Klein Tools CL440 Manuel utilisateur

- Catégorie

- Mesure, test

- Taper

- Manuel utilisateur

Ce manuel convient également à

INSTRUCTION MANUAL

ENGLISH

FRANÇAIS pg. 37

ESPAÑOL pg. 19

HVAC Clamp Meter

HVAC Clamp Meter

HVAC Clamp Meter

HVAC Clamp Meter

True RMS

Measurement

Technology

750V

600V

600A

60M

Ω

• MICROAMP DC

• INRUSH CURRENT

• NON-CONTACT

VOLTAGE TESTING

• AUTO-RANGING

• TEMPERATURE

• AUDIBLE CONTINUITY

5001748

1m

-328° –

2462°F

-200° –

1350°C

CL440

CAT IV

600V

2

GENERAL SPECIFICATIONS

Klein Tools CL440 is an automatically ranging true root mean

square (TRMS) digital clamp meter that measures AC current and

inrush via the clamp, AC/DC voltage, DC microamps, resistance,

continuity, frequency, capacitance, and tests diodes via test-leads, and

temperature via a thermocouple probe.

• Operating Altitude: 6562 ft. (2000m)

• Relative Humidity: <95% non-condensing

• Operating Temp: 32° to 122°F (0° to 50°C)

• Storage Temp: 14° to 122°F (-10° to 50°C)

• Accuracy: Values stated at 65° to 83°F (18° to 28°C)

• Temp Coef cient: 0.1 × (Quoted Accuracy) per °C above

28°C or below 18°C, corrections are required when ambient

working temp is outside of Accuracy Temp range

• Dimensions: 10.04" × 3.77" × 1.57" (255 × 96 × 40 mm)

• Weight: 14.22 oz (403 g) including batteries

• Calibration: Accurate for one year

• Auto Power-Off (APO): After approx. 10 minutes of inactivity

• Standards: IEC EN 61010-1, 61010-2-032, 61010-2-033.

IEC EN 61326-1, 61326-2-2.

Conforms to UL STD.61010-1,

61010-2-032,61010-2-033;

Certified to CSA STD.C22.2 NO. 61010-1,

61010-2-032,61010-2-033.

• Pollution degree: 2

• Accuracy: ± (% of reading + # of least significant digits)

• Drop Protection: 3.3 ft. (1m)

• Safety Rating: CAT IV 600V

Class 2, Double insulation

CAT III: Measurement category III is applicable to test and

measuring circuits connected to the distribution part of the

building’s low-voltage MAINS installation.

CAT IV: Measurement category IV is applicable to test and

measuring circuits connected at the source of the building’s

low-voltage MAINS installation.

• Electromagnetic Environment: IEC EN 61326-1. This

equipment meets requirements for use in basic and controlled

electromagnetic environments like residential properties,

business premises, and light-industrial locations.

Specifications subject to change.

ENGLISH

5001748

3

ELECTRICAL SPECIFICATIONS

Function Range Resolution Accuracy

AC Voltage

(V AC)

600.0mV 0.1mV

±(1.8% + 5 digits)

6.000V 1mV

±(1.5% + 5 digits)

60.00V 10mV

±(1.2% + 5 digits)

600.0V 100mV

750V 1V ±(1.5% + 5 digits)

DC Voltage

(V DC)

600.0mV 0.1mV ±(1.0% + 8 digits)

6.000V 1mV

±(0.8% + 3 digits)

60.00V 10mV

600.0V 100mV ±(1.0% + 3 digits)

Input Impedance: 10MΩ

Frequency Range: 45 to 400Hz

Maximum Input: 750V AC RMS or 600V DC

AC Current

(A AC)

60.00A 10mA ±(2.5% + 10 digits)

600.0A 100mA ±(2.0% + 10 digits)

Frequency Range: 50 to 60Hz

DC Microamps

(µA DC)

600 μA 0.1 μA ±(1.2% + 5 digits)

Maximum Input: 750V AC RMS or 600V DC

Resistance

600.0Ω 0.1Ω ±(1.2% + 5 digits)

6.000KΩ 1Ω

±(1.2% + 3 digits)

60.00kΩ 10Ω

600.0kΩ 100Ω

6.000MΩ 1kΩ

60.00MΩ 10kΩ ±(2.0% + 5 digits)

Maximum Input: 750V AC RMS or 600V DC

4

OTHER MEASUREMENT APPLICATIONS

Maximum Input: 600V DC or 750V AC RMS

• Diode Test: Approx. 1mA, open circuit voltage ~3.0V DC

• Continuity Check: Audible signal <10Ω, max current 1.5mA

• Sampling Frequency: 3 samples per second

• Overload: "OL" indicated on display

• Polarity: "-" on display indicates negative polarity

• Display: 3-5/6 digit, 6000 Count LCD

ELECTRICAL SPECIFICATIONS

Function Range Resolution Accuracy

Capacitance

60.00nF 0.010nF ±(4% + 25 digits)

600.0nF 0.100nF

±(4% + 8 digits)

6.000μF 0.001μF

60.00μF 0.010μF

600.0μF 0.100μF

6.000mF 0.001mF ±(5% + 9 digits)

Maximum Input: 750V AC RMS or 600V DC

Temperature

°F

-328° to 54°F

1

°F

±(1.5% + 7 digits)

55° to 2462°F

±(1.2% + 6 digits)

Temperature

°C

-200° to 12°C

1

°C

±(1.5% + 4 digits)

13° to 1350°C

±(1.2% + 3 digits)

Maximum Input: 750V AC RMS or 600V DC

Frequency

10Hz to

60kHz

0.001Hz

to 0.01kHz

±(0.1% + 5 digits)

Duty Cycle

0.1% to 99.9%

(≤10kHz)

0.1%

±1.5%

(Range: 10% – 90%)

Maximum Input: 750V AC RMS or 600V DC

ENGLISH

5

WARNINGS

To ensure safe operation and service of the meter, follow these instructions.

Failure to observe these warnings can result in severe injury or death.

• Before each use verify meter operation by measuring a known voltage

or current.

• Never use the meter on a circuit with voltages that exceed the category

based rating of this meter.

• Do not use the meter during electrical storms or in wet weather.

• Do not use the meter or test leads if they appear to be damaged.

• Use only with CAT III or CAT IV rated test leads.

• Ensure meter leads are fully seated, and keep fingers away from the

metal probe contacts when making measurements.

• Use caution when working with voltages above 25V AC RMS or 60V DC.

Such voltages pose a shock hazard.

• To avoid false readings that can lead to electrical shock, replace batteries

when a low battery indicator appears.

• Do not attempt to measure resistance or continuity on a live circuit.

• Always adhere to local and national safety codes. Use personal protective

equipment to prevent shock and arc blast injury where hazardous live

conductors are exposed.

• To avoid risk of electric shock, disconnect leads from any voltage source

before removing battery door.

• To avoid risk of electric shock, do not operate meter while battery door is removed.

SYMBOLS ON METER

AC (Alternating Current)

AC/DC Current

DC (Direct Current)

Resistance (in Ohms)

Double Insulated Class II

Audible Continuity

Warning or Caution

Ground

Diode

Risk of Electrical Shock

Hz

Frequency

Capacitance

%

Duty-cycle V Voltage (Volts)

°

F/

°

C

Temperature (Fahrenheit / Celsius) A Amperage (Amps)

COM Common NCV

Non-Contact Voltage Tester

% Duty cycle SEL Select

Backlight Hz Frequency

Positive Negative

SYMBOLS ON LCD

AC AC (Alternating Current) DC DC (Direct Current)

Negative Reading Data Hold

Auto Ranging MAX Maximum Value Hold

MIN Minimum Value Hold Audible Continuity

Low Battery

°

C

Degrees (Celsius)

°

F

Degrees (Fahrenheit)

k

kilo (value × 10

3

)

M

Mega (value × 10

6

)

μ

micro (value × 10

-6

)

m

milli (value × 10

-3

)

V

Volts (Voltage)

n

nano (value × 10

-9

) Ohms (Resistance)

A

Amps (Amperage)

F

Farads (Capacitance)

Hz%

Frequency/Duty Cycle Auto Power-Off

NCV

Non-Contact Voltage Tester Diode Test

Hazardous Voltage Indicator Inrush

6

ENGLISH

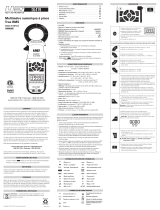

FEATURE DETAILS

NOTE: There

are no user-

serviceable parts

inside meter.

1.

6000 count LCD display

10.

Clamp trigger

2.

Function selector switch

11.

Arrow markings

3.

Clamp

12.

"SEL/NCV" button

4.

"COM" jack

13.

NCV Light

5.

"VΩµA" jack

14.

NCV Sensing Antenna

6.

Backlight button

15.

K-Type Thermocouple Inputs

7.

"RANGE" button

16.

Temperature/Voltage input switch

8.

"MAX/MIN" button

17.

"InRush" Button

9.

Data Hold button

NOTE: There

are no user-

serviceable parts

inside meter.

1

7

2

9

3

10

14

6

8

17

15

16

4 5

11

12

13

7

FUNCTION BUTTONS

ON/OFF

To power ON the meter, rotate the Function Selector switch

2

from

the OFF setting to any measurement setting. To power OFF the meter,

rotate the Function Selector switch

2

to the OFF setting. By default,

the meter will automatically power OFF after 10 minutes of inactivity.

If the meter automatically powers-OFF while in a measurement

setting, press any button to power the meter ON, or rotate Function

Selector

2

switch to OFF, then power ON the meter.

To deactivate

the power OFF functionality press and hold the "SELECT" button

12

before powering ON from the OFF setting. When auto power OFF

is deactivated, the Auto Power Off icon will not be visible in the

display.

SEL / NCV BUTTON (FOR NCV TESTING)

Press and hold the SEL/NCV button

12

to enter Non-contact Voltage

Testing (NCV) mode to test for presence of AC voltage. The NCV

icon and "EF" will be present on the display. Approach the conductor

under test leading with the sensing antenna

14

.

In the presence of AC

voltage, the red NCV light

13

will flash, audible signals (beeps) will

sound.

Release the SEL/NCV button to exit NCV testing mode.

NOTE: Only voltages of 40V AC or greater will be detected.

BACKLIGHT

Press Backlight button

6

to turn ON or OFF the backlight. The

backlight does not automatically power OFF.

RANGE

The meter defaults to auto-ranging mode . This mode

automatically determines the most appropriate measurement range

for the testing that is being conducted. To manually force the meter

to measure in a different range, use the "RANGE" button

7

.

1. Press the "RANGE" button

7

to manually select measurement

range ( is deactivated on the LCD). Repeatedly press the

"RANGE" button

7

to cycle through the available ranges, stopping

once the desired range is reached.

2. To return to auto-ranging mode, press and hold the "RANGE"

button

7

for more than two seconds ( is reactivated).

MAX/MIN

When the "MAX/MIN" button

8

is pressed, the meter keeps track of

the Maximum and Minimum values.

8

1. When measuring, press "MAX/MIN" button

8

to toggle between

the Maximum value (MAX), the Minimum value (MIN). If a new

maximum or minimum occurs, the display updates with that new

value.

2. Press "MAX/MIN" button

8

for more than two seconds to return

to normal measuring mode.

DATA HOLD

Press HOLD

9

to hold the measurement on the display. Press

HOLD

9

again to release the display to return to live measuring.

FUNCTION BUTTONS

ENGLISH

9

OPERATING INSTRUCTIONS

CONNECTING TEST LEADS

Do not test if leads are improperly seated. Results could cause

intermittent display readings. To ensure proper connection, firmly

press leads into the input jack completely.

TESTING IN CAT III MEASUREMENT LOCATIONS

Ensure the test lead shield is pressed firmly in place. Failure to use

the CATIII / CATIV shield increases arc-flash risk.

TESTING IN CAT II MEASUREMENT LOCATIONS

CAT III / CAT IV shields may be removed for CAT II locations. This

will allow testing on recessed conductors such as standard wall

outlets. Take care not to lose the shields.

5/32"

(4 mm)

.7" (18 mm)

INCORRECT

CORRECT

10

OPERATING INSTRUCTIONS

AC CURRENT (LESS THAN 600A)

AC Current is measured by pressing the clamp trigger

10

to open

the clamp and placing it around a current-carrying wire. When

measuring, care should be taken to ensure that the clamp is

completely closed with trigger

10

fully released, and that the wire

passes perpendicularly through the center of the clamp in line with

the arrow markings

11

.

To measure current:

1. Rotate the Function Selector switch

2

to the A~ setting.

2. Place clamp around wire. The current

measurement will be shown in the display.

Disconnect test leads when

measuring with the clamp.

ENGLISH

Red leadBlack lead

NOTE: Current

measurement can be

made by clamping

around single

conductors, but not

cables containing

both live and neutral

wires. In this case a

line splitter is required,

Klein Cat. No. 69409 is

recommended.

AC/DC VOLTAGE (LESS THAN 600V)

1. Insert RED test lead into VΩµA jack

5

, and BLACK test lead

into COM jack

4

, and rotate function selector switch

2

to the

V

setting for AC or DC measurements. The meter defaults to

AC measurement. To measure DC, press the "SELECT" button

12

to toggle between AC and DC modes. The AC or DC icon on

the LCD indicates which mode is selected. Note "AC" or "DC" on

the display.

the arrow markings

11

11

.

WIREWIRE

NOTE:

measurement can be

made by clamping

around single

conductors, but not

cables containing

both live and neutral

wires. In this case a

line splitter is required,

Klein Cat. No. 69409 is

11

OPERATING INSTRUCTIONS

Apply test leads to the circuit to be tested to measure voltage.

The meter will auto-range to display the measurement in the most

appropriate range.

NOTE: If "–" appears on the LCD, the test leads are being applied to

the circuit in reverse. Swap the position of the leads to correct this.

NOTE: To access mV range for V AC , the 'RANGE' button

7

must

be used.

NOTE: When in a voltage setting and the test leads are open,

readings of order mV may appear on the display. This is noise and

is normal. By touching the test leads together to close the circuit

the meter will measure zero volts.

INRUSH CURRENT

The Inrush feature captures starting current of a motor or transformer.

Starting current can assist in diagnosing a motor before it fails.

To measure inrush current:

1. Rotate the Function Selector switch

2

to the AC current A setting.

2. Place clamp

3

around wire. The current measurement will be

shown in the main display.

3. Press the InRush button

17

to enter the Inrush mode and manually

select 60A or 600A range

by pressing the RANGE button

7

.

Place the clamp around the compressor

start wire and turn motor on. The

starting current will hold on the main

display. The Inrush measurement period

is 100-miliseconds. The secondary

display measures running current.

4. Press InRush button

17

to exit.

Manual Mode Sequence

First

Press

Second

Press

Third

Press

Fourth

Press

Fifth

Press

AC Range 0-750V 0-600.0V 0-60.00V 0-6.000V

0-600.0mV

DC Range 0-60.00V 0-6.000V

0-600.0mV

0-600.0V 0-60.00V

12

ENGLISH

CONTINUITY

1. Insert RED test lead into VΩµA jack

5

, and BLACK test lead

into COM jack

4

, and rotate function selector switch

2

to the

Continuity/Resistance/Capacitance/Diode-Test

setting.

NOTE: The meter defaults to Continuity testing in this mode. Ensure

that the Continuity Testing icon is visible on the display. If not,

press the "SELECT" button

12

repeatedly until the icon is shown.

2. Remove power from circuit.

3. Test for continuity by connecting conductor or circuit with test

leads. If resistance is measured less than 10Ω, an audible signal

will sound and display will show a resistance value indicating

continuity. If circuit is open display will show "OL".

µA DC CURENT (LESS THAN 600 µA)

1. Insert RED test lead into VΩµA jack

5

, and BLACK test lead into

COM jack

4

, and rotate function selector switch

2

to the

µA

setting.

2. Remove power from circuit and open circuit at measurement point.

3. Connect test leads in series with the circuit.

4. Apply power to the circuit to take the measurement.

DO NOT attempt to measure continuity on a live circuit.

OPERATING INSTRUCTIONS

DO NOT attempt to measure more than 600 µA.

Red leadBlack lead

Red leadBlack lead

13

AC VOLTAGE

+

AC AMPERAGE FUNCTION

1. Insert RED test lead into VΩµA jack

5

, and BLACK test lead

into COM jack

4

, and rotate function selector switch

2

to the

V+A~ setting.

2. Press clamp trigger

13

to open clamp

3

and place around

current-carrying wire.

3. The main display will show AC Voltage and the secondary

display will show AC Amperage. Pressing the select button

will reverse the displays; the main display will show AC

Amperage and the secondary display will show AC Voltage.

OPERATING INSTRUCTIONS

RESISTANCE MEASUREMENTS

1. Insert RED test lead into VΩµA jack

5

, and BLACK test lead

into COM jack

4

, and rotate function selector switch

2

to the

Continuity/Resistance/Capacitance/Diode-Test

setting.

NOTE: The meter defaults to Continuity testing in this mode. Press

the "SELECT" button

12

once to enter Resistance testing mode. The

Resistance icon

will appear on the display.

2. Remove power from circuit.

3. Measure resistance by connecting test leads to circuit. The

meter will auto-range to display the measurement in the most

appropriate range.

NOTE: When in a Resistance setting and the test leads are open

(not connected across a resistor), or when a failed resistor is under

test, the display will indicate "O.L." This is normal.

DO NOT attempt to measure resistance on a live circuit.

Red leadBlack lead

Red leadBlack lead

14

ENGLISH

CAPACITANCE

1. Insert RED test lead into VΩµA jack

5

, and BLACK test lead

into COM jack

4

, and rotate function selector switch

2

to the

Continuity/Resistance/Capacitance/Diode-Test

setting.

NOTE: The meter defaults to Continuity testing in this mode. Press

the "SELECT" button

12

twice to enter Capacitance testing mode.

The Capacitance icon

will appear on the display. The meter

should read 0 nF with test leads open.

2. Remove power from circuit.

3. Measure capacitance by connecting test leads across the

capacitor. The meter will auto-range to display the measurement

in the most appropriate range.

OPERATING INSTRUCTIONS

Red leadBlack lead

15

OPERATING INSTRUCTIONS

DIODE TEST

1. Insert RED test lead into VΩµA jack

5

, and BLACK test lead

into COM jack

4

, and rotate function selector switch

2

to the

Continuity/Resistance/Capacitance/Diode-Test

setting.

NOTE: The meter defaults to Continuity testing in this mode. Press

the "SELECT" button

12

three times to enter Diode testing mode.

The Diode icon

will appear on the display.

2. Touch test leads to diode. A reading of 200-800mV on display

indicates forward bias, "OL" indicates reverse bias. An open

device will show "OL" in both polarities. A shorted device will

show approximately 0mV.

FREQUENCY / DUTY-CYCLE

1. Insert RED test lead into VΩµA jack

5

and BLACK test lead

into COM jack

4

, and rotate function selector switch

2

to the

Frequency/Duty-Cycle

setting.

NOTE: The meter defaults to Frequency testing in this mode. To enter

Duty-Cycle testing mode, press the "SELECT" button

12

once. Ensure

that the appropriate icon (either

Hz

or

%

) appears on the display.

2. Measure by connecting test leads across the circuit.

Red leadBlack lead

Red leadBlack lead

16

ENGLISH

OPERATING INSTRUCTIONS

TEMPERATURE

1. Remove leads from meter and slide the temperature probe input

switch

18

to close jacks and expose the K-Type thermocouple

ports.

2. Insert K-type thermocouple into port

15

( and rotate function

selector switch

2

to the Temperature setting.

NOTE: The meter defaults to Fahrenheit scale in this mode. To enter

Celsius scale, press the SEL button

9

. Ensure that the appropriate

icon (either

°F

or

°C

) appears on the display.

3. To measure temperature, make contact between the

thermocouple tip and the object being measured. When

thermocouple tip and object are in thermal equilibrium, the

measurement on the display will stabilize. The meter will auto-

range to display the measurement in the most appropriate range.

Remove thermocouple before switching meter to other

measurement functions.

T

he thermocouple included with the original purchase

is suitable for temperatures below 356°F / 180°C only.

To measure higher temperatures, a K-type thermocouple

with the appropriate measurement range should be used.

K-Type Thermocouple

17

MAINTENANCE

BATTERY REPLACEMENT

When indicator is displayed on LCD, batteries must be replaced.

1. Loosen captive screw and remove battery cover.

2. Replace 3 × AAA batteries (note proper polarity).

3. Replace battery cover and fasten screw securely.

T

o avoid risk of electric shock, disconnect leads from any voltage

source before removing battery door.

To avoid risk of electric shock, do not operate meter while

battery door is removed.

Replace battery cover and fasten screw securely.

18

ENGLISH

CLEANING

Be sure meter is turned off and wipe with a clean, dry lint-free

cloth.

Do not use abrasive cleaners or solvents.

STORAGE

Remove the batteries when meter is not in use for a prolonged

period of time. Do not expose to high temperatures or

humidity. After a period of storage in extreme conditions

exceeding the limits mentioned in the General Specifications

section, allow the meter to return to normal operating

conditions before using.

WARRANTY

www.kleintools.com/warranty

DISPOSAL / RECYCLE

Do not place equipment and its accessories in the trash.

Items must be properly disposed of in accordance with

local regulations. Please see www.epa.gov or www.

erecycle.org for additional information.

CUSTOMER SERVICE

KLEINTOOLS, INC.

450Bond Street

Lincolnshire, IL60069

1-800-553-4676

www.kleintools.com

19

5001748

CL440

CAT IV

600 V

MANUAL DE INSTRUCCIONES

Multímetro de gancho

Multímetro de gancho

Multímetro de gancho

Multímetro de gancho

para HVAC

Tecnología de medición de

media cuadrática

real

750 V

600 V

600 A

60 M

Ω

• MICROAMPERIOS CD

• CORRIENTE DE

INSERCIÓN

• PRUEBA DE VOLTAJE

SINCONTACTO

• RANGO AUTOMÁTICO

• TEMPERATURA

• INDICADOR DE

CONTINUIDAD AUDIBLE

-328 –

2462°F

-200 –

1350°C

ESPAÑOL

1m

20

ESPECIFICACIONES GENERALES

El CL440 de Klein Tools es un multímetro digital de gancho de rango

automático con media cuadrática real (TRMS) que mide corriente

CA y corriente de inserción con la pinza, así como el voltaje CA/CD,

microamperios CD, resistencia, continuidad, frecuencia y capacitancia,

prueba diodos con cables de prueba y mide temperatura con una sonda

de termopar.

• Altitud de funcionamiento: 6562' (2000m)

• Humedad relativa: <95%, sin condensación

• Temperatura de funcionamiento: 32 a 122°F (0 a 50°C)

• Temperatura de almacenamiento: 14 a 122°F (-10 a 50°C)

• Precisión: valores establecidos a una temperatura de 65 a 83°F

(18 a 28°C)

• Coe ciente de temperatura: 0,1 × (precisión indicada) por

cada °C por encima de los 28°C o por debajo de los 18°C; es

necesario realizar correcciones si la temperatura de trabajo se

encuentra fuera del rango de la temperatura de precisión

• Dimensiones: 10,04"×3,77"×1,57"(255×96×40mm)

• Peso: 14,22oz (403g) incluidas las baterías

• Calibración: precisa durante un año

• Función de apagado automático (APO): después de

aproximadamente 10minutos de inactividad

• Normas: IECEN61010-1, 61010-2-032, 61010-2-033.

IECEN61326-1, 61326-2-2.

Cumple con las normas UL STD.61010-1,

61010-2-032, 61010-2-033;

Certificado según las normas CSA STD.C22.2

n.º 61010-1, 61010-2-032, 61010-2-033.

• Grado de contaminación: 2

• Precisión: ± (% de lectura + cantidad de dígitos menos

significativos)

• Protección ante caídas: 3,3'(1m)

• Clasi cación de seguridad: CATIV 600V

Clase2, doble aislamiento

CATIII: la categoría III de medición es aplicable a los circuitos de

medición y prueba conectados a la distribución de la instalación

de redes eléctricas de bajo voltaje de un edificio.

CATIV: la categoría IV de medición es aplicable a los circuitos

de medición y prueba conectados a la fuente de la instalación de

redes eléctricas de bajo voltaje de un edificio.

• Entorno electromagnético: IEC EN 61326-1. Este equipo cumple

con los requisitos para su uso en entornos electromagnéticos

básicos y controlados, como propiedades residenciales,

establecimientos comerciales e instalaciones de industria ligera.

Especificaciones sujetas a cambios.

ESPAÑOL

5001748

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

Klein Tools CL440 Manuel utilisateur

- Catégorie

- Mesure, test

- Taper

- Manuel utilisateur

- Ce manuel convient également à

dans d''autres langues

- English: Klein Tools CL440 User manual

- español: Klein Tools CL440 Manual de usuario

Documents connexes

-

Klein Tools CL445 Manuel utilisateur

-

Klein Tools CL120 Manuel utilisateur

-

Klein Tools CL220 Manuel utilisateur

-

Klein Tools CL700 Manuel utilisateur

-

Klein Tools CL120KIT Mode d'emploi

-

Klein Tools M2O41255KIT Mode d'emploi

-

Klein Tools CL312 Mode d'emploi

-

Klein Tools CL330 Mode d'emploi

-

Klein Tools CL900 Manuel utilisateur

-

Klein Tools M2O41041KIT Mode d'emploi

Autres documents

-

General DAMP68 Manuel utilisateur

-

Amprobe AM-560 & AM-570 Mutimeter Manuel utilisateur

-

Metrix MX 350 Manuel utilisateur

-

UEi DL379 Le manuel du propriétaire

-

Ideal 61-405 Manuel utilisateur

-

UEi DL419 Le manuel du propriétaire

UEi DL419 Le manuel du propriétaire

-

Ideal 600A AC Clamp-Pro™ Clamp Meter Mode d'emploi

-

Ideal 61-744 Manuel utilisateur

-

Ideal 600A AC Clamp-Pro™ Clamp Meter Mode d'emploi

-

Ideal 61-744 Le manuel du propriétaire