Rigid Industries RIDGID OF45175A Manuel utilisateur

- Catégorie

- Compresseurs d'air

- Taper

- Manuel utilisateur

© 2008 RIDGID, INC.

Numéro de pièce IN624800AV 1/08 Nº de formulaire IN624800AV 1/08

GARANTIE LIMITÉE DE TROIS ANS DE COMPRESSEUR D'AIR RIDGID

Ce produit est fabriqué par Campbell Hausfeld. La marque de commerce et sous

licence de Ridgid, Inc. Toutes les communications sous garantie doivent être

adressées au service technique du compresseur d'air RIDGID au (numéro sans frais)

1-800-4-RIDGID.

CE QUI EST COUVERT SOUS LA GARANTIE LIMITÉE DE TROIS ANS

Cette garantie couvre tous les défauts de min d’œuvre ou de matériaux dans ce

compresseur d'air RIDGID pour une période de trois ans à partir de la date d'achat.

Cette garantie est pour ce compresseur d'air précis. Les garanties d'autres produits

RIDGID peuvent varier.

COMMENT OBTENIR LE SERVICE

Pour obtenir le service pour ce compresseur d'air RIDGID, vous devez le retourner,

frais de transport prépayés, à un centre de service autorisé pour effectuer les

réparations de compresseurs d'air RIDGID. Vous pouvez obtenir l'information sur le

centre de service le plus près de vous en appelant le (numéro sans frais) 1-800-4-

RIDGID ou en visitant le site Web www.ridgid.com. Pour toute demande de service

sous garantie, vous devez présenter la documentation de preuve d'achat qui inclut

une date d'achat. Le centre de service autorisé réparera tout problème de main

d’œuvre et réparera ou remplacera toute pièce défectueuse, à la discrétion de

Campbell Hausfeld sans frais pour vous.

CE QUI N'EST PAS COUVERT

Cette garantie est offerte seulement à l'acheteur original au détail et ne peut pas être

transférée. Cette garantie ne couvre pas les pièces sujettes à l’usure normale

(voir pièces de rechange) ou tout fonctionnement, défaillance ou défet résultant de

mauvaise utilisation, abuse, négligence, changement ou réparation par autres qu’un

centre de service autorisé pour la réparation de compresseurs d’air RIDGID. Les

matériaux courants tels qu'huile, filtres, etc. ne sont pas couverts sous cette garantie.

Les composants et moteurs à essence sont expressément exclus de la couverture et

vous devez vous conformer à la garantie du fabricant du moteur qui est fournie avec

le produit. CAMPBELL HAUSFELD N'OFFRE AUCUNE GARANTIE,

DÉCLARATION OU PROMESSE QUANT À LA QUALITÉ OU LA

PERFORMANCE DE SES COMPRESSEURS D'AIR AUTRES QUE CEUX

INDIQUÉS SPÉCIFIQUEMENT DANS CETTE GARANTIE. RIDGID INC

N'OFFRE AUCUNE GARANTIE OU DÉCLARATION, EXPRESSE OU

IMPLICITE Y COMPRIS CE QUI EST INDIQUÉ PLUS BAS.

LIMITES SUPPLÉMENTAIRES

Dans la mesure permise par la loi applicable, toutes les garanties implicites, y

compris les garanties DE COMMERCIALITÉ et D'ADAPTATION À UN USAGE

PARTICULIER, sont déclinées. Toutes les garanties implicites, y compris les garanties

de commercialité ou d'adaptation à un usage particulier, qui ne peuvent pas être

déclinées sous la loi de l'État sont limitées à trois ans à partir de la date d'achat.

Campbell Hausfeld n'est pas responsable des dommages directs, indirects,

accidentels, spéciaux ou consécutifs. Certains États ou certaines Provinces

n’autorisent pas de limitations de durée pour les garanties implicites, ni l’exclusion ni

la limitation des dommages fortuits ou indirects. Les limitations précédentes peuvent

donc ne pas s’appliquer. Cette garantie vous donne des droits juridiques spécifiques

et vous pouvez aussi avoir d'autres droits qui peuvent varier d'une juridiction à

l'autre.

QUESTIONS OU COMMENTAIRES

APPELER LE 1-800-4-RIDGID

www.ridgid.com

En appelant, veuillez avoir à portée de la main votre numéro de modèle et votre

numéro de série.

Catalogue numéro OF45175A

No de modèle OF45175A No de série _________

Les numéros de modèle et de série se trouvent sur votre

appareil. Vous devriez enregistrer les numéros de série et

de modèle dans un endroit sûr à titre de référence future.

OF45175A

OPERATOR’S MANUAL

TWIN STACK

PORTABLE AIR

COMPRESSOR

To reduce the risk of injury, the user

must read and understand the

Operator’s Manual before using this

product.

!

WARNING:

IN624800AV 1/08

Pièces de rechange

Pour les pièces de rechange, appeler le 1-800-4-RIDGID

S’il vous plaît fournir l’information suivante:

-Numéro du modèle

-Numéro de série (si applicable)

-Description de la pièce et son numéro sur la liste de pièces

No. No de Numéro

Ref. catalogue de pièce Description Qte

1 17948 WL010500AV Culasse 1

2— Boulon à tête 4

3—

*

Soupape d'échappement 1

4— Plaque de soupape 1

5 17958 , XA012100AV

*

Joint d'étanchéité de cylindre 1

6 17963

N/D

*

Montage du moteur (inclus l'assemblage excentrique/

roulement) Pour la commande, voir l’assemblage

pompe/moteur (pièce No. 1) à la page 19 1

7 —

(Inclus avec le

Vis à tête hexagonale, M5 x ,8 x 20 1

montage piston

voir n

o

11)

8— Vis à tête héx, M5 x ,8 x 12 (L.H.) vis 1

9— Rondelle 1

10 — Ventilateur 1

11 17968 WL210300SJ

*

Montage de piston (Comprend vis à tête hexagonale) 1

12 —

*

Soupape d'admission 1

13 17973 , XA010800AV

*

Joint d'étanchéité de culasse (joint métallique) 1

14 17978 , XA012001AV

*

Joint de soupape d'écoulement 1

15 MC507017AV Condensateur de démarrage (280-520 µF/250 VAC) 1

16 MC506908AV Condensateur de marche (40 µF/450 VAC) 1

TROUSSES DE PIÈCES DE RÉPARATION

17953 WL602801AJ Ensemble de boulons de tête (Jeu de 4) 1

17983 WL201405SJ Néc. de plaque de soupape (Comprend Soupape

d'échappement, plaque de soupape, joint d'étanchéité

de cylindre, soupape d'admission, joint d'étanchéité

de culasse et joint de soupape d'écoulement)

17988 WL209802SJ Néc. de ventilateur (Comprend Vis à tête héx,

rondelle, et ventilateur)

Table of Contents

Section Page

Table of Contents . . . . . . . . . . . . . . . .2

Safety Instructions . . . . . . . . . . . . . . .3

Safety Signal Words . . . . . . . . . . . . .3

Before Using the Air

Compressor . . . . . . . . . . . . . . . . . . . .3

Spraying Precautions . . . . . . . . . . . .5

Breathable Air Warning . . . . . . . . . . .5

Warning Labels . . . . . . . . . . . . . . . . .6

Motor Specifications and

Electrical Requirements . . . . . . . . . .7

Power Supply and Motor

Specifications . . . . . . . . . . . . . . . . . .7

General Electrical Connections . . . . .7

110-120 Volt, 60 Hz Tool

Information . . . . . . . . . . . . . . . . . . . .8

Extension Cords . . . . . . . . . . . . . . . .8

Thermal Overload Protector . . . . . . .9

Glossary of Terms . . . . . . . . . . . . . . .9

Unpacking and Checking

Content . . . . . . . . . . . . . . . . . . . . . . .10

Installation . . . . . . . . . . . . . . . . . . . .10

Section Page

Getting to Know Your Air

Compressor . . . . . . . . . . . . . . . . . . .11

Operating Your Air Compressor . . .13

Moisture in Compressed Air . . . . . .13

Operating Your Air Compressor . . .13

For Trouble-Free Operation . . . . . .13

Maintenance . . . . . . . . . . . . . . . . . . .14

Tank . . . . . . . . . . . . . . . . . . . . . . . . .15

Filter Removal, Inspection, and

Replacement . . . . . . . . . . . . . . . . . .15

Lubrication . . . . . . . . . . . . . . . . . . . .15

Storage . . . . . . . . . . . . . . . . . . . . . .15

Maintenance Schedule . . . . . . . . . .15

Troubleshooting . . . . . . . . . . . . . . . .16

Repair Parts . . . . . . . . . . . . . . . . . . .18

Notes . . . . . . . . . . . . . . . . . . . . . . . . .22

Warranty . . . . . . . . . . . . . . . . . . . . . .24

2 Fr 23

*

Pièces considérées comme sujettes à l’usure normale

N/D = articles de quincaillerie standard

La page est en cours de chargement...

Pièces de rechange

No. No de Numéro

Ref. catalogue de pièce Description Qte

1 25673 WL373001AV

*

Montage pompe/moteur 1

2 20448 ST085700AV Filtre 1

3 17723 WL003203AV Monture d’isolement 3

4 17713 ST158000AV Boulon d’épaulement 3

5 30538 WL038500AV Collecteur (Compris articles 6, 7, 9 et 10) 1

6 30543 V-215200AV Soupape de sûreté - 1379 kPa 1

7 17873 HF203300AV

*

Raccord 2

8 30548 CW214300AV Manostat 1

9 30553 GA032401AV

*

Manomètre de réservoir 1

10 30558 GA032400AV

*

Manomètre de refoulement 1

11 17893 ST119305AV Raccord de tube 1

12 17853 ST158300AV Butoir de caoutchouc moulé 4

13 18038 ST116400AV Boulon à tête hexagonale (hex.) 4

14 17783 ST071626AV Vis à six lobes à tête ronde 20

15 30563 WL038300AV Support 1

16 30568 ST195300AV

*

Manche 1

17 30573 WL212300AV Tuyau de décharge (écrou et virole inclus) 1

18 20358 ST085800AV Robinet de purge 1

19 17728 CV223800AV Clapet 1

20 30578 AR061100AV Assemblage de réservoir double 1

21 30583 ST188800AV Tuyau de déchargement

(insert de tuyau, écrou et virole inclus) 1

22 30588 WL038800AV Couvercle 1

23 25003 ST170800AV Tube de collecteur

(insert de tuyau, écrou et virole inclus) 1

24 — WL036200AV Régulateur 1

25 — N/A Plaques latérales 2

26 30593 WL038200AV Support de robinet de purge 1

27 — N/A Coude pour tuyau 6,3 mm (1/4 po) NPT 1

28 — N/A Coude mâle pour tuyau 6,3 mm (1/4 po) NPT 1

29 — N/A Raccord de compression 1/4 po 2

30 30598 WL038700AV Couvercle avant 1

31 17888 ST022500AV Bouchon 1/4 po 2

32 30603 ST170900AV Tuyau de vidange

(insert de tuyau, écrou et virole inclus) 1

*

Pièces considérées comme sujettes à l’usure normale

N/A = Article normal de quincaillerie ou Pas disponible

Fr 21

Pour les pièces de rechange, appeler le 1-800-4-RIDGID

S’il vous plaît fournir l’information suivante:

-Numéro du modèle

-Numéro de série (si applicable)

-Description de la pièce et son numéro sur la liste de pièces

8. Follow all local electrical and safety

codes, as well as the National

Electrical Code (NEC) and the

Occupational Safety and Health Act

(OSHA).

9. Wiring and fuses should follow electri-

cal codes, current capacity, and be

properly grounded.

10.Electric motors must be securely and

adequately grounded. See grounding

instructions and extension cord infor-

mation in this manual.

11. Always disconnect power source

before working on or near a motor, or

its connected load. If power discon-

nect point is out-of-sight, lock it in the

open position and tag to prevent

unexpected application of power.

12.Guard all moving parts; keep visitors

away. Never allow children in work

area.

13.Use only a properly grounded outlet

that will accept a three pronged plug,

and wear shoes to prevent shock

hazards.

14.Be careful when touching exterior of

operating motor; it may be hot

enough to cause injury.

15.Protect power cable from coming in

contact with sharp objects.

16.Clean electrical or electronic equip-

ment with an approved cleaning

agent, such as dry, nonflammable

cleaning solvent.

17.To avoid spontaneous combustion,

discard waste rags into approved

metal waste cans.

18.Never store flammable liquids or

gases in vicinity of compressor.

19.When spraying with solvent of toxic

chemicals, follow instructions provid-

ed by the chemical manufacturer.

20.Spray in a well ventilated area, to

keep fumes from collecting and caus-

ing health and fire hazards.

21.Do not spray in vicinity of open

flames or other places where a spark

can cause ignition. Do not smoke

when spraying paint, insecticides, or

other flammable substances.

22.Use a respirator when spraying.

23.NEVER reset safety valve or pres-

sure switch. Keep safety valve free

from paint and other accumulations.

This provides safety against over

pressure.

24.Do regular maintenance; keep all

nuts, bolts, and screws tight, to be

sure equipment is in safe working

condition .

25.Keep cleaning rags and other flam-

mable waste materials in a tightly

closed metal container and dispose of

later in the proper fashion.

26.Drain tanks of moisture after each

day’s use. If unit will not be used for a

while, it is best to leave drain cock

open until such time as it is to be

used. This will allow moisture to com-

pletely drain out and help prevent

corrosion of inside of tank.

27.Inspect tank yearly for rust, pin holes

or any other imperfections that could

cause it to become unsafe. NEVER

weld or drill holes in air tank.

Safety Instructions (continued)

4

La page est en cours de chargement...

La page est en cours de chargement...

PROBLÈME CAUSE PROBABLES SOLUTION

Le protecteur de sur-

charge thermique se

déclenche souvant

Perte de pression

dans le réservoir à

air quand le com-

presseur se coupe

Humidité excessive

dans l’air de

décharge

Le compresseur

fonctionne contin-

uellement

Le compresseur

vibre

Débit d’air plus bas

que normal

1. Tension basse

2. Filtre d’air obstrué

3. Ventilation

insuffisante/température

de l’endroit trop haute

4. L’unité est branchée à un

cordon prolongateur

1. Raccordements dégagés

(raccords, tuyaux, etc.)

2. Robinet de purge dégagé

3. Fuite du clapet

1. Eau excessive dans le

réservoir à air

2. Humidité élevée

1. Manostat défectueux

2. Utilisation d’air excessif

Boulons de montage

désserrés

1. Soupape d’admission en

panne

2. Filtre d’admission sale

3. Fuites de raccordements

1.Vérifier avec un voltmètre

2.Nettoyer le filtre (voir la

section d’Entretien)

3.Déménager le com-

presseur à un endroit bien

ventilé

4.L’unité est branchée à un

cordon prolongateur

1.Vérifier tous les raccorde-

ments avec de l’eau

savonneuse et les serrer

2.Serrer

3.Démonter l’assemblage du

clapet, nettoyer ou rem-

placer

Ne pas démonter le clapet

s’il y a de l’air dans le

réservoir; purger le réser-

voir

1.Purger le réservoir à air

2.Déménager à un endroit

moins humide; utiliser un

filtre en canalisation d’air

1.Remplacer le manostat

2.Diminuer l’utilisation d’air;

le compresseur n’est pas

assez puissant pour la

demande

Serrer

1.Faire réparer le modèle par

un agent autorisé

2.Nettoyer ou remplacer le

filtre d’admission

3.Serrer les raccordements

Dépannage (suite)

DANGER:

!

The A-C motor used on this compressor

is a capacitor start, capacitor run non-

reversible induction type, having the fol-

lowing specifications. It is wired at the

factory for operation on 110V-120V AC,

60 Hz service.

Voltage 110-120

Amperes 14

Hertz (Cycles) 60

Phase Single

RPM 3450

Motor Specifications and

Electrical Requirements

Fr 18 7

Power Supply and Motor Specifications

To reduce the risk of electrical

hazards, fire hazards or dam-

age to the tool, use proper cir-

cuit protection. Your tool is

wired at the factory for opera-

tion using the voltage shown.

Connect tool to a power line

with the appropriate voltage

and a 15-amp branch circuit.

Use a 15-amp time delay type

fuse or circuit breaker. To

reduce the risk of shock or fire,

if power cord is worn or cut, or

damaged in any way, have it

replaced immediately.

!

WARNING:

General Electrical Connections

To reduce the risk of electrocu-

tion:

1. Use only identical replace-

ment parts when servicing.

Servicing should be per-

formed by a qualified techni-

cian.

2. Do not use in rain or where

floor is wet. This tool is

intended for indoor residen-

tial use only.

!

DANGER:

Do not permit fingers to touch

the terminals of plug when

installing or removing the plug

to or from the outlet.

!

WARNING:

Dépannage

Pour votre propre sécurité ne

pas essayer et faire fonctionner

le compresseur d'air pendant le

dépannage

AVERTISSEMENT:

!

PROBLÈME CAUSE PROBABLES SOLUTION

Compresseur ne

fonctionne pas

Le moteur ronron

mais ne peut pas

fonctionner ou fonc-

tionne lentement

Fusibles sautés/le

disjoncteur se

déclenche à maintes

reprises

1. L’unité est branchée à un

cordon prolongateur

2. Manque de puissance

électrique

3. Fusible sauté

4. Disjoncteur déclenché

5. Surcharge thermique

déclenché

6. Manostat en panne

1. Tension basse

2. L’unité est branchée à un

cordon prolongateur

3. Bobinnage du moteur

court-circuité ou ouvert

4. Clapet ou déchargeur

défectueux

1. Taille de fusible incorrect,

surcharge

2. L’unité est branchée à un

cordon prolongateur

3. Clapet ou déchargeur

défectueux.

1. Quitter le cordon

2. Modèle branché? Vérifier

le fusible/disjoncteur ou

surcharge du moteur

3.Remplacer le fusible sauté

4.Rajuster et trouver la

source du problème

5.Le moteur se met en

marche une fois refroidit

6.Remplacer

1.Vérifier avec un voltmètre

2.Quitter le cordon

3.Remplacer le moteur

4.Remplacer ou réparer

1.Vérifier le type de fusible,

utiliser un fusible à retarde-

ment. Débrancher les

autres appareils élec-

triques du circuit ou faire

fonctionner le compresseur

sur un circuit unique.

2.Quitter le cordon

3.Remplacer ou réparer

8 Fr 17

The plug supplied on your tool may not

fit into the outlet you are planning to use.

Your local electrical code may require

slightly different power cord plug connec-

tions. If these differences exist refer to

and make the proper adjustments per

you local code before your tool is

plugged in and turned on.

In the event of a malfunction or break-

down, grounding provides a path of least

resistance for electrical current to reduce

the risk of electric shock. This tool is

equipped with an electric cord having an

equipment-grounding conductor and a

grounding plug, as shown. The plug must

be plugged into a matching outlet that is

properly installed and grounded in accor-

dance with all local codes and ordi-

nances.

Do not modify the plug provided. If it will

not fit the outlet, have the proper outlet

installed by a qualified electrician.

Improper connection of the equipment-

grounding conductor can result in a risk

of electric shock. The conductor with

insulation having an outer surface that is

green with or without yellow stripes is the

equipment-grounding conductor. If repair

or replacement of the electric cord or

plug is necessary, do not connect the

equipment-grounding conductor to a live

terminal.

If the grounding instructions are not com-

pletely understood, or if you are in doubt

as to whether the tool is properly ground-

ed check with a qualified electrician or

service personnel.

Motor Specifications and

Electrical Requirements (continued)

110-120 volt, 60Hz Tool Information

If not properly grounded, this

tool can cause an electrical

shock, particularly when used

in damp locations, in proximity

of plumbing, or out of doors.

!

WARNING:

TEST

RESET

Grounding Prong

3-Prong Plug

Properly

Grounded

3-Prong

Outlet

Extension Cords

1. The air compressor should be located

where it can be directly plugged into

an outlet. An extension cord should

not be used with this unit.

2. To avoid loss of power and overheat-

ing, additional air hose must be used

to reach work area instead of exten-

sion cords.

Entretien (suite)

Fr 16

Inspecter le réservoir au minimun une

fois par année. Rechercher les fissures

près des soudures. Si une fissure est vis-

ible, dissiper la pression du réservoir

immédiatement et le remplacer.

Réservoir

Ne jamais essayer de réparer ni

de modifier un réservoir! Le

soudage, perçage ou autre

modifications peuvent affaiblir

le réservoir et peuvent résulter

en dommage de rupture ou

d’explosion. Toujours remplac-

er un réservoir usé, fendu ou

endommagé.

DANGER:

!

Purger le liquide du réservoir

quotidiennement.

AVIS:

1. Entreposer les tuyaux et le com-

presseur dans un endroit frais et sec.

2. Le réservoir doit être purgé d’humidité.

3. Le tuyau doit être débranché et

accroché avec les bouts ouverts face

en bas afin de faire écouler toute l’hu-

midité.

Pour changer un filtre, retirer le couvercle

du boîtier du filtre. Si l'élément du filtre

est sale, remplacer l'élément ou tout le

filtre.

Enlevage, Inspection et Remplacement du Filtre

Ce compresseur est de type “sans huile”

et n’exige pas de graissage.

Graissage

Entreposage

Opération Quotidien Hebdomadaire

Purger le réservoir

Vérifier le filtre à air

Vérifier la soupape de sûreté

Souffler la saleté de l’intérieur du moteur

Horaire d'entretien

9

Thermal Overload Protector

If thermal overload protector shuts motor

OFF frequently look for the following

causes.

1. Low voltage.

2. Wrong gauge wire.

3. Clogged air filter.

4. Lack of proper ventilation.

5. Unit is being used with an extension

cord.

See Troubleshooting Chart for corrective

action.

This compressor is equipped

with an automatic reset thermal

overload protector which will

shut off motor if it becomes

overheated.

!

CAUTION:

The motor must be allowed to

cool down before start-up is

possible. The motor will auto-

matically restart without warn-

ing if left plugged into electrical

outlet, and the motor is turned

on.

!

CAUTION:

ASME Safety Valve

A safety valve that automatically releases

the air if the air receiver (tank) pressure

exceeds the preset maximum.

PSI (Pounds per Square Inch)

Measurement of the pressure exerted by

the force of the air. The actual psi output

is measured by a pressure gauge on the

compressor

SCFM (Standard Cubic Feet per

Minute)

Sometimes called CFM (Cubic Feet per

Minute). Measurement of air volume

delivered by the compressor.

Air Delivery

A combination of psi and SCFM. The air

delivery required by a tool is stated as

(number) SCFM at (number) psi. The

combination of these figures determines

what size unit is needed.

Air Tank Capacity

The volume of air stored in the tank and

available for immediate use. A large tank

allows the intermittent use of an air tool

with an air requirement higher than the

compressor’s rated delivery.

Volts or Voltage

A measurement of the force of an electri-

cal current.

Amps or Amperage

A measure of the electrical force minus

the resistance on an electrical line.

Ridgid air compressors require 15 amps

for operation. Be sure the compressor

will operate on an electrical line with the

proper amps. If other appliances operate

on the same line, they will reduce the

available amps. If the amperage is not

adequate, the result will be blown fuses

or tripped circuits.

Regulator

A control that adjusts the line pressure to

the proper amount needed to operate

spray guns and air tools.

Tank Pressure Gauge

Indicates tank pressure in psi.

Glossary of Terms

1. Inspecter le compresseur et vérifier

que le filtre d’air soit propre.

2. Tirer la bague sur la soupape de

sûreté et la permettre de retourner à la

position normale.

3.

Vidanger chaque jour l’humidité du

réservoir. Éteindre le compresseur.

Dépressuriser le système avant de

drainer le réservoir.

Drainer l’humidité

du réservoir en ouvrant le robinet de

vidange sous le réservoir.

4. Mettre le modèle hors circuit (OFF) et

nettoyer la poussière et la saleté du

moteur, du réservoir, des canalisations

d’air et des ailettes de refroidissement

de la pompe.

REMARQUE: Il faut vérifier et nettoyer

périodiquement le filtre à air dans le

boîtier du filtre du côté de la tête et plus

souvent s’il est utilisé sous des condi-

tions très poussièreuses ou lorsqu’il y a

beaucoup de brouillard créé par la pul-

vérisation et circulant près de l’unité.

IMPORTANT: Le modèle doit être situé

aussi loin que possible de l’endroit de

pulvérisation afin d’éviter l’obstruction du

filtre par la sur-pulvérisation.

Entretien

Dissiper toute la pression et

débrancher avant d’effectuer

n’importe quelle réparation.

AVERTISSEMENT:

!

Si la soupape de sûreté ne

fonctionne pas ou s’il y a une

fuite d’air après le relachement

de la bague, elle doit être rem-

placée.

AVERTISSEMENT:

!

10 Fr 15

Line Pressure Gauge

Displays the current line pressure. It is

regulated by the regulator knob.

Cut-in/Cut-off Pressure

Specific psi at which a compressor starts

and stops while refilling the air tank.

Glossary of Terms (Continued)

1. Remove the air compressor from the

carton.

2. Place the compressor on a secure,

stationary work surface and look it

over carefully.

Unpacking and Checking Contents

Do not operate unit if damaged

during shipping, handling or

use. Damage may result in

bursting and cause injury or

property damage.

!

WARNING:

For your own safety, never

operate unit until all assembly

steps are complete and until

you have read and understood

the entire operator’s manual.

!

WARNING:

To reduce the risk of injury, if

any parts are missing, do not

attempt to operate the air com-

pressor until the missing parts

are obtained and installed cor-

rectly.

!

WARNING:

1. Check and tighten all bolts, fittings,

etc., before operating compressor.

2. Operate compressor in a ventilated

area so that compressor may be

properly cooled.

3. Compressor should be located where

it can be directly plugged into an out-

let. An extension cord should not be

used with this unit.

4. To avoid loss of power and overheat-

ing, additional air hose must be used

to reach work area instead of exten-

sion cords.

Installation

Robinet de vidange

du réservoir

Fr 14

1. Lire les instructions: Lire attentivement

ce manuel de l’opérateur AVANT DE

FAIRE FONCTIONNER le nouveau

compresseur d’air. Il contient de

l’information concernant l’utilisation et

l’entretien du modèle.

2. Purger le réservoir quotidiennement:

Dépressuriser le système avant de

drainer le réservoir. Ouvrir le robinet de

vidange du réservoir et drainer

l’humidité du réservoir. Ceci aide à

prévenir la corrosion du réservoir et à

garder l’huile et l’humidité hors du

système d’air comprimé. S’assurer de

fermer le robinet fermement avant de

faire fonctionner le compresseur.

3. Changer le filtre d’air: Ne jamais utiliser

un compresseur sans filtre d’air ni avec

un filtre d’air obstrué. Remplacer avec

un nouveau filtre lorsque l’élément est

sale.

Fonctionnement de votre compresseur d’air

L’humidité dans l’air comprimé forme

des goutelettes en arrivant de la pompe

du compresseur. Si l’humidité est

élevée ou si le compresseur est utilisé

continuellement, cette humidité s’accu-

mulera dans le réservoir. En utilisant un

pistolet à peinture ou un pistolet pour

décapage au sable, cette eau sera

transportée du réservoir par moyen du

tuyau, et en forme de goutelettes hors

du tuyau, mélangée avec le matériel

utilisé.

IMPORTANT: Cette condensation peut

avoir comme résultat des tâches d’eau

sur votre travail de peinture, surtout en

pulvérisant la peinture qui n’a pas de

base d’eau. Pendant la décapage au

sable, cette eau servira à tenir le sable

ensemble et à causer une obstruction

dans le pistolet.

Pour un Fonctionnement sans Problème

L’Humidité dans l’Air Comprimé

S’assurer de fermer le robinet de vidange

du réservoir, que le bouton du régulateur

est entièrement tourné dans le sens

contraire des aiguilles d’une montre et

que l’interrupteur marche/arrêt est en

position d’arrêt.

Brancher le compresseur dans un circuit

réservé de 15 ampères (au moins).

Mettre l’interrupteur MARCHE/ARRÊT à

la position MARCHE. Le compresseur

commencera alors à accumuler de la

pression.

Lorsqu’il atteint la pression de coupure,

installer un tuyau (à l’accessoire voulu

installé) sur le raccord de sortie. Ajuster

le bouton du régulateur à la pression

voulue.

Le compresseur est maintenant prêt à

être utilisé.

Fonctionnement de votre compresseur d’air

Ne pas surpressuriser tout outil

pneumatique. Consulter les

instructions de l’outil pneuma-

tique pour connaître la bonne

pression pour l’outil.

AVERTISSEMENT:

!

11

Getting to Know Your Air Compressor

ridgid.com 1-800-474-3443

DK724300AV 0104

Model/Serial Number Decal

2 Regulated

Outlet Gauge

5 Tank Pressure

Gauge

4 Regulator

Knob

3 Handle

7 Air Outlet

Fittings

8 Air Filter

9 On/Off Switch

10 Tank DrainValve

6 Safety Valve

1 Air Storage

Tanks

1. Réservoirs de stockage d’air Le

réservoir stocke de l’air à utiliser plus

tard.

2. Manomètre Réglé de Sortie d’Air.

Ce manomètre indique la pression

d’air de sortie. La pression d’air est

mesurée en livres par pouce carré -

lb/po

2

(PSI). La plupart des outils ont

des capacités de pression maximum.

Ne pas dépasser la capacité de

pression maximum de l’outil utilisé.

S’assurer que le manomètre est à

ZERO avant de changer les outils

pneumatiques ou avant de débrancher

le tuyau.

3. Poignée. Utilisé pour déplacer le

compresseur.

4. Bouton de Régulateur. Ce bouton

contrôle la pression d’air vers un outil

pneumatique ou un pistolet de

pulvérisation de peinture. Tourner le

bouton dans le sens des aiguilles

d’une montre augmente la pression

d’air à la sortie. Tourner dans le sens

contraire des aiguilles d’une montre

réduit la pression d’air à la sortie.

Tourner entièrement dans le sens

contraire des aiguilles coupera

entièrement le débit d’air.

5. Manomètre du Réservoir. Le

manomètre indique la pression dans

le réservoir ce qui indique que le

compresseur fonctionne bien.

6. Soupape de Sûreté ASME. Cette

soupape dégage automatiquement

l’air si la pression du réservoir

dépasse le maximum préétabli.

7. Raccords de sortie d’air. Ces

raccords sont des raccords universels

rapides de 1/4 po et permettent des

changements d’outils rapides.

8. Filtre à Air. Le filtre à air empêche la

poussière et les débris d’entrer dans

la pompe de compresseur et réduit le

bruit du compresseur.

9. Interrupteur Marche/Arrêt. Ce

commutateur permet un contrôle

manuel du compresseur. Noter que

lorsque le commutateur est en

marche, le compresseur démarrera et

s’arrêtera automatiquement selon la

pression du réservoir.

10. Robinet de vidange du réservoir .

Le robinet de vidange du réservoir

permet de retirer l’humidité du

réservoir.

Ferme

Ouvre

Getting to Know Your Air

Compressor (Continued)

12 Fr 13

1. Air Storage Tanks. The tanks store

air for later use.

2. Regulated Outlet Gauge. This gauge

shows at-a-glance, air pressure at

outlet. Air pressure is measured in

pounds per square inch (PSI). Most

tools have maximum pressure ratings.

Never exceed the maximum pressure

rating of the tool you are using. Be

sure this gauge reads ZERO before

changing air tools or disconnecting

hose from outlet.

3. Handle. Used to move the compres-

sor.

4. Regulator Knob. This knob controls

air pressure to an air operated tool or

paint spray gun. Turning the knob

clockwise increases air pressure at

the outlet. Turning counterclockwise

will lower air pressure at the outlet.

Fully counterclockwise will shut off the

flow of air completely.

5. Tank Pressure Gauge. Gauge shows

pressure in air receiver indicating

compressor is building pressure prop-

erly.

6. ASME Safety Valve. This valve auto-

matically releases air if the tank pres-

sure exceeds the preset maximum.

7. Air Outlet Fittings. These fittings are

1/4” universal-style quick connect fit-

tings and allow rapid tool changes.

8. Air Filter. The air filter keeps dirt and

debris from entering the compressor

pump and reduces compressor noise.

9. On/Off Switch. This switch allows

manual control of the compressor.

Note that when the switch is turned

on, the compressor will automatically

start and stop depending on tank

pressure.

10. Tank Drain Valve. The tank drain

valve allows moisture to be removed

from the tank.

Close

Open

La page est en cours de chargement...

Fr11

1. Retirer le compresseur d’air du

carton.

2. Placer le compresseur sur une

surface de travail fixe, sécure et

vérifier attentivement.

Déballer et vérifier le contenu

Ne pas faire fonctionner

l’appareil s’il est endommagé

pendant l’expédition, la

manipulation ou l’utilisation.

Des dommages peuvent mener

à l’éclatement et provoquer des

blessures ou des dommages à

la propriété.

AVERTISSEMENT:

!

Pour votre propre sécurité, ne

jamais faire fonctionner

l’appareil avant de terminer

toutes les étapes d’assemblage

et d’avoir lu et compris tout le

manuel de l’opérateur.

AVERTISSEMENT:

!

Pour réduire les risques de

blessure, s’ils manquent des

pièces, ne pas essayer de faire

fonctionner le compresseur

d’air avant d’avoir obtenu les

pièces manquantes et de les

avoir installées correctement.

AVERTISSEMENT:

!

1. Vérifier et serrer tous les boulons,

raccords, etc., avant d’utiliser le com-

presseur.

2. Utiliser le compresseur dans un

endroit bien ventilé afin de le refroidir.

3. Le compresseur d’air doit être placé à

un endroit permettant de le brancher

directement dans une prise. Il ne faut

pas utiliser de rallonge avec cet

appareil.

4. Pour éviter toute perte de courant et

tout surchauffe, il est recommandé

d’utiliser un tuyau à air

supplémentaire plutôt qu’une

rallonge.

Installation

1. Check compressor for any visible

problems, especially check air filter to

be sure it is clean.

2. Pull ring on safety valve and allow it to

snap back to normal position.

3. Drain moisture from tank daily. Shut

compressor off. Depressurize system

prior to draining tank. Drain moisture

from tank by opening the tank drain

valve underneath the tank.

4. Turn power OFF and clean dust and

dirt from motor, tank, air lines and

pump cooling fins.

NOTE: The air filter in the filter housing

on the side of the head must be checked

and cleaned periodically, more often if

used under very dusty conditions or

when a great deal of fog from spraying is

allowed to circulate near unit.

IMPORTANT: Unit should be located as

far from spraying area as hose will allow

to prevent over-spray from clogging filter.

Maintenance

14

Safety valve must be replaced if

it cannot be actuated or it leaks

air after ring is released.

!

WARNING:

Tank Drain Valve

Release all pressure and dis-

connect power before making

any repair.

!

WARNING:

Fr 10

Soupape De Sûreté ASME

Cette soupape relâche l’air

automatiquement si la pression du

réservoir dépasse la pression maximum

réglé d’avance.

PSI (libres pour pouce carré)

Mesure la pression exercée par la force

de l’air. La sortie réelle en lb/po

2

se

mesure par un manomètre sur le

compresseur.

PCNM (pied cube normal par minute)

pi

3

/min (pied cube par minute) Mesure

du volume d’air livré par le compresseur

Soufflage d’air

Une combinaison de psi et PCNM. Le

soufflage d’air requis par un outil est

indiqué sous forme de (nombre) PCNM à

(nombre) psi. Le mélange de ces chiffres

détermine la taille d’appareil nécessaire.

Capacité de réservoir à air

Le volume d’air stocké dans le réservoir

et disponible pour une utilisation

immédiate. Un large réservoir permet

l’utilisation intermittente d’un outil

pneumatique exigeant de l’air à un

niveau plus élevé que la valeur nominale

du compresseur.

Volts ou tension

Une mesure de la force d’un courant

électrique.

A ou ampères

Une mesure de la force électrique moins

la résistance sur une ligne électrique. Les

compresseurs RIDGID exigent 15

ampères pour fonctionner. S’assurer que

le compresseur fonctionnera sur une

ligne électrique aux bons ampères. Si

d’autres appareils ménagers fonctionnent

sur la même ligne, ils réduiront les

ampères disponibles. Si l’ampérage n’est

pas adéquat, le résultat sera des fusibles

grillés ou des disjoncteurs déclenchés.

Régulateur

Un contrôle qui ajuste la pression de

fluide à la quantité appropriée nécessaire

pour faire fonctionner les pistolets de

pulvérisation et les outils pneumatiques.

Manomètre des réservoirs

Indique la pression du réservoir en psi.

Manomètre de canalisation

Affiche les pressions de canalisation

actuelles. Il est régulé par le bouton du

régulateur.

Pression de fermeture/d’ouverture

PSI précis lorsque le compresseur

démarre et s’arrête en remplissant le

réservoir d’air.

Glossaire des termes

1. When not in use, compressor should be

stored in a cool dry place.

2. Tank should be drained of moisture.

3. Hose should be disconnected and hung

open ends down to allow any moisture

to drain.

15

The tank should be carefully inspected at

a minimum of once a year. Look for

cracks forming near the welds. If a crack

is detected, remove pressure from tank

immediately and replace.

Tank

Never attempt to repair or modi-

fy a tank! Welding, drilling or

any other modification will

weaken the tank resulting in

damage from rupture or explo-

sion. Always replace worn,

cracked or damaged tanks.

!

DANGER:

Drain liquid from tank daily.

NOTICE:

To change a filter, pull off the filter housing

cover. If filter element is dirty, replace ele-

ment or entire filter.

Filter Removal, Inspection and Replacement

This is an oilless type compressor requir-

ing no lubrication.

Lubrication

Storage

Operation Daily Weekly

Drain Tank

Check Air Filter

Check Safety Valve

Blow Dirt From Inside Motor

Maintenance Schedule

Rallonges

1. Le compresseur d’air doit être placé à

un endroit permettant de le brancher

directement dans une prise. Il ne faut

pas utiliser de rallonge avec cet

appareil.

2. Pour éviter toute perte de courant et

toute surchauffe, il est recommandé

d’utiliser un tuyau à air supplémen-

taire plutôt qu’une rallonge.

Protecteur de Surcharge Thermique

Si le protecteur de surcharge thermique

coupe le moteur (OFF) à maintes

reprises, vérifier pour les causes

suivantes.

1. Tension basse.

2. Calibre de fil ou taille de cordon pro-

longateur incorrect.

3. Filtre d’air obstrué.

4. Ventilation insuffisante.

5. L’appareil est utilisé avec une rallonge.

Voir le tableau de dépannage pour la

mesure corrective.

Ce compresseur est équipé

avec un protecteur de sur-

charge thermique de rajuste-

ment automatique qui sert à

couper le moteur s’il devient

surchauffé.

ATTENTION:

!

Le moteur doit se refroidir

avant le démarrage si possible.

Le moteur se relancera sans

avis si branché dans une prise

de courant et s’il est en marche

(ON).

ATTENTION:

!

Troubleshooting

16 Fr 9

For your own safety do not try

and run the air compressor

while troubleshooting.

!

WARNING:

TROUBLE PROBABLE CAUSE REMEDY

Compressor will not

run

Motor hums but can-

not run or runs slow-

ly

Fuses blow/circuit

breaker trips repeat-

edly

1. Unit is plugged into

extension cord

2. No electrical power

3. Blown fuse

4. Breaker open

5. Thermal overload open

6. Pressure switch bad

1. Low voltage

2. Unit is plugged into

extension cord

3. Shorted or open motor

winding

4. Defective check valve or

unloader

1. Incorrect size fuse, circuit

overloaded

2. Unit is plugged into

extension cord

3. Defective check valve or

unloader

1. Remove extension cord

2. Plugged in? Check

fuse/breaker or motor

overload

3.Replace blown fuse

4.Reset, determining why

problem happened

5.Motor will restart when

cool

6.Replace

1.Check with voltmeter

2.Remove extension cord

3.Replace motor

4.Replace or repair

1.Check for proper fuse, use

time-delay fuse.

Disconnect other electrical

appliances from circuit or

operate compressor on its

own branch circuit

2.Remove extension cord

3.Replace or repair

Fr 8

Spécifications du moteur

et exigences électriques (suite)

La fiche fournie avec votre outil pourrait

ne pas s’ajuster dans la prise que vous

prévoyez utiliser. Votre code d’électricité

local pourrait exiger des connexions de

fiche de cordon d’alimentation un peu

différentes. Si c’est le cas, se reporter et

effectuer les ajustements appropriés

selon votre code local avant de brancher

et de mettre l’outil en marche.

Dans le cas de défaillance ou de panne,

la mise à la terre donne une voie de

moindre résistance au courant électrique

ce qui réduit les risques de choc

électrique. Cet outil est doté d’un cordon

électrique à conducteur de mise à la terre

de l’équipement et une fiche de masse,

tel qu’illustré. La fiche doit être branchée

dans une prise de courant assortie

installée et mise à la terre correctement

conformément à tous les codes et

ordonnances locaux.

Ne modifiez pas la fiche fournie. Si elle

n’entre pas correctement dans la prise,

faire installer une prise convenable par

un électricien qualifié.

Une mauvaise connexion du conducteur

de terre de l’équipement peut créer des

risques de chocs électriques. Le

conducteur à l’isolant vert à l’extérieur

(avec ou sans rayures jaunes) est le

conducteur de terre. S’il faut remplacer

ou réparer le cordon électrique ou la

fiche, ne pas brancher le conducteur de

terre à une borne sous tension.

Si l’on ne comprend pas entièrement les

instructions de mise à la terre ou s’il y a

des doutes quant à la mise à la terre

appropriée, vérifier auprès d’un

électricien qualifié ou du personnel de

service.

110-120 volts, 60Hz Information sur l’outil

Cet outil pourrait provoquer un

choc électrique s’il n’est pas

mis à terre correctement, tout

particulièrement quand utilisé

dans des emplacements

humides, près de la plomberie

ou à l’extérieur.

AVERTISSEMENT:

!

TEST

RESET

Broche de masse

Fiche à 3 broches

Prise à

3 broches

mise à la

terre

correcte-

ment

17

TROUBLE PROBABLE CAUSE REMEDY

Thermal overload

protector cuts out

repeatedly

Air tank pressure

drops when com-

pressor shuts off

Excessive moisture

in discharge air

Compressor runs

continuously

Compressor vibrates

Air output lower than

normal

1. Low voltage

2. Clogged air filter

3. Lack of proper ventila-

tion/room temperature

too high

4. Unit is plugged into

extension cord

1. Loose connections (fit-

tings, tubing, etc.)

2. Loose drain lock

3. Check valve leaking

1. Excessive water in air

tank

2. High humidity

1. Defective pressure

switch

2. Excessive air usage

Loose mounting bolts

1. Broken inlet valves

2. Intake filter dirty

3. Connections leaking

1.Check with voltmeter

2.Clean filter (see

Maintenance section)

3.Move compressor to well

ventilated area

4.Remove extension cord

1.Check all connections with

soap and water solution

and tighten

2.Tighten

3.Disassemble check valve

assembly, clean or replace

Do not disassemble

check valve with air in

tank; bleed tank

1.Drain tank

2.Move to area of less

humidity; use air line filter

1.Replace switch

2.Decrease air usage; com-

pressor not large enough

for a requirement

Tighten

1.Have authorized service

representative repair unit

2.Clean or replace intake fil-

ter

3.Tighten connections

!

DANGER:

Spécifications du moteur

et exigences électriques

Alimentation électrique et spécifications du moteur

Le moteur c.a. utilisé sur ce compresseur

est un type à induction non réversible à

condensateur permanent aux

spécifications suivantes. Il est câblé à

l’usine pour fonctionner sous

110 - 120 V c.a., 60 Hz.

Tension 110-120

Ampères 14

Hertz (cycles) 60

Phase Monophase

tr/min : 3 450

Pour réduire le risque

d’incendie, de choc électrique

ou de dommages aux outils,

utiliser la bonne protection de

circuit. Votre outil est câblé à

l’usine pour fonctionner à l’aide

de la tension indiquée.

Connecter l’outil à une ligne de

courant avec une tension

appropriée et un circuit de

dérivation de 15 ampères.

Utiliser un disjoncteurs ou un

fusible de type de surcharge de

15 ampères. Pour réduire les

risques d’incendie et de chocs

électriques, si le cordon est usé

ou coupé ou endommagé de

quelque façon que ce soit, le

remplacer immédiatement.

AVERTISSEMENT:

!

Connexions électriques générales.

Pour réduire les risques

d’électrocution :

1. Utiliser seulement des pièces

de rechange identiques pour

les réparations. Ces

dernières doivent être

effectuées par un technicien

qualifié.

2. Ne pas utiliser sous la pluie

ou lorsque le sol est humide.

L’appareil et prévu seulement

pour une utilisation

résidentielle intérieure.

DANGER:

!

Ne pas laisser les doigts

toucher les bornes de la prise

en installant ou retirant la fiche

de la prise.

AVERTISSEMENT:

!

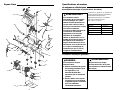

Repair Parts

18 Fr 7

1

19

20

21

22

24

26

16

27

28

30

32

2

5

6

7

8

9

10

12

25

14

18

31

4

11

23

15

29

17

3

13

Instructions de sécurité (suite)

Fr 6

Trouver et lire toutes les étiquettes

d’avertissement qui se trouvent sur le

compresseur d’air indiquées plus bas

Étiquettes d'avertissement

DK724100AV 100

0

Repair Parts

19

For Repair Parts, Call 1-800-4-RIDGID

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Ref. Catalog Part

No. Number Number Descriptons Qty

1 25673 WL373001AV

*

Pump/motor assembly 1

2 20448 ST085700AV Filter 1

3 17723 WL003203AV Isolation mount 3

4 17713 ST158000AV Shoulder bolt 3

5 30538 WL038500AV Manifold (Includes items 6, 7, 9, and 10) 1

6 30543 V-215200AV Safety valve- 200 psi 1

7 17873 HF203300AV

*

Coupler 2

8 30548 CW214300AV Pressure switch 1

9 30553 GA032401AV

*

Tank pressure gauge 1

10 30558 GA032400AV

*

Outlet pressure gauge 1

11 17893 ST119305AV Tube fitting 1

12 17853 ST158300AV Molded rubber bumper 4

13 18038 ST116400AV Hex. head bolt 4

14 17783 ST071626AV Button head torx screw 20

15 30563 WL038300AV Bracket 1

16 30568 ST195300AV

*

Grip 1

17 30573 WL212300AV Discharge tube (includes nut and ferrule) 1

18 20358 ST085800AV Drain valve 1

19 17728 CV223800AV Check valve 1

20 30578 AR061100AV Twin tank assembly 1

21 30583 ST188800AV Unloader tube (includes tube insert, nut and ferrule) 1

22 30588 WL038800AV Shroud 1

23 25003 ST170800AV Manifold tube(includes tube insert, nut and ferrule) 1

24 — WL036200AV Regulator 1

25 — N/A Side plates 2

26 30593 WL038200AV Drain valve bracket 1

27 — N/A Pipe elbow 1/4 inch NPT 1

28 — N/A Street elbow 1/4 inch NPT 1

29 — N/A 1/4 inch Compression fitting 2

30 30598 WL038700AV Front cover 1

31 17888 ST022500AV Plug 1/4 inch 2

32 30603 ST170900AV Drain tube (includes tube insert, nut and ferrule) 1

* Considered wear items

N/A = Standard Hardware Item or Not Available

Proposition 65 Californie

Ce produit ou son cordon contient des produits chimiques qui de

l’avis de l’État de Californie peut causer le cancer et des anomalies

congénitales ou autres problèmes de reproduction. Lavez-vous les

mains après la manipulation.

AVERTISSEMENT:

!

EASY DRAIN VALVE

LOCATED ON OPPOSITE SIDE

SOUPAPE DE PURGE FACILE

AU COTE OPPOSE

VÁLVULA PARA FÁCIL DRENAJE

UBICADA EN EL LADO OPUESTO

DK864800AV 1207

Ceci permet que l’humidité se vide

complètement et aide à empêcher la

corrosion.

27.Vérifier le réservoir quotidiennement

pour la rouille, trous d’épingle ou

autres imperfections qui peuvent

avoir un effet sur la sécurité. NE

JAMAIS souder ou percer le réservoir

à air.

1. Ne pas fumer pendant la pulvérisa-

tion de peinture, d’insecticides ou

d’autres substances inflammables.

2. Utiliser un masque/respi-

rateur pendant la pulvéri-

sation et pulvériser dans

un endroit bien ventilé

pour éviter les hasards de santé et de

feu.

3. Ne pas pulvériser vers le com-

presseur. Situer le compresseur aussi

loin que possible de l’endroit de pul-

vérisation pour minimiser l’accumula-

tion de surpulvérisation sur le com-

presseur.

4. Pour pulvériser ou nettoyer avec des

solvants ou produits chimiques tox-

iques, suivre les instructions fournies

par le fabricant du produit chimique.

Précautions de Pulvérisation

Ne pas pulvériser

des matériaux

inflammables près

d’une flamme ni près

d’une source d’igni-

tion y inclus le compresseur.

AVERTISSEMENT:

!

Avertissement D’Air Respirable

Ce compresseur n’est pas équipé pour et ne devrait pas être utilisé

“comme soi” pour fournir de l’air respirable. Pour les applications

d’air pour la consommation humaine, il est nécessaire d’équiper le

compresseur d’air/pompe avec de l’équipement de sécurité en

canalisation et d’alarme. Cet équipement additionnel est nécessaire

pour filtrer et purifier l’air afin d’atteindre les spécifications mini-

males pour la respiration Grade D décrit dans le Compressed Gas

Association Commodity Specification G 7.1 - 1966, OSHA 29 CFR

1910. 134, et/ou Canadian Standards Associations (CSA).

DÉNÉGATION DES GARANTIES

Si le compresseur est utilisé pour les applications d’air respirable et

l’équipement de sécurité en canalisation et d’alarme n’est pas utilisé

simultanément, les garanties en existance seront annulées, et

Campbell Hausfeld nie toute responsabilité pour n’importe quelle

perte, blessure personnelle ou dommage.

DANGER:

!

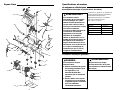

Repair Parts

20 Fr 5

13

1

3

4

12

5

11

7

6

10

9

8

2

14

15

16

8. Suivre toutes les codes locaux d’élec-

ticité et de sécurité, ainsi que le

National Electrical Code (NEC) et \le

Occupational Safety and Health Act

(OSHA).

9. L’installation des fils et fusibles

devraient suivre les codes élec-

triques, capacité du courant, et

doivent êtres mis à la terre correcte-

ment.

10.Les moteurs électriques doivent être

mis à la terre correctement. Voir les

instructions de mise à la terre et l’in-

formation concernant les cordons

prolongateurs dans ce manuel.

11. Toujours débrancher la source d’én-

ergie avant de travailler sur ou près

d’un moteur, ou son charge branché.

Si l’endroit de débranchement est

hors vue, le serrer dans la position

ouverte et l’étiquetter pour éviter une

application de puissance inattendue.

12.Protéger contre les pièces mobiles;

garder les visiteurs à l’écart de l’en-

droit de travail. Ne jamais permettre

les enfants dans l’endroit de travail.

13.Utiliser seulement une prise de

courant mise à la terre qui acceptera

une fiche à trois broches, et portez

des chaussures pour éviter le risque

de secousse électrique.

14.Prendre précaution de ne pas toucher

l’éxtérieur du moteur car il peut être

assez chaud pour causer des

blessures.

15.Protéger le câble électrique contre les

objets pointus.

16.Nettoyer l’équipement électrique ou

électronique avec un produit approu-

vé tel qu’un solvant de nettoyage

sèche qui n’est pas inflammable.

17.Mettre au rebut les torchons usés

dans les récipients en métal approu-

vés pour éviter la combustion spon-

tanée.

18.Ne jamais entreposer les liquides

inflammables ou gaz dans l’endroit du

compresseur.

19.Suivre les instructions du fabriquant

de produit chimique pour la pulvérisa-

tion des solvants ou produits chim-

iques toxiques.

20. Pour éviter la collection des vapeurs

et les risques de santé ou d’incendie,

pulvériser dans un endroit bien ven-

tilé.

21.Ne pas pulvériser dans l’endroit d’une

flamme ni dans un endroit où une

étincelle peut précipiter l’allumage.

Ne pas fumer pendant la pulvérisa-

tion de la peinture, d’insecticides ou

autres produits inflammables.

22.Utiliser un respirateur pendant la pul-

vérisation.

23.NE JAMAIS rajuster la soupape de

sûreté ou le manostat. Garder la

soupape de sûreté libre de peinture

et autres accumulations. Ceci sert à

éviter la sur-pression.

24.Suivre l’entretien ordinaire; garder

tous les écrous, boulons et vis serrés

pour assurer un bon état de marche

de l’équipeement.

25.Garder tous les torchons de nettoy-

age et autres produits inflammables

dans un récipient en métal fermé et

mettre au rebut de manière respons-

able.

26.Faire couler l’humidité du réservoir

quotidiennement. Si le modèle n’est

pas en service pour quelque temps,

laisser le robinet de vidange ouvert.

Instructions de sécurité (suite)

Fr 4

Débrancher et dissiper toute la

pression du système avant de

procéder à l’entretien du com-

presseur! (Mettre le com-

presseur hors circuit et tourner

le bouton de réglage de pres-

sion complètement au sens des

aiguilles d’une montre.)

AVERTISSEMENT:

!

Repair Parts

21

For Repair Parts, Call 1-800-4-RIDGID

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Ref. Catolog Part

No. Number Number Descriptons Qty

1 17948 WL010500AV Head 1

2— Head bolts 4

3—

*

Exhaust valve 1

4— Valve plate 1

5 17958 , XA012100AV

*

Cylinder gasket 1

6 17963 N/A

*

Motor assembly (includes eccentric/

bearing assembly) To order see pump/

motor assembly (part #1) on p. 19 1

7 — (Included with M5 x .8 x 20 HH cap screw 1

piston assembly,

Ref. No. 11)

8— M5 x .8 x 12 HHCS (L.H.) screw 1

9— Washer 1

10 — Fan 1

11 17968 WL210300SJ

*

Piston assembly (includes cap screw) 1

12 —

*

Intake valve 1

13 17973 , XA010800AV

*

Head gasket (metal gasket) 1

14 17978 , XA012001AV

*

Discharge valve gasket 1

15 MC507017AV Start Capacitor (280-520 µF/250 VAC) 1

16 MC506908AV Run Capacitor (40 µF/450 VAC) 1

REPAIR PARTS KITS

17953 WL602801AJ Head bolt kit (set of 4) 1

17983 WL201405SJ Valve plate kit (Includes exhaust valve, 1

valve plate, cylinder gasket, intake valve,

head gasket, and discharge valve gasket)

17988 WL209802SJ Fan kit (includes screw, washer and fan) 1

*

Considered wear components

N/A = Standard Hardware Item

Ce manuel contient de l’information très

importante qui est fournie pour la

SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT.

Rechercher les symboles suivants pour

cette information.

Mot signal de sécurité

Danger indique une situation hasardeuse

imminente qui, si pas évitée,

RÉSULTERAen perte de vie ou

blessures graves.

Avertissement indique une situation

hasardeuse potentielle qui, si pas évitée,

PEUT résulter en perte de vie ou

blessures graves.

Attention indique une situation

hasardeuse potentielle qui, si pas évitée,

PEUT résulter en blessures moderées.

Avis indique l’information importante pour

éviter le dommage de l’équipement.

AVIS:

ATTENTION:

!

AVERTISSEMENT:

!

DANGER:

!

Instructions de sécurité

Fr 3

Avant d'utiliser le compresseur d'air

Les compresseurs d’air sont utilisés dans

une variété d’applications. Puisque les

compreseurs d’air et autres pièces

détachées (pompe, pistolets, filtres,

graisseurs, tuyaux, etc.) forment un

système de pompage de haute pression,

observez les précautions de sécurités

suivants. Seules les personnes bien

familiarisés avec ces règles de sécurité

doivent êtres autorisées à se servir du

compresseur

1. Lire attentivement tous les manuels

d’instructions pour chaque pièce

détachée avant d’esssayer de mon-

ter, démonter ou de faire fonctionner

votre système.

2. Porter des lunettes de sécurité

(répondant à la norme ANSI Z87.1 ou

au Canada CSA Z94.3-99) et utiliser

une protection auditive en faisant

fonctionner la pompe ou l’appareil.

Les lunettes courantes ne sont pas

des lunettes de sécurité.

3. Ne pas dépasser l’évaluation de

pression de n’importe quelle pièce

détachée du système.

4. Protéger la tuyauterie et canalisations

d’air contre le dommage ou la perfo-

ration. Garder les tuyaux et câbles de

transport d’énergie à l’écart des

objets pointus, déversements chim-

iques, huile, solvants et planchers

trempes.

5. Ne jamais pointer un pistolet vers soi-

même ni vers une autre personne. Le

décharge accidentel peut causer des

blessures graves.

6. Vérifier les tuyaux pour rechercher

tout signe de faiblesse ou d’usure et

assurer que tous les raccordements

sont sûrs; ne pas utiliser si endom-

magé. Contacter un centre de service

autorisé pour l’inspection ou la répa-

ration.

7. Dissiper toute la pression du système

lentement; la poussière et le débris

peuvent être dangereux.

Seul un électri-cien qualifié

(autorisé ou diplômé) doit

effectuer les travaux élec-

triques. Sur un circuit installé

correctement, les fils noirs

fournissent une tension même

si le modèle est hors circuit

(OFF).

AVERTISSEMENT:

!

Notes

22

Table des matières

Section Page

Table des matières . . . . . . . . . . . . .Fr 2

Instructions de sécurité . . . . . . . .Fr 3

Termes de signaux de sécurité .Fr 3

Avant d’utiliser le compresseur

d'air . . . . . . . . . . . . . . . . . . . . . . .Fr 3

Précautions de Pulvérisation . . . .Fr 5

Avertissement D’Air Respirable . .Fr 5

Étiquettes d’avertissement . . . . . .Fr 6

Spécifications du moteur et

exigences électriques . . . . . . . .Fr 7

Moteur et alimentation électrique

Spécifications . . . . . . . . . . . . . . . .Fr 7

Connexions électriques

générales . . . . . . . . . . . . . . . . . . .Fr 7

Renseignements de l’outil

de110-120 volt, 60 Hz. . . . . . . . . .Fr 8

Rallonges . . . . . . . . . . . . . . . . . . .Fr 9

Protecteur de Surcharge

Thermique . . . . . . . . . . . . . . . . . . .Fr 9

Glossaire des termes . . . . . . . . .Fr 10

Déballage et vérification Contenu Fr 11

Installation . . . . . . . . . . . . . . . . . .Fr 11

Section Page

Apprendre à connaître votre

compresseur d’air . . . . . . . . . . . .Fr 12

Fonctionnement de votre

compresseur d’air . . . . . . . . . . . .Fr 14

L’Humidité dans l’Air

Comprimé . . . . . . . . . . . . . . . . . .Fr 14

Fonctionnement de votre

compresseur d’air . . . . . . . . . . . .Fr 14

Pour un Fonctionnement sans

Problème . . . . . . . . . . . . . . . . . . .Fr 14

Entretien . . . . . . . . . . . . . . . . . . . .Fr 15

Réservoir . . . . . . . . . . . . . . . . . . .Fr 16

Enlevage, Inspection et

Remplacement du Filtre . . . . . . .Fr 16

Graissage . . . . . . . . . . . . . . . . . .Fr 16

Entreposage . . . . . . . . . . . . . . . .Fr 16

Horaire d’entretien . . . . . . . . . . . .Fr 16

Dépannage . . . . . . . . . . . . . . . . . .Fr 17

Notes . . . . . . . . . . . . . . . . . . . . . . .Fr 19

Pièces de réparation . . . . . . . . . .Fr 20

Garantie . . . . . . . . . . . . . . . . . . . .Fr 24

Notes

Fr 2 23

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

Rigid Industries RIDGID OF45175A Manuel utilisateur

- Catégorie

- Compresseurs d'air

- Taper

- Manuel utilisateur

dans d''autres langues

Autres documents

-

RIDGID OF45175A Manuel utilisateur

-

RIDGID OF45150B Manuel utilisateur

-

RIDGID OL50135A Manuel utilisateur

-

RIDGID OF25135A Manuel utilisateur

-

RIDGID IN625301AV Manuel utilisateur

-

Husky FP2021 Operating Instructions Manual

-

RIDGID OL90150 Manuel utilisateur

-

Campbell Hausfeld FP2080 Mode d'emploi

-

RIDGID GP90150RB Manuel utilisateur

-

RIDGID GP90135 Manuel utilisateur