Operating Instructions Type TB82PH Series

ATEX multilingual version

pH/ORP/pIon Transmitters

Models TB82PH / ML82PH

TB82PH ATEX Product Instruction Manual ABB

2 TB82PH-ATEX-EN-A

CONTENTS

Section Page

CONTENTS.......................................................................2

USE OF INSTRUCTIONS .................................................2

INTRODUCTION...............................................................3

PRODUCT IDENTIFICATION ...........................................3

EUROPEAN ATEX DIRECTIVE INFORMATION..............4

TRANSMITTER MOUNTING DETAILS.............................7

ELECTRICAL CONNECTIONS - Power Wiring ................8

SENSOR CONNECTIONS – Model TB5 & TBX5

Sensor Connections ......................................................9

OPERATING PROCEDURES .........................................11

Commissioning the Instrument ..................................11

Flow Chart For Basic Operation Mode.......................12

CONFIGURE MODE .......................................................13

Flow Chart For Advanced Mode ................................15

CALIBRATE MODE.........................................................16

OUTPUT/HOLD MODE...................................................16

SECURITY MODE ..........................................................17

SECONDARY DISPLAY MODE......................................17

MAINTENANCE ..............................................................17

DISMANTLING AND RE-ASSEMBLY.............................18

SPECIFICATIONS ..........................................................19

USE OF INSTRUCTIONS

Although Warning hazards are related to personal injury,

and Caution hazards are associated with equipment or

property damage, it must be understood that operation of

damaged equipment could, under certain operational

conditions, result in degraded process system

performance leading to personal injury or death.

Therefore, comply fully with all Warning and Caution

notices.

Information in this manual is intended only to assist our

customers in the efficient operation of our equipment. Use

of this manual for any other purpose is specifically

prohibited and its contents are not to be reproduced in full

or part without prior approval of Technical

Communications Department, ABB Inc.

Warning.

An instruction that draws attention to the

risk of injury or death.

Caution.

An instruction that draws attention to the

risk of damage to the product, process or

surroundin

g

s.

Note.

Clarification of an instruction or additional

information.

Information.

Further reference for more detailed

information or technical details.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

1. The relevant sections of these instructions must be read carefully before proceeding.

2. Warning labels on containers and packages must be observed.

3. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in

accordance with the information given.

4. Normal safety precautions must be taken to avoid the possibility of an accident occurring when operating in

conditions of high pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal

safe handling procedures must be used.

6. When disposing of chemicals ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual or any relevant hazard data sheets

(where applicable) may be obtained from the Company address on the back cover, together with servicing and

spares information.

ABB TB82PH ATEX Product Instruction Manual

TB82PH-ATEX-EN-A 3

INTRODUCTION

This manual describes the installation, safe usage,

commissioning, adjustment, and maintenance procedures

related to the Analog versions of the TB82PH and

ML82PH pH/ORP/pION Product Family.

PRODUCT IDENTIFICATION

The data plates shown in Figure 1 identify the instrument.

The Nameplate (Reference A) provides information

concerning the product identity code (i.e., nomenclature),

product name, operating voltage range, output type, serial

number, test personnel badge number, and dielectric

strength verification stamp.

The Agency Approval label (Reference B) is included

when the transmitter is purchased for compliance with

hazardous area regulations (e.g., intrinsic safety

protection) for a specific country (e.g., CSA, FM, or

ATEX).

EC conformance is identified using a CE label (Reference

C). Optional tagging, as specified by customer

requirements, is provided via an additional tag. (Reference

D)

OUTPUT TO SENSOR IS SUITABLE FOR NONINCENDIVE FIELD WIRING FOR

CLASS I LOCATIONS WHEN USED WITH ABB SENSORS PER DRAWING P0806

CLASS I; DIVISION 2; GROUPS A, B, C, D

CLASS II; DIVISION 2; GROUPS E, F, G

CLASS III

INTRINSICALLY SAFE Exia T4

CLASS I; DIVISION 1; GROUPS A, B, C, D

CLASS II; DIVISION 1; GROUPS E, F, G

CLASS III

WHEN CONNECTED PER DRAWING P0806

Vmax=24V Imax=250mA Ci=0 Li=0mH

82 TWO-WIRE TRANSMITTER SERIES

2175 LOCKHEED WAY

CARSON CITY,

NEVADA 89706

TYPE 4X

2175 LOCKHEED WAY

CARSON CITY,

NEVADA 89706

82 TWO-WIRE TRANSMITTER SERIES

NONINCENDIVE T5

CLASS I; DIVISION 2; GROUPS A, B, C, D

CLASS II; DIVISION 2; GROUPS F, G

CLASS III

INTRINSICALLY SAFE T4

CLASS I; DIVISION 1; GROUPS A, B, C, D

CLASS II; DIVISION 1; GROUPS E, F, G

CLASS III

WHEN CONNECTED PER DRAWING P0807

Vmax=24V Imax=250mA Ci=0 Li=0mH

MAX. AMBIENT TEMPERATURE: 60 C

OUTPUT TO SENSORS IS SUITABLE FOR NONINCENDIVE FIELD

WIRING WHEN USED WITH ABB SENSORS PER DRAWING P0807

NEMA 4X

APPROVED

INTRINSICALLY SAFE EEx ia IIC T4

- 20 C Ta 60 C

Ui=24V Ii=250mA Ci=0 Li=0mH Pi=1.2W

82 TWO-WIRE TRANSMITTER SERIES

2175 LOCKHEED WAY

CARSON CITY,

NEVADA 89706

CENEL EC

LCIE 02 ATEX 6 115 X

Reference A

Reference D - Optional Tag

Reference B

Reference C - EC Conformance Label

TB82PHX2XXXXX

9 - 32 Vdc, Profile Type 113

Carson City, NV U.S.A Phone 775-883-4366

Product Nomenclature

‘X’ Si

g

nif

y

Product Options

TB82PHX2XXXXX

9 - 32 V dc, Profile Type 113

Carson City, NV U.S.A Phone 775-883-4366

TAG

Carson City, NV.

II 1G

0344

Product Nameplate is for Foundation Fieldbus

Product Variation and is only shown for

reference purposes.

Figure 1 – Product Identification

TB82PH ATEX Product Instruction Manual ABB

4 TB82PH-ATEX-EN-A

EUROPEAN ATEX DIRECTIVE INFORMATION

Special conditions for safe use

The TB82/ML82 product variations can be installed in explosive atmospheres designated by the product labeling. These

product variations must only be combined with an associated, certified intrinsically safe apparatus. This combination must

be compatible as far as intrinsic safety is concerned (See section A6 of the following ATEX certificate). Temperature

Class T4 corresponds to an ambient temperature range from –20°C to +60°C.

Deutsch

1 EG-TYPENPRÜFUNGSZERTIFIKAT

2 Gerät oder Schutzsystem für den Einsatz in potenziellen

Ex-Bereichen

Richtlinie 94/9/EG

3 Nummer des EG-Typenprüfungszertifikats: LCIE 02 ATEX

6115 X

4 Gerät oder Schutzsystem: pH- oder Leitfähigkeits-

Messumformer,

Typ: TB82…/ML82…

5 Antragsteller:

6 Adresse:

7 Dieses Gerät oder Schutzsystem und alle akzeptablen

Varianten werden in der Anlage dieses Zertifikats und in

den dort genannten Dokumenten angegeben.

8 LCIE, Benannte Stelle Nr. 0081 gemäß Artikel 9 der

Richtlinie 94/9/EG des Europäischen Parlaments und Rats

vom 23. März 1994, bestätigt hiermit, dass dieses Gerät

oder Schutzsystem die grundlegenden Gesundheits- und

Sicherheitsanforderungen an die Konstruktion und den

Aufbau des Geräts oder Schutzsystems erfüllt, das für den

Einsatz in potenziellen Ex-Bereichen nach Anhang II dieser

Richtlinie vorgesehen ist. Die Prüfung und die

Testergebnisse sind im vertraulichen Bericht Nr. 41 023

010 festgehalten.

9 Die Erfüllung der grundlegenden Gesundheits- und

Sicherheitsanforderungen wurde gemäß der folgenden

Richtlinien festgestellt: - EN 50014 (1997) + Anhang 1 und

2, - EN 50020 (1994)

10 Wenn die Zertifikatsnummer auf den Buchstaben „X“ endet,

bedeutet dies, dass das Gerät oder Schutzsystem den

besonderen Bedingungen für den sicheren Einsatz gemäß

der Anlage dieses Zertifikats unterliegt.

11 Dieses EG-Typenprüfungszertifikat erstreckt sich

ausschließlich auf die Konstruktionsprüfung und die

Prüfung des genannten Geräts oder Schutzsystems gemäß

Richtlinie 94/9/EG.

Das Fertigungsverfahren und die Lieferung dieses Geräts

oder Schutzsystems unterliegen weiteren Anforderungen

der Richtlinie, die durch dieses Zertifikat nicht abgedeckt

werden.

12 Die Kennzeichnung des Geräts oder Schutzsystems muss

Folgendes enthalten: Ex II 1 G, EEx ia IIC T4

Español

1 CERTIFICADO DE EXAMEN DE TIPO CE

2 Equipo o sistema de protección para uso en atmósferas potencialmente explosivas: Directiva 94/9EC

3 Número de certificado de examen de tipo CE: LCIE 02 ATEX 6115 X

4 Equipo o sistema de protección

transmisor de pH o de conductividad: Tipo: TB82…/ML82…

5 Solicitante:

6 Dirección:

7 Este equipo o sistema de protección y cualquier variación aceptable del mismo se especifica en el anexo al presente certificado y en los documentos

a los que se hace referencia en el mismo.

8 El LCIE, organismo notificado número 0081, de acuerdo con el artículo 9 de la directiva 94/9/EC del Parlamento Europeo y el Consejo del 23 de

marzo de 1994, certifica que este equipo o sistema de protección cumple con los Requisitos Esenciales de Salud y Seguridad relacionados con el

diseño y la fabricación de equipos y sistemas de protección para uso en atmósferas potencialmente explosivas, en virtud del Anexo II de la directiva.

El examen y los resultados de las pruebas han sido registrados en el informe confidencial No. 41 023 010.

9 El cumplimiento con los Requisitos Esenciales de Salud y Seguridad se ha asegurado con el cumplimiento de las normas: -EN 50014 (1997) +

enmiendas 1 y 2, -EN 50020 (1994)

10 Si el signo X aparece después del número de certificado, indica que el equipo o sistema de protección se encuentra sujeto a condiciones especiales

para su uso seguro especificado en el anexo al presente certificado.

11 El presente certificado de examen de tipo CE se refiere únicamente al examen de diseño y a las pruebas del equipo o sistema de protección

especificado de acuerdo con la directiva 94/9/EC.

Otros requisitos de la Directiva se aplican al proceso de fabricación y suministro de este equipo o sistema de protección. El presente certificado no

cubre dichos requisitos.

12 Las marcas identificatorias del equipo o sistema de protección deben incluir lo siguiente: Ex II 1 G, EEx ia IIC T4

ABB TB82PH ATEX Product Instruction Manual

TB82PH-ATEX-EN-A 5

Deutsch

(A1) ANLAGE

(A2) EG-TYPENPRÜFUNGSZERTIFIKAT

LCIE 02 ATEX 6115 X

(A3) Beschreibung des Geräts oder Schutzsystems

Die Messumformer TB82... oder ML82... liefern ein

Ausgangssignal von 4 bis 20 mA als Reaktion auf die Ausgabe

des angeschlossenen pH-Sensors (xx82PH) oder des

Leitfähigkeitssensors mit vier Elektroden (xx82EC) oder des

Leitfähigkeitssensors mit zwei Elektroden (xx82TE) oder des

Toroidal-Leitfähigkeitssensors (xx82TC). Das HART-

Datenübertragungsprotokoll kann dem 2-Leiter-Regelkreis

überlagert werden. Die Modelle ML82 sind elektronisch mit den

Modellen TB82 identisch; der Unterschied liegt in der Software.

Die Modellausführungen werden in der Beschreibung näher

erläutert.

Die Kennzeichnung lautet wie folgt:

ABB Inc.

Adresse: …

Typ: TB82…/ML82…

Seriennummer

Herstellungsjahr

Ex II 1 G

EEx ia IIC T4

LCIE 02 ATEX 6115 X

Das CE-Zeichen muss mit der ID-Nummer der benannten Stelle

versehen sein, die für die Überwachung des Qualitätssystems

zuständig ist (0081 für LCIE).

Das Gerät muss außerdem mit den üblichen Kennzeichnungen

gemäß den einschlägigen Fertigungsstandards für solche Geräte

versehen sein.

(A4) Dokumente mit Beschreibungen:

Technische Datei Nr. A27-TB82ATEX-ER02-002A.

Diese Datei umfasst 43 Punkte (97 Seiten).

Español

(A1) ANEXO

(A2) CERTIFICADO DE EXAMEN DE TIPO CE

LCIE 02 ATEX 6115 X

(A3) Descripción del equipo o sistema de protección

Los transmisores TB82… o ML82… proporcionan una señal de salida de 4-20 mA como respuesta a la salida del sensor de pH conectado (xx82PH) o del

sensor de conductividad de cuatro electrodos (xx82EC) o del sensor de conductividad de dos electrodos (xx82TE) o del sensor de conductividad toroidal

(xx82TC).Pueden configurarse para el protocolo de comunicación HART superpuesto sobre el lazo de 2 hilos. Los modelos ML82 son electrónicamente

idénticos a los modelos TB82, la única diferencia radica en el software. Remítase a las notas descriptivas para verificar el significado de modelo.

Las marcas identificatorias son las siguientes:

ABB Inc

Dirección:…

Tipo: TB82…/ML82…

Número de serie

Año de fabricación

Ex II 1 G

EEx ia IIC T4

LCIE 02 ATEX 6115 X

La marca identificatoria CE estará acompañada por el número de identificación del organismo notificado responsable de la supervisión del sistema de

calidad (0081 para el LCIE).

El equipo también debe presentar las marcas identificatorias convencionales requeridas por las normas de fabricación que se aplican a dichos equipos.

(A4) Documentos descriptivos:

Archivo técnico n° A27-TB82ATEX-ER02-002A.

Este archivo comprende 43 elementos (97 páginas).

TB82PH ATEX Product Instruction Manual ABB

6 TB82PH-ATEX-EN-A

Deutsch

(A1) ANLAGE

(A2) EG-TYPENPRÜFUNGSZERTIFIKAT

LCIE 02 ATEX 6115 X (Fortsetzung)

(A5) Besondere Bedingungen für den sicheren Einsatz

Das oben definierte eigensichere Gerät kann in Ex-Bereichen

aufgestellt werden.

Eine Kombination des Geräts ist ausschließlich mit einem

zugehörigen, ebenfalls eigensicheren, zertifizierten Gerät

zulässig. Diese Kombination muss zudem im Hinblick auf die

Eigensicherheit kompatibel sein (siehe (A6)).

Die Temperaturklasse T4 bezeichnet einen

Umgebungstemperaturbereich von –20 °C bis +60 °C.

Die nachstehenden Sensoren sind für den Anschluss an den

Klemmenblock TB2 vorgesehen.

TB82PH/ML82PH

Kombinierte pH-Sensoren der Advantage-Serie:

Kombinierte pH-Sensoren mit Festkörperreferenz:

Externe Thermokompensator-Sensoren:

TB82EC/ML82EC

Leitfähigkeitssensoren mit vier Elektroden:

TB82TE/ML82TE

Leitfähigkeitssensoren mit zwei Elektroden:

TB82TC/ML82TC

Toroidal-Leitfähigkeitssensor:

(A6) Grundlegende Gesundheits- und Sicherheitsanforderungen

Die Konstruktion des Geräts entspricht den europäischen

Normen EN 50014 (1997) + Anhang 1 und 2 sowie EN 50020

(1994).

Spezielle Parameter für den oder die betroffenen Schutzarten:

Individuelle Prüfungen und Tests:

Keine

Español

(A1) ANEXO

(A2) CERTIFICADO DE EXAMEN DE TIPO CE

LCIE 02 ATEX 6115 X (continuación)

(A5) Condiciones especiales para la utilización segura

Los aparatos intrínsecamente seguros descritos anteriormente pueden instalarse en atmósferas explosivas.

El aparato debe combinarse únicamente con aparatos asociados intrínsecamente seguros, certificados, y dicha combinación debe ser compatible en lo que

respecta a la seguridad intrínseca. (ver (A6)).

La clase de Temperatura T4 corresponde a un rango de temperatura ambiente de entre –20ºC y +60ºC.

Los siguientes sensores son aptos para la conexión con el bloque terminal TB2.

TB82PH/ML82PH

Sensores de la serie Advantage Combinación de sensores de pH

Referencia de estado sólido Combinación de sensores de pH

Sensor termocompensador externo

TB82EC/ML82EC

Sensores de conductividad de cuatro electrodos:

TB82TE/ML82TE

Sensor de conductividad de dos electrodos:

TB82TC/ML82TC

Sensor de conductividad toroidal:

(A6) Requisitos Esenciales de Salud y Seguridad

El diseño del equipo cumple con las normas europeas EN 50014 (1997 + enmiendas 1 y 2) y EN 50020 (1994).

Parámetros específicos de los modos de protección involucrados:

Exámenes y pruebas individuales:

Ninguno.

ABB TB82PH ATEX Product Instruction Manual

TB82PH-ATEX-EN-A 7

TRANSMITTER MOUNTING DETAILS

Warning.

For installation in Hazardous

Areas, i.e. areas with danger

of fire and/or explosion,

irrespective of the protection

mode used, the installation

must carried out in accordance

with local authority regulations.

Ensure also that the tem-

perature of the transmitter

does not exceed the value

indicated in the Agency

Approval Label.

Caution.

Besides the normal

precautions for storage and

handling of electronic equip-

ment, the transmitter contains

static sensitive devices. Since

semiconductors can be

damaged by the direct

discharge of static electricity,

avoid contact with terminal

block conductors and elec-

tronic components on the

circuit board.

Note.

When mounting the trans-

mitter, choose a location that

has ample clearance for the

removal of the front bezel and

rear cover. The location

should provide easy access

for maintenance procedures

and not be in a highly cor-

rosive environment. Excessive

mechanical vibrations and

shocks as well as relay and

power switches should not be

in the immediate area. Signal

wiring should not be placed in

conduit or open trays that

contain power wiring for heavy

electrical equipment.

5/16" U-BOLT (2)

PIPE

MOUNT

BRACKET

3/8"

LOCKWASHER (4)

3/8"

FLATWASHER (4)

3/8" X 5/8"

BOLT (4)

5/16"

FLATWASHER (4)

5/16"

LOCKWASHER (4)

5/16"

NUT (4)

Pipe

Figure 3 – Pipe Mounting Detail

Figure 4 – Hinge Mounting Detail

WALL

FASTENERS FOR

WALL (SUPPLIED BY

OTHERS)

3/8" NUT (8)

3/8"

FLATWASHER (8)

3/8"

FLATWASHER (4)

3/8"

LOCKWASHER (8)

3/8"

LOCKWASHER (4)

"L" BRACKET

FRONT VIEWTOP VIEW

3/8" X 3/4"

BOLT (8)

S.S. HINGE

PIPE MOUNT

BRACKET

3/8" X 5/8"

BOLT

Figure 5 – Wall Mounting Detail

WALL

PIPE

MOUNT

BRACKET

3/8"

FLATWASHER (4)

3/8" X 5/8"

BOLT (4)

3/8"

LOCKWASHER (4)

FASTENERS FOR WALL

(SUPPLIED BY OTHERS)

WALL

TB82PH ATEX Product Instruction Manual ABB

8 TB82PH-ATEX-EN-A

ELECTRICAL CONNECTIONS - Power Wiring

The TB82PH Transmitter is powered by DC voltage. See

the appropriate power requirements in the Specification

Section for the particular type of TB82 Transmitter in use

(Analog, HART, PROFIBUS or Foundation Fieldbus (FF)).

Power is connected to the POWER/OUTPUT area on

TB1, terminals 1 and 2 (see Figure 7).

The terminal blocks located in the rear of the transmitter

accept wire sizes from 12 to 24 AWG. Pin-style

terminations should be used for all connections. The

terminal block label identifies all electrical connections and

should be followed when wiring the transmitter.

Normal grounding practice is to terminate all grounds at

the control room side, in which case the field side of the

screen should be adequately protected to avoid contact

with metallic objects. The transmitter case should be

grounded. Ground connections are provided internally (in

the terminal compartment) and externally.

For IS systems the grounding should be at the safety

barrier earth connection. For bus-powered systems the

grounding of the screen should be close to the power

supply unit. The specific noise immunity and emitted

interference are only guaranteed when bus screening is

fully effective (e.g., ensuring that screening is maintained

through any existing junction boxes.) Appropriate equi-

potential bonding must be provided to avoid differences in

potential among the individual plant components.

To ensure fault-free communication on fieldbus (FF or PA)

installations, the bus must be properly terminated at both

ends. Only approved bus terminators must be used for

intrinsically safe circuits.

REAR COVER

REMOVED

EXTERNAL

GROUND SCREW

T01088E

PANEL GASKET

PA NE L

9.5

0.38

MAXIMUM PANEL

THICKN

ESS

EPTHNEL D

PA NE L

CUTOUT

MINIMUM PA = 144.8 MM (5.70 IN.)

11.9

0.4

7

135.4

+1.3

–

0.8

5.33

+0.05

–

0.03

135.4

+1.3

–

0.8

5.33

+0.05

–0.03

11.9

0.47

LOCK A

SHER (4)

REAR VIE

W

PANEL MOUNTING

BRACKET (4)

3/8-IN.

W

3/8-16 x 1/2-IN.

HEX SCREW (4)

PANEL MOUNTING

SCREWS (4

)

Figure 6 – Panel Mounting Detail

Warning.

Use this equipment only in those classes of

hazardous locations listed on the nameplate.

Uses in other hazardous locations can lead to

unsafe conditions that can injure personnel and

dama

g

e e

q

ui

p

ment.

Figure 7 - Power Connections

SENSOR CONNECTIONS

TB2

POWER/OUTPUT

CONNECTIONS

POWER

TEST

BLUE

YELLOW

BLACK

GREEN

RED

WHITE

HVY GRN

SENSE

GUARD

REF

SOL GND

RTD

RTD

SHIELD

1

2

3

4

5

6

7

8

+1

- 2

+3

- 4

SIGNAL

A

METER

TERMINALS

ABB TB82PH ATEX Product Instruction Manual

TB82PH-ATEX-EN-A 9

SENSOR CONNECTIONS – Model TB5 & TBX5 Sensor Connections

Figure 10 – TB5 cable with pin leads

RED

WHITE

BLACK

BLUE

To Sensor

Figure 9 - TB5 BNC cable & BNC adapter

To Sensor

RED

WHITE

4TB9515-0164 BNC Adapter

BLUE

BLACK

Figure 11 - TBX5 Advantage Sensor Cable

HEAVY

GREEN

YELLOW

RED

WHITE

BLACK

BLUE

GREEN

To Sensor

BLACK COAX with BNC

SENSOR CONNECTIONS

TB2

BLUE

YELLOW

BLACK

GREEN

RED

WHITE

HVY GRN

SENSE

GUARD

REF

SOL GND

RTD

RTD

SHIELD

1

2

3

4

5

6

7

8

Figure 8 – Sensor Connections

TB82PH ATEX Product Instruction Manual ABB

10 TB82PH-ATEX-EN-A

AP100, AP200, AP300 7660 and 7650 sensors have different color-coding in the cable assemblies than TB5 and TBX5

sensors. Use the table below to properly connect the sensor cable to the TB82PH.

TB82PH Terminal TB2

Color Number Description

ABB Models

TB5

ABB Models

TBX5

ABB Models

AP100

3

A

BB Models

AP200

ABB Models

AP300

ABB Models

7650/7660

Blue 1 Measuring electrode Blue

1

Blue Clear Clear Blue Clear

Yellow 2

Shield for measuring

electrode

None Yellow None None None None

Black 3 Reference Black

1

Black Black Red Black Black

Green 4

Solution (diagnostic)

Ground

None Green None Green/Yellow None None

Red

2

5 RTD Red

Red

Red Gray & Green Red

Red

4

(2 total)

White

2

6 RTD White White White White White White

Heavy Green 7 Shield (Screen) None

Heavy Green

(Shield)

None None None Yellow

None 8 Not Used None None None None None None

Notes:

1. BNC adapter required on sensors provided with BNC termination (See Figure 9).

2. Red and White wires not present on sensors sold without temperature compensators

3. Cut away and discard gray wire on AP100 sensors (if present)

4. Place both red wires in terminal 5

Note.

If an automatic temperature compensator is not used the

TB82PH must be configured for manual temperature

compensation. See the Configure Mode section for details.

Note.

TB5, AP100, AP300 and 7650/7660 sensors do not have a

solution ground rod required to fully utilize all the TB82PH

on-line sensor diagnostics. When configuring the

transmitter for use with these sensors the DIAGS

(diagnostics) choice must be set to OFF. See the

Configure Mode section for details.

ABB TB82PH ATEX Product Instruction Manual

TB82PH-ATEX-EN-A 11

Figure 12

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

7.00

25°

C

exit to

MEASURE

FAULT

info

SELECT

ENTER

YES

NEXT

NO

MENU

%

mV

pH

OUTPUT

HELD

SPIKE FAULT

M

ABB

TB82

Hidden Key

(

User Mode

)

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

7.00

25°

C

MENU

pH

M

Figure 13

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

7.00

Calibr

exit to

MEASURE

SELECT

MENU

pH

Figure 14

OPERATING PROCEDURES

Figure 12 shows the TB82PH keypad and display with all possible icons

in the display activated. For any given operation only the icons involved

in the operation will be shown.

Key Functions

Exit to MEASURE - Escapes back to the Measure Mode from all other

modes or programming states of operation.

FAULT Info - Accesses information on diagnostic or error conditions.

SELECT - Selects the mode or programming state of operation shown

in the secondary display region

ENTER - Accepts the mode or programming state of operation shown in

the secondary display region

NEXT - Increments through a series of programming states

YES - Affirms the action that is about to take place

NO - Denies the action that is about to take place.

MENU - Increments through the modes of operation

Increases numerals & moves through a series of parameters

Moves the flashing data entry value one space to the right

Decreases numeric values & moves through a series of parameters

Figure 13 shows the TB82PH in the MEASURE mode of operation.

Pressing the key at the far right, underneath the MENU icon, provides

access to all other instrument functions.

Figure 14 shows the display after the MENU key has been pressed

once. The CALIBRATE menu can now be accessed by pressing the key

underneath the SELECT icon. If the MENU key is pressed again the

display will change to the next menu function choice, OUT/HOLD.

Pressing again will activate the CONFIGURE menu choice, and so on.

There are six MENU functions:

MEASURE - Normal operational display

CALIBRATE – Allows calibration of the pH (ORP) and temperature

sensors, restoring calibration to the original factory values, tuning of

the analog output and also allows the ability to view or change the

sensor’s slope and offset.

OUT/HOLD - Allows the output to be re-ranged, held or released

(Analog version only)

CONFIGURE - Sets up how the transmitter operates

SECURITY - Sets password protection to the CONFIGURE,

CALIBRATE and OUTPUT menus

DISPLAY - Displays temperature in °F or °C, current output in mA,

reference impedance, mV input, spike output status and software

revision. Sets what will be displayed under the secondary display

when in the measure mode.

Commissioning the Instrument

To commission the TB82:

1. Configure the instrument as required for the application.

2. Calibrate the sensor(s).

3. Set up parameters on the receiving devices (e.g. PLC, DCS recorder) to properly recognize the TB82 outputs.

TB82PH ATEX Product Instruction Manual ABB

12 TB82PH-ATEX-EN-A

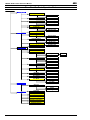

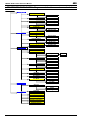

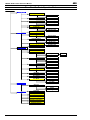

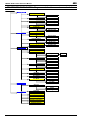

Flow Chart For Basic Operation Mode

MEASURE

CALIBRATE

pH Cal

1 Point Calibration

2 Point Calibration

Temperature Cal

Enter Temp

Edit Calibration

Enter Slope

Enter Offset

Reset Cal

Output Cal

Adjust 4 mA

Adjust 20 mA

Back to pH Cal

OUT/HOLD

Hold Output

Release Hold

Hold to XXX%

Rerange Output

4 mA Point

20 mA Point

Damping

XX.X Seconds

Back to Hold Output

CONFIGURE

Modify/View

Basic

Analyzer

pH

ORP

pIon

Temp. Sensor

None

3k Balco

Pt 100

Temp. Comp. Type

Manual

Auto

Output

4 mA Point

20 mA Point

Damping

Enter Seconds

Diagnostics

On or Off

Safe Mode

Fail Low

Fail High

SECURITY

Set Level

Calibrate

Output

Configure

Password

DISPLAY

Temperature °C

Temperature °F

Current Output

Diagnostic Alarms

Reference Impedance

Millivolt Input

Software Revision

pH Glass

Antimony

ABB TB82PH ATEX Product Instruction Manual

TB82PH-ATEX-EN-A 13

CONFIGURE MODE

Before the instrument can be put into a process measurement loop it must be configured. The TB82PH Transmitter

operation (non-fieldbus versions) can be set in either a BASIC or ADVANCED Mode. BASIC mode is sufficient for 95% of

all measurements. ADVANCED functions are described in Italic print in the ‘alternatives’ section of the default

configuration table and in the ‘Configure Mode - Flow Chart for ADVANCED Mode’ section. Figures 15 through 25 show

typical screen flows for a BASIC pH Configuration.

Default Configuration

Parameter Default Alternative

Mode BASIC ADVANCED

Analyzer pH ORP, pIon,

Ion Concentration

Analyzer input pH Glass Antimony,

Custom sensor

Reference Impedance

Temperature Sensor None 3K Balco

Pt100 RTD

Temperature

Compensation Type

Manual Auto,

Auto Solution

Output 4 mA = 0.00 pH

20 mA = 14.00 pH

Any 1 pH to 16 pH span,

any span above 100 mV from

–1999 mV to +1999 mV,

non-linear function generator,

Damping 00.5 seconds Adjustable to 99.9 seconds

Diagnostics Off On

Safe Mode* Fail low Fail high

Spike* 0% Spike Magnitude 0 to 100% magnitude

Note: Alternatives in Italics are available in ADVANCED mode only

* Safe Mode and Spike functions not available on fieldbus versions

7.00

CONFIG

exit to

MEASURE

SELECT

MENU

pH

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

7.00

MODIF

Y

exit to

MEASURE

SELECT

NEXT

pH

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

7.00

Basi

c

exit to

MEASURE

SELECT

NEXT

pH

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

7.00

ANALZR

exit to

MEASURE

SELECT

NEXT

pH

Figure 15 Figure 16

Figure 17 Figure 18

TB82PH ATEX Product Instruction Manual ABB

14 TB82PH-ATEX-EN-A

Note.

Diagnostics is a function valid only with a TBX5

Advantage pH sensors or an AP200 with a

solution ground rod that is connected to Terminal

TB2-4 (green, SOL GND). Diagnostics must be

turned ‘OFF’ if TB5, AP100, AP300, 7650/7660,

ORP or sensors without an integral solution

ground are used.

Caution.

If a programming change has been made,

pressing the Exit to MEASURE key will activate

the SAVE? display (Figure 25). YES and NO

keys will also appear. Press the YES key to save

the changes. If the NO key is pressed any

configuration or programming changes will not be

saved.

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

7.00

PH.GLAS

exit to

MEASURE

ENTER

NEXT

pH

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

0.00

4MA.P

T

exit to

MEASURE

ENTER

pH

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

OFF

DIAGS

exit to

MEASURE

ENTER

pH

0.05

SECS

exit to

MEASURE

ENTER

oH

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

7.00

SAFE.M

D

exit to

MEASURE

FAULT

info

ENTER

NEXT

pH

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

7.00

Fail.l

o

exit to

MEASURE

FAULT

info

ENTER

NEXT

pH

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

7.00

Save

?

exit to

MEASURE

YES

NO

pH

Figure 19 Figure 20

Figure 21 Figure 22

Figure 25

Figure 24

Figure 23

ABB TB82PH ATEX Product Instruction Manual

TB82PH-ATEX-EN-A 15

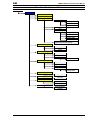

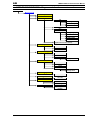

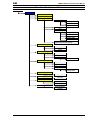

Flow Chart For Advanced Mode

MEASURE

CONFIGURE

Modify/View

Basic

Analyzer

pH

pH glass

Antimony

Custom

ORP

pIon

Ion Concentration

Units (ppm, ppb)

Valence

Magnitude (log)

End Magnitude

End Millivolt

Reference Impedance k-ohms

(appears for all sensor choices)

Temp. Sensor

None

3k Balco

Pt 100

Temp. Comp. Type

Manual

Auto

Auto - Solution

+/-X.XX pH/10C

Output

4 mA Point

20 mA Point

Linear

Non-linear

Program X1=Y1

through X5+Y5

Damping

Enter Seconds

Diagnostics

On or Off

Safe Mode

Fail Low

Fail High

Spike

Spike Magnitude

(0-100%)

TB82PH ATEX Product Instruction Manual ABB

16 TB82PH-ATEX-EN-A

CALIBRATE MODE

Before an instrument can properly measure pH the sensor must be calibrated to the instrument. Periodic update

calibrations must be performed during the time the sensor is in service. The frequency of re-calibration is application

dependent. This mode also defines calibration of the temperature input and fine tuning the 4-20 mA output for non-

fieldbus versions.

MEASURE

CALIBRATE

pH Cal

1 Point Calibration

Stable?

Enter New Value

2 Point Calibration

Change Temp

O

C

Low Value Buffer

Stable?

High Value Buffer

Stable?

PV Slope %

PV Offset mV

Temperature Cal

Enter Temp

Edit Calibration

Enter Slope

Enter Offset

Reset Cal

Output Cal

Adjust 4 mA

Adjust 20 mA

Back to pH Cal

OUTPUT/HOLD MODE

MEASURE

CALIBRATE

OUT/HOLD

Hold Output

Release Hold

Hold to XXX%

Rerange Output

4 mA Point

20 mA Point

Damping

XX.X Seconds

Back to Hold Output

Output/Hold screen flow only valid for non-fieldbus versions.

Caution.

The Reset Calibrate State will reset all

calibration values; therefore, the process sensor

and temperature sensor will require calibration

after performing the Reset Calibrate procedure.

ABB TB82PH ATEX Product Instruction Manual

TB82PH-ATEX-EN-A 17

SECURITY MODE

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

Set Level

Calibrate

Output

Configure

Password

Enter 3 digit code

SECONDARY DISPLAY MODE

MAINTENANCE

Preventative Maintenance Tasks Interval (months)

Check, tighten and clean all wiring and connections 12

Clean and lubricate all gaskets and o-rings Each time seals are disturbed

Analyzer Validation Per user’s requirements (minimum 12)

Clean and inspect sensor As required by application

(minimum monthly)

Sensor calibration As required by application

(minimum monthly)

MEASURE

CALIBRATE

OUT/HOLD

CONFIGURE

SECURITY

DISPLAY

Temperature °C

Temperature °F

Current Output

Diagnostic Alarms

Reference Impedance

Millivolt Input

Software Revision

Back to Temp °C

Note.

If an ‘M’ appears after the

temperature display (e.g. 25°C

M

)

the TB82PH is programmed for

manual temperature compensation

(default 25°C).

TB82PH ATEX Product Instruction Manual ABB

18 TB82PH-ATEX-EN-A

DISMANTLING AND RE-ASSEMBLY

Dismantling

1. Use the bladed screwdriver to loosen the four captive

screws that secure the Front Bezel and/or Rear Cover

Assemblies (depending on which component is being

replaced) and remove the cover(s).

2. Remove Power Supply and/or Input PCB Assemblies

by unscrewing the two Phillips screws and unplug the

assemblies from their connectors.

3. Remove Microprocessor/Display PCB Assembly by

unscrewing the four Phillips screws and unplug the

keypad cable by lifting the locking arms on the side of

the connector and remove the cable from the

connector.

4. Remove the cable hubs by screwing the retaining nut

and removing the hub from the Shell Assembly.

Reassembly

Check that the gaskets are not damaged and have a thin

layer of silicone grease. If the gaskets are damaged,

replace gaskets.

1. Install the Microprocessor/Display by securing the

assembly with the four Phillips screws and installing

the keypad cable into the connector and locking it into

place by pushing down the two locking arms on the

side of the connector.

2. Install the Power Supply and/or Input PCB

Assemblies into their respective connector and secure

the assemblies with the two Phillips screws per

assembly.

3. Attach cable hubs by installing the gaskets onto the

hubs and insert the hubs into the ports in the Shell

assembly. Secure the hubs by tightening the nut onto

the hub threads.

4. Install the Front Bezel and/or Rear Cover Assemblies

and secure by tightening the four captive screws per

assembly using a bladed screwdriver.

Caution.

Dismantling and reassembly should not be

carried out on site because of the risk of

damage to components and printed

circuits. The dismantling and reassembly

procedures should be carried out in the

listed order to avoid instrument damage.

Warning.

Substitution of any components other than

those assemblies listed in this section will

compromise the certification listed on the

transmitter nameplate. Invalidating the

certifications can lead to unsafe conditions

that can injure personnel and damage

e

q

ui

p

ment.

MICROPROCESSOR/DISPLAY PCB ASSY KITS:

HART/NON-HART VERSIONS -

TB82PH 4TB9515-0154

TB82EC/TC/TE 4TB9515-0178

FF VERSIONS -

TB82PH 4TB9515-0255

TB82EC 4TB9515-0256

TB82TE 4TB9515-0257

TB82TC 4TB9515-0258

POWER SUPPLY PCB ASSY KITS:

HART/NON-HART VERSIONS -

TB82 NON-HART 4TB9515-0158

TB82 HART 4TB9515-0159

FF VERSIONS -

TB82 4TB9515-0253

PA VERSIONS-

TB82 4TB9515-0254

PG9 LIQUID TITE FITTING KIT (TB84)

4TB9515-0191

4TB9515-0198

1/2” LIQUID TITE FITTING KIT

4TB9515-0165 (FOR TB5 SENSORS)

4TB9515-0163 (FOR TBX5/TB4 SENSORS)

PROFIBUS PA VERSIONS -

TB82PH 4TB9515-0260

TB82EC 4TB9515-0261

TB82TE 4TB9515-0262

TB82TC 4TB9515-0263

LINE POWER ANALYZER VERSIONS -

TB84PH 4TB9515-0199

TB84EC 4TB9515-0201

TB84TE 4TB9515-0205

TB82TC 4TB9515-0203

FRONT BEZEL KIT

TB82 VERSIONS:

4TB9515-0160 (TB82 non-FM)

4TB9515-0181 (TB82 FM)

4TB9515-0208 (TB84 non-FM)

4TB9515-0210 (TB84 FM)

POWER SUPPLY PCB ASSY KIT

4TB9515-0207 (TB84)

INPUT PCB ASSY KITS:

4TB9515-0153 (PH)

4TB9515-0176 (EC)

4TB9515-0226 (TC)

4TB9515-0187 (TE)

REAR COVER KITS:

4TB9515-0162 (82)

4TB9515-0214 (84)

SHELL KITS:

4TB9515-0161 (82PH)

4TB9515-0175 (82EC/TE)

4TB9515-0224 (82TC)

4TB9515-0212 (84PH)

4TB9515-0213 (84EC/TE)

4TB9515-0225 (84TC)

Figure 26 - TB82PH Transmitter Exploded View

ABB TB82PH ATEX Product Instruction Manual

TB82PH-ATEX-EN-A 19

SPECIFICATIONS

Property Characteristic/Value

Process Display Range

pH

ORP

pIon

Temperature

-2.00 to +16.00 pH

-1999 to +1999 mV

-1999 to +1999 mV

0 to 140°C

Power Requirements

Analog

HART Versions

PROFIBUS PA

FOUNDATION Fieldbus (FF)

13.5 to 55 VDC (13.5 to 42 VDC for agency certified applications).

See Figure 27 below

14 to 55 VDC (14 to 42 VDC for agency certified applications).

See Figure 27 below

9 to 32 VDC (9 to 24 VDC for agency certified applications)

15 mA quiescent current

9 to 32 VDC (9 to 24 VDC for agency certified applications)

15 mA quiescent current

Ambient Temperature Effect

pH

ORP

pION

Temperature

±0.007 pH/°C @ 95% Relative Humidity

±0.4 mV/°C @ 95% Relative Humidity

±0.4 mV/°C @ 95% Relative Humidity

±0.16°C/°C @ 95% Relative Humidity

Maximum Sensor Cable Length 100 ft (30.5 m)

Environmental

Operating temperature

LCD Range

Storage temperature

-20° to 60°C (-4° to 140°F)

-20° to 60°C (-4° to 140°F)

-40° to 70°C (-40° to 158°F)

Enclosure Classification NEMA 4X

IP65

Size

Height

Minimum panel depth

Maximum panel cutout

Recommended panel cutout

144 mm high x 144 mm wide x 171 mm long (5.67 in. high x 5.67 in. wide x 6.75 in.

long)

145 mm (5.70 in.)

136.7 mm x 136.7 mm (5.38 in. x 5.38 in.)

135 mm x 135 mm (5.33 in. x 5.33 in.)

Weight 1.9 kg (4.2 lb) without mounting hardware

3.4 kg (7.5 lb) with Pipe Mounting Hardware

250

14 19 24 29 34 39 44 49 54 (HART)

13.5 18.5 23.5 28.5 33.5 38.5 43.5 48.5 53.5 (Analog)

2100

1800

1500

1200

900

600

300

0

LOAD RESISTANCE

(OHMS)

2000

HART

COMMUNICATIONS

RANGE

Figure 27 – Supply Voltage Requirements, HART and Analog Versions

Supply Voltage VDC

ABB

ABB Inc.

9716 S. Virginia St., Suite E

Reno

Nevada 89521

USA

Tel: +1 (775) 850 4800

Fax: +1 (775) 850 4808

ABB Ltd

Oldens Lane

Stonehouse, Glos.

GL10 3TA

UK

Tel: +44 (0) 1453 826 661

Fax: +44 (0) 1453 829 671

ABB has Sales & Customer Support expertise

in over 100 countries worldwide

www.abb.com

The Company’s policy is one of continuous product

improvement and the right is reserved to modify the

information contained herein without notice.

Printed in USA (11.04.2003)

© ABB 2003

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

ABB TB82PH Operating Instructions Manual

- Taper

- Operating Instructions Manual

- Ce manuel convient également à

dans d''autres langues

- English: ABB TB82PH

- español: ABB TB82PH

- Deutsch: ABB TB82PH

Documents connexes

Autres documents

-

Hama 00093720 Le manuel du propriétaire

-

Memup SlidePad Elite Series SlidePad Elite 9716 Guide de démarrage rapide

Memup SlidePad Elite Series SlidePad Elite 9716 Guide de démarrage rapide

-

MEMUP SlidePad Elite 9716 Mode d'emploi

-

JVC SP-AP300 Manuel utilisateur

-

Thermo Fisher Scientific Elite ORP Tester Mode d'emploi

Thermo Fisher Scientific Elite ORP Tester Mode d'emploi

-

Compur 501 IR Manuel utilisateur

Compur 501 IR Manuel utilisateur

-

General Tools & Instruments MMD4E Manuel utilisateur

-

Hamilton 243187 Manuel utilisateur

-

Hach 1735 TRO Hazardous Location Installation Manual

Hach 1735 TRO Hazardous Location Installation Manual

-

Hach ORBISPHERE 3650 Atex Manuel utilisateur

Hach ORBISPHERE 3650 Atex Manuel utilisateur