cod. 3541F242 - 05/2018

WALL MOUNTED GAS BOILER

INSTALLATION, OPERATION & MAINTENANCE MANUAL

CHAUDIÈRE MURALE À GAZ

MANUEL D’INSTALLATION, D’UTILISATION ET D’ENTRETIEN

Model

Modèle

CHB-100 / CHB-130 / CHB-150

Manufactured by:

ECR International Inc.

2201 Dwyer Avenue, Utica, NY 13501

Tel. 800 253 7900

www.ecrinternational.com

PN 40010633 REV. F [05/15/2018]

2

EN

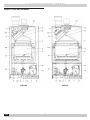

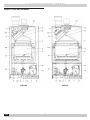

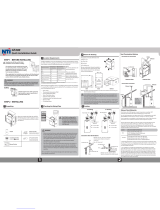

Figure 1 - Overall Dimensions

7 = Gas Inlet - 3/4” FPT

10 = System Delivery - G 3/4”

11 = System Return - G 3/4”

*209 = Hot Water Tank Delivery - 3/4” Capped

*210 = Hot Water Tank Return - 3/4” Capped

* BSPT To NPT Adapters Included

CHB 150

DIMENSIONS

CHB 100/130/150 CHB 100/130

3

EN

TABLE OF CONTENTS

1 - Introduction ................................................................................................................... 4

2 - Important Safety Information ........................................................................................... 5

3 - General view and main components .................................................................................. 6

4 - Locating Boiler ............................................................................................................... 9

5 - Hydronic Piping ............................................................................................................ 11

6 - Combustion Air And Vent Piping - Category I (Chimney Vent) ............................................ 16

6 - Combustion Air And Vent Piping- Category I (Chimney Vent) .............................................. 17

6 - Combustion Air And Vent Piping of direct vent and Category III .......................................... 18

7 - Gas Supply Piping ......................................................................................................... 23

8 - Electrical Connections ................................................................................................... 24

9 - Start Up Procedure ....................................................................................................... 25

10 - Operating Instructions ................................................................................................. 27

11 - General Maintenance And Cleaning ................................................................................ 33

12 - Ratings And Capacities ................................................................................................ 34

13 - Trouble Shooting......................................................................................................... 37

Wiring diagram ................................................................................................................. 38

Repair Parts List - CHB ....................................................................................................... 39

4

EN

1 - INTRODUCTION

1.1 Designated Use

• Hot water heating boiler.

• Indoor installation.

• Closet or alcove installation.

• Catagory I or III Venting.

• For use with natural gas, eld conversion kit for LP

available.

• Indirect heating is acceptable.

• Boiler is arranged for connection to an external

storage tank for hot water production (optional).

All functions relevant to domestic hot water

production are only active with the optional water

tank sensor connected.

1.2 The unit MUST NOT:

•

Directly heat potable water.

• Heat water with non-hydronic heating system chemicals

present (example, swimming pool water).

• Exceed 185°F (85°C) system design temperature.

• Exceed 43.5 PSIG

1.3 Operational Features

• Modulating: 3-1 turn down.

• Integral Dual Limit.

Information and specications outlined in this manual in effect at the

time of printing of this manual. ECR International, Inc. reserves the right to

discontinue, change specications or system design at any time without

notice and without incurring any obligation, whatsoever.

5

EN

2 - IMPORTANT SAFETY INFORMATION

NOTICE

Used to address practices not related to

personal injury.

CAUTION

Indicates a hazardous situation which, if not

avoided, could result in minor or moderate

injury.

!

WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

!

DANGER

Indicates a hazardous situation which, if not

avoided, WILL result in death or serious injury.

!

This is the safety alert symbol. Symbol alerts you to

potential personal injury hazards. Obey all safety messages

following this symbol to avoid possible injury or death.

2.2 Become familiar with symbols identifying

potential hazards.

WARNING

Fire, explosion, asphyxiation and electrical

shock hazard. Improper installation could

result in death or serious injury. Read this

manual and understand all requirements

before beginning installation.

!

2.3 Installation shall conform to requirements of

authority having jurisdiction or in absence of such

requirements:

•

United States

• National Fuel Gas Code, ANSI Z223.1/NFPA 54

.

• National Electrical Code, NFPA 70.

• Canada

• Natural Gas and Propane Installation Code,

CAN/CSA B149.1.

• Canadian Electrical Code, Part I, Safety Standard

for Electrical Installations, CSA C22.1

2.4 Requirements for Commonwealth of

Massachusetts:

Boiler installation must conform to Commonwealth of

Massachusetts code 248 CMR which includes but is not

limited to:

• Installation by licensed plumber or gas tter.

2.5 Requirements for CSD-1:

Where required by the authority having jurisdiction, the

installation must conform to the

Standard for Controls and Safety Devices for Automatically

Fired Boilers, ANSI/ASME CSD1.

2.1 General

Boiler installation shall be completed by qualied agency.

See glossary for additional information.

6

EN

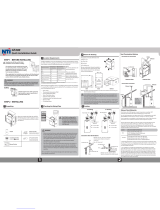

Figure 2 Component Listing

3 - GENERAL VIEW AND MAIN COMPONENTS

CHB 100 CHB 130

7

EN

5

Sealed Chamber

7

Gas Inlet

10

Supply System

11

System Return

16

Modulating Fan

19

Combustion Chamber

22

Burner

27

Copper Heat Exchanger

28

Exhaust Manifold

29

Exhaust Outlet Manifold

32

Heating Circulating Pump

36

Automatic Air Vent

44

Gas Valve

81

Ignition and Detection Electrode

95

3 Way Diverter Valve

114

Water Pressure Switch

209

Hot Water Tank Delivery

210

Hot Water Tank Return

278

Double Sensor - High Limit NTC

297

Air Pressure Switch

364

Condensation Coupling

LBS Kg

Unit Weight

CHB 100 61 27.5

CHB 130 65 29.5

CHB 150 69 31.5

Shipping Weight

CHB 100 65 29.5

CHB 130 69 31.5

CHB 150 73 33.0

3 - GENERAL VIEW AND MAIN COMPONENTS

CHB 150

8

EN

Remove Boiler Jacket

1.

Unscrew screws (A).

2.

Pivot jacket upwards. See gure 3.

3.

Raise Jacket up and off boiler. See gure 4.

1

3

2

A

A

Figure 3 - Jacket Removal - Screw

Locations

Figure 4 - Pivot Jacket and Raise to Remove

WARNING

Fire, explosion, asphyxiation and electrical

shock hazard. Disconnect electrical power

supply and turn off gas at shutoff valve before

attemting to remove boiler jacket. Failure to

follow these instructions could result in death

or serious injury.

!

3 - GENERAL VIEW AND MAIN COMPONENTS

9

EN

Figure 5 - Boiler Clearances

4 - LOCATING BOILER

4.1 Boiler Location Considerations

• Ambient room temperature always above 32°F (0°C) to

prevent freezing.

• Approved for installation in closets.

• Protect gas ignition system components from water

(dripping, spraying, rain, etc.) during operation and

service (circulator replacement, control replacement,

etc.).

• Wall mount only.

• Access to outdoors to meet minimum and maximum

pipe lengths for combustion air and vent piping. See

section 6.

• Drainage of water (or water - antifreeze solution) during

boiler service or from safety relief valve discharge. See

section 5.

• Access to system water piping, gas supply, and electrical

service. See sections 5, 7 and 8.

• Clearances to combustible materials and service

clearances. See Table 1 and gure 5.

• Boiler must not be installed on carpeting.

A

D

FLOOR

F

F

Boiler

(Side View)

Boiler

(Front View)

F

B C

Front

A

TABLE 1: BOILER CLEARANCES

Dimension

Combustible

Materials

(1)

Service

(1)(2)

Top (A)

16” (41cm) 16" (41cm)

Left Side (B)

0" (0 cm) 1” (3 cm)

Right Side (C)

0" (0 cm) 1” (3 cm)

Front (D)

0" (0 cm) 1" 3 cm)

Back (E)

0" (0 cm) 0” (0 cm)

Bottom (F)

0" (0 cm) 12" (30 cm)

Combustion Air/piping

0" (0 cm) 3/8" (1 cm)

Vent piping

6" (15 cm) 6" (15 cm)

(1)

Required distances measured from boiler jacket.

(2)

Service, proper operation clearance recommendation.

10

EN

Figure 6 - Wall Mounting Bracket

4 - LOCATING BOILER

4.2 Pre-pipe supply and return water connections

with factory ttings before wall mounting.

4.3 Wall Mounting

Mount boiler on wall using wall mounting bracket included

with unit.

• Structure must be capable of supporting boiler weight

plus 60 lbs (28 kg). See page 7.

• Wall mount bracket has 2 slots, spaced at

9¼”

(23.5cm) on center

.

• Attach wall mount bracket level on wall.

• Boiler must engage with wall mount bracket. See gure 6.

CAUTION

Boiler weight exceeds 75 pounds (34 kg). Do not

lift boiler onto wall without assistance.

!

NOTICE

Lift boiler using chassis. Using front jacket, vent

piping, water or gas ttings to lift boiler may cause

damage to the boiler.

11

EN

5 - HYDRONIC PIPING

5.1 General

• Install piping in accordance with authority having jurisdiction.

NOTICE

Use two (2) wrenches when tightening and tting

pipe to boiler's threaded ttings. Boiler's internal

piping can be damaged if subjected to excessive

torque.

• Support system piping and safety relief valve discharge

piping. Boiler's internal piping and wall mount bracket

can be damaged if subjected to excessive weight.

• Size central heating pump (and domestic hot water

pump, if used) for system requirements only. Internal

heat exchanger pump compensates for pressure drop

through boiler internal piping and heat exchanger.

• Thoroughly clean and ush system before connecting to boiler.

• If oil is present in system water, use approved detergent to

wash system.

• Flush system to remove any solid objects such as metal chips,

bers, or Teon tape, etc.

5.2 Water System Characteristics

• Water in the heating system must have protection of

metallic materials against corrosion.

• Filling water and subsequent replenishing, must be

clear, with hardness under 150 ppm CaCO3,

A. treated with approved conditioning chemicals

to ensure prevention of corrosion and attack on

metals and plastics, that gases do not form,

B. and bacterial or microbial masses do not proliferate

in low temperature systems.

• Hardness exceeding 150 ppm CaCO3, appropriate water

softening treatment and/or use of suitable anti-fouling

agents must be provided.

Water contained in the system must be checked at least

yearly and have:

A. pH above 7 and under 8.5 (under 8 with presence

of components in aluminum or light alloys),

B. iron content (Fe) less than 0.5 mg/l,

C. copper content (Cu) less than 0.1 mg/l,

D. total content of chlorides, nitrates and sulfates less

than 50mg/l,

E. must contain conditioning chemicals in

concentration sufcient to protect system for a

year.

There must be no microbial or bacterial loads in low

temperature systems.

Conditioners, additives, inhibitors and anti-freeze uids can

be used only if manufacturer guarantees they are suitable

for use in heating systems and they do not cause damage

to heat exchanger or other components and/or materials of

boiler and system.

Use of generic chemicals not specically suitable for use in

heating systems and/or incompatible with boiler materials

and system is forbidden.

Conditioning chemicals must ensure complete deoxygenation

of water and contain specic protective agents for yellow

metals (copper and its alloys), anti-fouling agents for

limescale at least up to 150 ppm CaCO3, pH neutral

stabilizers and, in low temperature systems, specic biocides

for use in heating systems.

In systems with continuous intake of oxygen (e.g. oor

systems without anti-diffusion pipes, open expansion

vessels), or intermittent (e.g. in case of frequent

replenishing), a separator must be provided. Regarding

domestic hot water (DHW), no type of treatment which

could prevent its possible food use can be provided for.

WARNING

• Poison hazard. Ethylene glycol is toxic. Do not

use ethylene glycol.

• Never use automotive or standard glycol antifreeze,

even ethylene glycol made for hydronic systems.

• Ethylene glycol can attack gaskets and seals used

in hydronic systems.

• Use only inhibited propylene glycol solutions

certied by uid manufacturer as acceptable for

use with closed water heating system.

• Thoroughly clean and ush any system that used

glycol before installing new Boiler.

• Provide user with Safety Data Sheet (SDS) on uid

used.

NOTICE

Do not expose boiler to freezing temperatures.

5.3 Special Conditions

• System piping exposed to freezing conditions: Use

inhibited propylene glycol solutions certied by uid

manufacturer for use with closed water heating system.

Do not use automotive or ethylene glycol.

• Boiler used in connection with refrigeration system.

Install piping in parallel with boiler, with appropriate

valves to prevent chilled medium from entering boiler.

• System piping connected to heating coils located in air

handling unit exposed to refrigerated air circulation. Install

ow control valves or other automatic means to prevent

gravity circulation of boiler water during cooling cycle

.

12

EN

Figure 7 - Indirect Tank Performance Chart

5.4 Storage Tank Connection For Domestic Hot

Water Production

• Unit’s electronic board is arranged for managing an

external storage tank for domestic hot water production.

• See gure 11 for hydronic plumbing.

• Make electrical connections as shown on wiring diagram

page 38.

• Boiler’s control system recognizes presence of hot water

tank probe and automatically congures DHW function,

activating display and controls.

• Match Indirect tank heat exchanger and boiler capacity.

• Indirect tank may require dedicated pump. See gure 7

and indirect tank specication to determine pump size.

• Incorrect tank size or insufcient ow may result in:

F. Unsatisfactory indirect tank performance.

G. Boiler short cycling

H. Extended DHW calls resulting in delayed response

to CH calls.

WARNING

Burn and Scald Hazard. Safety relief vlave

could discharge steam or hot water during

operation. Install discharge piping per these

instructions. Failure to do so could result in

death or serious injury.

!

5.5 Safety Relief Valve

NOTICE

Boiler rated at 43.5 psig (.30MPa) maximum allowable

working pressure. Boiler provided with 30 psig

(.21MPa) safety relief valve.

• Install safety relief valve using pipe ttings provided with

boiler. See gure 8.

• Install safety relief valve with spindle in vertical position.

• Do not install shutoff valve between boiler and safety

relief valve.

• Install discharge piping from safety relief valve. See

gure 9.

• Use ¾” or larger pipe.

• Use pipe suitable for temperatures of 375°F (191°C)

or greater.

• Individual boiler discharge piping shall be independent

of other discharge piping.

5 - HYDRONIC PIPING

Figure 8 - Safety Relief Valve & Air Vent

(Viewed from front of boiler)

Safety Relief

Valve

Street Elbow ¾”

Table 2

13

EN

5 - HYDRONIC PIPING

Check Local Codes

for Maximum

Distance to Floor

Safety Relief

Valve

Gas Shutoff

Valve

in Open

position

Figure 9 - Safety Relief Valve Discharge

Piping

• Size and arrange discharge piping to avoid reducing

safety relief valve relieving capacity below minimum

relief valve capacity stated on rating plate.

• Run pipe as short and straight as possible to location

protecting user from scalding and properly drain

piping.

• Install union, if used, close to safety relief valve outlet.

• Install elbow(s), if used, close to safety relief valve

outlet and downstream of union (if used).

• Terminate pipe with plain end (not threaded).

14

EN

5 - HYDRONIC PIPING

5.6 System Piping

• Systems with automatic ll valves require back ow

prevention device.

• Single boiler system.

Additional considerations:

• Boiler control is designed for single central heating

pump. Installer responsible for integration of

multiple central heating pumps.

5.6a Low Water Cut Off (LWCO)

• Boiler installed above radiation level (or as required by

authority having jurisdiction) shall have low water cutoff

protection. See gure 10.

• Connect LWCO switch leads and 120V power leads

to terminals provided. See Boiler Wiring Diagram.

Provide power to LWCO per manufacturer’s

instructions.

• Low Water Cutoff (LWCO) probe location. See gure 10

for minimum probe height. Do not install shutoff valve

between boiler and LWCO probe.

• If using separate stand pipe, install air vent using

tee to avoid nuissance shutdowns.

• See gure 10 for suggested probe location.

• Arrange piping to prevent water dripping onto boiler.

Figure 10 - LWCO Suggested Probe Location

Air Vent

LWCO

To

Supply

Gas

Supply

Minimum

acceptable height

for LWCO control

Safety Relief

Valve

Return

Water

Pipe

to Drain

15

EN

5 - HYDRONIC PIPING

8 Domestic Hot Water Outlet

9 Domestic Cold Water Inlet

10 Heating System Supply

11 Heating System Return

95 Diverter Valve

209 Hot Water Tank Delivery

210 Hot Water Tank Return

Figure 11 - Hydronic Piping - CHB 100/130/150

16

6 - COMBUSTION AIR AND VENT PIPING - CATEGORY I (CHIMNEY VENT)

6.1 Check Your Chimney

Chimney must be clean, right size, properly constructed

and in GOOD CONDITION.

1.

Installation must conform to requirements of the

authority having jurisdiction or, in absence of such

requirements, to the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and/or Natural Gas and Propane

Installation Code, CAN/CSA B149.1.

2.

Increaser fi tting is required on this boiler for Category I

venting, and 4” is minimum permissible vent diameter.

This does not imply vent connector is intended to be 4”

diameter pipe. Vent connector shall be sized according

to appropriate venting tables in the National Fuel

Gas Code and may be required to be larger than 4”

diameter.

NOTICE

Boiler installation for chimney venting is not

complete unless increaser fi tting is located and

secured.

3.

These are Category I and Category III high effi ciency

boilers with lower stack or exhaust temperature.

4.

Venting into masonry chimney without liner, line

chimney from top to bottom with either:

A. Listed Type B vent pipe

B. Listed fl exible vent liner

C. Poured ceramic liner.

5.

Outside chimneys should not be used unless they are

(choose one of the following):

A. Enclosed in a chase

B. Lined with Type B vent pipe

C. Use listed fl exible vent liner

D. Use certifi ed chimney lining system

6.

Vent connector from boiler to chimney should run as

directly as possible with as few elbows as possible.

7.

Boiler and other appliances can share a chimney.

Consult appropriate Vent Sizing Tables in National Fuel

Gas Code for specific requirements. See Application

Guide for more details.

8.

Boiler is only appliance connected to vent, Type B vent

pipe is recommended for vent connector.

9.

Slope pipe up from boiler to chimney not less than 1/4”

per foot (21mm/m).

10.

End of vent pipe must be fl ush with inside face of

chimney fl ue. Use sealed-in thimble for chimney

connection.

11.

Fasten sections of vent pipe with sheet metal screws to

make piping rigid. Use stovepipe wires to support pipe

from above.

12.

Do not connect to fi replace fl ue.

13.

Do not install damper on this boiler.

WARNING

Boiler and venting installations shall be performed

by a qualifi ed service agent and in accordance with

the appropriate manual. Installing or venting boiler

or other gas appliance with improper methods or

materials may result in serious injury or death due

to fi re or to asphyxiation from poisonous gases such

as carbon monoxide with is odorless and invisible.

!

WARNING

Do not connect boiler to any portion of mechanical

draft system operating under positive pressure.

!

Figure 11 - Combustion Air Fitting

3

3

Horizontal Venting requires fi eld supplied appliance adapter

for the boiler fl ue outlet.

Boiler is provided with a 3” vent connection, 3” x 4”

increaser must be fi eld sourced for chimney application.

This does not mean that the connection to the chimney will

always be 4”.

17

EN

6 - COMBUSTION AIR AND VENT PIPING- CATEGORY I (CHIMNEY VENT)

6.2 Minimum Vent Pipe Clearance

• Use Type B vent pipe through crawl space. Where vent

pipe passes through combustible wall or partition, use

ventilated metal thimble. Thimble should be 4 inches

larger in diameter than vent pipe.

• Boiler installed with single wall vent, must have 6”

clearance between its surface and any combustible

material. New Type B gas vent or exible liner must be

installed in accordance with instructions furnished with

vent. Maintain clearances as specied for vent pipe.

• Verify vent pipe is re-stopped where it goes through

oor or ceiling. It should have approved vent cap with

clearances from roof. If clearances are less than shown,

have vent checked by local authorities. Figure 14, Page

21.

• Vent connectors serving appliances vented by natural

draft shall not be connected into any portion of

mechanical draft systems operating under positive

pressure.

6.3 Removing Existing Boiler From Common

Venting System

When an existing boiler is removed from a common

venting system, common venting system is likely to be

too large for proper venting of the appliances remaining

connected to it.

1.

At the time of removal of an existing boiler, the

following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliance

remaining connected to the common venting system

are not in operation.

2.

Seal any unused openings in the common venting

system.

3.

Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deciencies

which could cause an unsafe condition.

4.

Insofar as is practical, close all building doors and

windows and all doors between the space in which the

appliances remaining connected to the common venting

system are located and other spaces of the building.

Turn on clothes dryers and any appliance not connected

to the common venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts, so

they will operate at maximum speed. Do not operate a

summer exhaust fan. Close replace dampers.

5.

Place in operation the appliance being inspected. Follow

the lighting instructions. Adjust thermostat so appliance

will operate continuously.

6.

Test for spillage at the draft hood relief opening after

5 minutes of main burner operation. Use ame of a

match or candle, or smoke from a cigarette, cigar, or

pipe.

7.

After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, replace dampers and

any other gas-burning appliance to their previous

conditions of use.

8.

Any improper operation of the common venting system

should be corrected so the installation conforms with

the National Fuel gas Code, ANSI Z223.1/NFPA 54,

and/or the Natural Gas and Propane Installation Code,

CAN/CSA B149.1. When re-sizing any portion of the

common venting system, the common venting system

should be re-sized to approach the minimum size

determined using the appropriate tables in Chapter 13

of the National Fuel Gas Code, ANSI Z223.1/NFPA 54,

and/or the Natural Gas and Propane Installation Code,

CAN/CSA B149.1.

9.

It is recommended that existing gas vents be checked

to be sure they meet local codes.

6.4 Modulating Fan

• Unit is equipped with an advanced combustion air, vent

ow control system, with modulating fan and pressure

sensor.

• Unit automatically adapts its operation to ue type

and length, without requiring adjustments during

installation or use of bafes in combustion circuit.

• Unit consistantly and automatically regulates

combustion air and vent ow according to change in

thermal load. Combustion and heat exchange occur in

optimum conditions. Unit’s thermal efciency remains

high throughout its power range.

6.5 Venting Materials

• See Table 3

Table 3 - Combustion Air and Vent Pipe Fittings

Category I (Chimney Vent)

Item Material Standards

Vent Pipe & Fittings

Type B Vent UL 441, ULC S605

Masonry Chimney

- must conform to

proper sizing and

materials

National Fuel

Gas Code, ANSI

Z223.1/NFPA 54

Combustion Air

Stainelss Steel,

PVC, CPVC, PP,

Aluminum

ANSI/ASTM

D2564, ANSI/

ASTM F493, UL

1738/ULC636-08

18

EN

6 - COMBUSTION AIR AND VENT PIPING OF DIRECT VENT AND CATEGORY III

Induced Draft Boilers

Horizontal (Category III) venting systems installation

shall conform to the requirements of the authority having

jurisdiction or, in the absence of such requirements, to

the National Fuel Gas Code, ANSI Z223.1/NFPA 54, and/

or Natural Gas and Propane Installation Code, CAN/CSA

B149.1

1.

Boilers may be vented horizontally. Vent pipe is pitched

down from boiler to vent termination. Do not connect

other appliances to this vent.

2.

Vent Pipe Material UL Listed - AL294C Stainless Steel

vent pipe and ttings.

3.

Clearance to Combustible Materials: For stainless steel

vent pipe maintain 6” minimum air space clearance to

combustible materials.

4.

Vent Pipe Size: 3” vent pipe connected directly to the

outlet of the induced draft blower.

5.

Vent Pipe Length:

A. For stainless steel vent pipe, the maximum

horizontal vent length is 65 equivalent feet.

B. Minimum horizontal vent length is 5 equivalent

feet.

C. For 3” 90° elbows = 5 equivalent feet of vent

length.

6.

Vent Termination Fitting: For all vent pipe materials,

you may use either:

A. 90° elbow pointing down, tted with a minimum

1/4” mesh screen to keep out rodents and birds.

The elbow shall be of the same material and size

as vent pipe. The elbow exit should be at least 6”

away from exterior wall.

-or-

B. Concentric side wall vent hood.

7.

Vent Pipe Termination Location :

A. When venting through combustible walls,

combustible clearances must be considered. ECR

vent termination, 5612601, is a certied direct vent

termination (for Catagory III venting) providing

both the outside vent termination and a double

wall pipe for passing through a combustible

wall up to 10” thick. Vent terminations by other

manufacturers may also be used as long as they

are certied for catagory III venting.

B. If the 90° elbow is the termination tting of choice,

then the single wall pipe will be passing through the

side wall. For combustible walls, a UL listed thimble

shall be used where the single wall pipe passes

through the wall.

C. For single wall pipe through non-combustible

walls, the hole through the wall need only be large

enough to maintain the pitch of the vent pipe, and

provide proper sealing. A thimble is not required for

single wall pipe passing through non-combustible

walls.

D. The venting system shall terminate at least 3 feet

0.9m) above any forced air inlet located within

10 feet (3m). The venting system shall terminate

at least 4 feet (1.2m) below, 4 feet (1.2m)

horizontally from, or 1 foot (300 mm) above any

door, window, or gravity air inlet into any building.

The bottom of the vent shall be located at least 12

inches (300mm) above grade. Termination of the

vent shall be not less than 7 feet (2.13m) above

adjacent public walkway. The vent terminal shall

not be installed closer than 3 feet (0.9m) from the

inside corner of an L shaped structure. Termination

of the vent should be kept at least 3 feet (0.9m)

away from vegetation. The venting system shall

terminate at least 4 feet horizontally from, and in

no case above or below, unless a 4 foot horizontal

distance is maintained, from electric meters, gas

meters, regulators, and relief equipment.

• The venting system shall terminate at least 4 feet

below any eave, soft, or roof overhang.

• The venting system shall not terminate

underneath any deck, patio, or similar structure.

• Put vent on a wall away from the prevailing

winter wind. Locate or guard the vent to prevent

accidental contact with people or pets.

• Terminate the vent above normal snow-line. Avoid

locations where snow may drift and block the

vent. Ice or snow may cause the boiler to shut

down if the vent becomes obstructed.

• Under certain conditions, ue gas will condense,

forming moisture. In such cases, steps should be

taken to prevent building materials at the vent

terminal from being damaged by exhaust of ue

gas.

United States - Terminate vent system at least

4 feet (1.22m) horizontally from, and in no case

above or below, unless a 4 feet (1.22m) horizontal

distance is maintained, from electric meters, gas

meters, regulators and relief equipment.

Canada - Terminate vent system at least 6 feet

(1.83 m) horizontally from, and in no case above

or below, unless a 6 feet (1.83m) horizontal

distance is maintained, from electric meters, gas

meters, regulators and relief equipment.

8.

Joining and Sealing the Vent Pipe: The vent pipe needs

to be both watertight and gas tight. Seal all joints and

seams following vent pipe manufacture’s installation

instructions.

9.

Support Spacing: Do not restrict thermal expansion

movement of the vent. The vent pipe must expand

and contract freely with temperature change. Each run

of vent piping shall be supported following vent pipe

manufacture’s instructions.

19

EN

WARNING

Vent extending through exterior wall shall not

terminate adjacent to wall or below building

extensions such as eaves, balconies, parapets or

decks. Failure to comply could result in death or

serious injury.

!

Table 4 - Combustion Air and Vent Pipe Fittings

Equivalent Length of Venting Components:

5 ft. equivalent for a 3” 90° elbow.

2 1/2 ft. equivalent for a 3” 45° elbow.

6 - COMBUSTION AIR AND VENT PIPING OF DIRECT VENT AND CATEGORY III

10.

If the horizontal vent must go through a crawl space or

other unheated space, the cool temperatures will likely

cause the ue gases to continuously condense inside

the vent pipe. Do not insulate the vent pipe. It must be

visible for monthly inspection. Insure that the vent pipe

is properly pitched away from the boiler, with no low

spots, so that condensate in the vent will drain away

from the boiler. An insulated enclosure or chase, with

access for inspection and servicing of the vent, may

be required to prevent freezing of liquid condensate.

Consult the vent pipe manufacturer’s instructions for

specic guidelines.

11.

At beginning of each heating season and monthly

during the heating season, check all vent pipes and

vent terminal to make sure there are no obstructions.

Periodically clean the screen in the vent terminal.

Type Item Diameter Min Lenght Max Lenght Material Standards

Direct vent

Vent 3” 5 ft 65 ft

AL294C Stainless

Steel, Aluminum

UL1738,

ULC S636

Air intake 3” 5 ft 65 ft

Stainelss Steel,

PVC, CPVC, PP,

Aluminum

ANSI/ASTM

D2564, ANSI/

ASTM F493, UL

1738/ULC636-08

Category III Vent 3” 5 ft 65 ft

AL294C Stainless

Steel, Aluminum

UL1738,

ULC S636

20

EN

6 - COMBUSTION AIR AND VENTILATION

Provide combustion air and ventilation air in accordance

with the section “Air for Combustion and Ventilation,”

of the National Fuel Gas Code, ANSI Z223.1/NFPA 54,

or Sections 8.2, 8.3 or 8.4 of Natural Gas and Propane

Installation Code, CAN/CSA B149.1, or applicable

provisions of local building codes.

Provide make-up air where exhaust fans, clothes dryers,

and kitchen ventilation equipment interfere with proper

operation.

National Fuel Gas Code recognizes several methods

of obtaining adequate ventilation and combustion air.

Requirements of the authority having jurisdiction may

override these methods.

• Engineered Installations. Must be approved by

authority having jurisdictions.

• Mechanical Air Supply. Provide minimum of 0.35

cfm per Mbh for all appliances located within space.

Additional requirements where exhaust fans installed.

Interlock each appliance to mechanical air supply

system to prevent main burner operation when

mechanical air supply system not operating.

• All Indoor Air. Calculate minimum volume for all

appliances in space. Use a different method if

minimum volume not available.

◊ Standard Method. Cannot be used if known air

inltration rate is less than 0.40 air changes per

hour. See Table 5 for space with boiler only. Use

equation for multiple appliances.

Volume ≥ 50 ft3 x Total Input [Mbh]

◊ Known Air Inltration Rate. See Table 5 for

space with boiler only. Use equation for multiple

appliances. Do not use an air inltration rate (ACH)

greater than 0.60.

Volume ≥ 15 ft3/ACH x Total Input [Mbh]

◊ Refer to National Fuel Gas Code for opening

requirements between connection indoor spaces.

• All Outdoor Air. Provide permanent opening(s)

communicating directly or by ducts with outdoors.

◊ Two Permanent Opening Method. Provide opening

commencing within 12 inches of top and second

opening commencing within 12 inches of bottom

enclosure.

Direct communication with outdoors or

communicating through vertical ducts. Provide

minimum free area of 1 in2 per 4 Mbh of total input

rating of all appliances in enclosure.

Communicating through horizontal ducts. Provide

minimum free area of 1 in2 per 2 Mbh of total input

rating of all appliances in enclosure.

◊ One Permanent Opening Method. Provide opening

commencing within 12 inches of top of enclosure.

Provide minimum clearance of 1 inch on sides

and back and 6 inches on front of boiler (does not

supersede clearance to combustible materials).

◊ Combination Indoor and Outdoor Air. Refer to

National Fuel Gas Code for additional requirements

for louvers, grilles, screens and air ducts.

• Combination Indoor and Outdoor Air. Refer toNational

Fuel Gas Code for application information. National Gas

and Propane Installation Code Requires providing air

supply in accordance with:

• Section 8.2 and 8.3 when combination of appliances

has a total input of up to and including 400 Mbh

(120kW).

Does not have draft control device.

• Section 8.4 when combination of appliances has total

input exceeding 400 Mbh (120 kW).

• Refer to Natural Gas and Propane Installation Code

for specic air supply requirements for enclosure or

structure where boiler is installed, including air supply

openings and ducts.

Table 5 - Air Inltration

Input Mbh

Standard

Method

Known Air Inltration Rate Method (Air Changes Per Hour)

0.1 0.2 0.3 0.4 .05 0.6

100 5000 15,000 7,500 5,000 3,750 3,000 2,500

130 6500 19,500 9,750 6,500 4,875 3,900 3,250

150 7500 22,500 11,250 7,500 6,625 4,500 3,750

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

Dunkirk Cub Installation, Operation & Maintenance Manual

- Taper

- Installation, Operation & Maintenance Manual

- Ce manuel convient également à

dans d''autres langues

- English: Dunkirk Cub

Documents connexes

-

Dunkirk DWB Series Installation, Operation & Maintenance Manual

-

Dunkirk DCC/DCB High Efficiency Wall Mounted Modulating Condensing Boiler Installation & Operation Manual

-

Dunkirk DCC/DCB High Efficiency Wall Mounted Modulating Condensing Boiler Installation & Operation Manual

-

Dunkirk DCC/DCB High Efficiency Wall Mounted Modulating Condensing Boiler Installation & Operation Manual

-

Dunkirk DCC/DCB High Efficiency Wall Mounted Modulating Condensing Boiler Installation & Operation Manual

-

Dunkirk DWB Series Installation, Operation & Maintenance Manual

Autres documents

-

Laars MT2H0300NACK2BXN Guide d'installation

-

Bradford White BMT2H0300 Manuel utilisateur

-

Laars JVS160P Guide d'installation

-

Bradford White BJX075 Manuel utilisateur

-

Bradford White BMGH1600 Manuel utilisateur

-

Smith RTS/HE Manuel utilisateur

-

NTI GF 200 Quick Installation Manual

NTI GF 200 Quick Installation Manual

-

Raypak HD101-HD401 Type H Manuel utilisateur

-

Enerco HEATSTAR HSU 45 Manuel utilisateur

-

Burham V11H Series Manuel utilisateur

Burham V11H Series Manuel utilisateur