OZ LIFTING PRODUCTS OZ4000EC Le manuel du propriétaire

- Taper

- Le manuel du propriétaire

ELECTRIC

CHAIN HOIST

H3 DUTY CLASS

Overload Protected

MODELS:

OZ1000EC

Capacity: 1000 lbs.

Lift: 20 Feet

Speed: 20 FPM

OZ2000EC

Capacity: 2000 lbs.

Lift: 10 Feet

Speed: 13 FPM

OZ4000EC

Capacity: 4000 lbs.

Lift: 10 Feet

Speed: 6.5 FPM

P.O. Box 845, Winona, MN 55987

Phone (800) 749-1064

(507) 474-6250

Tech Support (507) 457-3346

Fax (507) 452-5217

ozliftingproducts.com

OPERATOR’S MANUAL - EN

TABLE OF CONTENTS

Pg.2 .....................Warranty

Pg.3 .....................Dimensions and Specications / Safety Precautions / Product Warnings

Pg.5 .....................Terms and Summary / Operation Personnel

Pg.6 .....................Installation

Pg.9 .....................Maintenance

Pg.11 ....................Inspection

Pg.17 ....................Troubleshooting

Pg.18 ....................Repair Parts Ordering Instructions

Pg.19 ....................Wiring Diagram

Pg.20 ....................Parts Breakdown

Pg.21 ....................Parts List

WARRANTY

OZ Lifting Products LLC® guarantees this product to be free of defects in materials and workmanship

for one year from the date of shipment.

This warranty does not apply to products that show signs of misuse, overloading, alteration, improper

maintenance or negligence. The normal wear and tear of moving parts is excluded from the warranty.

Moving parts are dened as brake discs, wire rope and other wear components that are subject to use

conditions. This warranty does not cover any costs related to removal of this product, lost time, or any

other incidental or consequential damages/costs resulting from the claimed defects.

If this product fails during the rst year of operating due to defective materials or workmanship, it will be

repaired or replaced at the discretion of OZ Lifting Products LLC®. Any product subject to a warranty

claim must be returned, prepaid, to an authorized OZ Lifting Products LLC® warranty depot along with

proof of purchase. Upon repair, the product will be returned to the customer free of charge. If no defect

is found, the customer will be responsible for return shipping costs. The product’s warranty will be

effective for the remainder of the original warranty period (one year from shipment date).

OZ Lifting Products LLC® will not be held liable for the following arising from the use of this product:

injuries to persons or property, death, incidental, consequential, or contingent damages, whether

negligent or deliberate. It is the sole responsibility of the owner to install and operate the product

properly and safely.

This is OZ Lifting Products LLC®‘s only written warranty. This warranty is in lieu of all other warranties

implied by law such as merchantability and tness. The sale of products from OZ Lifting Products LLC®

under any other warranty or guarantee, expressed or implied, is not authorized.

NOTE: OZ Lifting Products LLC® has the right to alter the design of or discontinue the

production of any product without prior notice.

P.O. Box 845, Winona, MN 55987

Phone (800) 749-1064

(507) 474-6250

Tech Support (507) 457-3346

Fax (507) 452-5217

www.ozliftingproducts.com

EN pg.2

EN pg.3

DIMENSIONS AND SPECIFICATIONS:

MODEL SPECIFICATION

Model OZ1000EC OZ2000EC OZ4000EC

Lifting Top Layer 1000 lbs. 2000 lbs. 4000 lbs.

Load Chain Falls 1 1 2

Chain 6.3mmX6m 7.1mm x 3m 7.1mm x 3m

Lifting Speed 20 FPM 13 FPM 6.5 FPM

Motor 1.8HP 2.4HP 2.4HP

Motor KW 110V 1400W/10A 1800/13A 1800/13A

Duty Cycle 18 min. 18 min. 18 min.

Pendant Length 19’ 19’ 19’

Power Cord Length 15’ 15’ 15’

Net Weight 53 lbs. 64 lbs. 84 lbs.

SAFETY PRECAUTIONS:

Throughout the manual are safety precautions and instructions for awareness, along with information

on potential hazards. Due to the complexities of this hoist and the environment in which it operates,

situations may arise which are not directly discussed in detail in this manual.

This manual is provided as a guide to personnel involved with the operation and maintenance of the

hoist equipment. Only trained and qualied personnel can operate and maintain this equipment. We

recommend that all personnel who operate and maintain the hoist review and become familiar with

this manual. In addition, we recommend that this manual be kept readily available for reference before

beginning operation, maintenance and testing of this equipment.

Most accidents involving hoist are the result of violating safety rules during operation and/or lack of

inspection and maintenance procedures.

PRODUCT WARNINGS:

Warning indicates an imminently hazardous situation which, if not avoided,

could result in death or serious injury, and property damage.

DON’Ts

DON’T operate the hoist until you have read the Operating, Maintenance and parts manual.

DON’T use the hoist to lift, support or transport people.

DON’T lift loads over personnel.

DON’T operate the hoist until all personnel are clear of the supported load.

DON’T operate a hoist which has been modied without the manufacturer’s approval or without

certication that it is in conformity with ANSIIASME B30 volumes.

DON’T operate a hoist unless the load slings or other approved single attachments are properly sized

and seated in the hook saddle.

DON’T use load chain as a sling or wrap the chain around the load.

DON’T use hoist with twisted, kinked, damaged or worn load chain.

DON’T operate a hoist on which the safety place cards or decals are missing or illegible.

DON’T operate a damaged or malfunctioning hoist.

DON’T remove or obscure the warning labels on the hoist.

WARNING

EN pg.4

DON’T lift more than the rated load for the hoist.

DON’T apply the load unless load chain is properly seated in the chain sprocket(s).

DON’T operate hoist when it is restricted from forming a straight line from hook to hook in the direction

of loading.

DON’T operate beyond the limits of the load chain travel.

DON’T leave the load unattended unless specic precautions have been taken.

DON’T apply the load to the tip ofthe hook or to the hook latch.

DON’T attempt to lengthen the load chain or repair the damaged load chain.

DON’T apply load if bearing prevents equal loading on all load supporting chains.

DON’T operate unless load is centered under the hoist properly.

DON’T operate a hoist until it has been securely attached to a suitable support.

DON’T allow the load chain or hook to be used as an electrical or welding ground.

DON’T allow the load chain or hook to be touched by a live welding electrode.

DO’s

DO shut down a hoist immediately if it malfunctions or performs unusually and report such malfunction.

DO warn personnel of an approaching load.

DO make sure that the hoists limit switches function properly.

DO take up slack carefully - make sure the load is balanced and the load holding action is secure before

continuing.

DO protect the hoist’s load chain from weld splatter or other damaging contaminants.

PRODUCT CAUTIONS:

Caution indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury, or property damage.

DON’Ts

DON’T adjust or repair the hoist unless qualied to perform such adjustments or repairs.

DON’T allow the hoist to be subjected to sharp contact with other hoist, structures or objects

through misuse.

DON’T allow your attention to be diverted from operating the hoist.

DON’T use the hoist overload limiting clutch to measure the load.

DO’s

DO inspect the hoist regularly, replace damaged or worn parts and keep appropriate records

of maintenance.

DO lubricate load chain per hoist manufacturer’s recommendations.

DO use Mechanics Hoist CH recommended parts when repairing the hoist unit.

DO check brake function by tensioning the hoist prior to each lift operation.

DO maintain rm footing or be otherwise secured when operating the hoist.

DO make sure the hook latches are closed and not supporting any parts of the load.

DO use hook latches. Latches are to retain slings, chains, ect. under slack conditions only.

DO avoid swinging the load or hook.

DO make sure the load is free to move and will clear all obstructions.

DO make sure the hook travel is in the same direction as shown on the controls.

CAUTION

EN pg.5

TERMS AND SUMMARY:

Notice, Caution, Warning and Danger

This manual contains important information to help you properly install, operate and maintain the

OZ1000EC, OZ2000EC and OZ4000EC for maximum performance and safety purpose. Although you

may be familiar with this equipment or similar equipment, it is very strongly recommended that you read

this manual before attempting to operate, install or maintain the product. Please study the contents

thoroughly before putting the HOIST in operation. The following signal words are used to identify the

degree or level of hazard seriousness. Follow all instructions and warnings, failure to operate equipment

as directed in manual may cause injury or property damage.

Notice is used to notify people of installation, operation or maintenance information which is

important but not directly hazard related.

Warning indicates an imminently hazardous situation which, if not avoided, could result in

death or serious injury and property damage.

Caution indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury or property damage.

Caution indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury, or property damage.

OPERATION PERSONNEL:

For independent operation or maintenance of chain hoist, the owner may only employ

persons as following:

This manual contains important information to help you properly install, operate and maintain the

OZ1000EC, OZ2000EC and OZ4000EC for maximum performance and safety purpose. Although you

may be familiar with this equipment or similar equipment, it is very strongly recommended that you read

this manual before attempting to operate, install or maintain the product. Please study the contents

thoroughly before putting the HOIST in operation. The following signal words are used to identify the

degree or level of hazard seriousness. Follow all instructions and warnings, failure to operate equipment

as directed in manual may cause injury or property damage.

OZ1000EC, OZ2000EC and OZ4000EC operators should read and fully comprehend

this entire manual and all warnings on the hoist before use. If this manual is not read and

followed completely, injuries may occur.

All Persons MUST: Be trained in proper operation and in dealing with potential malfunctions of lifting

equipment. Abstain from use of alcohol, medications, or drugs while operating. Avoid operation while

tired or distracted. Avoid operation if they have a history of seizures or other medical issues that may

interfere with operation.

NOTE: Prior to operation, ensure that the hoist is in proper working condition and maintenance records

are up to date.

NOTICE

WARNING

WARNING

CAUTION

DANGER

EN pg.6

INSTALLATION:

A. PRE--INSTALLATION CHECKS:

1. Check for transit damage.

2. Check that all external wiring is in good order.

3. Check that the load chain is in good order.

4. Check that all fasteners and joints are tight and secure.

5. Check the capacity of the lifting unit and bottom block.

B. POWER SUPPLY SYSTEM:

To insure proper operation, to avoid damage to the hoist and electrical system, and to reduce the risk of

electrical shock or re, the branch circuit supplying power to the hoist must:

1. Effectively ground the hoist in accordance with the National Electrical Code and other applicable

codes. Proper grounding provides a path with the least resistance for the electrical current to travel

reducing the risk of electrical shock. The standard power cord is equipped with a three prong plug,

used with our 110V unit. Make sure that the receptacle opening that receives the longest prong is

properly grounded.

2. Be in accordance with the National Electrical Code (ANST/NFPA-70) and applicable National,

State and Local codes.

3. Include a disconnecting means capable of being locked in the ‘open’ position.

4. Have ample capacity to prevent excessive voltage drop during starting and operation. When

determining the size of branch circuit components and conductors, special consideration should be

given to the starting current amps (approximately three times that shown on the hoist identication

plate) and the length of the conductors. As a minimum, the system should be rated for 20 amps

and the system should have #14 AWG or larger, wiring.

5. Include slow blow type fuses or inverse trip time circuit breakers to permit the hoist to start and

accelerate the load.

Failure to properly ground the hoist presents the danger of electric shock.

To avoid injury: Permanently ground the hoist as instructed in this manual.

Failure to provide a proper power supply system for the hoist may cause hoist damage and

offers the potential for a re.

To avoid injury: Provide the hoist with a 20 amp, minimum, over current protected power

supply per the National Electrical Code (ANSI/NFPA 70) and applicable local codes as

instructed in this manual.

C. CONNECTION TO THE ELECTRICAL SUPPLY:

An adequate supply system is required along the total length of travel (where appropriate). The supply

voltage and frequency at which the hoist operates, is marked on the motor rating plate. It is imperative to

check before connecting the unit that these gures correspond with those of the supply voltage.

WARNING

WARNING

EN pg.7

D. MOUNTING THE HOIST:

Hang the hoist from its intended support. The structure used to support the hoist must have sufcient

strength to withstand several times the load amount. If you are not sure of the weight the structure can

hold, consult a registered engineer and the local building codes.

Suspending the hoist from an inadequate support could allow the hoist and load to fall and

cause personal injury and/or property damage.

To avoid injury: Make sure that the structure has sufcient strength to withstand several

times the hoist and its rated load amount. Using the upper hook, hang the hoist from the

support. Make sure the hoist is solidly held in the uppermost part of the hook arc and the

latch is tightly against the hook tip.

E. LOAD CHAIN:

The chain should feed smoothly into and away from the hoist and hook block (1/2 ton and 1 ton). If the

chain binds, jumps or is noisy, First clean and lubricate the chain, iftroub1e persists inspect chain and

mating parts for wear, distortion and other damages.

F. LOAD CHAIN LUBRICATION:

Always lubricate load chain weekly or more frequently depending on severity of service. Lubricate load

chain with a light coat of Lubriplate Bar and Chain Oil 10-R (Fiske Bros. Rening Co.) or equal lubricant.

Be sure the lubricant reaches the bearing surfaces between the links. Remove the excess oil from the

chain.

Used motor oils contain unknown carcinogenic materials.

To avoid health problems: Never use used motor oils as a chain lubricant. Only use

Lubriplate Bar and Chain Oil 10-R as a lubricant for the load chain.

G. HOOK AND EYE SUSPENSION HOISTS:

The suspension point should be of a correct size to admit the top hook or eye of the hoist and allow it

to rest properly on the saddle. It must be adequate to support the hoist while it is being operated at its

maximum capacity (safe working load).

H. CHAIN CONTAINER:

For installations where the slack chain hanging from the hoist may be objectionable or hazardous, the

use of a chain container is recommended.

Do not attempt to store more chain in the chain container than what is specied for the

hoist or serious damage to hoist may result and hazardous conditions may be created.

INSTALLATION OF STANDARD CHAIN CONTAINER:

1. Remove both bolts from the chain container

mounting bracket.

2. Attach the chain container to the bracket.

3. Reinsert the bolts.

WARNING

WARNING

WARNING

EN pg.8

I. TEST AND OPERATIONAL CHECKS:

On completion of installation, but before the hoist is put into regular service, the following procedure

should be carried out:

1. Record the hoist’s Code, Lot and Serial Number from the name plate on the hoist.

2. Check that the hoist is properly installed to either a xed point or trolley, whichever applies.

3. If hoist is installed on a trolley, ensure that:

- The trolley is properly installed on the beam.

- The stops for the trolley are correctly positioned and securely installed on the beam.

4. Isolate the power supply.

5. Check that all mechanical and electrical joints and connections are tight and secure.

6. Check that all nuts, bolts and split pins (cotter pins) are securely fastened.

7. Conrm proper operation:

- Before operating read and become familiar with this manual.

-Before operating check to ensure that the hoist (and trolley) meet the Inspection, Testing

and Maintenance requirements of ANSI!ASME B30.16.

-Before operating check that nothing will interfere with the full range of the hoist’s

(and trolley’s) operation.

8. Switch on the power supply.

9. Run lightly with no load, throughout the full extent of the hoist and check that the operation is

smooth at all times.

10. Check the operation of the hoist brake, run under light load and full load conditions.

Check supply voltage before everyday use. If the voltage varies more than 10% of the rated

value, electrical devices may not function normally.

Conrm the adequacy of the rated capacity for all slings, chains, wire ropes and all other

lifting attachments before use. Inspect all load suspension members for damage prior to

use and replace or repair all damaged parts.

Verify and correct all chain irregularities prior to operating the hoist.

J. UNPACKING:

Once package has been opened, carefully inspect the hoist frame, hooks, chain and control station for

damage that may have occurred during shipment.

Operating a unit with obvious external damage may cause load to drop and could result in

personal injury and/or property damage.

To avoid injury: Carefully check unit for external damage prior to installation.

Make sure to check that the power supply to which the hoist is to be connected matches the information

shown on the identication plate located on the bottom of the hoist.

BEFORE USING THE HOIST, FILL IN THE INFORMATION BELOW:

Model No.: _______________________________________

Serial No.: _______________________________________

Purchase Date: ___________________________________

WARNING

WARNING

WARNING

CAUTION

EN pg.9

MAINTENANCE:

A. CHAIN INSPECTION:

1. First clean chain with a non-caustic/non-acid type solvent and make a link by link inspection for

nicks, gouges, twisted links, weld splatter, corrosion pits, striations (minute parallel lines), cracks in

weld areas, wear and stretching. A chain with any of these defects must be replaced before use.

2. When checking the chain for wear, check the part of the chain that goes through the lift wheel

of the hoist most often. Check the interlink area of the chain links for the point of maximum wear.

Measure and record the stock diameter at this point of the link. Then measure stock diameter in the

same area on a link that does not pass through the lift wheel. Compare these two measurements.

If the stock diameter of the worn link is 0.010 inches or more, than the stock diameter of the

unworn link, the chain must be replaced.

3. Check the chain for stretch with a vernier caliper. Select an unused, unstretched section of

chain then measure and record the length. Measure and record the same length on a worn section

of chain. Obtain the amount of stretch and wear by subtracting the measurement of the unworn

section from the worn section. If the result is greater than 0.145 inch, the chain must be replaced.

4. Use only a ‘Knife-edge’ caliper to eliminate the possibility of false reading by not measuring full

pitch length.

5. These chains are specially heat treated and hardened, they should never be repaired.

IMPORTANT: Do not use replaced chain for other purposes such as lifting or pulling. Load chain may

break suddenly without visual deformation. For this reason, cut replaced chain into short lengths to

prevent use after disposal.

NOTE: A worn chain can be an indication of worn hoist components. For this reason, the hoist’s

chain guide, hook block and lift wheel should be examined for wear and replaced as necessary when

replacing worn chain.

Use of commercial or other manufactures’ chain and parts to repair OZ Electric Chain

Hoists may cause load loss. To avoid injury: Use only factory supplied replacement load

chain and parts. Chain and parts may look alike, but factory original chain and parts are

made of specic materials or processed to achieve specic properties.

A. CUTTING THE CHAIN:

The load chain is hardened and is difcult to cut. The following methods are recommended when cutting

a length of new chain from stock or cutting off worn chain. (Always wear eye protection when cutting the

load chain.)

1. Use a 7” minimum diameter by 1/8” thick abrasive wheel (or type recommended by your wheel

supplier) that will clear the adjacent links.

2. Use a grinder and nick the link on both sides, then secure the link with a vise and break off the

chain link with a hammer.

Cutting chain can produce ying particles.

To avoid health problems:

- Wear eye protection.

- Place shield over chain to prevent ying objects.

WARNING

WARNING

EN pg.10

C. LUBRICATION:

1. Load Chain: The full length of the chain must be lubricated, including where the chain passes

over the chain wheel(s). Ensure that the contact points between the links (I.E. the chain saddles) are

adequately lubricated. A small amount of lubrication will greatly increase the life of the load chain.

DO NOT allow the chain to run dry. Keep the chain clean and lubricate the chain at regular intervals

with Lubriplate Bar and Chain Oil 10-R or equal lubricant. Normally, weekly lubrication and cleaning

is satisfactory, but under hot and dirty conditions, it may be necessary to clean the chain at least

once daily and lubricate the chain several times between cleanings. When lubricating the chain,

apply sufcient lubricant to obtain natural run-off and full coverage, especially in the interlink area.

Used motor oils contain known carcinogenic materials.

To avoid health problems: Never use used motor oils as a chain lubricant. Only use

Lubriplate Bar and Chain Oil 10-R as a lubricant for the load chain.

2. Gearbox: For ambient temperature of approx., 50 F to 122 F, a gear oil of Mm /S at 104 F, with

mild high-pressure additives should be used. Examples of the oil types that can be used are:

Din 51502 Clp 220

E.G. Bp Energol Gr-Xp 20

Esso Spartan Ep 220

Shell Omala Oil 220

Mobil gear 630

Aral Degol Bg 220

3. Important: The bottom block must not touch the oor; if necessary adjust the position of the

chain stop on the slack end of the chain.

The lubricants used for the OZ Electric Chain Hoist may contain hazardous materials that

mandate specic handling and disposal procedures.

To avoid contact and contamination: Handle and dispose of lubricants only as directed in

applicable material safety data sheets and in accordance with applicable local, state and

federal regulations.

D. TESTING:

Before using, all altered, repaired or used hoists that have not been operated for the previous 12 months

must be tested by the user for proper operation.

1. Test the unit without a load and then test the unit with a light load of 50 pounds (23 kg) times

the number of load chain supporting parts to be sure that the hoist operates properly and that the

brake holds the load when control is released.

2. Next test with a load of 125% of the rated capacity. In addition, hoists in which load sustaining

parts have been replaced, you should test the load with 125% of rated capacity by or under an

appointed person and a written report prepared for record purposes.

3. In accordance with the CMAA 78, it is required to have a 100% load test preformed every

four years.

The hoist must only be inspected and maintained by qualied, competent and trained

personnel.

WARNING

CAUTION

EN pg.11

Table 7-1 Lubrication Chart

PART DESCRIPTION FREQUENCY

Cables Check control cables and strain relief elements Before each shift

Clutch Check operation of the slipping clutch (if tted) Before each shift

Pendant Check control pendant housing for damage Before each shift

Hook Check suspension eye/suspension hook assembly After 50-200 service hours

Electrical Check electrical switch gear and wiring Before each shift, Monthly

Hook Check tight t of securing bolts on load hook assembly Before each shift, After 50-200 service

hours

Chain Check ends of chain/chain bag to ensure they are

secure

Before each shift

Chain Lubricate chain, under normal usage

Lubricate chain, under heavy usage

After 50-200 service hours

Oil Check oil level and change oil (if needed) Before each shift

Hook Check hooks for cracks, deformation, pitting and wear After 50-200 service hours

Clips/Bolts/Nuts Check securing elements for tight t and corrosion After 50-200 service hours

Bottom Block Lubricate chain sprocket bearing and check for a tight

t of securing bolts.

After 50-200 service hours

Brakes Check operation of brakes After 50-200 service hours

Brake Check brake stroke, brake disc and adjust brake as

required

After 50-200 service hours

INSPECTION:

A. GENERAL:

The inspection procedure is based on ANSI/ASME B30.16. The following denitions are from ANSI/

ASME B30.16 and pertain to the inspection procedure below.

1. Qualied Person: A person who, by possession of a recognized degree or certicate of

professional standing, or who, by extensive knowledge, training and experience has successfully

demonstrated the ability to solve or resolve problems relating to the subject matter at work.

2. Designated Person: A person assigned or selected as being competent to perform the specic

duties to which he/she is assigned.

3.

Normal Service: A distributed service which involves operation with randomly distributed loads within

the rated load limit or uniform loads less than 65% of rated load for not more than 25% of the time.

4. Heavy Service: A service which involves operation within the rated load limit which exceeds

normal service.

5.

Severe Service: A service which involves normal or heavy service with abnormal operating conditions.

B. INSPECTION METHODS AND CRITERIA:

This section covers the inspection of specic items. The list of items in this section is based on those

listed in ANSI/ASME B30.16 for the Frequent and Periodic Inspection. In accordance with ANSI/ASME

B30 volumes listed under the General heading on the previous pages, these inspections are not intended

to involve disassembly of the hoist. Rather, disassembly for further inspection would be required if

frequent or periodic inspection results so indicate. Such disassembly and further inspection should only

be performed by a certied or qualied person trained in the disassembly and re-assembly of the hoist.

Table 8-1 Hoist Inspection Methods and Criteria

Item Method Criteria Action

Functional operat-

ing mechanisms

Visual,

Auditory

Mechanisms should be properly adjusted and should not

produce unusual sounds when operated.

Repair or replace as

required

Braking System

Operation

Function Braking distance with rated capacity should not exceed ap-

proximately ve chain links.

Repair or replace as

required

Hooks (surface

condition)

Visual Should be free of signicant rust, weld splatter, deep nicks or

gouges.

Replace

Hooks (stretch) Measure The “D” dimension should not exceed the measured value for

discard from Table 8-3.

Replace

Hooks (fretting

wear)

Measure The “F” and “T” dimensions should not be less than discard

value listed in Table 8-3.

Replace

Hooks (yoke as-

sembly)

Visual Should be free of signicant rust, weld splatter, nicks or

gouges. Holes should not be elongated, fasteners should not

be loose and there should be no gap between mating parts.

Tighten or replace as

required

Hooks (bent shank

or neck)

Visual Shank and neck portions of hook should be free of deforma-

tions.

Replace

Hooks (hook

latches)

Visual,

Function

Latch should not be deformed. Attachment of latch to hook

should not be loose. Latch spring should not be missing and

should not be weak. Latch movement should not be stiff-

when depressed and released latch should snap smartly to its

closed position.

Replace

Hooks (swivel

bearing)

Visual,

Function

Bearing parts and surfaces should not show signicant wear.

They should be free of dirt, grime and deformations. Hook

should rotate freely with no roughness.

Clean/Lubricate, or

replace as required

Load Chain (sur-

face condition)

Visual Should be free of rust, nicks, gouges, dents and weld spatter.

Links should not be deformed or show signs of abrasion.

Surfaces where links bear on one another should be free of

signicant wear.

Replace

Load Chain

(lubrication)

Visual,

Auditory

Entire surface of each link should be coated with lubricant and

free of dirt/grime. Chain should not emit cracking noise when

hoisting a load.

Clean/ Lubricate

Load Chain (pitch

and wire diameter)

Measure The “G” dimension should not be greater than maximum value

listed in Table 8-4. The “E” dimension should not be less than

minimum value listed in Table 8-4.

Replace. Inspect Load

Sheave by qualied

personnel

Load Chain

(reeving)

Visual Chain should be reeved properly through load sheave. Chain,

cushion rubbers, washers and stoppers should be installed

properly.

Reeve/ Install chain

properly

Chain Container Visual Container should not be damaged. Brackets should not be

deformed or missing.

Replace

Housing and

Mechanical Com-

ponents

Visual,

Auditory,

Vibration,

Function

Hoist components including load blocks, suspension housing,

chain attachments, clevises, yokes, suspension bolts, shafts,

gears, bearings, pins and rollers should be free of cracks,

distortion, signicant wear and corrosion. Evidence of same

can be detected visually or via detection of unusual sounds or

vibration during operation.

Replace

Bolts, Nuts and

Rivets

Visual,

Check with

proper

tool

Bolts, nuts and rivets should not be loose. Tighten or replace as

required

EN pg.12

Table 8-1 Hoist Inspection Methods and Criteria

Item Method Criteria Action

Motor Brushes Measure,

Visual

The “B” dimension should not be less than minimum value

listed in Table 8-2.

Replace

Cushion Rubber Visual Should be free of signicant deformation. Replace

Contactor

Contacts

Visual Contacts should be free of signicant pitting or deterioration. Replace

Pendant

(switches)

Function Depressing and releasing push buttons should make and

break contacts in switch contact block and result in cor-

responding electrical continuity or open circuit. Push buttons

should be interlocked either mechanically or electrically to

prevent simultaneous energization of circuits for opposing

motions. Example: Up and Down

Repair or replace as

necessary

Pendant (wiring) Visual Wire connections to switches in pendant should not be loose

or damaged.

Tighten or repair

Pendant

(housing)

Visual Labels denoting functions should be legible. Replace

Pendant (labels) Visual Pendant housing should be free of cracks and mating sur-

faces of parts should seal without gaps.

Replace

Pendant (cord) Visual,

Electrical

Continuity

Surface of cord should be free from nicks, gouges and abra-

sions. Each conductor in cord should have I 00% electrical

continuity even when cord is exed back and forth. Pendant

cord strain relief cable should absorb the entire load associ-

ated with forces applied to the pendant.

Replace

Warning Labels Visual Warning labels should be afxed to the hoist and they should

be legible.

Replace

Hoist Capacity

Label

Visual The label that indicates the capacity of the hoist should be

legible and securely attached to the hoist.

Replace

Table 8-2 Motor Brush Dimensions

Capacity (Ton) “B” Dimension (inches)

Discard

1/2 to 2 .315 in.

EN pg.13

EN pg.14

Table 8-3 Top Hook & bottom Hook Dimensions (Inches)

Capacity T/B a b c d e g

1000 lbs T/B 1.14 .76 1.02 .76 1.09 0.87

2000 lbs T/B 1.30 .91 1.14 .91 1.56 1.22

4000 lbs T/B 1.77 1.22 1.61 1.22 1.81 1.50

These values are nominal since the dimension is not controlled to a tolerance. The “D” dimension

should be measured when the hook is new, this becomes a reference measurement. Subsequent

measurements are compared to this reference to make determinations about hook deformation/stretch.

Table 8-4 Chain Wear Dimensions

Standard Dimension d Ø 6.3 Ø 7.1

Limit Dimension mm Ø 5.7 Ø 6.4

Wear Standard Dimension p 19.1 20.2

Wear Limit Dimension mm 20 21

C. INSPECTION CLASSIFICATION:

The inspection procedure for hoist in regular service is divided into two general classications based

upon the intervals at which inspection should be performed. The intervals in turn are dependent upon

the nature of the critical components of the hoist and the degree of their exposure to wear, deterioration

or malfunction. The two general classications are designated as Frequent and Periodic, with respective

intervals between inspections as dened below.

EN pg.15

Initial Inspection: Prior to initial use, all new, altered or modied hoist shall be inspected by

a designated person to ensure compliance with the applicable provisions of this manual.

FREQUENT INSPECTIONS - Frequent inspections are visual examinations by the operator or other

designated personnel with interval per the following criteria.

1. Normal Service- Monthly

2. Heavy Service - Weekly to Monthly

3. Severe Service- Daily to Weekly

4. Special or Infrequent Service - As recommended by a qualied person before and after each

occurrence.

PERIODIC INSPECTIONS - Periodic inspections are visual inspections by a designated person with

interval per the following criteria.

1. Normal Service - Yearly

2. Heavy Service- Semi-Annually

3. Severe Service - Quarterly

4. Special or Infrequent Service- As recommended by a qualied person before the rst occurrence.

D. FREQUENT INSPECTION:

Inspections should be made on a Frequent basis in accordance with Table 8-5, “Frequent Inspection.”

Included in these Frequent Inspections are observations made during operation for any defects or

damage that might appear between Periodic Inspections. Frequent Inspections shall be made by a

designated person to ensure that the hoist is maintained in safe working condition.

Table 8-5 Frequent Inspection

1. Check all functional operating mechanisms for maladjustment and unusual sounds.

2. Check the operation of the limit switch and associated components.

3. Check the hoist braking system for proper operation.

4. Check the hooks in accordance with ANSI/ASME B30.10.

5. Check the hook latch operation.

6. Check the Load Chain in accordance with Section 8B

7. Check the Load Chain reeving.

E. PERIODIC INSPECTION:

Inspections should be made on a Periodic basis in accordance with Table 8-6, “Periodic Inspection.”

Evaluation and resolution of the results of Periodic Inspections shall be made by a designated person to

ensure that the hoist is maintained in safe working condition.

Periodic Inspection: For inspections where load suspension parts of the hoist are

disassembled, a load test per ANSI/ASME B30.16 must be performed on the hoist after it is

re-assembled and prior to its return to service.

CAUTION

WARNING

EN pg.16

Table 8-6 Periodic Inspection

1. Complete the requirements of Frequent Inspection.

2. Check to ensure there is no evidence of loose bolts, nuts or rivets.

3. Check to ensure there is no evidence of damage or excessive wear of load and idler sheaves.

4. Check to ensure there is no evidence of damage to hook retaining nuts or collars and pins, and welds or rivets used to

secure the retaining members.

5. Check to ensure the warning label is properly attached to the hoist and legible.

6. Check to ensure the function labels on the pendant control stations are legible.

7. Check to ensure there is no evidence of worn, corroded, cracked or distorted parts such as load blocks, suspension

housing, chain attachments, clevises, yokes, suspension bolts, shafts, gears, bearings, pins and rollers.

8. Check to ensure there is no evidence of damage to the supporting structure or trolley, if used.

9. Check to ensure there is no evidence of damage to the end connections of the load chain.

10. Check to ensure there is no evidence of excessive wear on motor or load brake.

11. Check to ensure there is no electrical apparatus for signs of pitting or any deterioration of visible controller contacts.

F. OCCASIONALLY USED HOIST:

Hoists that are infrequently used shall be inspected as follows before placing the hoist in service:

1. Hoist idle more than one month, less than one year: Inspect per Frequent Inspection.

2. Hoist idle more than one year: Inspect per Periodic Inspection.

G. INSPECTION REPORTS:

Hoists that are infrequently used shall be inspected as follows before placing the hoist in service:

1. A long range chain inspection program should be established and should include records of an

examination of the chains that are removed from service. To create a relationship between visual

observation and actual condition of the chain.

2. Dated inspection reports and records should be maintained for the hoist Periodic Inspection

intervals. These records should be stored where they are available to personnel involved with the

inspection, maintenance or operation of the hoist.

EN pg.17

TROUBLESHOOTING:

Table 8-7 Troubleshooting Guide

Symptom Cause Remedy

Hoist will not

operate

Loss of power Check circuit breakers, switches, fuses and connections on power lines/

cable.

Wrong voltage or frequency Check voltage and frequency of power supply against the rating on the

nameplate of the motor.

Hoist overload Reduce load to within rated capacity of hoist.

Improper, loose or broken wire

in the hoist electrical system

Shut off power supply, check wiring connections on hoist control panel

and inside push button pendant.

Brush wear Inspect both motor brushes per Table 8-2 and replace if necessary.

Fuses burned out Replace fuses.

Motor burned out Replace motor frame/stator, shaft/rotor and any other damaged parts.

Hoist lifts but

will not lower

Faulty switch in pendant Check electrical continuity. Check electrical connections. Replace or

repair as needed.

Broken conductor in pendant

cord

Check the continuity for each conductor in the cable. If one is broken,

replace the entire cable.

Hoist lowers

but will not lift

Hoist overload Reduce load to within rated capacity of hoist.

Worn friction clutch Repair by a qualied person trained in the repair of hoists and proper

friction clutch adjustment procedures. Replace as needed.

Broken conductor in pendant

cord

Check the continuity for each conductor in the cable. If one is broken,

replace the entire cable.

Faulty switch in pendant Check electrical continuity. Check electrical connections. Replace or

repair as needed

Low voltage in hoist’s power

supply

Determine cause of low voltage and bring to within plus or minus 5% of

the voltage specied on the motor nameplate. The voltage should be

measured at the hoist contactor.

Hoist will

not lift rated

load or does

not have the

proper lifting

speed

Hoist overload Reduce load to within rated capacity.

Low voltage in hoist’s power

supply

Determine cause of low voltage and bring to within plus or minus 5% of

the voltage specied on the motor nameplate. The voltage should be

Faulty friction clutch If abnormal operation or slippage occurs do NOT attempt to disassem-

ble or adjust the Mechanical Load Brake with Friction Clutch. Replace

the worn or malfunctioning Mechanical Load Brake with Friction Clutch

as an assembly with a new, factory adjusted part.

Load drifts

excessively

when hoist is

stopped

Motor demagnetized Motor demagnetizing is generally caused from using the hoist beyond

its duty rating. Replace stator assembly and reduce usage to comply

with the duty rating stated.

Improper gear oil Replace oil with the correct gear oil.

Hoist operates

intermittently

Loose connection in circuit Check all wires and terminals for bad connections. Replace as needed.

Collectors making poor contact Check movement of spring loaded arm, weak spring, connections and

shoe. Replace as needed.

Broken conductor in pendant

cord

Check for intermittent continuity in each conductor in the pendant cord.

Replace the entire pendant cord if continuity is not constant.

EN pg.18

REPAIR PARTS ORDERING INSTRUCTIONS:

This parts and instruction manual contains information required to install and maintain your hoist. To

insure prompt service, each repair parts order should be placed with OZ Lifting Products, LLC, and must

contain the following information:

1. Serial number and Model number from the OZ hoist name plate, located on the side of the hoist.

2. Hoist capacity from the hoist name plate, located on the side of the hoist.

3. Voltage, Amp and Horse Power from the hoist name plate, located on the side of the hoist.

4. Hoist Speed from the hoist name plate, located on the side of the hoist.

5. Part name from the part list.

6. Item number of part from the part list.

7. Part number from the part list.

8. Quantity of parts requested.

Note: When ordering replacement parts, it is recommended that consideration be given to the need for

also ordering such items as gaskets, fasteners, seals, etc. These items may be damaged or lost during

disassembly or just unt for future use because of deterioration from age or service.

Use of commercial or other manufactures’ chain and parts to repair OZ Hoists may cause

load loss. To avoid injury: Use only factory supplied replacement load chain and parts.

Chain and parts may look alike, but factory original chain and parts are made of specic

materials or processed to achieve specic properties.

WARNING

EN pg.19

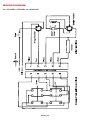

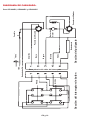

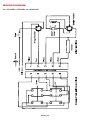

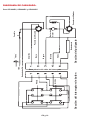

WIRING DIAGRAM:

For OZ1000EC, OZ2000EC and OZ4000EC

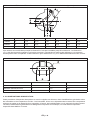

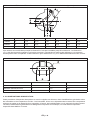

PARTS BREAKDOWN:

EN pg.20

For OZ1000EC, OZ2000EC and OZ4000EC

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

OZ LIFTING PRODUCTS OZ4000EC Le manuel du propriétaire

- Taper

- Le manuel du propriétaire

dans d''autres langues

Documents connexes

-

OZ LIFTING PRODUCTS OZ500EC Le manuel du propriétaire

OZ LIFTING PRODUCTS OZ500EC Le manuel du propriétaire

-

OZ LIFTING PRODUCTS OZ075-15LHOP Le manuel du propriétaire

OZ LIFTING PRODUCTS OZ075-15LHOP Le manuel du propriétaire

-

OZ LIFTING PRODUCTS OBH1000 Le manuel du propriétaire

OZ LIFTING PRODUCTS OBH1000 Le manuel du propriétaire

-

OZ LIFTING PRODUCTS OZ05PBTA-16 Le manuel du propriétaire

OZ LIFTING PRODUCTS OZ05PBTA-16 Le manuel du propriétaire

-

OZ LIFTING PRODUCTS OZ3BC Le manuel du propriétaire

OZ LIFTING PRODUCTS OZ3BC Le manuel du propriétaire

-

OZ LIFTING PRODUCTS OBH230-WALL Le manuel du propriétaire

OZ LIFTING PRODUCTS OBH230-WALL Le manuel du propriétaire

Autres documents

-

Milwaukee 9676-20 Manuel utilisateur

-

Milwaukee 9683-20 Manuel utilisateur

-

Ingersoll-Rand ELK25-1ND25 Information produit

-

Power Fist 8873150 Le manuel du propriétaire

-

Power Fist 8873275 Le manuel du propriétaire

-

Power Fist 8873267 Le manuel du propriétaire

-

Power Fist 8873101 Le manuel du propriétaire