www.quikoitaly.com

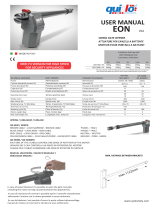

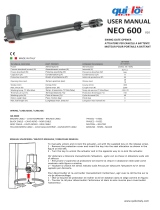

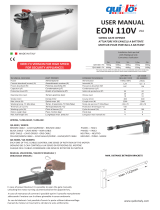

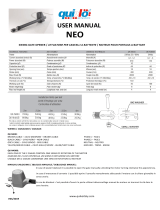

SWING GATE OPENER

ATTUATORE PER CANCELLI A BATTENTE

MOTEUR POUR PORTAILS A BATTANT

WIRING / CABLAGGIO / CABLAGE:

BROWN CABLE – CAVO MARRONE – BRUNES CABLE:

BLACK CABLE – CAVO NERO – NOIR CABLE:

GREY CABLE – CAVO GRIGIO - GRIS CABLE:

YELLOW/GREEN CABLE – CAVO GIALLO/VERDE -

JAUNE/VERT CABLE:

MANUAL UNLOCKING / SBLOCCO MANUALE / DEBLOCAGE MANUEL:

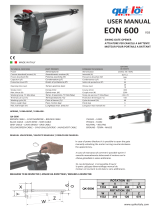

USER MANUAL V04

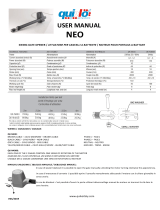

NEO

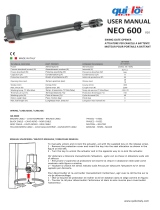

TECHNICAL FEATURES DATI TECNICI DONNEES TECHNIQUES

Power Alimentazione Alimentation 230Vac 50 / 60Hz

Current absorbed (motor) (A) Assorbimento motore (A) Intensité (A)

Power absorbed (W) Potenza assorbita (W) Puissance absorbée (W)

Capacitor (µF) Condensatore (µF) Condensateur (µF) 8

Protection level (IP) Grado di protezione (IP) Indice de protection (IP) 44

Opening time (sec) Tempo apertura (sec) Vitesse (sec) 20

Stroke (mm) Corsa (mm) Course (mm) 400

Max. thrust (N) Spinta max. (N) Couple max (N) 2200

Working temp. (°C Min/Max) Temp. di esercizio (°C Min/Max) Temp. de service (°C Min/Max) -30/+70

Thermal cut-out (°C) Termoprotezione (°C) Protection thermique (°C) 150

Working cycle (%) Ciclo di lavoro (%) Cycle de travail (%) 40

Motor weight (kg) Peso motore (kg) Poids (kg) 6

Max. leaf length (m) Lunghezza max. anta (m) Longueur maxi vantail (m) 4

0,9-1,5

350

QK-N400

MADE IN ITALY

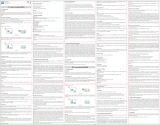

To manually unlock and re-lock the actuator, act with the supplied key on the release screw.

1 - Remove the protection cover and insert the key into the seat allocation as shown in the

figure on the left;

2 - Turn the key to unlock the actuator and in the opposite way to re-lock the actuator.

Per sbloccare e bloccare manualmente l'attuatore, agire con la chiave in dotazione sulla vite

di sblocco.

1 - Rimuovere il coperchio di protezione ed inserire la chiave in dotazione nella sede come

mostrato nella figura a sinistra;

2 – Ruotare la chiave nel senso indicato sulla freccia per sbloccare l'attuatore ed in senso

opposto per bloccarlo.

Pour déverrouiller et re-verrouiller manuellement l'actionneur, agir avec la clé fournie sur la

vis de déverrouillage.

1 - Ôter je bouche de protection et insérer la clé en dotation dans le siège comme en figure;

2 - Tourner la clé pour déverrouiller l'actionneur et dans le sens inverse pour reverrouiller

l'actionneur.

PHASE1 - FASE1 - PHASE1

PHASE2 - FASE2 - PHASE2

NEUTRAL - NEUTRO - NEUTRE

GROUND - TERRA - MASSE

Installation limits per leaf

Limiti di’impiego per anta

Contraintes d’utilisation

350kg

3m 4m

QK-N400 400kg 300kg

500kg

2m

700kg

2,5m 3,5m

The values shown within the table above can be considerably reduced in windy areas.

I valori mostrati nella tabella sopra possono essere ridotti considerevolmente in zone ventose.

Les valeurs indiquées dans le tableau peuvent être considérablement réduits dans les zones venteuses.

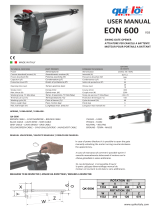

MEASURES TO BE RESPECTED / MISURE DA RISPETTARE / MESURES A RESPECTER:

A

B

MIN / MAX A AND B MEASURES

---------------------------------------------------------------

---------------------------------------------------------------------------------------------------------

max

1122mm

MAX. DISTANCE

BETWEEN BRACKETS PUSH TO OPEN SOLUTION

If necessary, when PUSH TO OPEN

installation is required, extending the

bracket on the pillar, it is possible to

install the motor internally and let the

gate open externally as per the image on

the right:

EU Declaration of Conformity

and Declaration of Incorporation of "quasi-machines" (pursuant to the Machinery Directive 2006/42/CE, Att.II, B)

Company name: QUIKO ITALY SRL

Postal address: Via Seccalegno, 19

Postcode and City: 36040, Sossano (VI) - Italy

Telephone number: +39 0444 785513

E-Mail address: [email protected]

declare that the DoC is issued under our sole responsibility and belongs to the following product:

Apparatus model/Product: Neo: QK-N400

Type: AUTOMATIONS FOR SWING GATES (230/110/24V)

Batch: See the label on the motor

The object of the declaration described above is in conformity with the relevant Union harmonisation legislation:

-Directive 2006/42/CE (MD Directive)

• It is declared that the relevant technical documentation has been drawn-up in compliance with attachment VII B.

• It is also declared that the following essential health and safety requirements have been respected: 1.1.1 - 1.1.2 - 1.1.3 - 1.1.5 -

1.2.1 - 1.2.6 - 1.3.1 - 1.3.2 - 1.3.3 - 1.3.4 - 1.3.7 - 1.3.9 - 1.5.1 - 1.5.2 - 1.5.4 - 1.5.5 - 1.5.6 - 1.5.7 - 1.5.8 - 1.5.10 - 1.5.11 - 1.5.13 -

1.6.1 - 1.6.2 - 1.6.4 - 1.7.2 - 1.7.3 - 1.7.4 - 1.7.4.1 - 1.7.4.2 - 1.7.4.3.

• The undersigned declares that the afore-mentioned “partly-completed machinery” cannot be commissioned until the final

machine, into which it has been incorporated, has been declared compliant with the Machinery Directive 2006/42/CE.

• On duly justified request, the manufacturer commits to transmitting the information regarding the “partly-completed

machinery” to the national authorities without prejudice to their intellectual proper ty rights.

-Directive 2014/53/EU (RED Directive)

-Directive 2011/65/EU (RoHS)

The following harmonised standards and technical specifications have been applied:

Title: Date of standard/specification

EN 61000-6-2 2005 + AC:2005

EN 61000-6-3 2007 + A1:2011+AC:2012,

EN 301 489-1 V2.2.3 2019

EN 301 489-3 V2.1.1 2017

EN 60335-2-103 2015

EN 12453 2017

EN 62479 2010

EN 300 220-2 V3.1.1 2017

EN IEC 63000 2018

Signed for and on behalf of:

Revision: Place and date of issue: Name, function, signature

01.00 (Borinato Luca, Legal Officer)

Sossano, 28/09/2021

-

1

1

-

2

2

dans d''autres langues

- italiano: quiko Neo Manuale utente

- English: quiko Neo User manual

Documents connexes

-

quiko Neo Manuel utilisateur

quiko Neo Manuel utilisateur

-

quiko EON Manuel utilisateur

quiko EON Manuel utilisateur

-

quiko NEO600 Manuel utilisateur

quiko NEO600 Manuel utilisateur

-

quiko EON110 Manuel utilisateur

quiko EON110 Manuel utilisateur

-

quiko EON600 Manuel utilisateur

quiko EON600 Manuel utilisateur

-

quiko SCARABEO Manuel utilisateur

quiko SCARABEO Manuel utilisateur

-

quiko EON600 Manuel utilisateur

quiko EON600 Manuel utilisateur

-

quiko EON600 Manuel utilisateur

quiko EON600 Manuel utilisateur

-

quiko QK-LIBWIFI Manuel utilisateur

quiko QK-LIBWIFI Manuel utilisateur

-

quiko Velos Manuel utilisateur

quiko Velos Manuel utilisateur