PROPOINT 8490336 Le manuel du propriétaire

- Taper

- Le manuel du propriétaire

Please read this manual before use.

User Manual

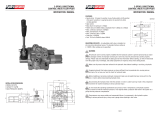

3.2 CU. IN. 2-BOLT

HYDRAULIC SPOOL

VALVE GEROLER MOTOR

V 3.04 8490366

2 For technical questions call 1-800-665-8685

V 3.04 8490366

3.2 CU. IN. 2-BOLT

HYDRAULIC SPOOL

VALVE GEROLER MOTOR

SPECIFICATIONS

Max. Continuous Pressure 2,030 PSI

Rotation Bi-Directional

Displacement 3.2 Cubic Inches

Case Drain 7/16-20 SAE

Max. Torque 886 in-lb

Max. Speed 950 RPM

Shaft Diameter 1 in.

Port Size 7/8-14 SAE

Horsepower Rating 15.6 HP

Model BMRS-50-H2

Mounting Type 2-Bolt Flange

Max. Continuous Flow 13 GPM

Operating Temperature -40°F to 176°F (-40°C to 80°C)

Weight 14.8 lb

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

Visit www.princessauto.com for more information 3

8490366 V 3.04

PERFORMANCE DATA

Pressure 725 1030 1352 1470 1766 2030

Max. Cont. 2355 2538

Max. Int.

FLOW

1 GPM Torque (in-lb) 310 399 540 593 682 780

Speed (RPM) 93 84 76 73 69 46

3 GPM Torque (in-lb) 319 407 549 611 709 842 957 1063

Speed (RPM) 186 178 166 162 153 136 118 97

4 GPM Torque (in-lb) 310 434 558 647 780 886 966 1090

Speed (RPM) 283 277 269 261 250 230 211 185

5 GPM Torque (in-lb) 306 416 540 611 735 850 966 1116

Speed (RPM) 377 375 365 361 346 330 302 270

8 GPM Torque (in-lb) 292 390 531 593 709 842 957 1116

Speed (RPM) 576 569 561 554 542 531 500 465

11 GPM Torque (in-lb) 266 363 514 585 700 815 939 1081

Speed (RPM) 760 758 753 750 738 724 700 670

12 GPM Torque (in-lb) 261 354 505 576 691 797 930 1072

Speed (RPM) 856 853 849 845 835 815 796 770

13 GPM

(Max. Cont.)

Torque (in-lb) 230 328 469 531 647 753 877 1010

Speed (RPM) 950 940 925 906 880 852 832 801

16 GPM

(Max. Int.)

Torque (in-lb) 177 292 425 496 611 717 842 966

Speed (RPM) 1138 1124 1100 1075 1056 1028 1006 970

Cont. = Maximum Continuous Operation. Int. = Maximum operating range for 6 seconds

per minute.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

4 For technical questions call 1-800-665-8685

V 3.04 8490366

INTRODUCTION

The BMRS series is a high torque/low speed hydraulic motor. This

compact unit is efficient and quiet, suitable for light to medium duty

applications such as grain augers and elevators, salt and sand spreaders,

car wash and sweeper brushes, conveyors, winches, scissor lifts and

similar applications.

FUNCTIONS

The BMRS hydraulic motor has an advanced gear set, a shaft distribution

flow design and inner rollers to reduce friction, leading to a longer life

and more efficient motor. The motor has Viton seals that offer better

compatibility to different types of hydraulic fluid as well better higher

temperature performance. The case drain equalizes the return pressure on

the shaft seal to prevent blow outs and maximizes the motor’s efficiency.

There are four different shafts available that can be swapped out for the

standard shaft (see Parts List).

• Shaft, Replacement (#9)

• Shaft, 6-Spline (#9.1)

• Shaft, .315 Crosshole (#9.2)

• Shaft, .406 Crosshole (#9.3)

• Shaft, 13-Spline (#9.4)

SAFETY

WARNING! Read and understand all instructions before using this

device. The operator must follow basic precautions to reduce the risk of

personal injury and/or damage to the equipment.

Keep this manual for safety warnings, precautions, operating or

inspection and maintenance instructions.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

Visit www.princessauto.com for more information 5

8490366 V 3.04

HAZARD DEFINITIONS

Please familiarize yourself with the hazard notices found in this manual. A

notice is an alert that there is a possibility of property damage, injury or

death if certain instructions are not followed.

WARNING! This notice indicates a specific hazard or unsafe practice

that could result in severe personal injury or death if the proper

precautions are not taken.

CAUTION! This notice indicates a potentially hazardous situation that

may result in minor or moderate injury if proper practices are not taken.

NOTICE! This notice indicates that a specific hazard or unsafe

practice will result in equipment or property damage, but not

personal injury.

WORK AREA

1. Operate in a safe work environment. Keep your work area clean,

well lit and free of distractions.

2. Keep anyone not wearing the appropriate safety equipment away

from the work area.

PERSONAL SAFETY

WARNING! Wear personal protective equipment approved by the

Canadian Standards Association (CSA) or American National Standards

Institute (ANSI).

PERSONAL PROTECTIVE EQUIPMENT

1. Always wear impact safety goggles that provide front and side

protection for the eyes.

2. Wear gloves that provide protection based on the work materials

or to reduce the effects of tool vibration.

3. Non-skid footwear is recommended to maintain footing and

balance in the work environment.

4. Wear protective clothing designed for the work environment

and device.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

6 For technical questions call 1-800-665-8685

V 3.04 8490366

PERSONAL PRECAUTIONS

Control the device, personal movement and the work environment to

avoid personal injury or damage to device.

1. Do not operate any device when tired or under the influence of

drugs, alcohol or medications.

2. Avoid wearing clothes or jewelry that can become entangled with

the moving parts of a device. Keep long hair covered or bound.

3. Use the correct device for the job. This device was designed for a

specific function. Do not modify or alter this device or use it for an

unintended purpose.

GENERAL SAFETY PRECAUTIONS

HYDRAULIC SAFETY

IMPORTANT! Seek immediate, professional medical treatment if

hydraulic fluid penetrates the skin. Do not wait for the appearance of

symptoms. An infection or toxic reaction may occur from the exposure.

1. The hydraulic components require regular inspection.

Replace damaged hydraulic parts with the same

manufacturer’s components.

2. Do not attempt makeshift repairs to a hydraulic system. Such

repairs can fail suddenly and create a hazardous condition.

3. Use wood or cardboard to check for hydraulic fluid leaks instead

of hands

4. Never exceed the load capacity of the hydraulic device

(see Specifications).

5. Do not adjust relief setting of hydraulic system.

6. Escaping hydraulic fluid under pressure may have sufficient force

to penetrate the skin.

6.1 Always check for leaks wearing a face shield or

safety goggles.

6.2 Wear rubberized gloves.

6.3 Wear protective clothes.

6.4 Do not use your hands to detect a leak. Use a piece of

cardboard or paper and watch for discolouration to find a

hydraulic fluid leak.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

Visit www.princessauto.com for more information 7

8490366 V 3.04

PARTS IDENTIFICATION

WARNING! Do not operate the device if any part is missing. Replace

the missing part before operating. Failure to do so could result in a

malfunction and personal injury.

Remove the parts and accessories from the packaging and inspect for

damage. Make sure that all items in the parts list are included.

Contents:

• Hydraulic Geroler Motor

A Hydraulic Input Port A

B Hydraulic Output Port B

C Mounting Flange

D Output Shaft

E Housing

F Case Drain

G End Plate

H Geroler Housing

I End Plate Bolts

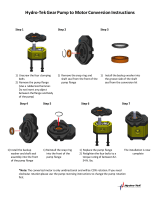

Fig.1

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

8 For technical questions call 1-800-665-8685

V 3.04 8490366

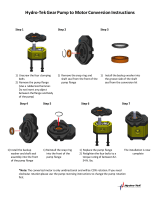

ASSEMBLY

When this manual refers to a part number, it refers to the included

Parts List.

The hydraulic motor is preassembled and ready for installation. There are

a range of optional cylindrical shafts available at Princess Auto Ltd. if the

job requires a different range of gear ratios or shaft lengths. Changing the

shaft requires the user to disassemble the motor.

PREPARING THE AREA

Clean the work area until it is free of debris and dust before diassembling

the motor. Contaminates can adhere to oil coating the parts and may

damage the mechanism. Have a clean container ready to place the parts

during the disassembly process.

TOOLS REQUIRED

• 1/2 in. Wrench or Socket

• 5/16 in. Allen Wrench

• 3/16 in. Allen Wrench

• Torque Wrench

• Vise, Bulldog or similar style

• Soft Jaws to protect the motor in vise. Pieces of hard rubber or

wood boards can be used.

• Plastic hammer

• Welding torch or Heat gun capable of reaching a temperature of

500 °F (260 °C).

• Cyanoacrylate glue AKA instant glue

• Solvent (acetone or methylene chloride)

• Wire brush (to clean screws of glue)

DISASSEMBLE THE MOTOR

CAUTION! The motor is heavy. When placing the motor in the vise,

support it from underneath until firmly clamped into place. Be careful

not to pinch your fingers when closing the vise jaws.

These instructions are to disassemble the motor before placing into

service. If the seals or the shaft are being swapped out after the motor

has been in service, drain oil from the hydraulic circuit and clean the outer

surface around the ports before disconnecting.

Do not separate seals, o-rings or washers from their parts when just

replacing the shaft before initial service.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

Visit www.princessauto.com for more information 9

8490366 V 3.04

REMOVING SCREWS AND BOLTS

The screws are held in place with cyanoacrylate glue or instant glue.

Heat the housing around the screws with a welding torch or heat gun

for approximately 5 to 10 seconds. The glue will release at a temperature

between 300 to 500 °F (149 to 260 °C). Remove heat as soon as the

screw is loose to avoid damaging the motor.

Blow loose debris and glue from the screw holes with dry air. The set glue

in the holes does not need to be removed, unless it interferes with

the screws.

Remove the cyanoacrylate glue left in the screw threads with a

combination of soaking the screws in acetone or methylene chloride and

working with a wire brush. Leave to dry before reinserting into

the housing.

Consult the manufacturer’s instructions on curing time when reapplying

the instant glue. Some instant glues can be combined with a curing agent

that will decrease the curing time.

WARNING! Follow the manufacturer’s Material Safety Data Sheet

instructions before handling cyanoacrylate glue, acetone or methylene

chloride. Avoid inhaling or coming in contact with all three. Become

familiar with first aid/medical instructions before using the glue

or solvents.

DISASSEMBLY

A plastic hammer may be required to loosen some parts after the motor

has been in service.

1. Remove the Woodruff Key (#10) by hand.

2. Clean the motor’s exterior of oil and debris. Ensure both Plugs

(#17) are still in place during cleaning.

3. Place the geroler motor in a vise with the flange face down. Close

the vise on either side of the flange. The vice should have soft jaws

or a protective material between the motor and jaws.

4. Remove the Inlet and Outlet Plugs (#17). Loosen with a 1/2 in.

wrench, then complete removal by hand.

5. Remove the Drain Plug (#29) with a 3/16 in. Allen wrench.

6. Remove the End Cover (#25) by loosening all Screws (#27) with a

1/2 in. wrench. Complete screw removal by hand.

7. Remove the geroler set as one unit. Do not separate the Stator

(#22), Roller (#23) and Rotor (#24) while removing them. Put aside

as a single unit.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

10 For technical questions call 1-800-665-8685

V 3.04 8490366

8. Remove the Drive Link (#21).

9. Remove the Distributor Plate (#20).

10. Remove the Axial Needle Bearing (#8) on the bottom of the Shaft

(#9).

11. Hold the motor from underneath and loosen the vise.

12. Turn motor with the flange facing upward and position so vise

clamps on either side of the inlet and outlet ports. Tighten the vice

to secure. Do not clamp across the housing as pressure can distort

the housing shape.

13. Use 5/16 in. Allen head spanner to remove the Flange Screws (#1).

14. Remove the Front Cover (#4). This will contain the Dust Seal (#3)

and Shaft Seal (#5).

15. Remove the second Axial Needle Bearing (#8) and Shaft (#9).

16. Remove both Check Valves (#12) and Balls (#13) from the Housing.

CLEANING AND PREPARING COMPONENTS

1. Check all mating surfaces for scratches and burrs that may leave

openings that will allow leaks. Replace any damaged part.

2. Clean parts in a compatible solvent and blow dry with air. Do not

use paper or fabric cloth to dry as fibers left behind could damage

the hydraulic system.

NOTICE! Ketone based solvents like acetone or methylene chloride can

ruin Viton seals. Take precautions to keep the solvents from coming

into contact with the seals. Should contact occur, replace the seal even

if there does not appear to be any damage to prevent the possibility of

leaks under pressure.

3. Check areas that will contact the seals during reassembly for burrs

or sharp edges. Remove nicks and burrs with a stone made of

novaculite (also called Arkansas stone). Do not use a file or grinder

to remove the edges.

4. Lubricate all mating surfaces with grease or petroleum jelly as they

are being reassembled.

5. Replace the shaft before replacing the seals and o-rings.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

Visit www.princessauto.com for more information 11

8490366 V 3.04

REPLACING THE SHAFT

1. Mark the rear end of shaft to identify the location of a commutation

slot (see B in Fig. 3). This will be required later to set the

shaft rotation.

2. Apply petroleum jelly or lubricant to the shaft.

3. Insert the shaft’s base into the Housing (#15) without forcing it in.

Once the wide part of the shaft is positioned, gently tap the shaft’s

end with your fingers until it slides into place. Once it has slid into

place, push down to seat the shaft.

4. Go to section Rebuild the Motor or Replacing the Seals

REPLACING THE SEALS

After a period of use, the worn rubber and plastic components should be

replaced. Princess Auto Ltd. has a Viton seal kit for this motor. Lubricate

all seals with grease or petroleum jelly before placing. A clean plastic

hammer may be required to tap the seals into place.

1. Fit the replacement O-ring (#19) in the groove of the geroler set

between the Geroler set (#22, #23, #24) and the End Cover (#25).

2. Fit the replacement O-ring (#19) in the groove on the Distributor

Plate (#20).

3. Fit the replacement O-ring (#19) into the groove on the posterior

end of the Housing (#15).

3. Fit the replacement O-ring (#7) between the Thrust Washer (#6)

and Axial Needle Bearing (#8).

4. Remove and replace the Shaft Seal (#5) from the Front Cover (#4).

Access the seal from the rear of the front cover.

5. Remove and replace the Dust Seal (#3) from the front.

6. Replace the O-ring (#11) on each end of both Check Valves (#12).

7. Go to the Rebuild the Motor section.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

12 For technical questions call 1-800-665-8685

V 3.04 8490366

REBUILD THE MOTOR

1. Place Balls (#13) in Check Valve (#12). Close up after the sealing

surface has been stamped.

2. Begin with the flange facing upward with the shaft in place. Clamp

the vise on either side of the inlet and outlet ports until tight.

3. Place an Axial Needle Bearing (#8) onto the shaft.

4. Place an O-ring (#7) onto the axial needle bearing.

5. Place the Thrust Washer (#6) onto the o-ring and press down

gently to seat.

6. Place the Front Cover (#4) over the shaft and press into position

on the Housing (#15).

7. Apply a small amount of instant glue to the end of each screw

before reinserting through the front cover into the housing.

8. Tighten the screws in increments with a torque wrench equipped

with an Allen head adapter until they are between 398 and 442 in-

lb. Alternate between screws so an even pressure is applied to the

seals and o-rings. Wipe off any residue with one of the solvents

mentioned earlier.

Fig.2

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

Visit www.princessauto.com for more information 13

8490366 V 3.04

9. Hold the motor housing from

underneath and release from the vise.

Flip over so the rear opening is up.

Again clamp on the flange so as not

to distort the housing.

10. Align the mark for the commutation

slot (B) with hole C in the housing

(see Fig. 3).

10.1 Also place a mark on the outer

housing to assist in aligning for

later steps.

11. Push down on the base of the shaft

to firmly seat it against the front

cover seal.

12. Place the Axial Needle Bearing (#8)

in the space created by step 11.

13. Place the O-ring (#19) it in the

housing seal groove. Tap into place

with the clean plastic hammer

if needed.

14. Place the Distributor Plate (#20) and

Drive Link (#21) in the internal spline

of the Shaft (#9).

14.1 Align the gear teeth of the rotor (A) and the Drive Link (#21)

with the mark on the housing, then put them into the Housing

(#15). The drive link will

rotate clockwise.

15. Place the End Cover (#25) over the gear wheel set and turn it to

align the screw holes.

16. Install the Washers (#26) and fasten the Screws (#27) using a

hexagon socket and 354 to 398 in-lb of torque.

17. Install the Washer (#28) and fasten

the Plug (#29) using a hexagon socket and 221 to 265 in-lb

of torque.

18. Press the Woodruff Key (#10) into the key slot using a

plastic hammer.

Fig.3

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

14 For technical questions call 1-800-665-8685

V 3.04 8490366

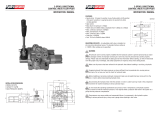

INSTALLATION

The hydraulic motor is one component of the hydraulic circuit. Place the

motor after the control mechanism such as a variable flow valve spool.

Check that the pressure hoses connecting the motor to the hydraulic

circuit can withstand the circuit’s maximum pressure.

1. Place the gerolor motor into position and bolt onto a frame or

appliance. Check the output shaft is properly connected to the

appliance, depending on the application, before tightening

the bolts.

2. Ensure motor is full of oil prior to attaching hoses.

3. Connect a hydraulic pressure hose from the Directional Control

Valve to the motor’s inlet port.

4. Connect another hydraulic pressure hose from the Directional

Control Valve to the motor’s outlet port.

5. Bleed the air from the system and check for leaks.

6. Proceed to prepare the rest of the hydraulic circuit.

INSTALLATION DIMENSIONS

Fig. 4

L = Motor Length: 5.67 in.

L1 =Geroler Width: 0.39 in.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

Visit www.princessauto.com for more information 15

8490366 V 3.04

Fig.5

MOTOR CASE DRAIN

Connect the motor’s case drain to the reservoir to avoid damaging the

motor’s shaft seal, when the pressure in the motor’s case (and return

line) exceeds the maximum Continuous Pressure (see Specifications).

The case drain hose should run directly to the reservoir and not be

connected into another return line. Connecting the case drain has several

other advantages including flushing contamination from the motor case,

helping cool the motor and extending the shaft seal life.

Fig.6 Fig.7

SIDE SHAFT LOAD

The motor performance when set up for use with a side load application

is outlined in Fig. 7. Operating the motor beyond the capacity indicated

by the curved line may harm the motor.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

16 For technical questions call 1-800-665-8685

V 3.04 8490366

OPERATION

Connect the motor output shaft to the appliance and the flow of oil

through the motor will provide the power to operate the appliance.

The motor is bi-rotational and the output shaft will rotate in the direction

of the oil flow through the input and output ports.

Oil flow is controlled with a Directional Control Valve built into the

hydraulic circuit. Flow Control Valves reduce the flow rate of oil from the

hydraulic system to the hydraulic motor.

The higher the max. torque of the motor, the lower the motor’s RPM.

Ensure the correct size geroler motor is selected for the task. A geroler

motor with a larger displacement will provide greater torque.

Fig.8

MAINTENANCE

1. Maintain the device with care. A device in good condition is

efficient, easier to control and will have fewer problems.

2. Inspect the device components periodically. Repair or replace

damaged or worn components.

3. Follow instructions for lubricating and changing accessories.

4. Have damaged or worn components repaired or replaced by an

authorized technician.

5. When servicing, use only identical replacement parts. Replace

damaged parts immediately.

6. Maintain the device’s label and name plate. These carry important

information. If unreadable or missing, contact Princess Auto Ltd.

for replacements.

WARNING! Only qualified service personnel should repair the device.

An improperly repaired device may present a hazard to the user and/

or others.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

Visit www.princessauto.com for more information 17

8490366 V 3.04

LUBRICATION

The gerolor motor is self-lubricating. Only use a good quality anti-wear

hydraulic oil with an ISO rating suitable for the maximum

operating temperature.

The hydraulic oil will break down if the temperature range is exceeded

during operation. Do not exceed the manufacturer’s recommended

temperature limits.

Oil filtration and cleanliness should meet ISO cleanliness level of 19/16/13.

The filtration system should use filters between 10 to 30 microns.

Seals and rubber/plastic washers can be protected with petroleum jelly or

grease during rebuilding.

DISPOSAL

Recycle a device damaged beyond repair at the appropriate facility.

Contact your local municipality for a list of disposal facilities or by-laws

for electronic devices, batteries, oil or other toxic liquids.

IMPORTANT! DO NOT pollute the environment by allowing uncontrolled

discharge of waste oil.

DISPOSAL OF HYDRAULIC FLUID

Do not drain hydraulic jack oil into the sewer system or dispose in an

uncontrolled location. Hydraulic fluid may take up to a year to breakdown

in the environment and the ingredients may still be toxic. Contact your

local municipality for proper disposal instructions or locations.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

18 For technical questions call 1-800-665-8685

V 3.04 8490366

TROUBLESHOOTING

Contact Princess Auto Ltd. for a solution if the device does not function

properly or parts are missing. If unable to do so, have a qualified

technician service the device.

Problem (s) Possible Cause (s) Suggested Solution (s)

Motor turning in

wrong direction.

Incorrect piping

between control valve

and motor.

Check circuit to

determine correct

piping.

Motor not

developing proper

speed or torque.

1. Incorrect setting or

blocked valves in

hydraulic circuit.

2. The motor does not

generate enough

torque, because the

working pressure is

too low.

3. Pump not delivering

sufficient pressure

or volume.

1. Check system

pressure and reset

relief valve.

2. Check the pressure

level in the system

and correct the

setting of the

pressure limit valve,

if necessary.

3. Check pump delivery

and pressure.

External oil leakage

from motor.

1. Gasket leaking (may

be due to case drain

not being connected

if this is required).

2. Perspiration

between the

coupling surfaces on

the motor (passive

oil or fluid residues).

3. Porous castings.

4. Shaft sealing

ring leaks.

1. Replace gasket. (if

drain line required, it

must be piped directly

to reservoir).

2. Clean the motor

and see whether the

problem persists.

3. Contact Princess

Auto Ltd. for

solution.

4. Replace sealing

ring. Kit available at

Princess Auto Ltd.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

Visit www.princessauto.com for more information 19

8490366 V 3.04

Problem (s) Possible Cause (s) Suggested Solution (s)

The motor is noisy. 1. Coupling misaligned.

2. Vibration or

rattling of motor/

coupling due to

worn or damaged

components.

3. Aeration or

cavitation caused by

pressure imbalance

or air entering

hydraulic system.

1. Align unit and check

condition of seals,

bearings and coupling.

2. Replace worn

and damaged

components.

3. Tighten leaking

connections. Fill

reservoir to proper

level (with rare

exception all return

lines should be

below fluid level in

reservoir). Bleed air

from system. Replace

shaft seal (and shaft if

worn). If bearings are

breaking, contact the

Princes Auto Ltd. for

a solution.

3.2 cu. in. 2-Bolt Hydraulic Spool Valve Geroler Motor

20 For technical questions call 1-800-665-8685

V 3.04 8490366

Problem (s) Possible Cause (s) Suggested Solution (s)

Motor heated. 1. Fluid heated-system

pressure too high.

2. Fluid heated-fluid

dirty or low supply.

3. Fluid heated-

incorrect fluid

viscosity.

4. Fluid heated-worn

pump, valve, motor,

cylinder or other

component.

1. Install pressure gauge

and adjust to correct

pressure (keep at

least 125 PSI

difference between

valve settings).

2. Change filters and

also system fluid if

improper viscosity; fill

reservoir to

proper level.

3. Change filters and

also system fluid if

improper viscosity; fill

reservoir to

proper level.

4. Overhaul or replace.

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

PROPOINT 8490336 Le manuel du propriétaire

- Taper

- Le manuel du propriétaire

dans d''autres langues

- English: PROPOINT 8490336 Owner's manual

Documents connexes

-

PROPOINT 8490039 Le manuel du propriétaire

-

PROPOINT 8490625 Le manuel du propriétaire

-

PROPOINT 8489957 Le manuel du propriétaire

-

PROPOINT 8489981 Le manuel du propriétaire

-

PROPOINT 8490062 Le manuel du propriétaire

-

PROPOINT 8490054 Le manuel du propriétaire

-

PROPOINT 8490369 Le manuel du propriétaire

-

PROPOINT 8490096 Le manuel du propriétaire

-

PROPOINT 8490401 Le manuel du propriétaire

-

PROPOINT 8490310 Le manuel du propriétaire

Autres documents

-

SCS Sentinel 3245060801076 Le manuel du propriétaire

SCS Sentinel 3245060801076 Le manuel du propriétaire

-

Hydro-Tek 8375453 Le manuel du propriétaire

Hydro-Tek 8375453 Le manuel du propriétaire

-

Hydroworks 8410755 Le manuel du propriétaire

Hydroworks 8410755 Le manuel du propriétaire

-

Ega Master 79916 Le manuel du propriétaire

-

Ega Master 79915 Le manuel du propriétaire

-

Powerfist 8500613 Le manuel du propriétaire

-

Power Fist 8666562 Le manuel du propriétaire

-

Power Fist 8727679 Le manuel du propriétaire

-

Power Fist 8513558 Le manuel du propriétaire

-

BLB 8669749 Le manuel du propriétaire

BLB 8669749 Le manuel du propriétaire