Page 1

OWNER’S MANUAL

AND INSTALLATION

INSTRUCTIONS

WARNING

If the information in these instructions are

not followed exactly, a re or explosion may

result causing property damage, personal

injury or loss of life.

— Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the re department.

—

Installation and service must be

performed by a qualied installer,

service agency or the gas supplier.

INSTALLER:

Leave this manual with the appliance.

CONSUMER:

Retain this manual for future reference.

Attention: Check local codes for venting requirements.

Young children should be carefully supervised when

they are in the same room as the appliance.

If installed in a direct-vent application, this appliance

may be installed in an aftermarket, permanently

located, manufactured home or mobile home, where

not prohibited by state or local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is not

convertible for use with other gases, unless a certied

kit is used.

Carton Contents:

UltraSaver 90 Plus Wall Furnace (with shroud attached)

Instruction Envelope Containing:

Owner’s Manual and Installation Instructions

Shut-off Valve

2-1/2” Hose Clamp

Hardware Pack Containing:

(4) - #10 x 1-1/2” Hex Head Screws

4’ - 3/8 I.D. Condensate Drain Hose

WARNING

If not installed, operated and maintained

in accordance with the manufacturer’s

instructions, this product could expose you

to substances in fuel or from fuel combustion

which can cause death or serious illness.

ULTRASAVER 90 PLUS

WALL FURNACE

MODELS

PVS18(N,P)-3

PVS35(N,P)-3

37873-0-0217Page 2

TABLE OF CONTENTS

SECTION PAGE

IMPORTANT SAFETY INFORMATION ........................................................................................3

SAFETY INFORMATION FOR USERS OF LP-GAS ...................................................................4

REQUIREMENTS FOR MASSACHUSETTS ...............................................................................5

GENERAL SAFETY INFORMATION ............................................................................................6

OWNER’S MANUAL AND OPERATION INSTRUCTIONS .................................................. 7 - 12

INSTALLATION INSTRUCTIONS ...................................................................................... 13 - 38

Introduction ..................................................................................................................... 14 - 20

FAQ - Installation Considerations ............................................................................................14

Accessories .............................................................................................................................15

Specications and Dimensions ...............................................................................................16

Clearances to Combustibles ...................................................................................................17

Wall Furnace Display ..............................................................................................................18

Wall Furnace Component Arrangement - Front ......................................................................19

Wall Furnace Component Arrangement - Rear .......................................................................20

Wall Furnace Installation ................................................................................................ 21 - 38

Mounting the Rear Shroud .............................................................................................. 21 - 22

Gas Supply ...................................................................................................................... 23 - 24

Vent Clearances ......................................................................................................................25

Venting Requirements .............................................................................................................26

Venting ............................................................................................................................. 27- 28

Vent Examples for Single Flue ........................................................................................ 29 - 30

Direct Vent Examples ...................................................................................................... 31 - 32

Lighting Instructions ................................................................................................................33

Wiring .............................................................................................................................. 34 - 35

Startup Checklist .....................................................................................................................36

Initial Startup and Adjustments ........................................................................................ 37 - 38

TROUBLESHOOTING ................................................................................................................39

MAINTENANCE & SERVICE ............................................................................................. 40 - 41

PARTS LIST ................................................................................................................................ 42

EXPLODED VIEW ......................................................................................................................43

MASTER PARTS DISTRIBUTOR LIST ......................................................................................44

HOW TO ORDER REPAIR PARTS ............................................................................................44

APPLIANCE SERVICE HITORY ........................................................................................ 45 - 46

WARRANTY ................................................................................................................................47

37873-0-0217 Page 3

IMPORTANT SAFETY INFORMATION

THIS IS A HEATING APPLIANCE

WARNING

This appliance must be installed and repaired by a qualied

service person. Installers who are not familiar with the

installation of the UltraSaver and have questions, should

contact Empire Comfort Systems, Inc. prior to installing the

appliance to avoid creating a hazardous operating condition.

• Due to high temperatures the appliance should be

located out of trafc and away from furniture and

draperies.

• Children and adults should be alerted to the hazards of

high surface temperatures and should stay away to avoid

burns or clothing ignition.

• Young children should be carefully supervised when they

are in the same room as the appliance.

• Clothing or other ammable material should not be

placed on or near the appliance.

• Any safety screen or guard removed for servicing an

appliance, must be replaced prior to operating the

appliance.

• Keep burner and control compartment clean.

• For manufactured home or mobile home or residen-

tial installation convertible for use with natural gas and

liqueed petroleum gases when provision is made for the

simple conversion from one gas to the other.

• Do not block warm air discharge. Do not allow anyone to

sleep directly in front of the wall furnace.

WARNING

The appliance should be inspected before use and at least

annually by a qualied service person. More frequent

cleaning may be required due to excessive lint from

carpeting, bedding materials, etc. It is imperative that control

compartments, burners and circulating air passageways of

the appliance be kept clean.

• DO NOT put anything around the appliance that will

obstruct the ow of combustion and ventilation air.

• DO keep the appliance area clear and free from combus-

tible material, gasoline and other ammable vapors and

liquids.

• Do examine venting system periodically and replace

damaged parts.

• Do make a periodic visual check of burner. Clean and re-

place damaged parts.

• DO NOT use the appliance if any part has been under

water. Immediately call a qualied service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

• DO NOT operate this appliance without the front panel

installed.

Note to the Installer

1. The installer must leave instruction manual with owner after

installation.

2. The installer must have the owner ll out and mail registration

card supplied with the wall furnace or register the wall furnace

online at www.empirezoneheat.com.

3. The installer should show the owner how to start and operate

wall furnace and thermostat.

4. The installer must locate wall furnace near a grounded wall

receptacle for 115VAC power and must provide gas supply

and vent the wall furnace properly for safe operation.

Safety markings are frequently used in this manual to designate a degree or level of

seriousness and should not be ignored.

DANGER: Indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING: Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Notice: Addresses practices not related to personal injury.

37873-0-0217Page 4

SAFETY INFORMATION FOR USERS OF LP-GAS

Propane (LP-Gas) is a ammable gas which can cause res

and explosions. In its natural state, propane is odorless and

colorless. You may not know all the following safety precautions

which can protect both you and your family from an accident.

Read them carefully now, then review them point by point with

the members of your household. Someday when there may not

be a minute to lose, everyone’s safety will depend on knowing

exactly what to do. If, after reading the following information,

you feel you still need more information, please contact your

gas supplier.

LP-GAS WARNING ODOR

If a gas leak happens, you should be able to smell the gas

because of the odorant put in the LP-Gas.

That's your signal to go into immediate action!

• Do not operate electric switches, light matches, use your phone.

Do not do anything that could ignite the gas.

• Get everyone out of the building, vehicle, trailer, or area. Do

that IMMEDIATELY.

• Close all gas tank or cylinder supply valves.

• LP-Gas is heavier than air and may settle in low areas such as

basements. When you have reason to suspect a gas leak, keep

out of basements and other low areas. Stay out until reghters

declare them to be safe.

• Use your neighbor’s phone and call a trained LP-Gas service

person and the re department. Even though you may not

continue to smell gas, do not turn on the gas again. Do not

re-enter the building, vehicle, trailer, or area.

• Finally, let the service man and reghters check for escaped

gas. Have them air out the area before you return. Properly

trained LP-Gas service people should repair the leak, then

check and relight the gas appliance for you.

NO ODOR DETECTED - ODOR FADE

Some people cannot smell well. Some people cannot smell

the odor of the chemical put into the gas. You must nd out if

you can smell the odorant in propane. Smoking can decrease

your ability to smell. Being around an odor for a time can affect your

sensitivity or ability to detect that odor. Sometimes other odors in

the area mask the gas odor. People may not smell the gas odor or

their minds are on something else. Thinking about smelling a gas

odor can make it easier to smell.

The odorant in LP-gas is colorless, and it can fade under some

circumstances. For example, if there is an underground leak, the

movement of the gas through soil can lter the odorant. Odorants in

LP-Gas also are subject to oxidation. This fading can occur if there

is rust inside the storage tank or in iron gas pipes.

The odorant in escaped gas can adsorb or absorb onto or into

walls, masonry and other materials and fabrics in a room. That will

take some of the odorant out of the gas, reducing its odor intensity.

LP-Gas may stratify in a closed area, and the odor intensity could

vary at different levels. Since it is heavier than air, there may be

more odor at lower levels. Always be sensitive to the slightest gas

odor. If you detect any odor, treat it as a serious leak. Immediately

go into action as instructed earlier.

SOME POINTS TO REMEMBER

• Learn to recognize the odor of LP-gas. Your local LP-Gas

Dealer can give you a “Scratch and Sniff” pamphlet. Use it to

nd out what the propane odor smells like. If you suspect that

your LP-Gas has a weak or abnormal odor, call your LP-Gas

Dealer.

• If you are not qualied, do not light pilot lights, perform service,

or make adjustments to appliances on the LP-Gas system. If

you are qualied, consciously think about the odor of LP-Gas

prior to and while lighting pilot lights or performing service or

making adjustments.

• Sometimes a basement or a closed-up house has a musty

smell that can cover up the LP-Gas odor. Do not try to light

pilot lights, perform service, or make adjustments in an area

where the conditions are such that you may not detect the odor

if there has been a leak of LP-Gas.

• Odor fade, due to oxidation by rust or adsorption on walls of

new cylinders and tanks, is possible. Therefore, people should

be particularly alert and careful when new tanks or cylinders

are placed in service. Odor fade can occur in new tanks, or

reinstalled old tanks, if they are lled and allowed to set too

long before relling. Cylinders and tanks which have been out

of service for a time may develop internal rust which will cause

odor fade. If such conditions are suspected to exist, a periodic

sniff test of the gas is advisable. If you have any question

about the gas odor, call your LP-gas dealer. A periodic

sniff test of the LP-gas is a good safety measure under

any condition.

• If, at any time, you do not smell the LP-Gas odorant and you

think you should, assume you have a leak. Then take the same

immediate action recommended above for the occasion when

you do detect the odorized LP-Gas.

• If you experience a complete “gas out,” (the container is under

no vapor pressure), turn the tank valve off immediately. If the

container valve is left on, the container may draw in some air

through openings such as pilot light orices. If this occurs, some

new internal rusting could occur. If the valve is left open, then

treat the container as a new tank. Always be sure your con-

tainer is under vapor pressure by turning it off at the container

before it goes completely empty or having it relled before it is

completely empty.

37873-0-0217 Page 5

REQUIREMENTS FOR MASSACHUSETTS

For all side wall horizontally vented gas fueled equipment installed

in every dwelling, building or structure used in whole or in part for

residential purposes, including those owned or operated by the

Commonwealth and where the side wall exhaust vent termination

is less than seven feet above nished grade in the area of the

venting, including but not limited to decks and porches, the

following requirements shall be satised:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS.

At the time of installation of the side wall horizontal vented

gas fueled equipment, the installing plumber or gastter shall

observe that a hard wired carbon monoxide detector with an

alarm and battery back-up is installed on the oor level where

the gas equipment is to be installed. In addition, the installing

plumber or gastter shall observe that a battery operated

or hard wired carbon monoxide detector with an alarm is

installed on each additional level of the dwelling, building or

structure served by the side wall horizontal vented gas fueled

equipment. It shall be the responsibility of the property owner

to secure the services of qualied licensed professionals for

the installation of hard wired carbon monoxide detectors

a. In the event that the side wall horizontally vented gas

fueled equipment is installed in a crawl space or an attic,

the hard wired carbon monoxide detector with alarm and

battery back-up may be installed on the next adjacent

oor level.

b. In the event that the requirements of this subdivision

can not be met at the time of completion of installation,

the owner shall have a period of thirty days to comply

with the above requirements; provided, however, that

during said thirty day period, a battery operated carbon

monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each

carbon monoxide detector as required in accordance with the

above provisions shall comply with NFPA 720 and be ANSI/

UL 2034 listed and IAS certied.

3. SIGNAGE. A metal or plastic identication plate shall be

permanently mounted to the exterior of the building at a

minimum height of eight feet above grade directly in line

with the exhaust vent terminal for the horizontally vented

gas fueled heating appliance or equipment. The sign shall

read, in print size no less than one-half (1/2) inch in size,

“GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL

OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the side

wall horizontally vented gas fueled equipment shall not

approve the installation unless, upon inspection, the inspector

observes carbon monoxide detectors and signage installed

in accordance with the provisions of 248 CMR 5.08(2)(a) 1

through 4.

(b) EXEMPTIONS: The following equipment is exempt from

248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled

“Equipment Not Required To Be Vented” in the most

current edition of NFPA 54 as adopted by the Board;

and

2. Product Approved side wall horizontally vented gas

fueled equipment installed in a room or structure

separate from the dwelling, building or structure

used in whole or in part for residential purposes.

(d) MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM NOT PROVIDED.

When the manufacturer of a Product Approved side

wall horizontally vented gas fueled equipment does not

provide the parts for venting the ue gases, but identies

“special venting systems”, the following requirements

shall be satised by the manufacturer:

1. The referenced “special venting system” instructions

shall be included with the appliance or equipment

installation instructions; and

2. The “special venting systems” shall be Product

Approved by the Board, and the instructions for

that system shall include a parts list and detailed

installation instruction.

(e) A copy of all installation instructions for all Product

Approved side wall horizontally vented gas fueled

equipment, all venting instructions, all parts lists for

venting instructions, and/or all venting design instructions

shall remain with the appliance or equipment at the

completion of the installation.

Commonwealth of Massachusetts: The installation must be

made by a licensed plumber or gas tter in the Commonwealth

of Massachusetts.

37873-0-0217Page 6

GENERAL SAFETY INFORMATION

WARNING

The safety information listed below must be followed

during the installation, service, and operation of this

product. Failure to following the safety recommendations

could result in possible damage to the equipment, serious

personal injury, or death.

General Information

This series is designed certied in accordance with American Na-

tional Standard/CSA Standard Z21.86 and CSA 2.32 as a power

vent wall furnace to be installed according to these instructions.

Any alteration of the original design, installed other than as

shown in these instructions will be the responsibility of the

person and company making the changes, and will void the

warranty. This product may not be used with any type of gas

other than what is shown on the rating plate unless converted

using an Empire approved conversion kit.

Installation

Installation and replacement of gas piping, gas utilization equip-

ment or accessories, and the repair and servicing of this equip-

ment must be performed by a qualied agency. The term “qualied

agency” means any individual, rm, corporation or company which

either in person or through a representative is engaged in and is

responsible for (a) the installation or replacement of gas piping or

(b) the connection, installation, repair or servicing of equipment,

who is experienced in such work, familiar with all precautions re-

quired and has complied with all the requirements of the authority

having jurisdiction.

• This installation must conform with local codes, or in the

absence of local codes, the National Fuel Gas Code,

NFPA 54/ANSI Z223.1.

• This appliance, when installed, must be electrically grounded

in accordance with local codes or. In the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70.

• Provide adequate clearances around the wall furnace for ser-

vicing and ensure there are no obstructions to the combustion

air intake situated at the back of the wall furnace. Refer to

Pages 16 and 17.

•

This wall furnace is equipped with a three-prong [ground-

ing] plug for your protection against shock hazard and

should be plugged directly into a properly grounded

three-prong receptacle. Do not cut or remove the ground-

ing prong from this plug. For an ungrounded receptacle,

purchase an adapter with two prongs and a wire for grounding.

• This installation must conform with local codes, or in the

absence of local codes, in Canada use Canadian Electrical

Code CSA C22.1 and in the United States use the National

Fuel Gas Code NFPA 54/ANSI Z223.1.

• This appliance, when installed, must be electrically ground-

ed in accordance with local codes or. In the absence of lo-

cal codes, in Canada with the Canadian Electrical Code CSA

C22.1 and in the United States with the National Electrical

Code ANSI/NFPA 70.

A manufactured home (USA only) or mobile home OEM installa-

tion must conform with the Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280, or when such a stan-

dard is not applicable, the Standard for Manufactured Home In-

stallations, ANSI/NCSBCS Z225.1, or Standard for Gas Equipped

Recreational Vehicles and Mobile Housing, CSA Z240.0.

Installation in Residential Garages

Gas utilization equipment in residential garages shall be installed so

that all burners and burner ignition devices are located not less than

18 inches (457 mm) above the oor. The equipment shall be locat-

ed, or protected, so it is not subject to physical damage by vehicles.

Operation of Wall furnace During Construction

The wall furnace shall not be used during construction.

WARNING

Any change to this wall furnace or its control can be dan-

gerous.

WARNING

This is a heating appliance and any panel, door or guard

removed for servicing the appliance must be replaced prior

to operating the appliance.

NOTICE: During initial ring of this wall furnace, residual oil from

the heat exchanger may bake off and smoke may occur.

Provide adequate ventilation to the area where the

wall furnace is installed to prevent triggering of smoke

alarms. Refer to page 36 for more detail.

Additional code information listed below is for reference pur-

poses only and does not necessarily have jurisdiction over

local or state codes. Always consult with local authorities be-

fore installing any gas appliance.

Attention: This appliance may be installed in the U.S. or in

Canada.

Combustion and Ventilation Air

U.S.: National Fuel Gas Code NFPA 54/ANSI Z223.1(NFGC),

Air for Combustion and Ventilation.

CANADA: National Standard of Canada for Natural Gas and

Propane Installation Codes (NSCNGPIC)

CAN/CGA-B149.1 and .2, Part 7, Venting Systems and Air

Supply for Appliances

Electrical Connections

U.S.: National Electrical Code (NEC) ANSI/NFPA 70

CANADA: Canadian Electrical Code CSA C22.1

Gas Piping and Gas Pipe Pressure Testing

U.S.: NFGC and National Plumbing Codes

CANADA: NSCNGPIC Part 5

General Installations

U.S.: Current edition of the NFGC and NFPA 90B. For copies con-

tact the National Fire Protection Association Inc., Batterymarch

Park, Quincy, MA 02269 or American Gas Association, 400 N.

Capitol, N.W., Washington DC 20001 or www.NFPA.org.

CANADA: NSCNGPIC. For a copy, contact Standard Sales, CSA

International, 178 Rexdale Blvd., Etobicoke (Toronto), Ontario,

M9W 1R3 Canada

Safety

U.S.: NFGC NFPA 5/ANSI Z223.1

CANADA: (NSCNGPIC) CAN/GCA-B149.1 and .2 National

Standard of Canada

37873-0-0217 Page 7

OWNER’S MANUAL

AND

OPERATION INSTRUCTIONS

www.empirezoneheat.com

37873-0-0217Page 8

OWNER’S MANUAL

Before You Start

1. Verify there is electrical power to the wall furnace.

Verify the Main Power Switch is turned on. See Figure 1.

Figure 1

If electrical power is present, the red and green control board

LED’s will begin to ash alternately. See Figure 3. Each light will

ash four times then the wall furnace will enter standby mode.

While in remote mode, the green LED will ash slowly and the

display panel will show a double dash “ - - “. See Figure 2.

Figure 2

Figure 3

If the control board LED’s do not activate, verify the wall furnace

is plugged in and the breaker is on. If the wall furnace is still not

activated, contact a qualied service technician.

2. Verify the main gas supply to the unit is on.

The shutoff valve should be in the “OPEN” position. See Figure 4.

CLOSED

OPEN

Figure 4

Starting the Wall Furnace

The wall furnace has three modes for controlling operation:

Remote, Manual and Local. When in Remote mode, the wall

furnace can be operated by an external Millivolt thermostat,

remote control, or on/off wall switch. When in Manual mode, the

wall furnace can be turned on and off and the heat level adjusted

manually from the display panel. When operating in Local mode,

the owner sets a desired room temperature on the display panel

and the wall furnace will automatically turn on and off and adjust

the heat level to achieve the set temperature.

Wall Furnace Operation - Remote Mode (External Millivolt

Thermostat or Remote)

1. To initiate the wall furnace Remote mode, press the “Mode

Select” button on the wall furnace display panel once from

OFF mode to display a double dash “ - - “. See Figure 5.

Figure 5

37873-0-0217 Page 9

2. When the external control is activated, the wall furnace dis-

play panel will illuminate and show the heat level along with

the remote signal symbol. The wall furnace will begin the

start up sequence automatically. See Figure 6.

Figure 6

Notice: When a Millivolt thermostat or on/off switch is used, the

wall furnace will only operate on high (Level 5).

Notice: When operating in Remote mode, a button sequence

may be used to lock the display panel. See page 12.

3. If a Millivolt thermostat or thermostatic remote is used, set to

the desired room temperature. The wall furnace will turn on

and off automatically in response to the thermostat.

Wall Furnace Operation - Manual Mode

Notice: When operating the wall furnace in Manual mode from

the display panel, only basic operations are available: On, off and

heat level adjustment.

1. To operate the wall furnace in Manual mode, press the “Mode

Select” button on the display panel twice from off mode until

a number appears in the Heat Level location on the display

panel. See Figure 7. The wall furnace will begin the start up

sequence.

Figure 7

2. Use the UP and DOWN adjustment buttons on the right of the

display panel to set the desired level. The display will illumi-

nate and the word “SET” will appear in the top right corner of

the display. After the level is set, the display panel will darken

and the heat level will be displayed.

Wall Furnace Operation - Local Mode (Internal Thermostat)

1. To operated the wall furnace in Local (thermostatic) mode,

press the Mode Select button on the wall furnace display

panel three times from the off mode. The display panel will

show the current room temperature. See Figure 8.

Figure 8

Notice: The temperature sensing probe is built into the left rear

of the wall furnace. A kit to relocate the probe is available. See

page 15.

2. Use the up and down adjustment buttons on the display

panel to set the desired room temperature.

The display will illuminate and the word “SET” will appear

in the top right corner of the display. See Figure 9. After the

temperature is set, the display panel will darken and return

to displaying the room temperature.

Figure 9

3. When the room temperature drops to 3°F below the set tem-

perature, the wall furnace will begin the start up sequence.

4. The wall furnace will automatically adjust the starting level to

meet the heat demand.

Notice: The greater the difference between the room and de-

sired temperatures the higher the starting level.

As the room temperature nears the desired temperature the

level will decrease.

5. The wall furnace will turn off if the room temperature rises

slightly above the set temperature when operating at level 1.

Notice: The wall furnace will adjust the heat level in order to

reach a point of equilibrium between the room and desired tem-

peratures. This may cause the wall furnace to operate for long

periods of time at low levels.

When the backlight button is pushed, the display will cycle be-

tween the level, set temperature and room temperature.

Notice: While the wall furnace is operating in Local mode, the

display will only show the room temperature unless the backlight

button is pushed.

OWNER’S MANUAL

37873-0-0217Page 10

Wall Furnace Operations Sequence

1. When the main power switch is turned on, the red and green

control board LED’s will begin to ash alternately. If using the

FRBTPL Remote accessory (page 15) the remote receiver

will search for the remote transmitter’s signal. See Figures

10 and 11.

Figure 10

Figure 11

Each light will pulse four times then the wall furnace will

enter Remote mode. While in Remote mode, the green LED

will ash slowly and the display panel will shown a double

dash “- -”. See Figure 12.

Figure 12

2. When a call for heat is received, the wall furnace display

panel will illuminate and show the level. See Figure 13.

Figure 13

3. Adjust level with the up and down adjustment buttons in Man-

ual Mode. If operating in Local mode, the heat level will adjust

automatically.

4. The red and green control panel LED lights will begin to ash

alternately while the wall furnace performs a safety test. After

approximately 45 seconds the test will complete and the wall

furnace will prepare to ignite.

5. After the safety test is complete, the ignitor will glow red and

the burner will light within approximately 30 seconds.

Notice: If the burner fails to light, the wall furnace will retry the

ignition sequence three times then enter lock-out mode if it fails

to light. See page 39 for the fault codes and their meanings.

6. After the burner lights, the ame icon on the display panel will

appear and the wall furnace will automatically adjust to the

heat level shown on the display. The wall furnace will always

ignite on Level 5 (High) prior to adjusting to the heat level

shown on the display panel. See Figure 14.

Figure 14

OWNER’S MANUAL

37873-0-0217 Page 11

7. The blower will activate after 45 to 70 seconds depending on

heat level. The blower will automatically adjust its speed to

match the heat level. The blower speed will be indicated on

the display panel. See Figures 16 to 19.

8. The heat level can be adjusted either up or down at any

point during the wall furnace’s operation in Manual Mode.

If using the Local mode, the wall furnace adjusts the level

automatically.

Notice: When changing from a low heat level to a higher heat

level, the wall furnace will automatically increase to Level 5

(High) prior to proceeding to the desired heat level. This is to

ensure consistent operation.

9. When the wall furnace is shut down, the inducer will operate

at full power for approximately 10 seconds after the burner is

extinguished. This is to clear any ue products from the wall

furnace’s combustion chamber. The circulating air blower will

continue to operate from 100 to 160 seconds to ensure the

wall furnace cools sufciently.

Turning the Wall Furnace Off - Display Panel

To turn the wall furnace off from the display panel, press the “Mode

Select” button on the wall furnace display panel until the panel

turns off.

Figure 15

The burner will instantly go off, but the circulating air blower will

continue to operate from 100 to 160 seconds to ensure the wall

furnace cools off.

Power Interruption

The wall furnace requires a 115VAC power source to operate. See

Specications on page 16.

When power is restored to the wall furnace after a power interrup-

tion, the wall furance will automatically reactivate in “Remote” (--)

mode and all operation settings will have reset to the factory de-

faults. If the wall furnace is normally operated using Manual mode

or with the built-in thermostat, the operation settings will need to

be manually reset to the desired mode and settings to resume

operation.

Installing an optional Millivolt thermostat allows the wall furnace to

automatically resume operation once power is restored.

Circulating Air Blower Operation

The circulating air blower is operated by a built in timer. The blower

will activate after approximately 45 to 70 seconds depending on

heat level. The blower will automatically adjust its speed to match

the heat level. The blower icon and speed are indicated on the

display panel. See Figures 16 to 19.

Figure 16 - Heat Levels 1 and 2, Blower Speed 1

Figure 17 - Heat Level 3, Blower Speed 2

Figure 18 - Heat Level 4, Blower Speed 3

Figure 19 - Heat Level 5, Blower Speed 4

After the wall furnace is turned off, the blower will continue to oper-

ate for 100 to 160 seconds to ensure the wall furnace cools suf-

ciently.

Notice: When the wall furnace is turned off, the blower speed will

be displayed while it is running.

OWNER’S MANUAL

37873-0-0217Page 12

OWNER’S MANUAL

Humidier Operation

With the optional humidication tray kit (page 15), as the wall fur-

nace operates condensate is collected and transferred to a pan in

the bottom of the wall furnace. When the condensate reaches a

certain level, a heating element evaporates the water into the air

stream.

While the condensate is being evaporated, the “AUX” symbol will

be displayed. See Figure 20.

Notice: The humidier may not operate with every cycle.

AUX

Figure 20

Troubleshooting

This wall furnace’s controls include a troubleshooting feature

which will display a code on the display panel should an error oc-

cur. See page 39 for a list of troubleshooting codes. Some codes

will require the system to be reset.

To reset the wall furnace, press the mode selection button on the

display panel repeatedly until the wall furnace cycles through the

“OFF” setting once. If the error has been cleared, the wall furnace

will operate normally. If the error is still present, consult a qualied

service technician.

Remote Mode - Anti-tamper

To lock the display panel when operating the wall furnace in

remote mode, press and hold the Mode, Up adjust and Down

adjust buttons for ten seconds. The display panel will display “At”.

See Figure 21.

Figure 21

After the display panel darkens it will show the level and blower

speed as normal during operation. When the wall furnace is in an

OFF cycle, the display panel will show “At”.

To deactivate the Anti-tamper mode, press and hold the Mode,

Up adjustment and Down adjustment buttons for ten seconds.

The display will return to the double dash “- -”.

37873-0-0217 Page 13

INSTALLATION

INSTRUCTIONS

www.empirezoneheat.com

37873-0-0217Page 14

What tools are needed for installation?

Pipe Wrench

Adjustable Wrench

Drill

Tape Measure

10” x 5/16” Nut Driver

Thread Sealant

Level

2-1/2” Diameter Hole Saw for 2” pipe

2” Diameter Hole Saw for 1-1/2” pipe

1” Diameter Hole Saw

Non-corrosive Leak Check Solution

Where will the wall furnace be installed?

• On the Floor - Wall Furnace comes equipped from

factory for this option. See Page 21.

• Wall Mounted - Wall mount shroud needed. See

Page 15 for kit number.

• Mount wall furnace at a height so that the con-

trols can still be observed.

• Interior Wall - Maximum vent length is 50 feet.

• Exterior Wall

• Locate Electrical Supply - Extension cords may

NOT be used.

• Wall Furnace Dimensions page 16.

• Clearances to Combustibles page 17.

What kind of venting application will be used?

• Single Flue - Wall Furnace comes equipped from

factory for this option. A 2” or 1-1/2” pipe may be

used. If a 1-1/2” pipe is used, it must be enlarged to

a 2” pipe prior to exiting the wall into the shroud.

• Direct Vent - An “Air Pipe Kit” is required and is

available for order. See page 15.

How will the venting be run?

• Straight out the back - Wall Furnace comes

equipped from factory for this option. Standard Rear

Shroud supplied. See page 27.

• In Front of the wall - Deep Shroud needed. Venting

option may NOT be done in Wall Mount installations.

See page 15 for kit number.

• Venting Guidelines pages 25 to 32.

• Maximum vent length is 50 feet.

• Notice: Clean all debris from the inside of the ue

pipe prior to applying the glue and nal assembly

of the pipe. Since the condensate is designed to

ow back to the appliance this debris will be carried

to the condensate trap resulting in a clog. An “A2”

error will appear on the display panel if this happens.

The clog, and the work required to x it, can be eas-

ily prevented by pulling a wet cloth through the pipe

prior to applying the glue and nal assembly.

How will the condensate be disposed?

• To a drain - Wall Furnace comes equipped from the

factory to drain up to 3 feet away from the appliance.

• An Extension Kit and External Condensate Pump

kit may also be used. See page 15 for kit numbers.

• Humidication - Optional Heated Humidication Tray

Kit available for order. See page 15 for kit number.

• Winterization information on page 41.

How will the wall furnace be operated?

• Remote - external Millivolt thermostat, wall switch or

remote control. See page 15 for kits available from

Empire Comfort Systems.

• Manual - use the display panel to control the heating

level and turn the wall furnace on and off.

• Local (Internal Thermostatic) - Factory installed

temperature probe on the wall furnace with a built-

in thermostatic function to control the wall furnace’s

operation.

• If it is desired to use the temperature sensed in

another part of the room, a wired temperature

probe accessory kit is available. See page 15 for

kit numbers.

• See Operation Instructions pages 7 to 12.

• Notice: Following a power outage, this wall furnace

will not automatically resume operation when oper-

ated manually or with the internal thermostat. Once

power is restored, the wall furnace will automatically

power on in “Remote Mode” (--), and the original op-

eration settings will need to be re-entered. Installing

an optional Millivolt thermostat control allows the wall

furnace to automatically resume operation under that

thermostat’s control once power is restored. Ask your

dealer for details.

INTRODUCTION

FAQ - INSTALLATION CONSIDERATIONS

37873-0-0217 Page 15

IMPORTANT

All correspondence regarding repair and service should

refer to complete Model Number, Serial Number and type

of gas.

ACCESSORIES

VENTING

Part Number Description Typical Uses

PVSA1 Air Pipe Kit

Converts wall furnace from single ue to direct-vent (Comes standard with heater)

PVSDV35A DV35 Vent Transition Cap Replaces DV35 Vent cap with a transition to PVC pipe for a 2” single ue

SHROUDS

Part Number Description Typical Uses

PVSDS1 Deep Rear Shroud Allows venting to be run in front of the wall in on the oor installations

PVSWS1 Wall Mount Shroud Allows installation of wall furnace off of the oor

CONDENSATE KITS

Part Number Description Typical Uses

PVSHT2 Heated Humidication Tray Evaporates condensate as humidity back into the room

PVSEP2 External Condensate Pump Pumps condensate away from wall furnace instead of gravity drain

PVSCT10 Condensate Hose Extension 10 ft condensate drain extension

CONTROLS

Part Number Description Features

PVSRT1 Temperature Sensor Relocation Kit Room Temperature Sensor Extension

Notice: Following a power outage, this wall furnace will not automatically resume operation when operated manually or with

the internal thermostat. Once power is restored, the wall furnace will automatically power on in “Remote Mode” (--), and the

original operation settings will need to be re-entered. Installing an optional Millivolt thermostat control allows the wall furnace

to automatically resume operation under that thermostat’s control once power is restored. Ask your dealer for details.

INTRODUCTION

ACCESSORIES

Removing the Front Panel

It may become necessary to remove the front panel of the

appliance to remove dropped or fallen objects.

Remove the front panel by lifting up then pulling out. Re-

place the panel by reversing this step.

WARNING

FOR YOUR SAFETY, TURN OFF POWER TO APPLIANCE.

WARNING

Do not operate this appliance without the front panel.

37873-0-0217Page 16

SPECIFICATIONS

Models PVS18(N,P) PVS35(N,P)

Maximum Input BTU/HR (KW/H)* 17,500 (5.13) 35,000 (10.26)

Minimum Input BTU/HR (KW/H)* 8,750 (2.56) 17,500 (5.13)

Height 27-7/8” 27-7/8”

Width 36-1/8” 36-1/8”

Depth with Shroud** 13 13

Gas Inlet (Pipe) 3/8” Pipe 3/8” Pipe

Electrical - The wall furnace comes equipped with a 5 foot (1.5m) 3 pronged cord exiting the rear left side of the wall furnace, for

connection to an approved 115 VAC, 60 Hz, 15A (maximum) wall receptacle. The Minimum Circuit Amp (MCA) is 8A, 920W and with

an accessory heated humidication tray installed, the MCA is 10A, 1150W.

Vent Pipe: 1-1/2 or 2 inch diameter pipe, 50 feet maximum equivalent length. See pages 26 and 29 to 32. The vent termination elbow

does not contribute to the overall vent length measurement.

* Input ratings are based on sea level operation and may vary at different elevations. No orice change is required. The appliance will

de-rate automatically 1.5% per 1,000 feet.

** Add 3-3/8 inches for deep shroud.

All vent and combustion air pipes and ttings must be Schedule 40 PVC, ULC S636 and meet the ANSI/ASTM Standard D1785. Cement

must conform to ASTM Standard D2564. Empire-approved poly pipe with gasketed joints may also be used. Contact your Empire dealer

for availability.

Listed for Category IV venting.

INTRODUCTION

SPECIFICATIONS AND DIMENSIONS

Dimensions - Figure 22

Approved Alternate Vent Systems

Manufacturer Vent System

Duravent PolyPro

Centrotherm InnoFlue

37873-0-0217 Page 17

Select a location with adequate accessibility clearances for servicing

and proper installation. Locate the wall furnace within 5 feet of a 115

VAC wall receptacle to properly power the wall furnace. Do NOT

use an extension cord.

When facing the front of the wall furnace the minimum clearances

from casing to combustible construction are 12" (305mm) on top, 0"

(0mm) on each side and 0” (0mm) from the oor, 0” (0mm) to rear

wall, and 36” (914mm) in front of the wall furnace to walls or furniture.

Notice: It is recommend to leave 8" (203mm) clearance on each

side for servicing, furniture and other easily moved items may be

placed to the sides (not the front) of the wall furnace. See Figure 23.

CLEARANCES TO COMBUSTIBLES

INTRODUCTION

12”

0”

(8” service area

recommended)

36”

0”

(8” service area

recommended)

Figure 23

37873-0-0217Page 18

INTRODUCTION

WALL FURNACE DISPLAY

SET

AUX

RESET

Temperature Display

Shows room temperature

and set temperature

Level

Shows heating

level

Blower Speed

Shows current

blower speed

Flame Icon

Shows when

burners are on

SET

Shows while adjusting the heat level or set temperature.

Also shows in Local Mode when the backlight button is

pushed when the set temperature is displayed. It will

disappear when the room temperature is displayed.

RESET

Shows when heater

needs to be reset

Blower Icon

Shows when room air

blower is running

ºC/ºF

Changes temperature units

from Fahrenheit to Celsius

Mode Select

Changes between modes

Off/Remote/Manual/Local

AUX

Shows during operation of

heated tray accessory

Backlight

Activates back lighting of display.

Also shows set temperature and

heat/blower level information in

Local Mode.

Up Adjustment

Adjusts heat level or

set temperature up

Signal Icon

Shows during

Remote Mode

Down Adjustment

Adjusts heat level or

set temperature down

Figure 24

37873-0-0217 Page 19

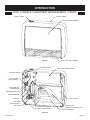

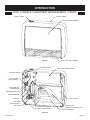

INTRODUCTION

WALL FURNACE COMPONENT ARRANGEMENT - FRONT

CONTROL BOARD

BLOWER MOTOR

MAIN POWER

ON/OFF SWITCH

BURNER COMPARTMENT

GAS VALVE

GAS VALVE

ON/OFF SWITCH

CIRCULATING AIR BLOWER

INDUCER

INDUCER MOTOR

HEAT EXCHANGER

FRONT SHIELD

INNER SHIELD

(SINGLE TUBE UNITS ONLY)

FRONT LOUVER ASSEMBLY

DISPLAYPANEL

OUTER CASING

FRONT COVER ASSEMBLY

CONDENSATE TRAP

AIR PRESSURE

TRANSDUCER

PRESSURE SWITCH

Figure 25

Figure 26

37873-0-0217Page 20

INTRODUCTION

COMBUSTION AIR DUCT

FILTER

COMBUSTION AIR INTAKE

TEMPERATURE SENSOR

FLUE OUTLET

DISPLAYPANEL

FILTER COVER

REAR SHROUD

COMBUSTION AIR INTAKE

(DIRECT VENT)

FLUE OUTLET

GAS LINE OPENING

ALTERNATE GAS LINE OPENINGS

ALTERNATE ELECTRICAL

CORD OPENING

WALL FURNACE COMPONENT ARRANGEMENT - REAR

Figure 27

Figure 28

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

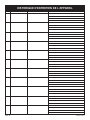

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

Empire PVS35N-3 Le manuel du propriétaire

- Taper

- Le manuel du propriétaire

- Ce manuel convient également à

dans d''autres langues

- English: Empire PVS35N-3 Owner's manual

Documents connexes

-

Empire DV-210-7SG Le manuel du propriétaire

-

Empire Heating Systems Direct-Vent Wall Counterflow Le manuel du propriétaire

-

Empire Heating Systems DV55E Le manuel du propriétaire

-

Empire Heating Systems Direct-Vent Wall Furnace (DV210/215) Le manuel du propriétaire

-

Empire DVC-35-2IP Le manuel du propriétaire

-

Empire DVC-35-1SPP Le manuel du propriétaire

-

Empire Heating Systems Direct-Vent Wall Furnace (DV25/35) Le manuel du propriétaire

-

Empire Heating Systems UltraSaver90Plus Wall Mount Shroud Le manuel du propriétaire

-

Empire Heating Systems UltraSaver90Plus Condensate Pump Kit Le manuel du propriétaire

-

Empire Heating Systems PVSRT1-1 Le manuel du propriétaire

Autres documents

-

Maytag FG7MQ Guide d'installation

-

Empire Heating Systems DV210SGXNAT-1 Le manuel du propriétaire

-

Empire Heating Systems DV-35-2SG Le manuel du propriétaire

-

Ashley Hearth Products AGDV20L Guide d'installation

-

Empire Heating Systems Direct-Vent Wall Furnace (DV25/35) Le manuel du propriétaire

-

Eskabe 9089848 Le manuel du propriétaire

Eskabe 9089848 Le manuel du propriétaire

-

Bradford White DH1-504T6FBN Guide d'installation

-

Bradford White DH1-504T6FBN Guide d'installation

-

Empire Heating Systems UltraSaver90Plus Humidification Tray Kit Le manuel du propriétaire

-

PolyPro 3PPS-12B Guide d'installation

PolyPro 3PPS-12B Guide d'installation