OPERATION AND INSTALLATION

FUNCIONAMIENTO E INSTALACIÓN

MODE D’EMPLOI ET INSTALLATION

Indirectly red water heater with electric backup heating element

Calentador de agua a fuego indirecto con calentador eléctrico de refuerzo

Chauffe-eau à chauffage indirect avec élément de chauffage électrique auxiliaire

» SB 300 E

» SB 400 E

2 |SB 300-400 E www.stiebel-eltron-usa.com

CONTENTS

SPECIAL INFORMATION

OPERATION

1. General information ������������������������������������3

2. Safety ����������������������������������������������������� 3

2.1 Intended use ������������������������������������������������� 3

2.2 Incorrect use ������������������������������������������������� 3

2.3 General safety instructions ������������������������������� 3

2.4 Heat exchanger loop ���������������������������������������3

2.5 Test symbols ������������������������������������������������� 3

3. Register your product ����������������������������������4

4. Appliance description ����������������������������������4

4.1 Heating the DHW tank ������������������������������������� 4

5. Using the electric heating element ��������������������4

6. Maintenance and care ����������������������������������4

6.1 Temperature / pressure relief valve ��������������������� 5

6.2 Decalcification ����������������������������������������������� 5

6.3 Replacement of the sacrificial anode ������������������� 5

7. Plumbing troubleshooting �����������������������������5

7.1 Notifying a qualified contractor ������������������������� 5

7.2 Safety label �������������������������������������������������� 6

8. Safety ����������������������������������������������������� 6

8.1 General safety instructions ������������������������������� 6

8.2 Instructions, standards and regulations ���������������6

9. Preparations ���������������������������������������������6

9.1 Transport ����������������������������������������������������� 6

9.2 Storage �������������������������������������������������������� 7

9.3 Delivery configuration ������������������������������������� 7

9.4 Installation site ���������������������������������������������� 7

9.5 Siting the appliance ���������������������������������������� 7

10. Installation �����������������������������������������������8

10.1 Water connection ������������������������������������������� 8

10.2 Heating connection ����������������������������������������� 9

10.3 Power supply ������������������������������������������������ 9

11. Commissioning ���������������������������������������� 10

11.1 Commissioning �������������������������������������������� 10

11.2 Recommissioning ����������������������������������������� 10

12. Shutting down ����������������������������������������� 10

13. Electrical Troubleshooting ��������������������������� 10

13.1 Resetting the high limit safety cut-out ��������������� 11

14. Maintenance and cleaning ��������������������������� 11

14.1 Removing the heating element cover ����������������� 11

14.2 Draining the tank ����������������������������������������� 11

14.3 Descaling the electric element ������������������������� 11

14.4 Valves ������������������������������������������������������� 11

14.5 Replacing the electric element cover ����������������� 11

15. Specifications ������������������������������������������ 12

15.1 Features ���������������������������������������������������� 12

15.2 Dimensions ������������������������������������������������ 13

15.3 Data table ���������������������������������������������������14

15.4 Spare parts������������������������������������������������� 15

15.5 Spare parts list �������������������������������������������� 15

SPECIAL INFORMATION

- Observe all applicable national and regional reg-

ulations and instructions during installation.

- The appliance is not approved for outdoor

installation.

- If the appliance is permanently connected to the

power supply, ensure that the appliance can be

separated from the power supply by an isolator

that disconnects all poles with at least 1/8˝/4 mm

contact gap. Contactors, disconnect switches or

circuit breakers can be used for this.

- Observe the safety regulation to prevent contact

with dangerous ‘live’ currents.

- The appliance is pressurized. During the heat-up

process, expansion water will drip from the safety

valve.

- Regularly activate the safety valve to prevent

it from becoming blocked, e.g. by limescale

deposits.

- Install a type-tested safety valve in the cold water

supply line.

- The maximum pressure in the cold water supply

line must be at least 20% below the response

pressure the safety valve. If the maximum pres-

sure in the cold water supply line is higher, install

a pressure reducing valve.

- Size the drain so that water can drain off unim-

peded when the safety valve is fully opened.

- Fit the discharge pipe of the safety valve with a

constant downward slope and in a room without

risk of frost.

- The safety valve discharge aperture must remain

open to atmosphere.

- Never set the heat exchanger loop pressure

greater than the potable (domestic) water supply

pressure. If potable water pressure is too low, a

booster pump may be needed to assure that it ex-

ceeds the required heat exchanger loop pressure.

15.6 Wiring diagram ������������������������������������������������� 16

16. Environment and Recycling ������������������������������� 16

17. Warranty ���������������������������������������������������� 17

OPERATION

General information

www.stiebel-eltron-usa.com SB 300-400 E | 3

ENGLISH

OPERATION

1. General information

The chapters “Special information” and "Operation" are intended

for appliance users and qualified contractors.

The chapter "Installation" is intended for qualified contractors.

Note

Read these instructions carefully before using the appli-

ance and retain them for future reference.

Pass on the instructions to a new user if required.

2. Safety

2.1 Intended use

The appliance is intended for DHW heating within the application

limits. See 15.3, “Data table”, pg. 14.

The appliance is intended for domestic use, i.e. it can be used

safely by untrained persons. The appliance can also be used in a

non-domestic environment, e.g. in a small business, as long as it

is used in the same way.

Any other use beyond that described shall be deemed inappropri-

ate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

2.2 Incorrect use

The following are not permitted:

- Heating liquids other than potable water

- Operating the appliance with an empty DHW tank

- Operating the appliance outside the application limits (See

15.3, “Data table”, pg. 14)

- Interrupting the power supply

2.3 General safety instructions

Only qualified contractors should carry out the electrical work and

installation of this appliance. Qualified contractors are responsible

for adherence to all applicable regulations.

Operate the appliance only when fully installed and with all safety

equipment fitted.

WARNING

Contact with live components presents a threat to life.

Damage to the electric insulation or to individual com-

ponents may result in a threat to life.

If there is damage to the insulation, disconnect the

power supply and arrange a repair.

All work on the electrical installation must be carried

out by a qualified contractor.

WARNING Scalding

The water in the DHW tank can be heated to tempera-

tures in excess of 149°F. There is a risk of scalding at

outlet temperatures in excess of 110°F.

Ensure you do not come into contact with the water

when discharged.

WARNING Burns

Touching hot components can lead to burns.

When working on hot components, always wear protec-

tive working clothing and safety gloves.

The pipework connected to the DHW outlet of the appli-

ance can reach temperatures in excess of 149°F.

!

CAUTION

Install temperature and pressure protective equipment

required by local codes and no less than a combina-

tion temperature and pressure relief valve certified by a

nationally recognized testing laboratory that maintains

periodic inspection of production of listed equipment or

materials, as meeting the requirements for Relief Valves

and Automatic Gas Shutoff Devices for Hot Water Supply

Systems, ANSI Z21.22. This value must be marked with a

maximum set pressure not to exceed the marked max-

imum working pressure of the water heater. Install the

valve into an opening provided and marked for this pur-

pose in the water heater, and orient it or provide tubing

so that any discharge from the valve exits only within 6

inches above, or at any distance below, the structural

floor, and does not contact any live electrical part.

!

Caution

Only operate the appliance when the DHW tank has been

filled.

!

Caution

Keep the appliance installation room free from air con-

taminated with oil or salt and corrosive or explosive sub-

stances.

2.4 Heat exchanger loop

The SB E tanks have an indirectly fired heat exchanger loop. This

may be used in a variety of scenarios which include boiler loops,

geothermal systems, radiant floor loops, etc. Since the interior

of the heat exchanger is uncoated carbon steel, they must be

configured in a closed loop.

Use only a mixture of inhibited propylene glycol and de-ionized

water. The percentage of the glycol in the mixture depends upon

the climate. Some areas require that the propylene glycol be

GRAS, which is a food grade liquid (Heat exchanger type SW,

AWWA Fluid Class II - see MSDS for handling instructions).

2.5 Test symbols

See 7.1.1, “Sample type plate”, pg. 5.

OPERATION

Register your product

4 |SB 300-400 E www.stiebel-eltron-usa.com

3. Register your product

NOTE:

You must register this product within 90 days

of purchase on our web site in order to acti-

vate any standard warranty or to be eligible for

the extended warranty. Go to our website at:

www.stiebel-eltron-usa.com and click on “Register Your

Product.”

Before beginning the registration process, we suggest that you

gather the necessary information as follows:

Model, Example: SB 300 E (from the label that is on the side of

the unit)

Number listed after “Nr.”

Place of Purchase

Purchase Date

First & Last Name

Email address

Physical Address

Phone Number

If you have any questions concerning the registration process or

warranty options, please contact Stiebel Eltron USA directly at

(800)-582-8423.

4. Appliance description

The appliance is designed for indoor installation. The appliance

is equipped to heat water through a number of different heating

methods.

There are three ways that this unit can heat water:

- 3 kW electric resistance heating element

- Indirect heat via internal coil heat exchanger

- Indirect heat via auxiliary inlet/outlet ports

The entire heater and hot water system must be filled with water

and have adequate air ventilation. If used, please refer to the solar

collectors and the boilers installation instructions.

4.1 Heating the DHW tank

The first method of heating is by the 3 kW electric resistance heat-

ing element. This is the appliances most basic mode of operation.

An integral temperature sensor detects the thermal energy content

of the amount of heat in the DHW tank. The water in the DHW

tank is heated if the amount of heat is lower than that required to

achieve the set temperature.

The second method of heating is by the internal coil heat ex-

changer. This heat exchanger is designed to have a heat transfer

fluid circulate through it from an indirect heater. This indirect

heater can be a closed loop solar thermal system, boiler or other

traditional appliance that generates heat and transfers it through

a corrosion inhibited heat transfer fluid.

The third method of heating is by auxiliary ports located on the

side of the unit. These auxiliary ports offer direct access to the

domestic water in the tank. A flat plate heat exchanger should be

used to exchange heat between an indirect heater and the water

in the tank.

If either of the last two heating methods require a temperature

sensor, 2 ports are provided on the opposite side of the tank from

the auxiliary and heat exchanger connections.

5. Using the electric heating element

A 3 kW electric heating element comes standard with this product.

The element has a built-in temperature probe that detects the tank

water temperature.

The appliance’s 3 kW electric resistance heating element is factory

preset at 125 °F (52 °C). The setpoint of the heating element can

be changed easily. A knob is located under the heating element

and can change the level of comfort to meet the needs of the user.

The heating element can be either unplugged during a period of

disuse or removed entirely.

For convenience, the heating element can be removed from the

tank without draining it.

Thermostat knob

Setpoint notch

6. Maintenance and care

Routine care and maintenance extends the life expectancy and

operating safety of the hot water storage unit. The outer casing

should be cleaned with a slightly damp cloth and commercially

available neutral cleaning agent. This should be done on a regular

basis.

WARNING

Never spray the appliance with water.

Never spray water into the appliance.

!

WARNING Injury

Maintenance work, such as checking the electrical safe-

ty, must only be carried out by a qualified contractor.

OPERATION

Plumbing troubleshooting

www.stiebel-eltron-usa.com SB 300-400 E | 5

ENGLISH

Appliance compo-

nents

Care and maintenance tips

Casing Use a damp cloth to clean the casing sections. Never

use abrasive or corrosive cleaning agents.

DHW tank

The DHW tank is equipped with a sacrificial anode

and wear indicator to safeguard it against corrosion.

The wear indicator should be checked regularly. Oth-

erwise there is a risk of corrosion.

Electric resistance

heater

Check the condition of the electric resistance heater.

This will extend the expected life of the element.

6.1 Temperature / pressure relief valve

!

WARNING: The T&P relief valve is designed to relieve

built up pressure in the water heater. Fluid may be

discharged at high temperature and/or pressure. Scalding hot

water injuries can occur.

The proper function of the Temperature / Pressure (T&P) relief

valve is required to prevent damage to the hot water storage unit.

The T&P valve needs to be open during cold-water filling of the

unit. When water flows from the relief line at full stream, the tank

is filled, and the T&P valve can be returned to its normal position.

6.2 Decalcification

With hard tap water, a deposit of scale will form on the inside of

the storage unit. Based on professional experience, it is necessary

to decalcify with commercially available solvents at timely inter-

vals. Follow the manufacturers instructions for solvent use. The

hot water storage unit needs to be emptied to do this process. The

clean-out port cover must be removed and sediments on the tank

bottom must be flushed.

6.3 Replacement of the sacrificial anode

Depending on the composition of the tap water, an inspection of

the sacrificial anode at timely intervals is recommended. With

heavy wear, an original equipment replacement anode must be

installed to protect the inner container from corrosion. An inspec-

tion should be performed at least once per year.

7. Plumbing troubleshooting

7.1

Problem Cause Remedy

Inadequate

water pressure

Shut-off valve is not com-

pletely open.

OR

Cold or hot water line is ob-

structed.

Open shut-off valve. Clean or

replace pipes.

Hot water flow

inadequate

Indirect boiler setpoint tem-

perature is too low.

Recommended 176 to 185 °F.

OR

Heat Exchanger is calcified.

Set boiler to recommended

temperature

OR

Clean heat exchanger.

Hot water

storage tank not

being heated

Program selection at the

heater control is not properly

selected.

Select and set program per

instructions.

Faucet flow rate

inadequate

Aerator at the extraction

point is blocked.

Unscrew aerator and clean.

Hot water sup-

ply exhausted

too quickly

Flow rate is too high. Recom-

mended 2.6 to 3.9 gal./min.

Restrict spigot valve rate.

Notifying a qualified contractor

If you cannot remedy a failure, notify your qualified contractor. To

facilitate and speed up your request, provide the serial number

from the type plate (000000-0000-00000). The type plate can be

found on the left, above the "DHW outlet" connection.

7.1.1 Sample type plate

Technical data

Datos técnicos

Données techniques

Made in EU

Hecho en EU

Fabriqué en EU

Volume:

Volumen:

Volume:

293 l / 77.4 gal

1 MPa / 145 PSI

Max. pressure:

Presión máxima:

Pression max:

Heat exchanger

Intercambiador de calor

Échangeur de chaleur

Max. pressure:

Presión máxima:

Pression max.:

Heating surface:

Superficie de calefacción:

Surface de chauffe:

1.5 m

2

/ 16.1 ft

2

9.5 l / 2.37 gal

SB 300 E

M-NO.: 234110

S-NO.:

315277-38053

Supply:

Alimentación:

Alimentation:

220-240 V AC, 60 Hz

SINGLE PHASE L-L ONLY

3 kW / 10,239 BTU/h

Power:

Potencia:

Puissance:

2.8 kWh/24h

Standby loss:

Pérdida de calor:

Pertes en mode de veille:

1 MPa / 145 PSI

Volume:

Volumen:

Volume:

Max. temp.:

Temperatura máxima:

Temp. max.:

1.5 MPa / 217 PSI

Testing pressure:

Presión de prueba:

Pression d'essai:

95 °C / 203 °F

Conforms to UL STD. 174

Certified to CAN/CSA STD. C22.2 No.110-94

4010487

6 |SB 300-400 E www.stiebel-eltron-usa.com

INSTALLATION

Safety

Technical data

Datos técnicos

Données techniques

Made in EU

Hecho en EU

Fabriqué en EU

Volume:

Volumen:

Volume:

413 l / 109.1 gal

1 MPa / 145 PSI

Max. pressure:

Presión máxima:

Pression max:

Heat exchanger

Intercambiador de calor

Échangeur de chaleur

Max. pressure:

Presión máxima:

Pression max.:

Heating surface:

Superficie de calefacción:

Surface de chauffe:

1.92 m

2

/ 20.6 ft

2

11.1 l / 2.9 gal

SB 400 E

M-NO.: 234111

S-NO.:

315298-38054

Supply:

Alimentación:

Alimentation:

220-240 V AC, 60 Hz

SINGLE PHASE L-L ONLY

3 kW / 10,239 BTU/h

Power:

Potencia:

Puissance:

95 °C / 203 °F

Max. temp.:

Temperatura máxima:

Temp. max.:

3.0 kWh/24h

Standby loss:

Pérdida de calor:

Pertes en mode de veille:

1 MPa / 145 PSI

Volume:

Volumen:

Volume:

1.5 MPa / 217 PSI

Testing pressure:

Presión de prueba:

Pression d'essai:

Conforms to UL STD. 174

Certified to CAN/CSA STD. C22.2 No.110-94

4010487

7.2 Safety label

CAUTION

To reduce the risk of electric shock or fire use only on a utility supply

having a maximum 250 volt, three wire system.

CAUTION

Risk of Electric Shock. Connect branch circuit equipment grounding

means to water heater. For detailed information, refer to instructions.

CAUTION

Risk of Electric Shock and Fire Hazard. Do not connect to supply

by extension cord.

FOR INSTALLED RATING SEE ELEMENT MARKING

Install temperature and pressure protective equipment required by

local codes, but not less than a combination temperature and

pressure relief valve certified as meeting the requirements for Relief

Valves and Automatic Gas Shutoff Devices for Hot Water Supply

Systems, ANSI Z21.22, by a nationally recognized testing laboratory

that maintains periodic inspection of production of listed equipment

or materials. The valve must be oriented, provided with tubing, or

otherwise installed so that discharge can exit only within 6 inches

(15 cm) above, or at any distance below, the structural floor, and

cannot contact any live electrical part.

CAUTION

If the water heater is retrofitted with supplemental heating

equipment, you must adjust both the thermostat controlling the

supplemental heat source (located in the water piping) and the

thermostat on the water heater (behind the access panel) to the

same temperature. Failure to adjust both thermostats to the same

temperature can cause loss of proper temperature control.

When a supplemental heat source is connected to the

appliance, a provision must be made to limit the heat

source temperature not to exceed that of the water heater

thermostat setting.

ATTENTION

Pour réduire le risque d’électrocution et de feu, utiliser seulement

sur un réseau de 250 volt maximum avec mise à la terre.

ATTENTION

Risque de décharge électrique. Branchez l’appareil uniquement

à une prise équipée d’une mise à la terre. Pour l'information

détaillée, référez-vous aux instructions.

ATTENTION

Risque de décharge électrique et de risque d'incendie. Ne reliez

pas l’appareil à l’aide d’une rallonge ou une extension.

POUR LE BRANCHEMENT ÉLECTRIQUE RÉFÉREZ-VOUS

AU MANUEL.

Installer une soupape de sécurité approuvée par le code du bâtiment

de votre région et muni d’une rallonge de sortie permettant d’évacué

l’excédant de pression d’une hauteur minimale de 6 pouces (15 cm)

du sol. Assurez-vous d’orienter la soupape de sécurité de manière à

ne pas éclabousser aucuns circuits électriques

Note : Ne pas installer une soupape de sécurité inférieure à une

température de combinaison et d’une soupape de décharge de

pression certifié comme répondant à l'exigence des soupapes de

décharge et dispositifs de gaz automatique de coupure pour les

systèmes d'approvisionnement en eau chaude, ANSI Z 21.22, par un

laboratoire de test reconnu au niveau national qui maintient

l'inspection périodique de la production d'équipements cotée ou de

matériaux.

ATTENTION

Si le chauffe-eau est rajouter un chauffage d'appoint

équipement, vous devez régler à la fois le thermostat contrôle la

source de chaleur supplémentaire (située dans la tuyauterie d'eau)

et le thermostat sur le chauffe-eau (derrière le panneau d'accès) à l'

même température. Le défaut de régler les deux thermostats à la

même température peut entraîner une perte de contrôle de la

température.

Quand une source de chaleur supplémentaire est reliée à l'

appareil, une disposition doit être fait pour limiter la chaleur

température de la source ne doit pas dépasser celle de l'appareil de

chauffage de l'eau le réglage du thermostat.

PRECAUCIÓN

Para reducir el riesgo de descarga eléctrica o incendio, use solamente

en una fuente de alimentación con un máximo de 250 Voltios,

con sistema de tres cables.

PRECAUCIÓN

Riesgo de descarga eléctrica. Conecte el equipo de circuito de puesta

a tierra con el calentador de agua. Para obtener información detallada,

consulte las instrucciones.

PRECAUCIÓN

Riesgo de descarga eléctrica y peligro de incendio. No conecte a la

fuente de alimentación con una extensión de cable.

PARA EL RATING THE INSTALACIÓN MIRE LA ETIQUETA

DE LA RESISTENCIA.

Instale el equipamiento de protección de temperatura y presión

requerido por los códigos locales, que como mínimo debe ser una

combinación de válvula de seguridad y temperatura certificada para

cumplir con los requisitos para las válvulas de alivio y dispositivos

de cierre automático de gas para sistemas de suministro de agua

caliente, ANSI Z21.22, realizado por un laboratorio de pruebas

reconocido a nivel nacional que mantenga inspecciones periódicas

de la producción de los equipamientos enumerados o de los

materiales. La válvula debe estar orientada, provista de tubo, o

instalada de otro modo de manera que la descarga pueda salir

sólo 6 pulgadas (15 cm) por encima o en cualquier distancia por

debajo de la planta estructural y no pueda ponerse en contacto

con cualquier parte de corriente activa.

PRECAUCIÓN

Si el aparato está adaptado con calentamiento suplementario

equipos, debe ajustar tanto el termostato controla el

fuente de calor suplementaria (que se encuentra en la tubería de

agua) y la termostato del calentador de agua (detrás del panel de

acceso) a la misma temperatura. Si no se ajusta ambos termostatos a

la misma temperatura puede causar la pérdida de control de la

temperatura adecuada.

Cuando una fuente de calor suplementaria está conectado a la

aparato, una disposición debe hacerse para limitar el calor

temperatura de la fuente que no exceda de que el calentador de agua

ajuste del termostato.

Safety label on the appliance

INSTALLATION

8. Safety

Only a qualified contractor should carry out the installation, com-

missioning, maintenance and repair of the appliance.

8.1 General safety instructions

To prevent the necessity of a warranty claim, use only origi-

nal accessories and spare parts. If you need spare parts, call

800.582.8423.

8.2 Instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

Take note of the appliance type plate and See 15, “Specifications”,

pg. 12.

9. Preparations

9.1 Transport

!

CAUTION Injury

Take note of the weight of the appliance.

Use suitable transport aids (e.g. a hand truck) and

enough personnel for transportation.

!

Caution

The appliance is top heavy.

Make sure the unit is not tilted.

Only set the appliance down on an even base.

Do not unpack the appliance until it has arrived in the final in-

stallation room.

Leave the appliance in its packaging and on the pallet. This enables

horizontal transport and provides places to rest during transport.

Vehicular transport

!

Caution

The appliance must generally be stored and transported

vertically.

Observe the information on the packaging.

www.stiebel-eltron-usa.com SB 300-400 E | 7

ENGLISH

INSTALLATION

Preparations

D0000034797

1

1 Recessed grips

Transport from vehicle to installation room

The cardboard box has reinforced recessed grips along the top of

the appliance. You can use these recessed grips, as well as the

pallet at the lower end, to carry the appliance into the installation

room. Take note of the weight of the appliance and ensure a suffi -

cient number of personnel is available for handling the appliance.

9.2 Storage

If it is necessary to store the appliance for a prolonged period

before installation, observe the following information:

- Only store the appliance in a vertical position. Never store

the appliance horizontally.

- Store the appliance in a location that is dry and largely

dust-free.

- Protect the appliance from coming into contact with corrosive

substances.

9.3 Delivery confi guration

The hot water storage tank arrives with the following equipment:

- Storage unit

- Welded steel plain-ended pipe heat exchanger

- Hot water corrosion protection with special enamel coating

- Three immersion sleeves for housing of temperature probes

- Magnesium sacrifi cial anode

- Circulation port

- Two auxiliary heating ports

- Attached fl ange inspection cover

- PU foam insulation 2 in. thick

- Steel outer cover

9.4 Installation site

The appliance is not approved for outdoor installation except for

garages.

Further requirements regarding the installation room and appli-

ance positioning, to prevent appliance damage:

- The installation location must be free from fl ammable, highly

combustible gases and substances, as well as high levels of

dust.

- The installation room must be free from the risk of frost.

- The fl oor of the installation room must be level and have suf-

fi cient load bearing capacity. Take note of the weight of the

appliance with a full DHW tank (See 15.3, “Data table”, pg.

14). A fl oor with insuffi cient weight capacity is in danger of

collapse. If the appliance is not evenly balanced, there may

be a risk of appliance damage.

- Always leave suffi cient distance to provide access for instal-

lation, maintenance and cleaning. Observe the required min-

imum clearances (See 9.5, “Siting the appliance”, pg. 7).

- Ensure that the operation of other equipment in the installa-

tion room is not impaired.

- To reduce the required plumbed tube length, install the unit

very close to the point.

The following installation locations are not permissible, due to

risk of appliance damage:

- Locations where the air is contaminated with oil or salt

- Saline environments

- Areas in proximity to high frequency machines

- Places where the air contains ammonia (e.g.sewage works)

- Places where the air contains chlorine (e.g.swimming pools)

- Generally places where the air is strongly contaminated, e.g.

due to dust, or contains aggressive substances

9.5 Siting the appliance

Carefully undo the cardboard packaging at the clips.

D0000034797

1

1 Cardboard packaging clips

The appliance is secured to the pallet with metal brackets and

screws. The metal brackets are hooked on to the feet underneath

the fl oor plate of the appliance.

8 |SB 300-400 E www.stiebel-eltron-usa.com

INSTALLATION

Installation

1 Metal bracket fi xing screw

Remove the fi xing screw of the metal bracket from the pallet.

Tilt the appliance to the side for each foot. Screw out the

adjustable tank foot, remove the brackets, and screw in the

adjustable tank foot.

!

Caution

Take note of the appliance's weight and top-heaviness.

Slightly tip the appliance and carefully roll the appliance off

the pallet.

Bring the appliance in its fi nal location.

Minimum clearances

Maintain the minimum clearances.

!

Caution

The appliance must be straightened vertically to avoid

appliance damage.

The feet under the floor plate of the appliance are

height-adjustable.

Level the appliance horizontally using the height-ad-

justable feet.

10. Installation

!

WARNING Injury

Incorrect installation can lead to serious personal injury.

Before any work, ensure suffi cient clearances for the

installation.

Handle sharp-edged components carefully.

10.1 Water connection

!

Caution

Carry out all water connection and installation work in

accordance with local plumbing regulations.

The following material combinations are approved for metal pipe-

work installations:

Cold water inlet DHW outlet

Copper pipe Copper pipe

Steel pipe Steel pipe or copper pipe

Thoroughly fl ush the pipework before connecting the ap-

pliance. Foreign bodies, such as welding pearls, rust, sand

or sealant can impair the operational reliability of the

appliance.

!

Caution

To protect the stubs against corrosion the water tube con-

nection must be made with fl at gaskets. The use of hemp

on stub threads is not permissible.

Safety valve

The appliance is a sealed unvented DHW tank. Provide the

appliance with a pressure relief valve.

Install a type-tested safety valve in the T&P port on the side

of the unit. The response pressure of the safety valve must be

below or equal to the permissible operating pressure of the

DHW tank.

The safety valve protects the appliance against unacceptable ex-

cess pressure.

Ensure that the expansion water escaping from the safety

valve can drip into a drain, e.g. a tank or sink.

Ensure the drain cannot be shut off.

Size the drain in a way that water can drain off unimpeded

when the safety valve is fully opened.

Ensure that the discharge pipe of the safety valve is open to

atmosphere.

Fit the discharge pipe of the safety valve with a constant

downward slope and in a room free from the risk of frost.

Pressure reducing valve

The maximum pressure in the cold water supply line must be at

least 20% below the response pressure the safety valve. If the

maximum pressure in the cold water supply line is higher, install

a pressure reducing valve.

Drain valve

Install a suitable drain valve at the lowest point in the cold

water inlet line.

DHW circulation

The heat losses incurred in the DHW circulation line and the elec-

trical power consumption of the circulation pump reduce the effi -

ciency of the system. The cooled water in the circulation line mixes

with the tank content. Where possible, avoid installing a DHW

www.stiebel-eltron-usa.com SB 300-400 E | 9

ENGLISH

INSTALLATION

Installation

circulation line. Where that is not possible, the DHW circulation

pump must be controlled thermally or by time switch.

Thermal insulation

Insulate the DHW line against heat loss in accordance with

locally applicable regulations.

10.2 Heating connection

The heating system can be configured in a variety of ways. The

methods described here are for the most common installation

method. For more questions on installation and configuration of

the heating system, contact Stiebel Eltron.

10.2.1 Connecting to the internal coil heat exchanger

The internal coil heat exchanger connections are 1˝ NPT female.

A common use of this coil is for closed-loop solar thermal appli-

cations, like in the below image.

V

T

V

T

Ball valve

Check valve

T&P valve

Expansion tank

Temp. gauge

Pres. gauge

Flow meter

Circulation pump

To solar

From solar

Air separator

A few necessary features of this system include:

- Corrosion inhibiting propylene glycol

- Air separator/eliminator

- Circulation pump

10.2.2 Connecting to the auxiliary ports

The auxiliary ports can be used to add another heating source,

or to supply heat stored in the tank to another location. If the

auxiliary ports are unused for heating, they can be used for a

DHW recirculation loop.

From aux.

heat source

To aux.

heat source

Check valve

Circulation pump

Air/dirt separator

Flat-plate HX

It is necessary for both sides of the heat exchanger to have circu-

lation pumps and air/dirt separators. A check valve is also recom-

mended to prevent thermosiphoning.

Consult your local plumbing code for requirements regarding heat

exchanger properties (double wall, brazed, stainless steel, etc.)

10.3 Power supply

WARNING

Carry out all electrical connection and installation work

in accordance with national and regional regulations.

If the appliance is permanently connected to the power supply,

ensure that the appliance can be separated from the power sup-

ply by an isolator that disconnects double terminal with at least

3mm contact gap. Contactors, mains isolators or fuses can be

used for this.

Disconnect the appliance from the power supply before carrying

out work on the control panel. Prevent the power supply from

being switched on while you are working on the system.

Ensure the appliance is earthed according to locally applicable

requirements.

10.3.1 Installing the power cable

10 |SB 300-400 E www.stiebel-eltron-usa.com

INSTALLATION

Commissioning

!

Caution

Never connect the appliance to the power supply before

the DHW tank is filled.

The power to this appliance is delivered with a power cable with

a mains plug.

Use minimum 14-2 (with ground) AWG copper wire for instal-

lation. For long wire lengths, you may need to increase the

gauge size. Always install in accordance with all national and

local electrical codes.

Unit shall be connected to a 15 A dual pole breaker.

Using the 14-2 wire (or larger if the code calls for it), connect

the 14-2 wire to the 3 wires in the junction box as shown.

Use the proper strain relief grommet where the wire enters

the junction box.

See 15.6, “Wiring diagram”, pg. 16.

11. Commissioning

11.1 Commissioning

!

Caution

Never connect the appliance to the power supply before

the DHW tank is filled.

11.1.1 Filling the DHW tank

Fill the DHW tank and vent the pipework by following the proce-

dure below:

Close the drain valve.

Open all DHW tap points and the shut-off valve in the cold

water supply.

Close the DHW tap points as soon as water starts to emerge

from them.

11.1.2 Appliance handover

Explain the appliance function to users and familiarize them

with its operation.

Make users aware of potential dangers, especially the risk of

scalding.

Make users aware of critical environmental factors and re-

quirements concerning the installation location.

Inform users that water may drip from the safety valve

during the heating operation.

Hand over these operating and installation instructions to

users for safe-keeping.

11.2 Recommissioning

If the appliance is switched off due to an interruption to the power

supply, no specific measures for restarting are required once the

power supply has been restored.

12. Shutting down

!

Caution

If the appliance is disconnected from the power supply,

it is no longer protected against frost.

Only disconnect the appliance from the power sup-

ply for longer periods if you are also draining the

DHW tank.

If there is no usage of hot water for a long period of time, always

drain the DHW tank. See 14.2, “Draining the tank”, pg. 11.

The appliance can only be switched off by interrupting the power

supply.

Pull the mains plug from the socket or disconnect the appli-

ance from the mains in the fuse box.

13. Electrical Troubleshooting

WARNING Risk of Electric Shock

Prior to all work on the appliance, isolate it from the

power supply.

!

Caution

If you disconnect the appliance from the power supply, it

is no longer protected against frost.

Only disconnect the appliance from the power sup-

ply for longer periods if you are also draining the

DHW tank.

For work on the electric heating element, remove the heating

element cover (See 14.1, “Removing the heating element

cover”, pg. 11).

If the unit does not provide hot water, then the heating element

is likely not heating the water.

1 Check that the circuit breaker is in the on position. Reset if

necessary.

2 Inspect the connections inside the junction box. Repair if

necessary.

3 Check the voltage at the junction box connections. The volt-

age should be 240 VAC.

4 Check for proper resistance of the heating element.

Turn off circuit breaker.

Disconnect wire nuts on L1 and L2 and separate wires.

Measure the resistance between the two black wires going

into the conduit of the tank. It should measure 17.6 Ω ±10%.

If the measurement is off, there may be an internal wiring

problem or a faulty heating element. Call Stiebel Eltron for

technical support.

Note

Refit the heating element cover after completing your

work. See 14, “Maintenance and cleaning”, pg. 11).

www.stiebel-eltron-usa.com SB 300-400 E | 11

ENGLISH

INSTALLATION

Maintenance and cleaning

13.1 Resetting the high limit safety cut-out

The high limit safety cut-out protects the appliance from overheat-

ing. The cut-out switches off the electric element when the tank

water temperature exceeds 199-208°F.

Once the cause of the failure has been removed, press the reset

button of the high limit safety cut-out on the rod thermostat. To

do so, remove the appliance cover.

Thermal safety

cut-out

14. Maintenance and cleaning

WARNING

Prior to all work on the appliance, isolate it from the

power supply.

14.1 Removing the heating element cover

Undo the screws that fasten the heating element cover to the

appliance.

Pull off the cover.

Note

Refit the heating element cover after completing your

work.

14.2 Draining the tank

WARNING Burns

Hot water may escape when draining the DHW tank.

To drain the DHW tank, e.g. when shutting the appliance down,

proceed as follows:

Unplug the appliance from the power supply.

Close the shut-off valve in the cold water supply line.

The DHW tank is drained via the cold water supply line.

Open the drain valve installed in the cold water supply line

(See 10.1, “Water connection”, pg. 8). If no drain valve

has been installed, undo the cold water supply line at the

"cold water inlet" connection.

Open one tap in one sink.

Some residual water will remain in the lower section of the DHW

tank.

14.3 Descaling the electric element

Only descale the flange of the electric booster heater after re-

moving it, and never treat the interior of the DHW tank and the

sacrificial anode with descaling agents.

14.4 Valves

Regularly check the system's valves (safety valve, pressure reduc-

ing valve, drain valve, vacuum breaker, mixing valve), to ensure the

operational reliability of the appliance. The amount of limescale

deposits depends on the local water quality.

Check all valves in the system and remove limescale deposits.

Replace the valves if necessary.

Check the function of the valves.

Whether a sand filter is installed.

14.5 Replacing the electric element cover

WARNING

Reconnect the earth cable to the appliance cover.

Place cover back in its original position.

Secure the screws holding the cover onto the appliance.

12 |SB 300-400 E www.stiebel-eltron-usa.com

INSTALLATION

Specications

15. Specifications

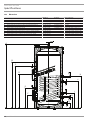

15.1 Features

1 Cold water inlet

2 Hot water outlet

3 Lower heat exchanger port

4 Upper heat exchanger port

5 Lower auxiliary port

6 Upper auxiliary port

7 Clean-out port

8 T&P valve port

9 Anode replacement indicator

10 Junction box

11 Analog thermometer

12 Upper temperature sensor sleeve

13 Electric heating element

14 Lower temperature sensor sleeve

t

8

1

2

3

4

5

6

7

10

11

12

13

14

30˚

9

30˚

9

www.stiebel-eltron-usa.com SB 300-400 E | 13

ENGLISH

INSTALLATION

Specications

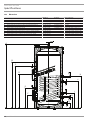

15.2 Dimensions

SB 300 E SB 400 E Connection

A Height to hot water outlet (overall height)

61

1

/ 8 in. / 1552 mm 60

13

/ 16 in. / 1544 mm

1˝ NPT male

B Height to thermometer

44

7

/ 16 in. / 1128 mm 45

1

/ 16 in. / 1145 mm

C Height to upper temperature sensor sleeve 40 ½ in. / 1028 mm 42 ¾ in. / 1085 mm ∅ 9mm

D Height to heating element port 32 ½ in. / 825 mm

34

7

/ 8 in. / 886 mm

E Height to lower temperature sensor sleeve 30 ½ in. / 775 mm

32

11

/ 16 in. / 830 mm

∅ 9mm

F Height to clean-out port

12

3

/ 8 in. / 315 mm

∅ 115mm

G Height to cold water inlet

5

1

/ 16 in. / 129 mm 4

5

/ 16 in. / 110 mm /

1˝ NPT male

H Height to heat exchanger lower port

10

13

/ 16 in. / 275 mm

11 in. / 280 mm 1˝ NPT female

I Height to auxiliary heat source lower port

14

9

/ 16 in. / 370 mm

1˝ NPT female

J Height to auxiliary heat source upper port

25

9

/ 16 in. / 650 mm 27

9

/ 16 in. / 700 mm

1˝ NPT female

K Height to heat exchanger upper port

19

5

/ 8 in. / 498 mm

1˝ NPT female

L Height to T&P valve port 48.3 in. / 1228 mm ¾˝ NPT female

A

B

C

D

E

F

G

H

I

J

K

14 |SB 300-400 E www.stiebel-eltron-usa.com

INSTALLATION

Specications

15.3

L

Data table

SB 300 E SB 400 E

234110 234111

Hydraulic data

Nominal capacity 300 l / 79.3 gal. 400 l / 105.6 gal

Water volume 293 l / 77.4 gal. 413 l / 109.1 gal

Internal coil heat exchanger volume 9.5 l / 2.4 gal. 11.1 l / 2.9 gal

Internal coil heat exchanger area 1.5 m² / 16.1 ft² 1.9 m² / 20.6 ft²

Heating element

Heating element voltage 220-240

Heating capacity 3.0 kW/ 10,239 BTU/hr

Frequency 60

Rated current 12.5 A

Required circuit breaker 20 A

Heating element type Dome element

Heating element material Ceramic

Temperature control Knob with °F & °C scale under the heating element cover

Set range of thermostat 86 °F–167 °F / 30 °C–75 °C

Miscellaneous

Maximum allowed pressure (tank) 145 PSI / 10 bar

Maximum allowed pressure (heat exchanger) 145 PSI / 10 bar

Maximum tank temperature 203 °F / 95 °C

Tank heat loss in 24 hours at 149°F / tank temperature 2.8 kWh / 9,553 BTU 3.0 kWh / 10,236 BTU

Empty weight 313 lb / 142 kg 399 lb / 181 kg

Filled weight 1,010 lb / 458 kg 1,334 lb / 605 kg

Type of anode Magnesium with wear indicator

Dimensions

Height

61

1

/ 8 in. / 1552 mm 60

13

/ 16 in. / 1544 mm

Diameter

25

9

/ 16 in. / 650 mm

29 ½ in. / 750 mm

Insulation thickness 2 in. / 50 mm

Diameter without insulation

21

5

/ 8 in. / 550 mm 25

9

/ 16 in. / 650 mm

www.stiebel-eltron-usa.com SB 300-400 E | 15

ENGLISH

INSTALLATION

Specications

15.4 Spare parts

15.5 Spare parts list

Pos.

Name Part #

1 Heating element assembly cover 315268

2 Clean-out port cover 315266

3 Enameled flange 309859

4 Flange gasket 315300

5 Foam insulation for clean-out port 299891

6 3 kW heating element 296391

7 Segmented sacrificial anode 1¼˝ 143499

8 Anode sleeve 166375

9 Thermostat 269978

10 Thermal safety cut-out 279006

11 Thermostat knob 315423

12 Junction box 4x4˝ 315357

13 Electric element holder 315269

14 Gasket cap 298307

15 Terminal block 309566

16 Connection cable (not shown) 315272

17 Adjustable tank foot 291975

18 Thermometer (32-248 °F) 315265

19 Rivets for outer jacket 298745

20 T&P valve 100 PSI 315664

21 Top cover for SB 300 E 315264

21a Top cover for SB 400 E 315297

22 Washer for thermostat (DIN 6797-A6.4)

23 Junction box holder 315271

24 Nut for thermostat (I4032-M6)

25 Screw for element holder (DIN7981-M4.2x16)

26 Washer for clean-out port (125-A13-140)

27 Bolt for clean-out port (DIN 933-M12x25)

28 Cable gland 298306

29 Junction box nut 315287

30 Washer (125-3.2-140HV-ZN)

31 Nut (I4032-M 4-4-A0E)

32 Screw for thermostat (DIN7985-M4x6)

33 Screw for terminal block (I4075-M3-18)

34 Nut for terminal block (I4032-M3-6)

35 Screw (DIN 7500 CE M5x8-Z-AoE)

Cable loop 315273

Insulating bushing 315540

16 |SB 300-400 E www.stiebel-eltron-usa.com

INSTALLATION

Environment and Recycling

15.6 Wiring diagram

15 A Dual Pole

Circuit Breaker

240 VAC

Breaker Box

SB E Junction Box

Outlet (Optional)

L1

L2

Green/Yellow

Black

Black

Wire Nuts

The above wiring diagram shows the connection between the

circuit breaker and the SB E junction box.

SB E Junction Box

SB E Heating Element

Green/Yellow

Black

Black

L1L2

Heating Element

Safety Cutout

Thermostat

Anode

Outer Casing

Tank

Wiring Terminal

Wire Nuts

The above wiring diagram shows the internal pre-wired con-

nection of the SB E.

16. Environment and Recycling

We ask you to help protect the environment. After use, dispose

of the various materials in accordance with national and local

regulations.

www.stiebel-eltron-usa.com SB 300-400 E | 17

ENGLISH

WARRANTY | ENVIRONMENT AND RECYCLING

WARRANTY

ENVIRONMENT AND RECYCLING

All SB 150 S, SB 200 S, SB 300 E, SB 400 E, SBB 300 S, SBB 400 S, SBB 300 Plus, SBB 400 Plus,

& SBB 600 Plus Models

Subject to the terms and conditions set forth in this limited

lifetime warranty, Stiebel Eltron, Inc. (the “Manufacturer”)

hereby warrants to the original purchaser (the “Owner”) that

each storage tank (the “Tank”) shall be free from defects in the

Manufacturer’s materials or workmanship for a period of:

1. (Lifetime) for the tank and heat exchanger from the date

of purchase;

2. (8 Years) for part(s) not referenced above from the date of

purchase;

3. (Excluded) sacrifi cal anode

As Owner’s sole and exclusive remedy for the above warranty,

Manufacturer shall, at the Manufacturer’s discretion, either

factory repair or replace the defective Tank with a replacement

unit or part(s) with comparable operating features.

Manufacturer’s maximum liability under all circumstances shall

be limited to the Owner’s purchase price for the Tank.

This limited warranty shall be the exclusive warranty made by

the Manufacturer and is made in lieu of all other warranties,

express or implied, whether written or oral, including, but

not limited to warranties of merchantability and fi tness for

a particular purpose. Manufacturer shall not be liable for

incidental, consequential or contingent damages or expenses

arising directly or indirectly from any defect in the Tank or the

use of the Tank. Manufacturer shall not be liable for any water

damage or other damage to property of Owner arising, directly

or indirectly, from any defect in the Tank or the use of the Tank.

Manufacturer alone is authorized to make all warranties on

Manufacturer’s behalf and no statement, warranty or guarantee

made by any other party shall be binding on Manufacturer.

Manufacturer shall not be liable for any damage whatsoever

relating to or caused by:

1. any misuse or neglect of the Tank, any accident to the Tank,

any alteration of the Tank, or any other unintended use;

2. acts of God and circumstances over which Manufacturer

has no control;

3. installation of the Tank other than as directed by

Manufacturer and other than in accordance with

applicable building codes;

4. improper installation and/or improper materials used

by any installer and not relating to defects in parts or

workmanship of Manufacturer;

5. failure to maintain the Tank or to operate the Tank in

accordance with the Manufacturer’s specifi cations;

6. failed components not originally installed by the

Manufactuer as a part of the unit at the time of sale;

7. exposure to freezing conditions;

8. exposure to harmful chemicals, contaminated water,

corrosive fl uids or atmosphere, liquids harmful to steel

tubing including improperly applied or maintained heat

transfer fl uids.

9. utilizing the tank as an open loop heat exchanger, e.g.,

do not use in drainback systems or continually pass fresh

potable water through the units internal heat exchanger.

10. installing the Tank in a closed system without a properly

sized and installed thermal expansion tank;

11. operating the Tank without the factory installed sacrifi cal

anode;

12. operating the Tank under fl uctuating or excessive water

pressure or in the event the Tank is supplied with non-

potable water for any duration;

13. operating the Tank when it is empty or partially full of

potable water;

14. Installing and operating the Tank outdoors;

15. operating the Tank at temperatures higher than

recommended by Manufacturer;

16. (SB E models) replacing the electric heating element

with a unit not manufactured by Stiebel Eltron or greater

in power than the originally installed element;

17. (SB E models) connecting the Tank to improper voltage

or service;

Should owner wish to return the Tank to manufacturer for

repair or replacement under this warranty, Owner must fi rst

secure written authorization from Manufacturer. Owner shall

demonstrate proof of purchase, including a purchase date, and

shall be responsible for all removal and transportation costs.

If Owner cannot demonstrate a purchase date this warranty

shall be limited to the period beginning from the date of

manufacture stamped on the Tank. Manufacturer reserves

the right to deny warranty coverage upon Manufacturer’s

examination of the Tank. This warranty is restricted to the

Owner and cannot be assigned.

Some States and Provinces do not allow the exclusion or

limitation of certain warranties. In such cases, the limitations

set forth herein may not apply to the Owner. In such cases this

warranty shall be limited to the shortest period and lowest

damage amounts allowed by law. This warranty gives you

specifi c legal rights and you may also have other rights which

vary from State to State or Province to Province.

Owner shall be responsible for all labor and other charges

incurred in the removal or repair of the Tank in the fi eld. Please

also note that the Tank must be installed in such a manner that

if any leak does occur, the fl ow of water from any leak will not

damage the area in which it is installed.

Simply the Best

17 West Street

West Hatfi eld, MA 01088

TOLL FREE 800.582.8423

PHONE 413.247.3380

FAX 413.247.3369

info

@

stiebel-eltron-usa.com

www.stiebel-eltron-usa.com

This Warranty is valid for U.S.A. & Canada only. Warranties

may vary by country. Please consult your local Stiebel Eltron

Representative for the Warranty for your country.

DHW SOLAR & INDIRECT STORAGE TANKS

LIMITED WARRANTY

This Warranty is valid for all purchases on or after October 1, 2014.

17. Warranty

18 |SB 300-400 E www.stiebel-eltron-usa.com

NOTES

www.stiebel-eltron-usa.com SB 300-400 E | 19

ESPAÑOL

ÍNDICE | FUNCIONAMIENTO

INFORMACIÓN ESPECIAL

FUNCIONAMIENTO

1. Información general ���������������������������������� 20

2. Seguridad ���������������������������������������������� 20

2.1 Uso correcto ����������������������������������������������� 20

2.2 Uso incorrecto ��������������������������������������������� 20

2.3 Instrucciones generales de seguridad ���������������� 20

2.4 Circuito del intercambiador del agua ����������������� 20

2.5 Símbolos de prueba �������������������������������������� 21

3. Registre su producto ��������������������������������� 21

4. Descripción del artefacto ����������������������������� 21

4.1 Calentamiento del tanque de agua ������������������� 21

5. Uso del calentador eléctrico de refuerzo ����������� 21

6. Cuidado y mantenimiento ���������������������������� 22

6.1 Válvula de alivio de temperatura / presión ���������� 22

6.2 Descalcificación ������������������������������������������� 22

6.3 Reemplazo del ánodo de sacrificio �������������������� 22

7. Resolución de problemas de plomería ������������� 22

7.1 Informar a un técnico calificado ����������������������� 23

7.2 Etiqueta de seguridad ����������������������������������� 23

8. Seguridad ���������������������������������������������� 23

8.1 Instrucciones generales de seguridad ���������������� 23

8.2 Instrucciones, normas y regulaciones ���������������� 23

9. Preparativos ������������������������������������������� 24

9.1 Transporte �������������������������������������������������� 24

9.2 Almacenamiento ������������������������������������������ 24

9.3 Configuración de la entrega ���������������������������� 24

9.4 Lugar de instalación �������������������������������������� 24

9.5 Colocación del artefacto ��������������������������������� 25

10. Instalación ��������������������������������������������� 25

10.1 Conexión de tuberías ������������������������������������ 25

10.2 Conexión de calentamiento ����������������������������� 26

10.3 Suministro eléctrico �������������������������������������� 27

11. Puesta en marcha ������������������������������������� 27

11.1 Puesta en marcha ���������������������������������������� 27

11.2 Reinicio ����������������������������������������������������� 27

12. Apagado ������������������������������������������������ 28

13. Resolución de problemas eléctricos ���������������� 28

13.1 Reinicio después del corte de seguridad por

exceso del límite de temperatura ��������������������� 28

14. Limpieza y mantenimiento ��������������������������� 28

14.1 Remoción de la cubierta del calentador de

refuerzo ����������������������������������������������������� 28

14.2 Drenaje del tanque ��������������������������������������� 28

14.3 Limpieza del depósito de cal del calentador

eléctrico de refuerzo ������������������������������������� 29

14.4 Válvulas ����������������������������������������������������� 29

14.5 Remplazo de la cubierta del calentador eléctrico

de refuerzo ������������������������������������������������� 29

15. Especificaciones ��������������������������������������� 29

15.1 Características ��������������������������������������������� 29

INFORMACIÓN

ESPECIAL

- Respete todas las regulaciones e instrucciones nacionales y

regionales pertinentes durante la instalación.

- El artefacto no es apto para instalar en exteriores.

- Si el artefacto está permanentemente conectado al suminis-

tro eléctrico, se debe establecer una manera de separarlo de

la red eléctrica mediante un aislante que desconecte todos

los polos con al menos 4 mm (1/8˝) de distancia entre con-

tactos. Para ello, es posible usar contactores, interruptores

de desconexión o disyuntores.

- Respete las regulaciones de seguridad para evitar el contacto

con piezas peligrosas que conduzcan la electricidad.

- El artefacto se encuentra presurizado al expandirse el agua

durante el proceso de calentamiento, parte del agua escapa-

rá por la válvula de seguridad.

- Active con regularidad la válvula de seguridad para evitar

que se bloquee, por ejemplo, por depósitos de cal.

- Instale una válvula de seguridad testeada para el tipo especí-

fico en la red de suministro de agua fría.

- La presión máxima de la red de suministro de agua fría debe

ser al menos un 20% menor que la presión de respuesta de

la válvula de seguridad. Si la presión máxima de la red de

suministro de agua fría supera la presión de respuesta de

la válvula de seguridad, instale una válvula de reducción de

presión.

- El drenaje debe tener un tamaño suficiente para que el agua

pueda drenar de forma ininterrumpida cuando la válvula de

seguridad está totalmente abierta.

- Instale el tubo de descarga de la válvula de seguridad con

una pendiente descendiente constante y en una habitación

que lo proteja contra la escarcha.

- La abertura de descarga de la válvula de seguridad debe

tener salida al aire libre.

- La presión del circuito del intercambiador de calor nunca

debe fijarse de manera que supere a la presión de la red de

suministro de agua (doméstica) potable. En caso de que la

presión del agua potable sea demasiado baja, es posible que

deba utilizar una bomba de refuerzo a fin de garantizar que

supere la presión requerida del circuito del intercambiador

de calor.

15.2 Dimensions ������������������������������������������������������ 30

15.3 Tabla de datos ��������������������������������������������������� 31

15.4 Repuestos �������������������������������������������������������� 32

15.5 Lista de repuestos ���������������������������������������������� 33

15.6 Diagrama de instalación eléctrica ��������������������������� 33

16. Medio ambiente y reciclaje ������������������������������� 34

FUNCIONAMIENTO

Información general

20 |SB 300-400 E www.stiebel-eltron-usa.com

FUNCIONAMIENTO

1. Información general

Los capítulos “Información especial” y “Funcionamiento” están

destinados a usuarios e instaladores autorizados.

El capítulo “Instalación” está destinado solo a instaladores au-

torizados.

Nota

Lea estas instrucciones atentamente antes de usar el ar-

tefacto y consérvelas para consultas futuras.

Entregue las instrucciones a cualquier nuevo usuario que

las necesite.

2. Seguridad

2.1 Uso correcto

El artefacto está diseñado para el calentamiento del agua do-

méstica dentro de los límites de aplicación. Véase 15.3, “Tabla de

datos”, pág. 31

El artefacto está diseñado para el uso doméstico, es decir, no hace

falta un entrenamiento especial para utilizarlo con seguridad. El

artefacto también puede usarse en un entorno no doméstico, por

ejemplo una pequeña empresa, con la condición de que se utilice

de la misma manera.

Cualquier otro uso que no esté estipulado se considerará inapro-

piado. El cumplimiento de estas instrucciones y de las instruccio-

nes de uso de cualquier accesorio también forma parte del uso

correcto del calentador.

2.2 Uso incorrecto

Los siguientes usos no están permitidos:

- Calentar otro líquido que no sea agua potable

- Hacer funcionar el artefacto con el tanque de agua vacío

- Hacer funcionar el artefacto fuera de los límites de aplicación

(Véase 15, “Especificaciones”, pág. 29)

- Interrumpir el suministro de electricidad

2.3 Instrucciones generales de seguridad

Solo los instaladores autorizados deben realizar los trabajos rela-

cionados con la electricidad y la instalación de este artefacto. Los

instaladores autorizados son responsables de cumplir con todas

las regulaciones pertinentes.

Haga funcionar el artefacto solo cuando se haya completado la

instalación y tenga incorporados todos los elementos de seguri-

dad.

ADVERTENCIA

El contacto con partes que conducen electricidad pone

en riesgo la vida. Los daños en el aislante eléctrico o

las piezas individuales pueden poner en riesgo la vida.

Si existen daños en el aislante, corte el suministro

de electricidad y solicite una reparación.

Todos los trabajos relacionados con la electricidad deben

ser llevados a cabo por un electricista calificado.

ADVERTENCIA Quemaduras por agua caliente

El agua del tanque puede calentarse hasta alcanzar tem-

peraturas que superan los 149 °F/65 °C. Existe el riesgo

de quemaduras por agua caliente cuando la temperatura

del agua que sale supera los 110 °F/43 °C.

Asegúrese de no entrar en contacto con el agua que

sale durante la descarga.

ADVERTENCIA Quemaduras

El contacto con piezas calientes puede causar quema-

duras.

Cuando trabaje cerca de las piezas calientes, utilice

siempre indumentaria de protección y guantes de se-

guridad.

Las tuberías conectadas a la salida de agua caliente del

artefacto pueden alcanzar temperaturas superiores a

los 149 °F/65 °C.

!

PRECAUCIÓN

Instale equipos de protección de la temperatura y la pre-

sión requeridos por los códigos locales y al menos una

válvula combinada de alivio de temperatura y presión

certificada por un laboratorio de pruebas reconocido

a nivel nacional que realice inspecciones periódicas de

la producción de los equipos o materiales enumerados,

cumpliendo con los requisitos para Válvulas de Alivio y

Artefactos de Cierre de Gas Automáticos para Sistemas

de Suministro de Agua Caliente, ANSI Z21.22. Esta

válvula debe marcarse con una presión de ajuste máxima

que no supere la presión de trabajo máxima marcada del

calentador de agua. Instale la válvula en una abertura

provista y marcada para este propósito en el calentador

de agua, y oriéntela o instale las tuberías de manera

que cualquier escape de la válvula salga solo a 152 mm

(6 pulgadas) por encima, o a cualquier distancia por de-

bajo del piso estructural, y que no entre en contacto con

ninguna pieza que conduzca electricidad.

!

Precaución

Haga funcionar el artefacto solamente con el tanque de

agua lleno.

!

Precaución

Mantenga el ambiente donde se instaló el artefacto libre

de aire contaminado con aceite o sales, o sustancias co-

rrosivas o explosivas.

2.4 Circuito del intercambiador del agua

Los tanques SB E cuentan con un circuito del intercambiador de

calor a fuego indirecto. Puede utilizarse en diversos entornos que

incluyen circuitos de caldera, sistemas geotérmicos, circuitos de

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

STIEBEL ELTRON SB 400 E Mode d'emploi

- Taper

- Mode d'emploi

- Ce manuel convient également à

dans d''autres langues

- English: STIEBEL ELTRON SB 400 E User guide

- español: STIEBEL ELTRON SB 400 E Guía del usuario

Documents connexes

-

STIEBEL ELTRON SHP-A 220-300 (X) Plus Operation Instruction

-

STIEBEL ELTRON SHP-F 220-300 Premium Operation Instruction

-

STIEBEL ELTRON SHC 2.5 Guide d'installation

-

STIEBEL ELTRON SB 300 E Manuel utilisateur

-

STIEBEL ELTRON Beilage ErP SBB 301-302 WP Operation Instruction

-

STIEBEL ELTRON All Mini Tankless Electric Domestic Hot Water Heaters Manuel utilisateur

-

STIEBEL ELTRON SBB 200 WP classic Operation Instruction

-

STIEBEL ELTRON HSBB 200_S Operation Instruction

-

STIEBEL ELTRON SBB 300-500-1_Plus Operation Instruction

-

STIEBEL ELTRON HSBC 300_L_cool Operation Instruction