Kobalt SGY-AIR223 Manuel utilisateur

- Catégorie

- Outils électroportatifs

- Taper

- Manuel utilisateur

ATTACH YOUR RECEIPT HERE

Serial Number Purchase Date

Questions, problems, missing parts?

Before returning to your

retailer, please call our Customer Service Department at

1-888-3KOBALT, 8 a.m. – 8 p.m., EST, Monday – Friday.

ITEM #0858975

MODEL #SGY-AIR223

6 IN. PALM SANDER

Français p. 16

Español p. 31

AB17997

Kobalt

®

is a registered trademark of LF, LLC.

All rights reserved.

1

2

TABLE OF CONTENTS

Safety Information..........................................................................................3

Compressor Requirements.............................................................................2

Package Contents..........................................................................................9

Product Specifications....................................................................................3

Preparation...................................................................................................10

Assembly Instructions...................................................................................10

Operating Instructions..................................................................................12

Care and Maintenance.......................................

Removal of Sanding Pad..............................................................................13

..........................................13

Troubleshooting............................................................................................14

Warranty.......................................................................................................15

COMPRESSOR REQUIREMENTS

4.5

SCFM

90

PSI

Tool Requirements

Exigences relatives aux outils

Requisitos de herramientas

@

IMPORTANT: To operate correctly, this tool requires airflow that is at least 4.5

Standard Cubic Feet per Minute (SCFM) at 90 pounds per square inch (PSI).

Check the specifications of your air compressor to be sure that it can support

both the minimum SCFM and PSI required. The air hose length could affect

how much air pressure the tool is actually receiving. You may need to adjust

the air pressure higher on the air regulator to achieve the working pressure

of 90 PSI.

3

PRODUCT SPECIFICATIONS

SPECIFICATIONS

COMPONENT

SAFETY INFORMATION

Please read and understand this entire manual before attempting to

assemble, operate or maintain this product. If you have any questions,

please call our Customer Service Department at 1-888-3KOBALT,

8 a.m. – 8 p.m., EST, Monday – Friday.

WARNING

WARNING

Drilling, sawing, sanding or machining wood products can expose you to

wood dust, a substance known to the state of California to cause cancer.

Avoid inhaling wood dust or use a dust mask or other safeguards for personal

protection. For more information, go to www.P65Warnings.ca.gov/wood.

6 IN.

10,000 RPM

4.5 SCFM

1/4 IN. NPT

3/8 IN.

90 PSI

SANDING PAD

FREE SPEED

AVERAGE AIR CONSUMPTION

AIR INLET

AIR HOSE

WORKING PRESSURE

Improper operation or maintenance of this tool could result in serious injury

and property damage. Read and understand all warnings and operation

instructions before using this tool. When using any tool, basic safety

precautions should always be followed to reduce the risk of personal injury.

Use each tool for its intended function only. Do not use this product in

unsafe work conditions. It is always recommended to keep a fire

extinguisher and first aid kit near work areas.

FAILURE TO OBSERVE AND FOLLOW SAFETY INSTRUCTIONS COULD

RESULT IN INJURY OR DEATH.

To reduce your exposure to these chemicals, work in a well-ventilated area,

and work with approved safety equipment, such as a respirator or dust

masks which are specially designed to filter microscopic particles.

4

SAFETY INFORMATION

RISK OF EYE OR HEAD INJURY

WARNING

WARNING

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT

WHAT COULD HAPPEN HOW TO PREVENT IT

WHAT COULD HAPPEN HOW TO PREVENT IT

This air powered tool can be capable

of propelling materials such as

fasteners, metal chips, sawdust,

and other debris at high speed which

could result in serious injury.

Always wear ANSI approved Z87.1

safety glasses.

Never leave operating tool

unattended.

Disconnect air hose when tool is not

in use or when changing accessories.

Compressed air can be hazardous

and propel objects and other

particles that can cause injury to soft

tissue areas of the body, such as

eyes and ears. Particles or objects

propelled by the air coming from the

exhaust can cause injury.

For additional protection, use an

approved face shield in addition to

safety glasses.

Tools attachments can become

loose or break and fly apart,

propelling articles at the operator

and others in the work area.

Make sure that any attachments are

securely fastened and properly

assembled before use.

Always use the tool at a safe

distance from others in the work area

and ensure the work area is safe at

all times.

RISK OF LOSS OF HEARING

RISK OF FIRE OR EXPLOSION

Always wear ANSI S3.19 hearing

protection.

Exposure to noise produced from the

operation of air tools can lead to

permanent hearing loss.

A rotary tool is capable of generating

sparks, which can result in ignition

of flammable materials.

Never operate tools near flammable

substances such as gasoline,

naphtha, cleaning solvents, etc.

Work in a clean, well-ventilated area

free of combustible materials.

Never use oxygen, carbon dioxide

or other bottled gasses as a power

source for air tools.

5

SAFETY INFORMATION

RISK OF ENTANGLEMENT

WARNING

WARNING

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT

WHAT COULD HAPPEN HOW TO PREVENT IT

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF CUT OR BURNS

RISK OF ELECTRIC SHOCK

Loose hair, clothing, jewelry or other

loose objects can become entangled

in the moving elements of this tool

and can cause serious injury.

Do not wear loose clothing, jewelry,

or anything that may get caught or

tangled when using tool.

Remove any jewelry which may be

caught by the tool.

Always keep hands and body parts

away from moving parts.

Always wear properly fitted clothing

and other properly fitted safety

equipment when using this tool.

A rotary tool is capable of causing

serious injury if operated in an

improper way, or used in a manner

which is not intended for the tool.

Keep the working part of the tool

away from hands and body.

This tool is not provided with an

insulated gripping surface. Contact

with a “live” wire will also make

exposed metal parts of the tool “live”

and can result in electrical shock,

electrocution or death.

Air tool accessories that come into

contact with hidden electrical wiring

could cause electrocution or death.

Avoid body contact with grounded

surfaces such as pipes, radiators,

refrigerators, and ranges. There is

an increased risk of electrical shock

if your body is grounded.

Thoroughly investigate the work

piece/area for possible hidden wiring

before performing work.

6

SAFETY INFORMATION

RISK OF PERSONAL INJURY

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT

A tool left unattended or with the air

hose attached can be activated by

unauthorized persons leading to their

injury or injury to others.

Air tools can propel fasteners or

other materials throughout the work

area.

Remove air hose when tool is not in

use and store tool in secure location

away from reach of children and

untrained users.

Use only parts, fasteners and

accessories recommended by the

manufacturer.

Keep work area clean and free of

clutter.

Do not allow children to operate tool,

and keep children away from the

work area.

Keep work area well lit.

Air tools can become activated by

accident during maintenance or tool

changes.

Remove air hose to lubricate.

Never carry the tool by the air hose.

Air tools can cause the workpiece to

move upon contact, leading to injury.

Loss of control of the tool can lead to

injury to self or others in the work

area.

Before changing accessories,

making repairs, or when tool is not in

use, shut off air supply and

release/drain air pressure from hose.

Disconnect tool from air supply and

store in a safe location.

Use clamps or other devices to

prevent movement.

Never use the tool while using drugs

or alcohol.

Only an authorized service

representative should service the tool.

Never carry the tool with the trigger

depressed or engaged.

7

SAFETY INFORMATION

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF PERSONAL INJURY

Loss of control of the tool can lead

to injury to self of others in the work

area.

Poor quality, improper or damaged

tools and attachments can fly apart

during operation, propelling particles

through the work area causing

serious injury.

Improperly maintained tools and

accessories can cause serious injury.

There is a risk of bursting if the tool

is damaged.

Check for misalignment or binding of

moving parts, breakage of parts and

any other condition that affects the

tool's operation. If damaged, have

the tool serviced before using.

Wiping or cleaning flammable waste

materials that may have been used

on tool must be placed in a tightly

closed metal container and disposed

of in a proper manner.

Maintain the tool and accessories

with care.

Keep tools clean and properly oiled

for best and safest performance.

Always use tools attachments rated

for the speed of the power tool.

Never use tools which have been

dropped, impacted, or are damaged.

Do not apply excessive force to the

tool; let the tool perform the work.

Never use a tool that is leaking air,

has missing or damaged parts, or

requires repairs.

Keep proper footing at all times. Do

not overreach, as slipping, tripping,

and or falling can be a major cause

of serious injury and/or death. Be

aware of excess air hose and power

plugs in the working area or work

surface.

Keep handles dry, clean and free

from oil/grease.

Stay alert. Use common sense. Do

not operate tool when you are tired.

8

SAFETY INFORMATION

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF PERSONAL INJURY

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT

INHALATION HAZARD

There is a risk of bursting if the tool

is damaged.

Abrasive tools such as grinders,

sanders and cut-off tools generate

dust and abrasive materials, which

can be harmful to human lungs and

respiratory system.

Wear a respirator in accordance with

ANSI Z88.2

Always work in a clean, dry,

well-ventilated area.

Some materials such as adhesives

and tar contain chemicals whose

vapors could cause serious injury

with prolonged exposure.

Use of an accessory not intended for

use with a specific tool increases the

risk of injury to operator and anyone

in the work area.

Use of an accessory not intended for

use with the specific tool increases

the risk of injury to persons.

Follow lubrication instructions for

best and safest operation.

Follow instructions on how to

properly change accessories.

9

PACKAGE CONTENTS

DESCRIPTION

QUANTITY

1

1

1

1

1

PART

A

B

C

D

1

1

1

E

F

G

H

6 in. Palm Sander

Sanding Pad

Crank Shaft

Air Regulator

Trigger Lever

Air Inlet

Spindle Lock

Exhaust

A

E

D

G

F

B

H

C

10

ASSEMBLY INSTRUCTIONS

1

2

PREPARATION

Before beginning the assembly of the product, make sure all parts are

present. Compare parts with package contents list and hardware contents

list. If any part is missing or damaged, do not attempt to assemble the

product.

Estimated Assembly Time: 1 – 3 minutes

Tools and Materials Required For Assembly:

• 9/16 in. or adjustable wrench

• Thread Sealant Tape

• Tool Oil

• Male Plug

• Sanding Disc

• Flathead Screwdriver

1. Remove the air inlet protective cap from

the air inlet (F) (See Figure 1).

NOTE Use threaded sealant tape

(not included) on the threading of the

male plug.

F

F

Tighten male plug (not included), turning

clockwise with a wrench (not included) for

air tight connection (See Figure 2).

DO NOT OVERTIGHTEN.

2.

11

ASSEMBLY INSTRUCTIONS

3

3. Place 2 - 3 drops of air tool oil

(not included) into the male plug before

each use (See Figure 3).

4. To attach the sanding pad (B), turn the

spindle lock (G) using a flathead

screwdriver or your fingers 1/4 inch

counterclockwise. The ARROW on the

knob will be pointing to the word "LOCK"

and the spindle lock shaft will pop out

(See Figure 4). Screw the sanding pad into

the crank shaft (C) by spinning the sanding

pad clockwise. Ensure to tighten properly

(See Figure 5).

Only use sanding pads that have an RPM

rating to or greater than the tool itself. Before

using tool, always make sure attachments

are properly secured. If attachments are not

properly secured, they can present a serious

hazard and may cause bodily injury for the

operator or anyone in or around the work

area. Always follow the attachment

manufacturer’s specifications for properly

attaching accessories to tool.

WARNING

5

C

B

G

LOCK

UNLOCK

LOCK

G

4

UNLOCK

LOCK

G

UNLOCK

LOCK

UNLOCK

LOCK

12

OPERATING INSTRUCTIONS

ASSEMBLY INSTRUCTIONS

1. To start the tool, press down on the

trigger lever (E) (See Figure 1).

1

D

E

WARNING Starting the sander while the

spindle lock (G) is in the LOCK position

may damage the locking mechanism.

If this happens, you may not be able to

remove the sanding pad.

5. After attaching the sanding pad, push in

the spindle lock (G) using a flathead

screwdriver or your fingers and turn the

knob 1/4 inch clockwise. The ARROW on

the knob will be pointing to the word

UNLOCK. The sander is now ready to be

used (See Figure 6).

6. Connect air supply hose to the male plug.

Set the working pressure at 90 PSI for

best tool performance (See Figure 7).

Working pressure refers to the air line

pressure set to tool when tool is under

working conditions.

NOTE

7

B

UNLOCK

LOCK

G

6

UNLOCK

LOCK

G

UNLOCK

LOCK

UNLOCK

LOCK

13

CARE AND MAINTENANCE

ALWAYS DISCONNECT TOOL FROM THE AIR SUPPLY BEFORE

PERFORMING ANY MAINTENANCE ON THE TOOL.

Always make sure the tool is properly lubricated during operation. Proper

Clean the entire tool with a rag and lubricate the tool after each use. If storing

the tool for an extended period, run for approximately 30 seconds to

ensure oil has been evenly distributed throughout the tool. Always store tools

in a clean, dry environment away from the reach of children.

lubrication is shown in this instruction manual.

1

C

B

G

UNLOCK

OPERATING INSTRUCTIONS

REMOVAL OF SANDING PAD

1. To remove the sanding pad, push in on

the spindle lock shaft and turn the

spindle lock (G) 1/4 inch clockwise. The

arrow on the knob will be pointing to the

word "UNLOCK". Unscrew the sanding

pad from the crank shaft (C) by spinning

the sanding pad counterclockwise

(See Figure 1).

2. To adjust the speed of the sander, push

the air regulator (D) to the left gradually

to increase speed or push the air

regulator (D) to the right to decrease speed

(See Figure 2).

2

D

-

+

Recommended lubricants: air-tool oil or any other high grade turbine oil

containing moisture absorbent, rust inhibitors, metal wetting agents and an

EP (Extreme Pressure) additive. Consult your local retailer for further

assistance in selecting air tool oil best suited for proper lubrication.

14

5. Pressure drops.

7. Moisture blowing

out of tool exhaust.

6. Worn rotor blade. 6. Replace rotor blade.

7. Water in tank; a. drain tank. (See air

compressor manual). b. Oil tool and

run until no water is evident. Oil tool

again and run 1 - 2 seconds.

5. a. Be sure the hose is the proper size.

Tool using large volumes of air may

require a hose with an I.D. of 1/2 in.

or larger depending on the total

length of the hoses.

b. Do not use a multiple number of

hoses connected together with

quick-connect fittings. This causes

additional pressure drops and

reduces the tool power. Directly

connect the hoses together.

TROUBLESHOOTING

PROBLEM POSSIBLE PROBLEM CORRECTIVE ACTION

Tool runs

slowly or will

not operate.

1. Grit or gum in tool.

2. No oil in tool.

3. Low air pressure.

4. Air hose leaks.

1. Flush the tool with air-tool oil or gum

solvent.

2. Lubricate the tool.

3. Adjust the compressor regulator to

tool maximum of 90 PSI.

4. Tighten and seal hose fittings if

leaks are found. Use sealing tape.

STORING:

Tool must be well cleaned and lightly lubricated before storing.

Store tool in a dry, safe place out of the reach of children.

CARE AND MAINTENANCE

15

WARRANTY

This tool is warranted by the manufacturer to the original purchaser from the

original purchase date for three (3) years subject to the warranty coverage

described herein.

This tool is warranted to the original user to be free from defect in material

and workmanship. If you believe that a tool is defective, return the tool with

proper proof of purchase to the point of purchase. If it is determined that the

tool is defective and covered by this warranty, the distributor will replace the

tool or refund the purchase price.

This warranty is void if: defects in materials or workmanship or damages

result from repairs or alterations which have been made or attempted by

others or the unauthorized use of nonconforming parts; the damage is due

to normal wear, damage is due to abuse (including overloading of the tool

beyond capacity), improper maintenance, neglect or accident; or the damage

is due to the use of the tool after partial failure or use with improper

accessories or unauthorized repair or alteration.

This warranty gives you specific legal rights, and you may also have other

rights that vary from state to state.

For warranty questions, call our customer service department at

1-888-3KOBALT, 8:00 a.m.-8:00 p.m. EST, Monday-Friday.

Printed in China

JOIGNEZ VOTRE REÇU ICI

Numéro de série Date d'achat

Des questions, des problèmes, des pièces manquantes? Avant

de retourner l'article au détaillant, communiquez avec notre service

à la clientèle au 1 888 3KOBALT, entre 8 h et 20 h (HNE), du lundi

au vendredi.

ARTICLE #0858975

MODÈLE #SGY-AIR223

PONCEUSE ORBITALE DE 6 PO

Kobalt est une marque de commerce

déposée de LF, LLC. Tous droits réservés.

®

16

17

TABLE DES MATIÈRES

Consignes de sécurité..................................................................................18

Exigences relatives au compresseur...........................................................................17

Contenu de l'emballage................................................................................24

Caractéristiques du produit...........................................................................18

Préparation...................................................................................................25

Instructions pour l'assemblage.....................................................................25

Mode d'emploi..............................................................................................27

Entretien.......................................................................................................28

Retrait du tampon de ponçage.....................................................................28

Dépannage...................................................................................................29

Garantie........................................................................................................30

EXIGENCES RELATIVES AU COMPRESSEUR

4.5

SCFM

90

PSI

Tool Requirements

Exigences relatives aux outils

Requisitos de herramientas

@

IMPORTANT : Pour fonctionner convenablement, cet outil nécessite un

débit d’air d’au moins 4,5 pi³/min standard à une pression de 90 lb/po².

Vérifiez les spécifications de votre compresseur d’air afin de vous assurer

qu’il satisfait aux exigences minimales (pi³/min standard et lb/po²). La

longueur du tuyau à air peut avoir une incidence sur la pression d’air reçue

par l’outil. Il est possible que vous ayez à augmenter la pression d’air sur le

régulateur de débit d’air afin d’atteindre la pression de service de 90 lb/po².

18

CARACTÉRISTIQUES DU PRODUIT

CARACTÉRISTIQUES

COMPOSANTE

CONSIGNES DE SÉCURITÉ

Veuillez vous assurer de lire et de comprendre l'intégralité du présent guide

avant d'assembler, d'utiliser ou d'installer ce produit. Si vous avez des

questions concernant ce produit, veuillez téléphoner au service à la clientèle

au 1 888 3KOBALT, entre 8 h et 20 h (HNE), du lundi au vendredi.

AVERTISSEMENT

Le perçage, le sciage, le ponçage et l’usinage des produits en bois peuvent

vous exposer à de la poussière de bois, une substance reconnue par l’État

de la Californie comme étant la cause de cancers. Évitez d’inhaler la

poussière de bois ou utilisez un masque antipoussières ou d’autres mesures

de sécurité pour vous protéger. Pour plus de renseignements, rendez-vous

au www.P65Warnings.ca.gov/wood.

Afin de limiter votre exposition à des produits chimiques, travaillez dans un

endroit bien ventilé et utilisez de l’équipement de sécurité approuvé, tel qu’un

appareil respiratoire ou un masque antipoussières conçu spécialement pour

filtrer les particules microscopiques.

6 PO

10 000 TOURS/MINUTE

4,5 PI

3

/MIN STD

1/4 PO NPT

3/8 PO

90 LB/PO

2

TAMPON DE PONÇAGE

VITESSE LIBRE

CONSOMMATION D'AIR MOYENNE

ENTRÉE D'AIR

TUYAU À AIR

PRESSION DE SERVICE

AVERTISSEMENT

Une utilisation ou un entretien inadéquats de cet outil peut entraîner des

blessures graves ou des dommages matériels. Assurez-vous de lire et de

comprendre tous les avertissements et toutes les instructions avant d’utiliser

l’outil. Lorsque vous utilisez un outil, observez toujours les mesures de

sécurité de base afin de réduire les risques de blessure. Utilisez uniquement

un outil, quel qu’il soit, pour l’usage auquel il est destiné. N’utilisez pas cet

article dans des conditions de travail dangereuses. Il est toujours

recommandé d’avoir un extincteur d’incendie et une trousse de premiers

soins à proximité des aires de travail.

LE NON-RESPECT DES CONSIGNES DE SÉCURITÉ PEUT ENTRAÎNER

DE GRAVES BLESSURES OU LA MORT.

19

CONSIGNES DE SÉCURITÉ

RISQUES DE BLESSURE AUX YEUX OU À LA TÊTE

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

RISQUES MESURES PRÉVENTIVES

RISQUES MESURES PRÉVENTIVES

RISQUES MESURES PRÉVENTIVES

Cet outil pneumatique peut projeter

des fixations, des fragments de

métal, des sciures de bois et

d’autres débris, ce qui peut causer

des blessures graves.

Portez toujours des lunettes de

sécurité conformément à la norme

ANSI Z87.1.

Ne laissez jamais un outil en marche

sans supervision.

Débranchez le tuyau à air lorsque

vous n’utilisez pas l’outil ou que

vous changez d’accessoire.

L’air comprimé peut être dangereux,

car il est susceptible de projeter des

objets et des particules pouvant

causer des blessures aux tissus

mous du corps, notamment les yeux

et les oreilles. Les débris et les

objets propulsés par le jet d’air de la

sortie d’air peuvent entraîner des

blessures.

Pour plus de protection, utilisez un

écran facial approuvé en plus de

lunettes de sécurité.

Les accessoires de l'outil peuvent se

desserrer ou se briser et être

projetés en direction de l'utilisateur

ou d'autres personnes présentes

dans l'aire de travail.

Assurez-vous que les accessoires

sont bien fixés et assemblés avant

d’utiliser l’article.

Utilisez toujours l’outil à une distance

sécuritaire des autres personnes

présentes dans l’aire de travail et

assurez-vous que l’aire de travail est

sécuritaire en tout temps.

RISQUE DE PERTE AUDITIVE

RISQUES D'INCENDIE OU AVERTISSEMENT D'EXPLOSION

Portez toujours des protecteurs auditifs

conformes à la norme ANSI S3.19.

Une exposition prolongée au bruit

produit par l'utilisation d'outils

pneumatiques peut entraîner une

perte auditive permanente.

Un outil rotatif peut produire des

étincelles susceptibles d’enflammer

certains matériaux.

N'utilisez jamais un outil à proximité

d'une substance inflammable

comme de l'essence, du naphta, des

solvants de nettoyage, etc.

Travaillez dans un endroit propre,

bien ventilé et dépourvu de

matériaux combustibles.

N'utilisez jamais d'oxygène, de

dioxyde de carbone ni d'autre gaz

embouteillé comme source

d'alimentation pour les outils

pneumatiques.

20

CONSIGNES DE SÉCURITÉ

RISQUE D'EMMÊLEMENT

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

RISQUES MESURES PRÉVENTIVES

RISQUES MESURES PRÉVENTIVES

RISQUES MESURES PRÉVENTIVES

RISQUE DE COUPURE OU DE BRÛLURE

RISQUE DE CHOC ÉLECTRIQUE

Les pièces mobiles de cet outil

peuvent s’emmêler dans les

cheveux, les bijoux ou les vêtements

amples et causer des blessures

graves.

Ne portez pas de vêtements amples,

de bijoux ni tout autre article qui

pourrait s’accrocher ou s’emmêler

dans l’outil lors de son utilisation.

Retirez tout bijou susceptible de

s’accrocher dans l’outil.

Gardez toujours vos mains et les

autres parties de votre corps à

distance des pièces en mouvement.

Portez toujours un respirateur ou un

écran facial bien ajusté lorsque vous

utilisez ce genre d'outils.

Un outil rotatif peut causer des

blessures graves s’il n’est pas utilisé

adéquatement ou s’il est utilisé

d’une manière autre que celle pour

laquelle il est conçu.

Prenez garde à vos mains lorsque

vous utilisez l'outil.

La poignée de cet outil n'est pas

isolée. Lorsque l'outil entre en

contact avec un fil sous tension, ses

parties métalliques exposées

peuvent causer des chocs

électriques potentiellement mortels.

Le contact d’accessoires pour outils

pneumatiques avec des fils

électriques dissimulés peut causer

des chocs électriques ou la mort.

Évitez de toucher à des surfaces

mises à la terre, par exemple un

tuyau, un radiateur, une cuisinière

ou un réfrigérateur. Le contact de

votre corps avec une surface mise à

la terre augmente les risques de

choc électrique.

Avant de commencer à travailler,

vérifiez soigneusement la surface

pour déceler les fils dissimulés.

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

Kobalt SGY-AIR223 Manuel utilisateur

- Catégorie

- Outils électroportatifs

- Taper

- Manuel utilisateur

dans d''autres langues

- English: Kobalt SGY-AIR223 User manual

- español: Kobalt SGY-AIR223 Manual de usuario

Documents connexes

-

Kobalt SGY-AIR221 Manuel utilisateur

-

Kobalt SGY-AIR221 Manuel utilisateur

-

Kobalt SGY-AIR220 Manuel utilisateur

-

Kobalt SGY-AIR225 Manuel utilisateur

-

Kobalt SGY-AIR222 Manuel utilisateur

-

Kobalt 0840781 Manuel utilisateur

-

Kobalt SGY-AIR226 Manuel utilisateur

-

Kobalt SGY-AIR224 Mode d'emploi

-

Kobalt sgy-air217 Manuel utilisateur

-

Kobalt SGY-AIR184 Manuel utilisateur

Autres documents

-

DeWalt DWMT70780 Le manuel du propriétaire

-

Crafstman CMXPTSG1014NB Le manuel du propriétaire

-

DeWalt DWMT70781L Manuel utilisateur

-

DeWalt DWMT70781 Manuel utilisateur

-

storke 200077 Guide d'installation

storke 200077 Guide d'installation

-

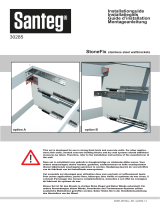

Santeg 30285 Guide d'installation

Santeg 30285 Guide d'installation

-

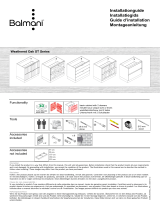

Balmani 34935 Guide d'installation

Balmani 34935 Guide d'installation

-

Graymills OAPOilAbsorbentPad Le manuel du propriétaire