Write the model and serial

numbers here:

Model # _________________

Serial # _________________

You can find them on the rating

label on the front side of your

water heater.

GE is a trademark of the General Electric Company. Manufactured under trademark license.

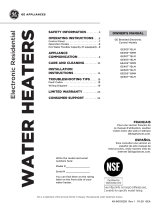

OWNER’S MANUAL

WATER HEATERS

Electronic Residential

49-6000226 Rev. 4 08-20 GEA

GE Branded Electronic

Control Models

GE30S**BLM

GE30S**BMM

GE30T**BLM

GE40S**BLM

GE40S**BMM

GE40T**BLM

GE50S**BLM

GE50S**BMM

GE50T**BLM

SAFETY INFORMATION ..........3

OPERATING INSTRUCTIONS ....6

Control Panel .........................7

Operation Modes ......................8

Hot Water Flexible Capacity (if equipped) . .8

APPLIANCE

COMMUNICATION ................9

CARE AND CLEANING ..........10

INSTALLATION

INSTRUCTIONS ..................14

TROUBLESHOOTING TIPS ......18

Fault Codes .........................19

Wiring Diagram

......................19

LIMITED WARRANTY ...........23

CONSUMER SUPPORT ......... 24

ESPAÑOL

Para consultar una version en

español de este manual de

instrucciones, visite nuestro sitio de

internet GEAppliances.com.

FRANÇAIS

Pour une version français de

ce manuel d’utilisation, veuillez

visiter notre site web à l’adresse

GEAppliances.com.

See http://info.nsf.org/Certified/Lead_

Content/ for specific model listing

2 49-6000226 Rev. 4

THANK YOU FOR MAKING GE APPLIANCES A PART OF YOUR HOME.

Whether you grew up with GE Appliances, or this is your first, we’re happy to have you in the family.

We take pride in the craftsmanship, innovation and design that goes into every GE Appliances

product, and we think you will too. Among other things, registration of your appliance ensures that we

can deliver important product information and warranty details when you need them.

Register your GE appliance now online. Helpful websites and phone numbers are available in the

Consumer Support section of this Owner’s Manual. You may also mail in the pre-printed registration

card included in the packing material.

49-6000226 Rev. 4 3

READ AND SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE

SAFETY INFORMATION

WARNING

For your safety, the information in this manual must be followed to minimize the risk of fire or explosion, electric

shock, or to prevent property damage, personal injury, or loss of life.

Be sure to read and understand the entire Owner’ s Manual before attempting to install or operate this water

heater. It may save you time and cost. Pay particular attention to the Safety Instructions. Failure to follow these

warnings could result in serious bodily injury or death. Should you have problems understanding the instructions

in this manual, or have any questions, STOP and get help from a qualified service technician or the local electric

utility.

CAUTION

Risk of Fire - Hydrogen gas can be produced in a hot water system served by this water heater that has

not been used for a long period of time (generally two weeks or more). HYDROGEN GAS IS EXTREMELY

FLAMMABLE!! To dissipate such gas and to reduce risk of injury, it is recommended that the hot water faucet be

opened for several minutes at the kitchen sink before using any electrical appliance connected to the hot water

system. If hydrogen is present, there will be an unusual sound such as air escaping through the pipe as the water

begins to flow. Do not smoke or use an open flame near the faucet at the time it is open.

WARNING

Risk of Fire - DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance. Keep rags and other combustibles away.

FOR INSTALLATIONS IN THE STATE OF CALIFORNIA

California Law requires that residential water heaters must be braced, anchored or strapped to resist falling

or horizontal displacement due to earthquake motions. For residential water heaters up to 52 gallon (197 L)

capacity, a brochure with generic earthquake bracing instructions can be obtained from: Office of the State

Architect, 400 P Street, Sacramento, CA 95814 or you may call 916.324.5315 or ask a water heater dealer.

Applicable local codes shall always govern installation. For residential water heaters of a capacity greater than

52 gallons (197 L) consult the local building jurisdiction for acceptable bracing procedures.

WARNING

If the water heater has been subjected to flood, fire, or physical damage, turn off power and water to the

water heater.

Do not operate the water heater again until it has been thoroughly checked by qualified service personnel.

Safety Precautions

A. Do turn off power to water heater if it has been subjected to overheating, fire, flood or physical damage.

B. Do Not turn on water heater unless it is filled with water.

C. Do Not turn on water heater if cold water supply shut-off valve is closed.

NOTE: Flammable vapors may be drawn by air currents from surrounding areas to the water heater.

D. If there is any difficulty in understanding or following the Operating Instructions or the Care and Cleaning

section, it is recommended that a qualified person or serviceman perform the work.

4 49-6000226 Rev. 4

SAFETY INFORMATION

READ AND SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE

Time/Temperature Relationship in Scalds

Temperature Time to Produce a Serious Burn

120°F (49°C) More than 5 minutes

125°F (52°C) 1-1/2 to 2 minutes

130°F (54°C) About 30 seconds

135°F (57°C) About 10 seconds

140°F (60°C) Less than 5 seconds

145°F (63°C) Less than 3 seconds

150°F (66°C) About 1-1/2 seconds

155°F (68°C) About 1 second

Table courtesy of Shriners Burn Institute

!

Water temperature over 125°F can

cause severe burns instantly or

death from scalds.

Temperature control settings

usually approximate tap water

temperature. However, factors

could cause water temperature

to reach 160°F regardless of the

control settings.

Children, disabled and elderly

are at highest risk of being scalded.

See instruction manual before

setting temperature at water

heater.

Feel water before bathing or

showering.

Temperature limiting valves are

available; see manual.

The chart shown above may be used as a guide in determining

the proper water temperature for your home.

DANGER

There is a Hot Water SCALD Potential if the

water temperature thermostat is set too high. Households

with small children, disabled or elderly persons may require

a 120°F (49°C) or lower thermostat setting to prevent contact

with “HOT” water.

Control has been set at the factory to 120°F (49°C) to reduce the

risk of scald injury. This is the recommended starting temperature

setting, but it can be adjusted to any temperature between 100°F

and 140°F (38°C and 60°C).

To Adjust the Temperature

Follow these steps:

1. Press the + or - buttons on the control panel key pad to desired

temperature.

2. Press ENTER to accept the new setting.

NOTE: To change between °F and °C, press and hold MODE.

WATER TEMPERATURE ADJUSTMENT

Safety, energy conservation, and hot water capacity are factors

to be considered when selecting the water temperature setting

of the water heater. Water temperatures above 125°F can cause

severe burns or death from scalding. Be sure to read and follow the

warnings outlined on the label pictured to the left. This label is also

located on the water heater near the top of the tank.

49-6000226 Rev. 4 5

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE

SAFETY CONTROLS

The water heater is equipped with a combination

temperature sensor and high limit Energy-Cut-Off

control (ECO) that is located above the upper heating

element in contact with the tank surface. If for any

reason the water temperature becomes excessively

high, the high limit control (ECO) breaks the power

circuit to the heating element. Once the control

opens, it must be reset manually. Resetting of the

high limit control should be done by a qualified service

technician.

CAUTION

The cause of the high temperature

condition must be investigated by a qualified

service technician and corrective action must be

taken before placing the water heater in service

again.

To reset the temperature-limiting control:

1. Turn off the power to the water heater.

2. Remove the electronic control display and insulation.

Open the electronic control housing by removing

the screw beneath the display using a phillips-head

screwdriver. Push the control display down and

rotate the panel from the top to open and remove

the insulation.

The thermostat protective cover should not be

removed.

3. Press the red RESET button.

4. Replace the insulation, control housing, and screw

before turning on the power to the water heater.

5. Ensure water heater is operating properly after

resetting the ECO.

READ AND SAVE THESE INSTRUCTIONS

SAFETY INFORMATION

1. Once the Power is turned off at

breaker, remove screw at base

on control housing with Phillps

head screw driver.

2. With a flat blade screw driver,

lower control housing about

1/8” at top pry location, to allow

rotation of control for opening.

ECO reset button location

3. Control can now be rotated

downward to access ECO reset

(beneath insulation insert).

6 49-6000226 Rev. 4

Operating Instructions

Water Heater Capacity and Increasing Temperature

Setpoint (For Water Heaters without an Integrated

Mixing Valve):

The water heater temperature setting strongly impacts

the amount of usable hot water available for showers

and baths.

• Energy consumption/savings and efficiency testing of

water heaters is performed according to Department

of Energy (DOE) requirements specified at the date of

manufacture.

• Safety regulations require a factory setting no greater

than 125°F (52°C) for all new water heaters. Therefore,

if your old water heater was set to a hotter temperature

than your new water heater with a factory set setpoint of

120°F (49°C), the new water heater may seem to provide

lower capacity than your old water heater. This can be

corrected by increasing the temperature setpoint.

• If more hot water capacity is desired, increasing the

temperature from 120°F to 135°F (49°C to 57°C) will

enable the same tank of hot water to last about 25%

longer because less hot water is mixed in at the shower

or faucet.

• Increasing the water temperature setpoint may improve

the cleaning performance of dishwashers and washing

machines.

• The user can adjust the temperature setting to meet

their needs. Always read and understand the safety

instructions contained in the owner’s manual before

adjusting the temperature setpoint.

Mixing Valves

• For models with an integrated electronic mixing valve,

hot water capacity can be increased by changing

capacity selection from control, while maintaining

outlet water temperature. See page 8 for instructions

to increase hot water capacity.

• If your model does not include an integrated Electronic

mixing valve: a supplimental mixing valve for reducing

point-of-use water temperature by mixing hot and cold

water in branch water lines are commercially available.

Contact a licensed plumber or the local plumbing

authority for further information.

Extended Shutdown Periods

If the water heater is to remain idle for an extended

period of time, the power and water to the appliance

should be turned off and the water heater drained to

conserve energy and prevent a buildup of dangerous

hydrogen gas. This unit has no power button, power

can only be shut off at the circuit breaker or disconnect

switch.

The water heater and piping should be drained if they

might be subjected to freezing temperatures.

After a long shutdown period, the water heater’s

operation and controls should be checked by qualified

service personnel. Make certain the water heater is

completely filled again before placing it in operation.

NOTE: Refer to the Hydrogen Gas Caution in the

Operating Instructions (see page 3).

OPERATING INSTRUCTIONS

49-6000226 Rev. 4 7

About the Control Panel

ABOUT THE CONTROL PANEL

Control Features

1. Display

2. Mode Select Button and Mode Indicator

Use this button to alternate between Normal and Vacation

modes. Enter key must be depressed to confirm selection.

3. Tank Capacity Selection Button and Indicator

Status (on some models)

Use this button to alternate between Normal, High and

X-High tank capacities. Enter key must be depressed to

confirm selection.

4. + Select Button

Use these buttons to increase the temperature setting or

vacation days.

5. - Select Button

Use these buttons to decrease the temperature setting or

vacation days.

6. Enter Key

Use this button to confirm temperature setting following

adjustment.

7. Anode Reset and Replacement Indicator (if

equipped)

When the Anode text is illuminated and F70 fault is

displayed, the system has indicated that the anode rod

is approaching end of life and it is recommended to

replace it. Press button once to silence alarm. Press

and hold for 5 seconds to reset the anode alarm after

replacing. Call the Installer to replace the anode rod. The

Servicer contact info is located next to the rating plate of

the unit, or contact GE Appliances customer support at

GEAppliances.com/waterheater. Failure to replace the

anode rod will void warranty coverage and may result in

a tank leak. (See page 12 for instructions to change the

anode rod.)

8. Wifi Indicator Light

Lit when connected, flashing during configuration set up

mode.

9. Appliance Communication Module Port

For use with Service and optional accessory modules.

Visit GEAppliances.com/waterheaters for more

information.

Displaying Temperature Setpoint

The

control will display the temperature

setpoint anytime a button on the control

is pressed. After 30 seconds of inactivity,

the display will go blank. Note that the

Mode and Capacity selection (if equipped)

will remain illuminated in sleep mode. To

wake the control at any time to see the

temperature setpoint, press any button on

the control.

Turning on the Water Heater

There is no power button for this unit. Once

the water heater is wired and power is

supplied, it will be on. The display will show

the current water temperature setting.

To comply with safety regulations, the

controls are factory preset to 120°F (49°C).

To Adjust the Temperature

Follow these steps:

1. Press the + or - button on the control

panel key pad to desired temperature.

2. Press ENTER to accept the new setting.

Note: To change between °F and °C, press

and hold the Mode Select button.

4

6

5

7

9

8

1

2

3

8 49-6000226 Rev. 4

Operation Modes

OPERATION MODES

This water heater defaults to the Normal operating mode.

To select Vacation Mode:

1. Press the MODE button until “Vacation” is

illuminated.

2. Press Enter to confirm selection.

3. To return to “Normal” mode, repeat steps 1 and 2, once

“Normal” text is illuminated.

Vacation Mode

This feature is recommended when you will be away

from the home for an extended period of time and hot

water is not needed. In this mode, the unit will reduce the

water temperature setting to 50ºF (10°C) and will use the

most efficient heating mode to conserve energy while the

heater is sitting idle. The unit will automatically resume

heating one day before your return, so that hot water will

be available.

To set Vacation Mode:

1. Select Vacation by pressing the MODE button.

2. Input the total number of days you will be gone

by pressing the +/- select button. The default is 7

days, maximum 199, or remain in Vacation Mode

indefinitely by selecting “---”.

3. Press Enter to confirm selection

For example, if you will be gone 14 days, set Vacation

mode for 14 days using the steps above. The

temperature setting will automatically reduce to 50

0

F

(10

0

C) for 13 days. At the end of the 13th day, unit will

return to normal operating mode and temperature setting

will reset to ensure hot water is available upon your

return.

When activated this feature stores water at higher

temperatures. As hot stored water leaves the tank, cold

water is mixed in to maintain the desired set point. This

mixing allows more usable hot water to be available.

The water heater defaults to Normal hot water Capacity

setting, which is used to calculate annual operating cost,

(and a 125F outlet water setting).

To change tank Capacity setting:.

1. Press the “Capacity” button until High, X-High or

Normal text is illuminated.

2. Confirm selection by pressing “Enter” key.

Capacity Options (based on 120°F default outlet water

temperature setting and 58°F inlet water temperature):

Normal: No increase of hot water capacity from outlet

water setting

High: Increases hot water capacity up to 40%

X-High: Increases hot water capacity up to 60%

Hot Water Flexible Capacity Selection (on some models)

49-6000226 Rev. 4 9

Appliance Communication

APPLIANCE COMMUNICATION

GE Appliances WiFi Connect (for customers in the United States)

GE Appliances WiFi Connect Enabled*

If your water heater has a Connected Appliance Information label located

on the outside as shown below, your model is GE Appliances WiFi Connect Enabled. A WiFi communication card is

built into the product allowing it to communicate with your smart phone for remote monitoring, control and notifications.

Please visit GEAppliances.com/connect to learn more about connected appliance features, and to learn what

connected appliance apps will work with your smart phone.

*Select models only

Network: GE_Module_XXXX

PASSWORD: XXXXXXXX

MAC: XX-XX-XX-XX-XX-XX

CONTAINS FCCID: ZKJ-WCATA006

CONTAINS IC: 10229A-WCATA006

184D2604P001

WiFI Connectivity: For assistance with the appliance or the ConnectPlus network connectivity (for models that are WiFi

enabled or WiFi optional), please call 1-800-220-6899.

REGULATORY INFORMATION

FCC/IC Compliance Statement:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/television technician for help.

Labelling: Changes or modifications to this unit not expressly approved by the manufacturer could void the user’s

authority to operate the equipment.

This product has WiFi capability and requires Internet connectivity and a wireless router to enable interconnection

with an Energy Management System, and/or with other external devices, systems, or applications.

10 49-6000226 Rev. 4

Routine Preventive Maintenance

DANGER

Risk of Scald - Before manually

operating the relief valve, make certain no one will

be exposed to the danger of coming in contact with

the hot water released by the valve. The water may

be hot enough to create a scald hazard. The water

should be released into a suitable drain to prevent

injury or property damage.

NOTE: If the temperature and pressure-relief valve

on the hot water heater discharges periodically, this

may be due to thermal expansion in a closed water

system. Contact the water supplier or your plumbing

contractor on how to correct this. Do not plug the

relief valve outlet.

Properly maintained, your water heater will provide years

of dependable trouble-free service. It is suggested that

the following annual preventive maintenance program be

established.

1. Inspect Temperature & Pressure Relief Valve.

2. Inspect heating elements, ECO, and wiring to each.

3. Drain and Flush the water heater tank.

4. Anode rod must be removed and inspected.

Temperature and Pressure-Relief Valve:

Once a year, it is recommended to lift and release the

lever handle on the temperature and pressure-relief

valve, located on the front-right side of the water heater,

to make certain the valve operates freely. Allow several

gallons to flush through the discharge line to an open

drain.

Heating Elements and ECO:

Once a year, it is recommended to inspect the heating

elements, ECO, and wiring to each. Inspection should

be completed by service personnel qualified in electrical

appliance repair.

Most electrical appliances, even when new, make some

sound when in operation. If the hissing or singing sound

level increases excessively, the electric heating element

may require cleaning. Contact a qualified installer or

plumber for inspection.

Draining and Flushing the Water Heater

CAUTION

Risk of Shock - Shut off power to

the water heater before draining water.

DANGER

Risk of Scald - Before manually

operating the relief valve, make certain no one will

be exposed to the hot water released by the valve.

The water drained from the tank may be hot enough

to present a scald hazard and should be directed to

a suitable drain to prevent injury or damage.

A water heater’s tank can act as a settling basin for

solids suspended in the water. It is therefore not

uncommon for hard water deposits to accumulate in the

bottom of the tank. To clean the tank of these deposits,

it is recommended to drain and flush the water heater

tank once a year. To drain the water heater, follow these

steps:

1. Turn off power to the unit. The electric heating

elements will become damaged if operated without

water.

2. Attach a garden hose to the drain valve located at the

bottom of the unit and direct that hose to a drain.

3. Turn off the cold water supply.

4. Admit air to the tank by opening a hot water faucet or

lifting the handle on the relief valve.

5. Open the drain valve.

Flushing the Tank:

1. Follow steps above to drain the water heater.

2. Once the water heater is empty, with the drain valve

open and garden hose attached to the drain valve,

turn on the cold water supply.

3. Allow several gallons to flush through the drain valve

and hose to an open drain.

4. Turn off the water supply and allow any water

remaining in the tank to drain.

5. Repeat steps 3 and 4 until water runs clear.

6. Close the drain valve and fill the tank before returning

power to the unit. The tank is full when water runs out

of a nearby open hot water faucet.

Flushing should be done with an empty tank to promote

additional removal of sediment.

Care and Cleaning

Exterior Surfaces

Hand wash with damp cloth, using only warm water. Wipe dry using a dry, clean cloth.

Use a flat blade screwdriver

to turn brass drain valve or an

adjustable open-end wrench to

turn black stem on plastic drain

valve.

Straight Brass

Drain Valve

CARE AND CLEANING

49-6000226 Rev. 4 11

CARE AND CLEANING

Anode Rod

Anode rods are designed and installed to protect and

extend the life of residential water storage tanks.

The anode rod must be removed from the water heater’s

tank and inspected annually, and replaced when more

than 6” (15.2 cm) of core wire is exposed at either end of

the rod.* NOTE: Artificially softened water will cause the

anode rod to consume more rapidly.

Due to shock hazard and to prevent accidental water

leaks, this inspection should be done by a qualified

servicer or plumber, and requires that the electric power

and cold water supply be turned off before servicing the

anode rod.

NOTICE: Do not remove the anode rod from the water

heater’s tank except for inspection and/or replacement,

as operation with the anode rod removed will shorten

the life of the glass-lined tank and will void warranty

coverage.

Some areas have water conditions that may cause

an odor to develop in the water heater. Special alloy

replacement rods are available to address this condition.

*NOTE: Failure to replace the anode rod when

consumed voids the warranty for the tank. Warranty

coverage for all other components remains intact,

and is unaffected by this maintenance requirement.

The replacement anode rod, and the inspection for

consumption are not covered by warranty.

Additional information for models with an anode

depletion sensing feature (Anode button on the control,

on equipped models):

When the depletion-sensing anode rod nears end of life,

the ANODE text will illuminate and the control will beep

and display F70. When this occurs, the anode rod must

be inspected and replaced if the core wire at the top of

the anode rod is exposed.* It is recommended to replace

the anode rod as soon as possible to ensure that the tank

will continue to be protected from corrosion. Call installer/

servicer to order or to replace the anode rod. (See page 12

for instructions to change the anode rod.)

Press the ANODE button once to silence the alarm. Once

replaced, reset the alarm by pressing and holding the

ANODE button for 5 seconds until the control beeps and the

Anode Light will turn off.

If special alloy anode rod is installed to address a water

odor condition, the anode depletion sensing feature must

be disabled. If disabled, annual inspections of the anode

rod are required since the water heater will no longer be

capable of alerting for a depleted anode rod.

To disable the feature:

1. Upon power-up following a special alloy anode rod

installation, the control will sound an alarm and F41 will

display. Press the ANODE button to quiet the alarm.

2. Press the ANODE button 3 times. “Off” or “On” will

display confirming that the feature has been disabled/

enabled.

To enable the feature if a new anode depletion sensing

anode rod is installed, follow Step 2 above.

Note: If the display is blank, press any button to wake the

control before entering a button combination.

NOTE: If the water heater has been installed with a

device that periodically cuts power to the water heater, the

accuracy of the anode rod depletion sensing feature may

become compromised and anode rod inspection every 2-3

years is required.

If the water heater will be inactive for a long period of time

and the water heater cannot be drained, it is recommended

to leave the power turned on with the water heater in

vacation mode to ensure that the feature will continue to

operate properly while still conserving energy.

NOTE: Refer to the Hydrogen Gas Caution in the

Operating Instructions (see page 3).

Care and Cleaning

Routine Preventative Maintenance

12 49-6000226 Rev. 4

Tools needed:

• Flat Head Screwdriver

• Phillips head screwdriver

• Socket/Torque Wrench

• 1

1

/16” Socket

• Pipe Joint Compound or Pipe Thread Sealant Tape

• Anode Rod, if needed

* See page 22 for part ordering instructions

To Service Anode Rod:

1. Disconnect power, shut off the water supply, drain the

water lines of the home. Drain 1 to 2 gallons of water

from the water heater through the lower drain valve.

2. Skip to step 3, for models without Integrated Mixing

Valve. For models with Integrated Mixing Valve,

remove (4) screws and front section of shroud using

Phillips screwdriver per Illustration B.

3. Remove anode cap and foam insulation in hole with

flat head screwdriver to expose anode fitting as shown

in illustration B.

NOTE: For models with sensing anode feature, anode

fitting is already exposed (see illustration C). Wire

attached to anode fitting must be detached prior to

next step.

4. Using a 1 1/16” socket/wrench, unscrew the anode

rod, then lift out to inspect as shown in illustration D.

Anode Rod Maintenance and Service

CAUTION - IMPORTANT SAFETY NOTICE

This information is intended for use by individuals

possessing adequate background of electrical,

electronic and mechanical experience. Any attempt

to repair a major appliance may result in personal

injury and property damage. The manufacturer or

seller cannot be responsible for the interpretation

of this information, nor can it assume any liability in

connection with its use.

Illustration B (Appearance will vary by model)

Illustration C (Appearance will vary by model)

Illustration D (Appearance will vary by model)

Remove anode

cap and foam

insulation in

hole to expose

anode fitting

Remove (4) phillips

screws (if equipped)

on front shroud on

integrated mixing

valve model to

expose anode rod

aceess.

Remove anode

wire if equiped

with sensing

anode.

Replace anode rod

if more than 6” of

core wire exposed

CARE AND CLEANING

49-6000226 Rev. 4 13

CARE AND CLEANING

5. Replace Anode Rod (with same anode type that was

removed — sensing vs. standard), if more than 6” of

core wire is exposed. Contact Installer/Servicer for

correct replacement anode or GEA Customer Support

at GEAppliances.com/waterheater.

6. To Install anode rod:

a. Seal the threads with pipe joint compound or pipe

thread sealant tape.

b. Thread into the port and tighten with torque wrench

to 50 +/- 5 ft-lbs of torque.

7. Turn water supply on, open a tap to remove any

trapped air in water lines and inspect for leaks. Repair

any leaks, prior to proceeding.

8. Reconnect wire to anode fitting (for anode depleteion

sensing models) or replace anode cap (for standard

non-sensing anode)

9. Reassemble front shroud, previously removed in step

2, if equipped.

10. Turn power On. If sensing anode was replaced with

a special alloy (non-sensing) anode rod, the anode

depletion sensing feature must be disabled and the

unattached wire end must be covered with electrical

tape. See page 12 for instructions on enabling or

disabling sensing anode.

11. Reset ANODE replacement indicator light (if

equipped) by pressing and holding ANODE button for

10 seconds to indicate that a new anode depletion

sensing anode rod is installed.

Anode Rod Maintenance and Service

14 49-6000226 Rev. 4

Installation Instructions

INSTALLATION INSTRUCTIONS

The location chosen for the water heater must take

into consideration the following:

LOCAL INSTALLATION

REGULATIONS

This water heater must be installed in accordance

with these instructions, local codes, utility codes,

utility company requirements or, in the absence of

local codes, the latest edition of the National Electrical

Code. It is available from some local libraries or

can be purchased from the National Fire Prevention

Association, Batterymarch park, Quincy, MA 02169 as

booklet ANSI/NFPA 70.

POWER REQUIREMENTS

Check the markings on the rating plate of the water

heater to be certain the power supply corresponds

to the water heater requirements. NOTE: 208V

installations may experience lower performance.

LOCATION

The water heater and water lines should be protected

from freezing temperatures and high-corrosive

atmospheres. Do not install the water heater in outdoor,

unprotected areas.

Locate the water heater in a clean dry area as near as

practical to the area of greatest heated water demand.

Long uninsulated hot water lines can waste energy

and water. Unit must be installed in a level location.

If required, add shims under base of unit to level for

proper operation.

NOTE: This unit is designed for any common indoor

installation.

Servicing the water heater requires proper installation

such that front panels can be removed to permit

inspection and servicing. Reference installation

instructions found in this manual.

Moving the water heater or other appliances to provide

service to the water heater is not covered under

warranty.

CAUTION

Risk of Property Damage -

The water heater should not be located in an

area where leakage of the tank or connections

will result in damage to the area adjacent to it

or to lower floors of the structure. Where such

areas cannot be avoided, it is recommended

that a suitable catch pan, adequately drained, be

installed under the water heater.

LOCATION (Cont).

Required clearances:

There must be sufficient clearance between any

object and the top, rear and sides of the water

heater in the event service is needed. The controls

and drain at front of unit must have clear access

for operation and service. Installations that require

minimal clearance on the sides or rear of the water

heater for earthquake straps are also acceptable.

In these cases, additional clearance should be

provided on the opposite side of the unit to

allow for service access. Integrated electronic

mixing valve models should not be installed

with pre-heated water from solar or other heated

sources (higher than intended user set point).

CATCH PAN INSTALLATION

(If required)

NOTE: Auxiliary catch pan MUST conform to local

codes. Catch Pan Kits are available from the store

where the water heater was purchased, a builder

store or any water heater distributor. The catch

pan should be 2” (5.1 cm) minimum larger than the

Water Heater base diameter. To prevent corrosion

and improve Drain Valve access it is recommended

that the water heater be placed on spacers inside

the catch pan.

Relief Valve

Drain Line

Catch Pan

Catch Pan

Drain (piped to

suitable drain)

THERMAL EXPANSION

If a check valve is present on the inlet water line,

it will create a “closed system.” Heating water in

a closed system creates an increase in pressure

within the water system because the pressure is not

able to dissipate in the main supply line. Referred to

as “thermal expansion”, the rapid pressure increase

can cause the relief valve to operate (releasing

water) during each heating cycle, potentially causing

premature failure to the valve or even the water

heater. The suggested method of controlling thermal

expansion is to install an expansion tank in the cold

water line between the water heater and the check

valve as shown in the following illustrations. Contact

your installing contractor, water supplier, or plumbing

inspector for additional information.

49-6000226 Rev. 4 15

Installation Instructions

WATER SUPPLY CONNECTIONS

Refer to the illustration below for recommended installation. The HOT and COLD water connections are clearly

marked and are ¾” NPT on all models. When connecting to the inlet/outlet ports, the use of ¾” female NPT

tapered thread fittings with use of thread sealant is recommended. The installation of unions is recommended

on the hot and cold water

connections so that the

water heater may be easily

disconnected for servicing if

necessary. Piping should be

routed to allow anode rod

removal.

NOTE: Install a shut-off valve

in the cold water line near the

water heater. This will enable

easier service or maintenance

of the unit later.

IMPORTANT: Do not apply

heat to the HOT or COLD

water connections. If sweat

connections are used, sweat

tubing to adapter before

fitting the adapter to the cold

water connections on heater.

Any heat applied to the hot

or cold water connection

will permanently damage

the internal plastic lining in

these ports.

Install a vacuum relief valve

and/or anti-siphon device when

required by local jurisdictions.

HOT AND COLD PIPE INSULATION INSTALLATION (if

supplied with product)

For increased energy efficiency, some water heaters have

been supplied with two 24” sections of pipe insulation.

Please install the insulation, according to the illustrations

below, that best meets your requirements.

INSTALLATION INSTRUCTIONS

Typical vertical

piping arrangement

Typical horizontal

piping arrangement

Illustration E (Appearance will vary by model)

Hot water

outlet to

fixtures

Unions

Water Heater

Electrical

Junction Box

Temperature

and Pressure

Relief Valve

Integrated

Electronic Mixing

Valve Shroud (if

Equipped)

Shut-off valve

Conduit to Electrical

Junction Box (use only

copper conductors)

Thermal expansion

tank (Install per

manufacturer’s

instructions, if required.)

Drain Valve Catch Pan

Relief Valve discharge within 6” of

floor and no closer than 2 times the

pipe diameter per local code.

Cold Water Supply

16 49-6000226 Rev. 4

Installation Instructions

TO FILL THE WATER HEATER

WARNING

Risk of Unit Damage - The

tank must be full of water before heater is turned

on. The water heater warranty does not cover

damage or failure resulting from operation with

an empty or partially empty tank.

Make certain the drain valve is completely closed.

Open the shut-off valve in the cold water supply line.

Open each hot water faucet slowly to allow the air to

vent from the water heater and piping.

A steady flow of water from the hot water faucet(s)

indicates a full water heater.

Condensation can form on the tank and fittings when

it is first filled with water. Condensation may also

occur with a heavy water draw and very cold inlet

water temperature.

This condition is not unusual and will disappear once

water is heated. If condition persists, examine fittings

for potential leaks and repair, as required.

NOTICE

Do not mis-wire electrical connections. 240VAC or

208VAC must be applied across L1 and L2 wires as

shown in ‘Water heater junction box’ illustration.

If a 4-conductor wire is supplied to the water heater,

cap the neutral, and connect the remaining wires as

illustrated.

RELIEF VALVE

WARNING

Risk of Unit Damage - The

pressure rating of the relief valve must not

exceed 150 PSI (1.03 MPa), the maximum working

pressure of the water heater as marked on the

rating plate.

A new combination temperature and pressure-relief

valve, complying with the Standard for Relief Valves

and Automatic Gas Shut-Off Devices for Hot Water

Supply Systems, ANSI Z21.22, is supplied and must

remain installed in the opening provided and marked

for this purpose on the water heater. No valve of any

type should be installed between the relief valve and

the tank. Local codes shall govern the installation of

relief valves.

The BTUH rating of the relief valve must not be less

than the input rating of the water heater as indicated

on the rating label located on the front of the heater

(1 watt=3.412 BTUH).

Connect the outlet of the relief valve to a suitable

open drain so that the discharge water cannot contact

live electrical parts or persons and to eliminate

potential water damage.

Piping used should be of a type approved for hot

water distribution. The discharge line must be no

smaller than the outlet of the valve and must pitch

downward from the valve to allow complete drainage

(by gravity) of the relief valve and discharge line. The

end of the discharge line should not be threaded or

concealed and should be protected from freezing.

No valve of any type, restriction or reducer coupling

should be installed in the discharge line.

(Model appearance may vary)

CAUTION

To reduce the risk of excessive pressures and

temperatures in this water heater, install temperature

and pressure protective equipment required by local

codes and no less than a combination temperature

and pressure relief valve certified by a nationally

recognized testing laboratory that maintains periodic

inspection of production of listed equipment or

materials, as meeting the requirements for Relief

Valves and Automatic Gas Shutoff Devices for Hot

Water Supply Systems, ANSI Z21.22. This valve

must be marked with a maximum set pressure not

to exceed the marked maximum working pressure

of the water heater. Install the valve into an opening

provided and marked for this purpose in the water

heater, and orient it or provide tubing so that any

discharge from the valve exits only within 6 inches

above, or at any distance below, the structural floor,

and does not contact any live electrical part. The

discharge opening must not be blocked or reduced in

size under any circumstances.

Relief Valve

Insulation

INSTALLATION INSTRUCTIONS

49-6000226 Rev. 4 17

INSTALLATION INSTRUCTIONS

Installation Instructions

ELECTRICAL CONNECTIONS

A separate branch circuit with copper conductors,

overcurrent protective device and suitable

disconnecting means must be provided by a qualified

electrician.

All wiring must conform to local codes or latest edition

of National Electrical Code ANSI/NFPA 70.

The water heater is completely wired to the junction

box at the top of the water heater. An opening for 1/2”

electrical fitting is provided for field wiring connections.

The voltage requirements and wattage load for the

water heater are specified on the rating label on the

front of the water heater.

The branch circuit wiring should include

either:

1. Metallic conduit or metallic sheathed cable approved

for use as a grounding conductor and installed with

fittings approved for the purpose.

2. Nonmetallic sheathed cable, metallic conduit or

metallic sheathed cable not approved for use

as a ground conductor shall include a separate

conductor for grounding. It should be attached to

the ground terminals of the water heater and the

electrical distribution box.

To connect power to the water heater:

1. Turn the power off.

2. Remove the screw/screws holding the junction box

top cover.

3. Install L1 to L1, L2 to L2 and ground wire onto the

fixed junction box cover, per illustration below.

4. Reconnect all screws attaching the junction box

covers.

WARNING

Risk of fire or electrical shock.

Ensure both junction box covers and ground

screws are securely fastened for proper

grounding.

NOTE: Install electric connections according to local

codes or latest edition of National Electrical Code

ANSI/NFPA 70.

WARNING

Proper ground connection is

essential. The presence of water in the piping

and water heater does not provide sufficient

conduction for a ground. Nonmetallic piping,

dielectric unions, flexible connectors, etc., can

cause the water heater to be electrically isolated.

Do not disconnect factory ground.

The manufacturer’s warranty does not cover any

damage or defect caused by installation, attachment

or use of any type of energy-saving or other

unapproved devices (other than those authorized by

the manufacturer) into, onto or in conjunction with the

water heater. The use of unauthorized energy-saving

devices may shorten the life of the water heater and

may endanger life and property.

The manufacturer disclaims any responsibility for

such loss or injury resulting from the use of such

unauthorized devices.

If local codes require external application of insulation

blanket kits, the manufacturer’s instructions included

with the kit must be carefully followed.

Application of any external insulation, blankets

or water pipe insulation to this water heater will

require careful attention to the following:

• Do not cover the temperature and pressure-relief

valve.

• Do not cover access panels to the heating elements.

• Do not cover the electrical junction box of the water

heater.

• Do not cover the operating or warning labels

attached to the water heater or attempt to relocate

them on the exterior of the insulation blanket.

NOTE: This guide recommends minimum branch

circuit sizing based on the National Electric Code.

Refer to wiring diagrams in this manual for field

wiring connections.

BRANCH CIRCUIT SIZING GUIDE

Total

Water

Heater

Wattage

Recommended Over-

Current Protection

(fuse or circuit breaker

amperage rating)

Copper Wire Size AWG

Basedon N.E.C. Table

310-16 (167°F/75°C.)

@240V 208-240V 208-240V

3,000 20 12

4,000 25 10

4,500 25 10

5,000 30 10

5,500 30 10

6,000 35 8

8,000 45 8

9,000 50 8

10,000 – –

11,000 – –

12,000 – –

Junction

Box Cover

Junction

Box Cover

House

Ground

(Green)

Water Heater Junction Box

L1

(Black)

Factory Ground

L2

(Red)

18 49-6000226 Rev. 4

Troubleshooting

Before you call for service....

Save time and money! Review the chart below first and you may not need to call for service.

CAUTION

For your safety, DO NOT attempt repair of electrical wiring, controls, heating elements or other

safety devices. Refer repairs to qualified service personnel.

Problem Possible Causes What To do

OPERATION AND PERFORMANCE

Not enough or no hot water Water temperature may be set too

low

• See the Water Temperature Adjustment and Water Heater

Capacity sections (see pages 4 and 6). If the product has an integrated mixing

valve, turn capacity setting up to “High” or “X-High” to increase available hot

water capacity.

Cold water inlet temperature may

be colder during the winter months

•

This is normal. The colder inlet water takes longer to heat.

• Consider increasing the set temperature as described in the Water Temperature

Adjustment section or increase capacity setting on models equipped with

electronic mixing valve.

Leaking or open hot water faucets • Make sure all faucets are closed.

Long runs of exposed pipe, or hot

water piping on outside wall

• Insulate piping.

Dip tube damaged • Contact your local installer, plumbing contractor, or previously agreed upon

service agency.

A fuse is blown, circuit breaker

tripped, or electric service to your

home may be interrupted

• Replace fuse or reset circuit breaker.

• Contact the local electric utility.

Inadequate wiring • See the Installation Instructions.

Manual reset high limit (ECO) • See the Safety Controls section, see page 5.

Water Connections to unit reversed • Correct piping connections.

Recirculating System Interference

(if installed)

• Check flow rate is not set too high.

• Insulate piping

Water is too hot Water temperature is set too high • See the Water Temperature Adjustment section.

Electronic Control has failed

• Contact your local installer, plumbing contractor, or previously agreed upon

service agency.

Control Panel

The heater is beeping, the

anode light is on (on some

models), and the display says

F70

The anode rod is approaching end

of life and it is recommended to

replace it in order to continue to

offer protection from corrosion.

• Call for service or follow the instructions on how to replace the anode rod on

page 12. Ensure that the anode depletion sensing anode rod or other GE

Appliances approved anode rod is installed. Installation of an unapproved anode

rod will VOID the warranty.

The heater is beeping and the

display says F41

The anode rod is not connected

properly and the water heater may

not be protected from corrosion.

• Check that the tank is filled completely with water.

• If the tank is full of water and the F41 code persists, contact GE Appliances

service.

• Press anode button to silence alarm.

The heater is beeping and the

screen flashes, F78.

Unit is not receiving 240VAC as

intended.

• Turn off power to water heater (generally at the breaker panel). Then read

Electrical Connections section of the installation Instructions, see page 17, then

contact the installer to verify electrical input to the water heater.

OTHER

Rumbling noise Water conditions in your home

caused a buildup of scale or

mineral deposits on the heating

elements

• Remove and clean the heating elements. This should only be done by a

qualified service person or plumbing contractor.

Squealing/Chirping sound

when drawing hot water

In certain usage conditions, noise

may transmit through plumbing

from the integrated mixing valve.

• Increasing user set point or lowering capacity setting may address this condition

on integrated mixing valve models. Consult a plumbing professional to install a

pressure limiting device, if due to high water pressure.

Intermittent EMV motor noise

on integrated mixing valve

models

A soft motor noise may be heard

during normal operation due to

movement of control valve.

• This noise is normal and does not indicate any issue with product

Water dripping down the

outside of the heater

Hot/Cold water connections or

other parts have loosened

•

Tighten the loose connections. This should only be done by a qualified service

person or plumbing contractor.

Relief valve producing

popping sound or draining

Pressure buildup caused by

thermal expansion to a closed

system

• This is an unacceptable condition and must be corrected. See Thermal

Expansion section on page 14. Do not plug the relief valve outlet. Contact a

plumbing contractor to correct this.

Hot water has a rotten egg or

sulfur smell

Certain water supplies with high

sulfate content will react with

the anode rod that is present in

all water heaters for corrosion

protection of the tank

• The odor can be reduced or eliminated in most water heaters by replacing

the anode rod with less-active material rod. In some cases, an added step of

chlorinating the water heater and all hot water lines may be necessary, contact

your local water professional or plumber for options and instructions.

Go to GEAppliances.com/waterheater for information on purchasing this

replacement anode rod. A qualified servicer or plumber should do this

replacement. Use of a non-GE Appliances approved anode rod, or operating

the water heater without a GE Appliances approved anode rod will VOID the

warranty.

• In certain cases, increasing the tank temperature to 140°F (60°C) can reduce

this odor issue. Reference the Water Temperature Adjustment section of the

Important Safety Information of this manual for procedure and dangers of

scalding water. Installation of temperature limiting valves can be used to reduce

risk of scalding.

TROUBLESHOOTING

49-6000226 Rev. 4 19

TROUBLESHOOTING

Fault Codes

Wiring Diagram

Fault Code Displayed Condition Action

F10 or F12 Lower Heating Element Failure Call Service to replace heating element

F11 or F13 Upper Heating Element Failure Call Service to replace heating Element

F16* Mixing Valve Outlet DC TCO Tripped Call Service to correct issue causing fault

and replace TCO.

F17 Missing jumper wire on non-EMV models Call Service to confirm issue and install

jumper wire plug.

F18*, F63* or F64* Mixing Valve Failure Call service to diagnose and repair

F19 Runaway Heat Source Call Service to repair

F30 Tank Temperature (T1) Failure open/short Call Service to replace sensor

F31 Tank Temperature (T2) Failure open/short Call Service to replace sensor

F32 or F33 Tank Temperature, (T1 or T2) Failure Call Service to replace required sensor

F38* Mixing Valve Outlet Temperature (T6) Failure Call Service to replace required sensor

F39* Mixing Valve Cold Inlet Temperature (T7) Failure Call Service to replace required sensor

F40 Current Sensor Failure Call Service to diagnose and correct

F41# Sensing Anode miswired Confirm wire is connected to sensing anode

terminal. Call Service otherwise.

F44 or F45 Micro Fault Call Service to repair

F70# Anode Depleted Call Service to replace sensing anode (see

anode replacement section in manual).

F71 AC Current Transformer Miswire Call Service to diagnose and repair

F76 Voltage too low Call Service for probable miswire

F77 Stuck Key Failure Call Service to diagnose and repair

F90 E2 module unplugged or damaged Call Service to diagnose and repair

F94 WiFi Board Failure (WiFi icon dark) Call Service to diagnose and repair

* Applies to models with integrated mixing valve

# Applies to models with sensing anode

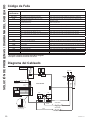

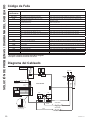

TC01(ECO)

HI LIMIT

(180F)

1

2

3

4

1

11

L1 L2

UPPER ELEMENT

LOWER ELEMENT

5500W 10.5 ё ~22.9 A

5500W 10.5 ё ~22.9 A

M403

M401

•

NO

•

COM

M402

•

NO

•

COM

•

NC

K402

BLACK

RED

BLACK

BLUE

RED

BLUE

K401

••

•

•

•

•

•

•

•

•

•

•

•

•

•

T7

T6

MIXING

VALVE

TCO1

TCO1

AQUA

AQUA

RED

RED

ORANGE

AQUA

BROWN

YELLOW

RED

BLACK

BLACK

BLACK

BLACK

e2 Personality

module

J802

1

11

•

•

•

•

•

•

•

•

•

•

•

J802

J808

YELLOW

PURPLE

J801

•

•

•

•

•

•

T1

T2

BLUE

BLUE

RED

RED

6

1

•

•

ANODE

J807

•

GND

GREEN

RED

•

•

J301

WHITE

BLACK

SENSOR

•

•

J602

RED

WHITE

WIFI

MODULE

•

•

NAVY

BLUE

1

4

1

2

2

1

MAIN BOARD

J403

Non-EMV models: Use

J802 Jumper plug

(if equipped)

(if equipped)

20 49-6000226 Rev. 4

Notes

NOTES

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

dans d''autres langues

- English: GE GE50T12BLM User guide

- español: GE GE50T12BLM Guía del usuario

Documents connexes

-

GE RE2H80R6-1NCWW Le manuel du propriétaire

-

GE GeoSpring GEH50DXSRGA Owner's Manual & Installation Instructions

-

GE GE50T10BAM01 Le manuel du propriétaire

-

GE GE30S08BAM Le manuel du propriétaire

-

GE GE50T12BLM Manuel utilisateur

-

GE GEH50DXSRGA Le manuel du propriétaire

-

GE GEH50DEEDSRB Le manuel du propriétaire

-

GE GEH50DXSRGA Manuel utilisateur

Autres documents

-

GE Appliances GE30T12BLM Le manuel du propriétaire

GE Appliances GE30T12BLM Le manuel du propriétaire

-

Hotpoint-Ariston GL8Ti Le manuel du propriétaire

-

Bradford White RE2H50S10 Manuel utilisateur

-

GE Appliances Standard Electronic and Integrated Electronic Mixing Valve Water Heaters Mode d'emploi

-

Haier QAWF01A Le manuel du propriétaire

-

Camco 8615817 Le manuel du propriétaire

-

HTW TERMO SMART PLUS Manuel utilisateur

-

Weil-McLain AquaLogic Manuel utilisateur

-

HME NEXEO|HDX Crew Communication Platform Guide d'installation