PERCENT

REDUCTION

MAXIMUM

EFFLUENT

CONCENTRATION

(mg/L)

ARSENIC10.31 0.003 99 0.006

BARIUM 9.4 0.11 98.8 0.47

CADMIUM 0.031 0.0005 98.3 0.0019

CHROMIUM

(HEXAVALENT) 0.31 0.003 99 0.006

CHROMIUM

(TRIVALENT) 9.4 0.11 98.8 0.47

COPPER 3.0 0.049 98.4 0.15

CYST 130000 7 >99.99 19

NITRATE/NITRITE 232 7.5 76.2 11

FLUORIDE 9.2 0.6 93.8 1.2

LEAD 0.031 0.0005 98.3 0.0019

RADIUM 226/228 25 pCi/L 5 pCi/L 75 5 pCi/L

SELENIUM 9.2 0.6 93.8 1.2

TDS 760 51 93.3 60

TURBIDITY 11 NTU 0.2 NTU 98.7 0.4 NTU

NSF/ANSI STANDARD 58 TEST CONDITION: 50 ± 3 psi, pH 7.5 ± 0.5, 77 ± 2 ºF

NSF/ANSI STANDARD 58 CERTIFIED TO REDUCE CYSTS SUCH AS

CRYPTOSPORIDIUM AND GIARDIA BY MECHANICAL MEANS

EPA EST NO: 002623-IL-003

20

PERFORMANCE DATA SHEET - page 2 of 4

Ultrefiner II - FMV

PREMIUM DRINKING WATER SYSTEM

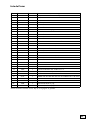

CONTAMINANT INFLUENT CHALLENGE

CONCENTRATION

mg/L

MAXIMUM PERMISSIBLE

PRODUCT WATER

CONCENTRATION mg/L

USEPA

MCL (MG/L)

ALACHLOR 0.050 0.001 0.002

ATRAZINE 0.100 0.003 0.003

BENZENE 0.081 0.001 0.005

CARBOFURAN 0.190 0.001 0.04

CARBON TETRACHLORIDE 0.078 0.0018 0.005

CHLOROBENZENE 0.077 0.001 0.1

CHLOROPICRIN 0.015 0.0002 --------

2,4-D 0.110 0.0017 0.07

DIBROMOCHLOROPROPANE (DBCP) 0.052 0.00002 0.0002

O-DICHLOROBENZENE 0.080 0.001 0.60

P-DICHLOROBENZENE 0.040 0.001 0.075

1,2-DICHLOROETHANE 0.088 0.0048 0.005

1,1-DICHLOROETHYLENE 0.083 0.001 0.007

CIS- 1,2-DICHLOROETHYLENE 0.170 0.0005 0.07

TRANS- 1,2-DICHLOROETHYLENE 0.086 0.001 0.10

1,2-DICHLOROPROPANE 0.080 0.001 0.005

CIS-1,3-DICHLOROPROPYLENE 0.079 0.001 --------

DINOSEB 0.170 0.0002 0.007

ENDRIN 0.053 0.00059 0.002

ETHYLBENZENE 0.088 0.001 0.70

ETHYLENE DIBROMIDE (EDB) 0.044 0.00002 0.00005

HALOACENTONITRILES (HAN):

BROMOCHLOROACETONITRILE 0.022 0.0005 ----------

DIBROMOACETONITRILE 0.024 0.0006 ----------

DICHLOROACETONITRILE 0.0096 0.0002 ----------

TRICHLOROACETONITRILE 0.015 0.0003 ----------

HALOKETONES (HK):

1,1-DICHLORO-2-PROPANONE 0.0072 0.0001 --------

1,1,1-TRICHLORO-2-PROPANE 0.0082 0.0003 --------

HEPTACHLOR 0.025 0.00001 0.0004

HEPTACHLOR EPOXIDE 0.011 0.0002 0.0002

HEXACHLOROBUTADIENE 0.044 0.001 --------

HEXACHLOROCYCLOPENTADIENE 0.060 0.000002 0.05

LINDANE 0.055 0.00001 0.0002

METHOXYCHLOR 0.050 0.0001 0.04

PENTACHLOROPHENOL 0.096 0.001 0.001

SIMAZINE 0.120 0.004 0.004

STYRENE 0.150 0.0005 0.10

1,1,2,2-TETRACHLOROETHANE 0.081 0.001 --------

TETRACHLOROETHYLENE 0.081 0.001 0.005

TOLUENE 0.078 0.001 1.00

TRIBROMOACETIC ACID 0.042 0.001 --------

2,4,5-TP (SILVEX) 0.270 0.0016 0.05

1,2,4-TRICHLOROBENZENE 0.160 0.0005 0.07

1,1,1-TRICHLOROETHANE 0.084 0.0046 0.20

1,1,2-TRICHLORETHANE 0.150 0.0005 0.005

TRICHLOROETHYLENE 0.180 0.001 0.005

TRIHALOMETHANES 0.300 0.015 0.08

XYLENES (TOTAL) 0.070 0.001 10

NSF/ANSI STANDARD 53 TEST CONDITION: 60 ± 3 psi, pH 7.5 ± 0.5, 68 ± 5 ºF

1. THESE SYSTEMS HAVE BEEN TESTED FOR THE TREATMENT OF WATER

CONTAINING PENTAVALENT ARSENIC (ALSO KNOWN AS As(V), As(+5),

OR ARSENATE) AT CONCENTRATIONS OF 0.30 mg/L OR LESS. THIS SYS-

TEM REDUCED PENTAVALENT ARSENIC, BUT MAY NOT REMOVE OTHER

FORMS OF ARSENIC. THIS SYSTEM IS TO BE USED ON WATER SUPPLIES

CONTAINING A DETECTABLE FREE CHLORINE RESIDUAL AT THE SYSTEM

INLET OR ON WATER SUPPLIES THAT HAVE BEEN DEMONSTRATED TO

CONTAIN ONLY PENTAVALENT ARSENIC. TREATMENT WITH CHLORAMINE

(COMBINED CHLORINE) IS NOT SUFFICIENT TO ENSURE COMPLETE CON-

VERSION OF TRIVALENT ARSENIC TO PENTAVALENT ARSENIC. PLEASE

SEE THE ARSENIC FACT SECTION OF THE PERFORMANCE DATA SHEET

FOR FURTHER INFORMATION.

2. THE ULTREFINER II IS ACCEPTABLE FOR TREATMENT OF INFLUENT

CONCENTRATIONS OF NO MORE THAN 27 MG/L NITRATE AND 3 MG/L

NITRITE IN COMBINATION MEASURED AS “N” AND IS CERTIFIED FOR

NITRATE/NITRITE REDUCTION ONLY FOR WATER SUPPLIES WITH A PRES-

SURE OF 280 KPA (40 PSIG) OR GREATER. ADDITIONAL TREATMENT OR

INDIVIDUAL DESIGN SHALL BE REQUIRED FOR HIGHER INFLUENT LEV-

ELS. IF YOU ARE RELYING ON THE ULTREFINER II FOR NITRATE REDUC-

TION, WE RECOMMEND TESTING YOUR WATER PERIODICALLY (2 TIMES A

YEAR MINIMUM) WITH A NITRATE TEST KIT (SUPPLIED) TO ENSURE THAT

THE SYSTEM IS PERFORMING PROPERLY. ADDITIONAL NITRATE TEST

KITS (PART NUMBER 12061) CAN BE PURCHASED FROM YOUR LOCAL

RAINSOFT DEALER.

3. EFFICIENCY RATING MEANS THE PERCENTAGE OF INFLUENT WATER TO

THE SYSTEM THAT IS AVAILABLE TO THE USER AS REVERSE OSMOSIS

TREATED WATER UNDER OPERATING CONDITIONS THAT APPROXIMATE

TYPICAL DAILY USAGE.

4. RECOVERY RATING MEANS THE PERCENTAGE OF THE INFLUENT WATER

TO THE MEMBRANE PORTION OF THE SYSTEM THAT IS AVAILABLE TO

THE USER AS REVERSE OSMOSIS TREATED WATER WHEN THE SYSTEM IS

OPERATED WITHOUT A STORAGE TANK OR WHEN THE STORAGE TANK IS

BYPASSED.

5. REDUCTIONS SHOWN ARE FOR VOLATILE ORGANIC CHEMICALS/COM-

POUNDS (VOC) AS PER NSF TABLES. CHLOROFORM WAS USED AS A

SURROGATE FOR VOC CLAIMS REDUCTION. THE ACTUAL REDUCTION

RATE OF CHLOROFORM WAS 99.7% AS TESTED BY NSF INTERNATIONAL

AT 200% CAPACITY (I.E 450 GALLONS) PER NSF/ANSI 53 STANDARD.

VOC, Standard 53 Reduction Claims 5

THIS SYSTEM HAS BEEN TESTED ACCORDING TO

NSF/ANSI 42 FOR REDUCTION OF THE SUBSTANCES

LISTED BELOW. THE CONCENTRATION OF THE INDICAT-

ED SUBSTANCES IN WATER ENTERING THE SYSTEM WAS

REDUCED TO A CONCENTRATION LESS THAN OR EQUAL

TO THE PERMISSIBLE LIMIT FOR WATER LEAVING THE

SYSTEM, AS SPECIFIED IN NSF/ANSI 42.

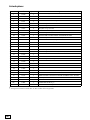

CONTAMINANT

AVERAGE

INFLUENT

CHALLENGE

CONCENTRATION

MAXIMUM

PERMISSIBLE

PRODUCT WATER

CONCENTRATION/

PERCENT

REDUCTION

REQUIREMENT

ACTUAL

REDUCTION

CHLORAMINE 3.0 mg/L E10% 0.5 mg/L 97.7 %

CHLORINE 2.0 mg/L E10% P50% 97.7 %

NSF/ANSI STANDARD 42 TEST CONDITION: 60 E3 psi, pH 9 E0.25, 68 E5 ºF

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

dans d''autres langues

- italiano: RainSoft HDINSTIUDWS Manuale utente

- English: RainSoft HDINSTIUDWS User manual

- español: RainSoft HDINSTIUDWS Manual de usuario

Autres documents

-

Watts 7100104 Guide d'installation

-

GE GXRM10RBL Manuel utilisateur

-

GE GXRM10RBL Manuel utilisateur

-

OmniFilter RO2050 Le manuel du propriétaire

-

GE GXRM10GBL Manuel utilisateur

-

GE GXRM10G Manuel utilisateur

-

Everpure ROM IV Le manuel du propriétaire

-

Pentek RO-2550 Le manuel du propriétaire

-

Pentair GRO-575 Le manuel du propriétaire

-

Star Water Systems S07UF06C Le manuel du propriétaire

Star Water Systems S07UF06C Le manuel du propriétaire