Hangar 9 HAN2990 Le manuel du propriétaire

- Catégorie

- Jouets télécommandés

- Taper

- Le manuel du propriétaire

P-47D Thunderbolt 20cc

Instruction Manual

Bedienungsanleitung

Manuel d’utilisation

Manuale di Istruzioni

2

SPECIFICATIONS • SPEZIFIKATIONEN • SPÉCIFICATIONS • SPECIFICHE

67 in (1700 mm)

825 sq in (53.2 dm2) Total/Totale

58 in (1473 mm)

11–13 lbs (5–6 kg)

2-Stroke Gas: 20cc, 4-Stroke gas/petrol: 20cc

2-Takt Benziner: 20cc, 4-Takt Benzin: 20 cc

2 temps Essence: 20cc, 4 temps essence: 20cc

2-Tempi Gas: 20cc, 4 tempi benzina: 20 cc

Electric Power: Power 60, 470Kv Brushless

Elektro Antrieb Power: Power 60, 470Kv Brushless

Moteur électrique (EP): Power 60, 470Kv Brushless

Motore elettrico: Power 60, 470Kv Brushless

7-channel (or greater) with 8 servos

7-Kanal (oder größer) mit 8-Servos

7 voies (ou plus) avec 8 servos

a 7 canali (o più) con 8 servo

Spinner: 1-inch (Not Included)

Spinner: 25mm (Nicht enthalten)

Cône: 25mm (Non fourni)

Ogiva dell’elica: 25mm (Non inclusa)

6

1

/

4

inches (159mm)

A

H

K

S

R

L

T

O

N

Q

F

B

C

D

E

M

P

J

I

U

G

3

P-47D Thunderbolt 20cc

Part # English Deutsch Français Italiano

REPLACEMENT PARTS • ERSATZTEILE • PIÈCES DE RECHANGE • PEZZI DI RICAMBIO

A

HAN299001 Fuselage with Hatch Rumpf mit Haube Fuselage avec capot Fusoliera con portello

B

HAN299002 Left Wing with Aileron and Flap Tragfl äche Links mit Querruder und Klappe Aile gauche avec aileron et volet Semiala sinistra con alettone e fl ap

C

HAN299003 Right Wing with Aileron and Flap Tragfl äche Rechts mit Querruder und Klappe Aile droite avec aileron et volet Semiala destra con alettone e fl ap

D

HAN299004 Stabilizer with Elevator Höhenruderset Set Plan horizontal et Gouverne de profondeur Set stabilizzatore ed elevatore

E

HAN299005 Rudder Seitenleitwerk Gouverne de direction Timone

F

HAN299006 Cowling Motorhaube Capot moteur Carenatura

G

HAN299007 Top Hatch Obere Abdeckung Trappe supérieure Portello superiore

H

HAN299008 Canopy Kabinenhaube Verrière Calotta

I

HAN299009 Pilot Lackierter Pilot Pilote peint Pilota verniciato

J

HAN299010 Pushrod Set Gestänge / Anlenkungen Set Jeu de tringleries Set dell’asta di spinta

K

HAN299012 Main Wheels Fahrwerksräder Set Paire de roues principales Set ruota principale

L HAN299013 Decal Set (3) Dekorbogen (3) Planche de décoration (3) Set di decalcomanie (3)

M

HAN299014 Tailwheel Spornrad Roue de queue Ruotino di coda

N

HAN299015 Fixed Landing Gear Starres Fahrwerk Train d’atterrissage fi xe Set del carrello di atterraggio fi sso

O

HAN299016 Main Landing Gear Struts Hauptfahrwerk-Streben Jambes du train d’atterrissage principal Gambe del carrello di atterraggio principale

P HAN299017 Wing Tube Tragfl ächenverbinder Clé d’aile Tubo dell’ala

Q

HAN299018 Fuel Tank Kraftstofftank Réservoir de carburant Serbatoio del carburante

R

HAN299019 Engine/Motor Mount Motor-/Motorhalterung Support du moteur Supporto motore

S

HAN299020 Radiators and Exhausts Kühler und Auspuffe Radiateurs et échappements Radiatori e scarichi

T

HAN299021 Gear Door Set Fahrwerkklappen-Satz Jeu de trappes de train Set portello del carrello

U

HAN299022 Scale Detail Parts Maßstabsgetreue Details Pièces de détails à l’échelle Dettagli in scala

SMALL PARTS (NOT SHOWN) • KLEINTEILE (NICHT ABGEBILDET) • PETITES PIÈCES (NON REPRÉSENTÉES) • PARTI DI PICCOLE DIMENSIONI (NON MOSTRATE)

HAN299011 Hardware Set Kleinteile Set Sachet de visserie Set dei pezzi

REQUIRED RADIO EQUIPMENT • ERFORDERLICHE RC AUSRÜSTUNG • ÉQUIPEMENT RADIO REQUIS • APPARECCHIATURE RADIO NECESSARIE

SPMA3000 (3) Heavy-Duty Servo Extension 3-inch Servokabelverlängerung 75 mm (3 inch) Rallonge de servo, 75 mm Estensione servo 3 pollici

SPMA3001 (2) Heavy-Duty Servo Extension 6-inch Servokabelverlängerung 150 mm (6 inch) Rallonge de servo, 151 mm Estensione servo 6 pollici

SPMA3002 (2) Heavy-Duty Servo Extension 9-inch Servokabelverlängerung 230 mm (9 inch) Rallonge de servo, 230 mm Estensione servo 9 pollici

SPMA3003 (2) Heavy-Duty Servo Extension 12-inch Servokabelverlängerung 300 mm (12 inch) Rallonge de servo, 300 mm Estensione servo 12 pollici

SPMA3008 Heavy-Duty Y-Harness 6-inch Heavy Duty Y-Kabelbaum, 152mm (6Zoll) Harnais résistant en Y de 15 cm (6 po) Prolunga a Y Heavy Duty, 15 cm

SPMAR9350 AR9350 9 Channel AS3X Receiver AR9350 9-Kanal AS3X-Empfänger Récepteur AS3X 9 canaux AR9350 Ricevitore AS3X a 9 canali AR9350

4

Part # English Deutsch Français Italiano

2-STROKE GAS • 2-TAKT BENZINER • 2 TEMPS ESSENCE • 2-TEMPI A BENZINA

APC15080 Competition Propeller, 15 x 8 Competition Propeller, 15 x 8 Hélice 15 x 8 Competition Elica da competizione, 15 x 8

DUB799 Tygon Gas Tubing, 3-foot Medium Tygon-Gasrohre, 1 m (3 Fuß) m Durchschnitt Tube à essence Tygon, 91,4 cm (3 pi) moyen Tubo per carburante Tygon, 3 piedi, medio

EVOA112 (2) Evolution 3 Wire Ignition/Receiver Switch Evolution Zündschalter Interrupteur Evolution 3 fi ls Allumage/RX

Evolution, interruttore a 3 fi li accensione/

ricevitore

EVOE20GX2 20GX Gas Engine with Pumped Carb 20GX 20cc (1.20 cu. in.) Benzinmotor Moteur essence 20GX 20cc Motore a benzina 20GX 20cc (1.20 cu. in.)

HAN116 Fuel Filler with “T” and Overfl ow Fitting Hangar 9 Tanknippel mit T Stück u. Überlauf Fitting Point de remplissage de carburant avec coupleur en T Bocchettone di riempimento carburante con

HAN279012 1-inch Spinner Nut 5/16 x 24: P-47D-1 1Zoll Spinner-Mutter, 5/16 x 24: P-47D-1 Écrou de cône de 2,54 cm (1 po), 5/16 x 24: P-47D-1 Dado dell’ogiva da 2,54 mm 5/16 x 24: P-47D-1

SPMB2000LPRX 2000mAh 2S 7.4V LiPo Receiver Battery LiPo-Empfängerakku (7,4 V / 2000 mAh) Batterie Li-Po de récepteur 7,4 V 2000 mAh Batteria per ricevitore da 7,4 V Li-Po, 2.000 mAh

SPMB4000LPRX 4000mAh 2S 7.4V LiPo Receiver Battery LiPo-Empfängerakku (7,4 V / 4000 mAh) Batterie Li-Po de récepteur 7,4 V 4000 mAh Batteria per ricevitore da 7,4 V Li-Po, 4.000 mAh

SPMSA6110 (8) A6110 HV Standard Servo A6110 HV Standard Servo Servo standard A6110 HV Servo standard A6110 HV

ELECTRIC POWER • ELEKTROANTRIEB • MOTEUR ELECTRIQUE (EP) • MOTORE ELETTRICO

EFLM4060B Power 60 BL Outrunner Motor, 470Kv Bürstenloser Außenläufer-Motor Leistung 60, 470Kv

Moteur à cage tournante sans balais

Power 60 de 470Kv

Motore brushless a cassa rotante

Power 60, 470Kv

CSE010009700 Talon 90-Amp 25V BL ESC W/20amp BEC

Talon 90 A 25 V bürstenloser

Geschwindigkeitsregler mit 20 A BEC

Variateur ESC Talon 90 A 25 V BL avec BEC 20 A ESC BL Talon 90-Amp 25 V con BEC 20amp

EFLB50006S50 5000mAh 6S 22.2V 50C LiPo, 10AWG: EC5 5000 mA 6S 22,2 V 30C LiPo-Akku,10 AWG EC5

Batterie Li-Po 6S 22,2V 5000mA 30C, 10AWG prise

EC5

Batteria LiPo 30C 22,2V 6S 5000 mAh,10AWG

EC5

KXSB0029

22.2V 7000mAh 30C 6S LiPo Battery,

10AWG: EC5 (Optional)

22,2V 7000mAh 30C 6S LiPo-Akku,

10AWG: EC5 (Optional)

Batterie LiPo 30 C 6 S, 22,2 V, 7000 mAh,

10 AWG: EC5 (Facultatif)

Batteria 7000 mAh 6S 22,2 V 30C LiPo,

10 AWG: EC5 (opzionale)

APC16080E Electric Propeller, 16 x 8E Elektro Propeller, 16 x 8E Hélice électrique, 16 x 8E Elica elettrica sottile, 16 x 8E

EFLM1934 Propeller Adapter, 8mm Shaft: Power 46/60 Propelleradapter: Power 46/52/60 Adaptateur d’hélice : 46/52/60 Adattatore dell’elica: Power 46/52/60

HAN279011 1-inch Spinner Nut 8 x 1.25: P-47D-1 1-Zoll Spinner-Mutter, 8 x 1,25: P-47D-1 Écrou de cône de 2,54 cm (1 po), 8 x 1,25: P-47D-1 Dado dell’ogiva da 2,54 mm 8 x 1,25: P-47D-1

EFLAEC506 EC5 Extension Lead with 6-inch Wire, 10Awg EC5 Verlängerungsleitung mit 6-Zoll-Kabel, 10Awg Rallonge EC5 avec fi l de 15 cm (6 po), 10 AWG

Cavo di prolunga EC5 con fi lo da 15,24 cm, 10

AWG

SPMSA6110 (7) A6110 HV Standard Servo A6110 HV Standard Servo Servo standard A6110 HV Servo standard A6110 HV

OPTIONAL ELECTRIC RETRACTS • OPTIONALES ELEKTRISCHES EINZIEHFAHRWERK • TRAINS RÉTRACTABLES ÉLECTRIQUES OPTIONNELS • ELEMENTI RETRATTILI ELETTRICI OPZIONALI

EFLG510

60-120 85-degree Strut Ready

Main Electric Retract

60-120 85-Grad-Hauptfahrwerkstrebe, elektrisch

einziehbar

Système de rentrée électrique principal à 85 degrés

60-120, prêt à être monté sur jambe

Elemento retrattile elettrico principale 60-120,

85 gradi, pronto da montare

EFLG510P47 60-120 P-47 Main Strut Set 60-120 P-47 Hauptfahrwerk-Strebensatz Ensemble de jambes principal P-47, 60-120 Set gamba principale 60-120 P-47

SPMA3001 (2) Heavy-Duty Servo Extension 6-inch Servokabelverlängerung 150 mm (6 inch) Rallonge de servo, 151 mm Estensione servo 6 pollici

REQUIRED ADHESIVES • ERFORDERLICHE KLEBSTOFFE • TYPES DE COLLES • ADESIVI NECESSARI

DLMAD44 Roket Rapid CA 5-10 sec: 20g Roket Rapid CA 5-10 s: 20g Colle cyano Roket Rapid 5-10 sec: 20g Colla cianoacrilica Roket Rapid 5-10 sec: 20 g

DLMAD45 Roket Max CA 10-20 sec: 20g Roket Max CA 10-20 s: 20g Colle cyano Roket Max 10-20 sec: 20g Colla cianoacrilica Roket Max 10-20 sec: 20 g

PAAPT715 CA Accelerator Sekundenkleber (CA) Aktivator Accélérateur de colle CA Accelerante colla CA

PAAPT37 5-Minute Epoxy 5 Minuten Epoxy Époxy 5 minutes Colla epossidica 5 minuti

PAAPT35 15-Minute Epoxy 15 Minuten Epoxy Époxy 15 minutes Colla epossidica 15 minuti

PAAPT39 30-Minute Epoxy 30 Minuten Epoxy Époxy 30 minutes Colla epossidica 30 minuti

PAAPT42 Threadlock Schraubensicherungslack Frein-fi let Frenafi letti

DLMAD12 R/C Modeller Canopy Glue: 4 oz R/C Modeller Kanzelkleber: 113,4g (4 oz) Colle à verrière R/C Modeller: 113g Colla per capottine R/C Modeller: 4 oz

5

P-47D Thunderbolt 20cc

Part # English Deutsch Français Italiano

REQUIRED TOOLS • BENÖTIGTES WERKZEUG • OUTILS REQUIS • ATTREZZI NECESSARI

Box wrench: 1/2-inch Ringschlüssel: 1/2-inch Clé hexagonale: 1/2-inch Chiave esagonale: 1/2-inch

Drill Bohrer Mini-perceuse Trapano

Drill bit: 1/16-inch, 5/64-inch, 1/8-inch

5/32-inch, 3/16-inch

Bohrer: 1,5mm, 2mm, 3mm, 4mm, 4,5mm Forêt : 1,5mm, 2mm, 3mm, 4mm, 4,5mm

Punte per trapano: 1,5mm, 2mm, 3mm, 4mm,

4,5mm

Felt-tipped pen Faserstift Feutre fi n effaçable Pennarello

Epoxy brush Pinsel Pinceau Epoxy Spazzole epoxy

Flat fi le Flachfeile Lime plate Lima piatta

Hemostats Klemme Pince Hemostat Pinzetta

Hex wrench: 3/32-inch, 1.5mm, 2mm, 2.5mm,

3mm, 4mm

Inbusschlüssel: 3/32-inch, 1,5mm, 2mm, 2,5mm,

3mm, 4mm

Tournevis hexagonal: 3/32-inch, 1,5mm, 2mm, 2,5mm,

3mm, 4mm

Chiave esag.: 3/32-inch, 1,5mm, 2mm, 2,5mm,

3mm, 4mm

Hobby knife with #11 blade Hobbymesser mit # 11 Klinge Couteau : Lame numéro 11 Taglierino: #11 lama

Isopropyl alcohol Isopropyl Alkohol Alcool isopropylique Alcol isopropilico

Low-tack tape Kreppband Adhésif de masquage Nastro a bassa aderenza

Needle nose pliers Spitzzange Pince fi ne Pinze a becco stretto

Nut driver: 1/4-inch, 4mm, 5.5mm Steckschlüssel. 1/4-inch, 11/32-inch Clés à douilles : 1/4-inch, 11/32 pouce Chiave per dadi: 1/4-inch, 11/32-inch

Paper towels Papiertücher Papier absorbant Asciugamani di carta

Pencil Stift Crayon à papier Matita

Phillips screwdriver: #1 Phillips Schraubendreher: #1 Tournevis cruciforme: #1 Cacciavite a croce: #1

Pin vise Handbohrer Porte forets Trapano manuale

Pliers Zange Pince Pinze

Ruler Lineal Réglet Righello

Sandpaper Schleifpapier Papier de verre Carta vetrata

Scissors Schere Ciseaux Forbici

Side cutters Seitenschneider Pince coupante Lama laterale

Square Geodreieck Équerre Squadra

Tap and drill set, English Gewindeschneider und Bohrerset Taraud et foret Set punte e maschi, Inglese

Tap Handle Halter für Gewindeschneider Épingles Impugnatura per maschiare

T-pins T- Nadeln Epingles Spilli a T

Toothpicks Zahnstocher Cure dents Stuzzicadenti

OPTIONAL ITEMS • OPTIONALE TEILE • ÉLÉMENTS OPTIONNELS • ARTICOLI OPZIONALI

EVOA100 Optical Ignition Kill Switch Optischer Zünd-Notausschalter Coupe-circuit optique d’allumage Sezionatore ottico accensione

SPMA3008 (2) Heavy-Duty Y-Harness 6-inch Heavy Duty Y-Kabelbaum, 152mm (6Zoll) Harnais résistant en Y de 15 cm (6 po) Prolunga a Y Heavy Duty, 15 cm

SPMA3054 Servo Connector Clips (25) Servosteckerklemmen (25) Attaches de connexion du servo (25) Morsetti servocomando (25)

6

NOTICE

All instructions, warranties and other collateral documents are subject to change at the sole discretion of Horizon

Hobby, LLC. For up-to-date product literature, visit horizonhobby.com and click on the support tab for this product.

The following terms are used throughout the product literature to indicate various levels of potential harm when

operating this product:

Meaning of Special Language

WARNING: Procedures, which if not properly followed, create the probability of property damage, collateral damage,

and serious injury OR create a high probability of superfi cial injury.

CAUTION: Procedures, which if not properly followed, create the probability of physical property damage AND a

possibility of serious injury.

NOTICE: Procedures, which if not properly followed, create a possibility of physical property damage AND a little or

no possibility of injury.

WARNING: Read the ENTIRE instruction manual to become familiar with the features of the product before operating.

Failure to operate the product correctly can result in damage to the product, personal property and cause serious

injury.

This is a sophisticated hobby product. It must be operated with caution and common sense and requires some basic

mechanical ability. Failure to operate this Product in a safe and responsible manner could result in injury or damage

to the product or other property. This product is not intended for use by children without direct adult supervision. Do

not attempt disassembly, use with incompatible components or augment product in any way without the approval

of Horizon Hobby, LLC. This manual contains instructions for safety, operation and maintenance. It is essential to

read and follow all the instructions and warnings in the manual, prior to assembly, setup or use, in order to operate

correctly and avoid damage or serious injury.

AGE RECOMMENDATION: NOT FOR CHILDREN UNDER 14 YEARS. THIS IS NOT A TOY.

USING THE MANUAL

This manual is divided into sections to help make assembly easier to understand.

SAFETY WARNINGS AND PRECAUTIONS

Read and follow all instructions and safety precautions before use. Improper use can result in fi re, serious injury and

damage to property.

Components

Use only with compatible components. Should any compatibility questions exist, please refer to the product

instructions, component instructions or contact the appropriate Horizon Hobby offi ce.

Flight

Fly only in open areas to ensure safety. It is recommended fl ying be done at radio control fl ying fi elds. Consult local

ordinances before choosing a fl ying location.

Propeller

Keep loose items that can become entangled in the propeller away from the prop. This includes loose clothing or other

objects such as pencils and screwdrivers. Keep your hands away from the propeller as injury can occur.

Batteries

Always follow the manufacturer’s instructions when using and disposing of any batteries. Mishandling of Li-Po

batteries can result in fi re causing serious injury and damage.

Small Parts

This kit includes small parts and should not be left unattended near children as choking and serious injury could result.

SAFE OPERATING RECOMMENDATIONS

• Inspect your model before every fl ight to ensure it is airworthy.

• Be aware of any other radio frequency user who may present an interference problem.

• Always be courteous and respectful of other users in your selected fl ight area.

• Choose an area clear of obstacles and large enough to safely accomodate your fl ying activity.

• Make sure this area is clear of friends and spectators prior to launching your aircraft.

• Be aware of other activities in the vicinity of your fl ight path that could cause potential confl ict.

• Carefully plan your fl ight path prior to launch.

• Abide by any and all established AMA National Model Aircraft Safety Code.

BEFORE STARTING ASSEMBLY

• Remove parts from bag.

• Inspect fuselage, wing panels, rudder and stabilizer for damage.

• If you fi nd damaged or missing parts, contact your place of purchase.

• Charge transmitter and receiver batteries.

• Center trims and sticks on your transmitter.

• For a computer radio, create a model memory for this particular model.

• Bind your transmitter and receiver, using your radio system’s instructions.

IMPORTANT: Rebind the radio system once all control throws are set. This will keep the servos from moving to

their endpoints until the transmitter and receiver connect. It will also guarantee the servo reversal settings are

saved in the radio system.

FAA INFORMATION

If you own this product, you may be required to register with the FAA.

For up-to-date information on how to register with the FAA, please visit https://registermyuas.faa.gov/.

For additional assistance on regulations and guidance on UAS usage, visit knowbeforeyoufl y.org/.

BUILDING PRECAUTIONS

During assembly, we recommend resting the parts on a soft surface such as a soft towel to help prevent denting the

sheeting.

7

P-47D Thunderbolt 20cc

Propeller

Halten Sie lose Gegenstände die sich im Propeller verfangen können weg vom Propeller. Dieses gilt auch für Kleidung

oder andere Objekte wie zum Beispiel Stifte oder Schraubendreher.

Halten Sie ihre Hände weg vom Propeller, es besteht akute Verletzungsgefahr.

Akkus

Folgen Sie immer den Herstelleranweisungen bei dem Gebrauch oder Entsorgung von Akkus. Falsche Behandlung von

LiPo Akkus kann zu Feuer mit Körperverletzungen und Sachbeschädigung führen.

Kleinteile

Dieser Baukasten beinhaltet Kleinteile und darf nicht unbeobachtet in der Nähe von Kindern gelassen werden, da die

Teile verschluckt werden könnten mit ernsthaften Verletzung zur Folge.

EMPFEHLUNGEN ZUM SICHEREN BETRIEB

• Überprüfen Sie zur Flugtauglichkeit ihr Modell vor jedem Flug.

• Beachten Sie andere Piloten deren Sendefrequenzen ihre Frequenz stören könnte.

• Begegnen Sie anderen Piloten in ihrem Fluggebiet immer höfl ich und respektvoll.

• Wählen Sie ein Fluggebiet, dass frei von Hindernissen und groß genug ist.

• Stellen Sie vor dem Start sicher, dass die Fläche frei von Freunden und Zuschauern ist.

• Beobachten Sie den Luftraum und andere Flugzeuge/Objekte die ihren Flugweg kreuzen und zu einem Konfl ikt

führen könnten.

• Planen Sie sorgfältig ihren Flugweg vor dem Start.

VOR DEM ZUSAMMENBAU

• Entnehmen Sie zur Überprüfung jedes Teil der Verpackung.

• Überprüfen Sie den Rumpf, Tragfl ächen, Seiten- und Höhenruder auf Beschädigung.

• Sollten Sie beschädigte oder fehlende Teile feststellen, kontaktieren Sie bitte den Verkäufer.

• Laden des Senders und Empfängers.

• Zentrieren der Trimmungen und Sticks auf dem Sender.

• Sollten Sie einen Computersender verwenden, resetten Sie einen Speicherplatz und benennen ihn nach dem Modell.

• Sender und Empfänger jetzt nach den Bindeanweisung des Herstellers zu binden.

WICHTIG: Wir empfehlen dringend nachdem alle Einstellungen vorgenommen worden sind, das Modell neu zu binden.

Dieses verhindert, dass die Servos in die Endanschläge laufen bevor sich Sender und Empfänger verbunden haben. Es

garantiert auch, dass die Servoreverseeinstellungen in der RC Anlage gesichert sind.

HINWEISE ZUM BAU

Während des Zusammenbaus empfehlen wird, dass die Teile auf einer weichen Oberfl äche, wie einem Handtuch,

abgelegt werden, um ein Eindrücken der Bleche zu verhindern.

HINWEIS

Alle Anweisungen, Garantien und anderen zugehörigen Dokumente können im eigenen Ermessen von Horizon Hobby,

LLC. jederzeit geändert werden Die aktuelle Produktliteratur fi nden Sie auf horizonhobby.com unter der Registerkarte

„Support“ für das betreffende Produkt.

Spezielle Bedeutungen

Die folgenden Begriffe werden in der gesamten Produktliteratur verwendet, um auf unterschiedlich hohe

Gefahrenrisiken beim Betrieb dieses Produkts hinzuweisen:

WARNUNG: Wenn diese Verfahren nicht korrekt befolgt werden, ergeben sich wahrscheinlich Sachschäden,

Kollateralschäden und schwere Verletzungen ODER mit hoher Wahrscheinlichkeit oberfl ächliche Verletzungen.

ACHTUNG: Wenn diese Verfahren nicht korrekt befolgt werden, ergeben sich wahrscheinlich Sachschäden UND die

Gefahr von schweren Verletzungen.

HINWEIS: Wenn diese Verfahren nicht korrekt befolgt werden, können sich möglicherweise Sachschäden UND geringe

oder keine Gefahr von Verletzungen ergeben.

WARNUNG: Lesen Sie die GESAMTE Bedienungsanleitung, um sich vor dem Betrieb mit den Produktfunktionen

vertraut zu machen. Wird das Produkt nicht korrekt betrieben, kann dies zu Schäden am Produkt oder persönlichem

Eigentum führen oder schwere Verletzungen verursachen.

Dies ist ein hochentwickeltes Hobby-Produkt. Es muss mit Vorsicht und gesundem Menschenverstand betrieben

werden und benötigt gewisse mechanische Grundfähigkeiten. Wird dieses Produkt nicht auf eine sichere und

verantwortungsvolle Weise betrieben, kann dies zu Verletzungen oder Schäden am Produkt oder anderen Sachwerten

führen. Dieses Produkt eignet sich nicht für die Verwendung durch Kinder ohne direkte Überwachung eines

Erwachsenen. Verwenden Sie das Produkt nicht mit inkompatiblen Komponenten oder verändern es in jedweder Art

ausserhalb der von Horizon Hobby, LLC vorgegebenen Anweisungen. Diese Bedienungsanleitung enthält Anweisungen

für Sicherheit, Betrieb und Wartung. Es ist unbedingt notwendig, vor Zusammenbau, Einrichtung oder Verwendung

alle Anweisungen und Warnhinweise im Handbuch zu lesen und zu befolgen, damit es bestimmungsgemäß betrieben

werden kann und Schäden oder schwere Verletzungen vermieden werden.

NICHT GEEIGNET FÜR KINDER UNTER 14 JAHREN. DIES IST KEIN SPIELZEUG.

ÜBER DIESE ANLEITUNG

Diese Anleitung ist zur Vereinfachung des Zusammenbaues in Sektionen unterteilt.

WARNUNGEN UND SICHERHEITS-VORKEHRUNGEN

Bitte lesen und befolgen Sie alle Anweisungen und Sicherheitsvorkehrungen vor dem Gebrauch. Falscher, nicht

sachgemäßer Gebrauch kann Feuer, ernsthafte Verletzungen und Sachbeschädigungen zur Folge haben.

Komponenten

Verwenden Sie mit dem Produkt nur kompatible Komponenten. Sollten Fragen zur Kompatibilität auftreten, lesen Sie

bitte die Produkt- oder Bedienungsanweisung oder kontaktieren den Service von Horizon Hobby.

Fliegen

Fliegen Sie um Sicherheit garantieren zu können, nur in weiten offenen Gegenden. Wir empfehlen hier den Betrieb auf

zugelassenen Modellfl ugplätzen. Bitte beachten Sie lokale Vorschriften und Gesetze, bevor Sie einen Platz zum Fliegen

wählen.

8

L’hélice

Gardez éloignés tous les éléments qui pourraient être attrapés par l’hélice. Cela inclut les vêtements larges ou les

objets comme des outils par exemple. Gardez toujours vos mains à distance pour éviter tout cas de blessures.

Les batteries

Suivez toujours les instructions du fabricant de vos batteries. Une mauvaise manipulation d’une batterie Li-Po peut

entraîner un incendie causant de graves dégâts matériels et des blessures corporelles.

Petites pièces

Ce kit contient des petites pièces qui ne doivent pas être laissées à la portée des enfants, ces pièces sont dangereuses

pour eux et peuvent entraîner de graves blessures.

CONSIGNES DE SÉCURITÉ CONCERNANT L’UTILISATION

• Inspectez votre modèle avant chaque vol.

• Surveillez les fréquences utilisées à proximité.

• Soyez toujours courtois et respectueux des autres utilisateurs de la zone de vol.

• Choisissez une zone dégagée de tout obstacle et suffi samment grande pour voler en toute sécurité.

• Contrôlez que la zone est libre de spectateurs avant de lancer votre modèle.

• Soyez conscient des autres activités aux alentours de votre vol, risque de confl it potentiel.

• Planifi ez votre vol avant de le commencer.

AVANT DE COMMENCER L’ASSEMBLAGE

• Retirez toutes les pièces des sachets pour les inspecter.

• Inspectez soigneusement le fuselage, les ailes et les empennages.

• Si un élément est endommagé, contactez votre revendeur.

• ll est recommandé de préparer tous les éléments du système de la radio.

• Cela inclut la charge des batteries comme la mise au neutre des trims et des manches de votre émetteur.

• Si vous utilisez une radio programmable, sélectionnez une mémoire libre afi n d’y enregistrer les paramètres de ce

modèle.

• Nous vous recommandons d’affecter maintenant le récepteur à l’émetteur en suivant les instructions fournies avec

votre radio.

IMPORTANT: Il est hautement recommandé de ré-affecter le système une fois que les courses seront réglées. Cela

empêchera les servos d’aller en butée lors de la connexion du système. Cela garantit également que la direction des

servos est enregistrée dans l’émetteur.

PRÉCAUTIONS D’ASSEMBLAGE

Lors de l’assemblage de votre modèle, nous vous recommandons de poser les pièces sur une surface douce comme

une serviette douce pour éviter d’abîmer l’entoilage.

REMARQUE

La totalité des instructions, garanties et autres documents est sujette à modifi cation à la seule discrétion d’Horizon

Hobby, LLC. Pour obtenir la documentation àjour, rendez-vous sur le site horizonhobby.com et cliquez sur l’onglet de

support de ce produit.

Signifi cation de certains termes spécifi ques

Les termes suivants sont utilisés dans l’ensemble du manuel pour indiquer différents niveaux de danger lors de

l’utilisation de ce produit:

AVERTISSEMENT: Procédures qui, si elles ne sont pas suivies correctement, peuvent entraîner des dégâts matériels

et des blessures graves OU engendrer une probabilité élevée de blessure superfi cielle.

ATTENTION: Procédures qui, si elles ne sont pas suivies correctement, peuvent entraîner des dégâts matériels ET des

blessures graves.

REMARQUE: Procédures qui, si elles ne sont pas suivies correctement, peuvent entraîner des dégâts matériels ET

éventuellement un faible risque de blessures.

AVERTISSEMENT: Lisez la TOTALITÉ du manuel d’utilisation afi n de vous familiariser avec les caractéristiques du

produit avant de le faire fonctionner. Une utilisation incorrecte du produit peut entraîner sa détérioration, ainsi que des

risques de dégâts matériels, voire de blessures graves.

Ceci est un produit de loisirs sophistiqué. Il doit être manipulé avec prudence et bon sens et requiert des aptitudes

de base en mécanique. Toute utilisation irresponsable de ce produit ne respectant pas les principes de sécurité peut

provoquer des blessures, entraîner des dégâts matériels et endommager le produit. Ce produit n’est pas destiné à

être utilisé par des enfants sans la surveillance directe d’un adulte. N’essayez pas de modifi er ou d’utiliser ce produit

avec des composants incompatibles hors des instructions fournies par Horizon Hobby, LLC. Ce manuel comporte des

instructions relatives à la sécurité, au fonctionnement et à l’entretien. Il est capital de lire et de respecter la totalité

des instructions et avertissements du manuel avant l’assemblage, le réglage et l’utilisation, ceci afi n de manipuler

correctement l’appareil et d’éviter tout dégât matériel ou toute blessure grave.

14 ANS ET PLUS. CECI N’EST PAS UN JOUET.

UTILISATION DU MANUEL

Ce manuel est divisé en sections pour vous aider à comprendre plus facilement l’assemblage.

AVERTISSEMENTS RELATIFS À LA SÉCURITÉ

Lisez et suivez toutes les instructions relatives à la sécurité avant utilisation. Une utilisation inappropriée peut entraîner

un incendie, de graves blessures et des dégâts matériels.

Composants

Utilisez uniquement des composants compatibles. Si vous avez des questions concernant la compatibilité, référez-vous

à ce manuel ou contactez le service technique Horizon Hobby.

Le vol

Volez uniquement dans des zones dégagées pour un maximum de sécurité. Il est recommandé d’utiliser les pistes des

clubs d’aéromodélisme. Consultez votre mairie pour connaître les sites autorisés.

9

P-47D Thunderbolt 20cc

AVVISO

Tutte le istruzioni, le garanzie e gli altri documenti pertinenti sono soggetti a cambiamenti a totale discrezione di

Horizon Hobby, LLC. Per una documentazione aggiornata sul prodotto, visitare il sito www.horizonhobby.com e fare

clic sulla sezione Support per questo prodotto.

Signifi cato dei termini particolari

In tutta la documentazione relativa al prodotto sono utilizzati iseguenti termini per indicare vari livelli di potenziale

pericolo durante il funzionamento:

AVVERTENZA: Procedure che, se non debitamente seguite, espongono alla possibilità di danni alla proprietà fi sica

opossono omportare un’elevata possibilità di provocare ferite superfi ciali. Ulteriori precauzioni per la sicurezza e

avvertenze.

ATTENZIONE: Procedure che, se non sono seguite correttamente, possono creare danni materiali E possibili gravi

lesioni.

AVVISO: Procedure che, se non sono seguite correttamente, possono creare danni materiali E nessuna oscarsa

possibilità di lesioni.

AVVERTENZA: Leggere TUTTO il manuale di istruzioni e prendere familiarità con le caratteristiche del prodotto, prima

di farlo funzionare. Un utilizzo scorretto del prodotto può causare danni al prodotto stesso, alle persone oalle cose,

provocando gravi lesioni.

Questo è un prodotto di hobbistica sofi sticato e NON un giocattolo. È necessario farlo funzionare con cautela e

responsabilità e avere conoscenze basilari di meccanica. Se questo prodotto non è utilizzato in maniera sicura e

responsabile potrebbero verifi carsi lesioni odanni al prodotto stesso oad altre proprietà. Non è un prodotto adatto

aessere utilizzato dai bambini senza la diretta supervisione di un adulto. Non usare componenti non compatibili

o alterare il prodotto in nessuna maniera al di fuori delle istruzioni fornite da Horizon Hobby, LLC. Questo manuale

contiene le istruzioni per un funzionamento e una manutenzione sicuri. È fondamentale leggere e seguire tutte le

istruzioni e le avvertenze del manuale prima di montare, confi gurare ofar funzionare il Prodotto, al fi ne di utilizzarlo

correttamente e di evitare danni olesioni gravi.

MINIMO 14 ANNI. NON È UN GIOCATTOLO.

COME USARE IL MANUALE

Questo manuale è diviso in sezioni per rendere più facile la comprensione del montaggio.

AVVERTIMENTI E PRECAUZIONI PER LA SICUREZZA

Prima dell’uso leggere attentamente tutte le istruzioni e le precauzioni per la sicurezza. In caso contrario si potrebbero

procurare incendi, danni o ferite.

Componenti

Usare solo componenti compatibili. Se ci fossero dubbi riguardo alla compatibilità, è opportuno far riferimento alle

istruzioni relative al prodotto o ai componenti oppure rivolgersi al reparto Horizon Hobby di competenza.

Volo

Per sicurezza volare solo in aree molto ampie. Meglio se in campi volo autorizzati per modellismo. Consultare le

ordinanze locali prima di scegliere luogo dove volare.

Elica

Tenere gli oggetti liberi (vestiti, penne, cacciaviti, ecc.) lontano dall’elica, prima che vi restino impigliati. Bisogna fare

attenzione anche con le mani perché c’è il rischio di ferirsi anche gravemente.

Batterie

Quando si maneggiano o si utilizzano le batterie, bisogna attenersi alle istruzioni del costruttore; il rischio è di procurare

incendi, specialmente con le batterie LiPo, con danni e ferite serie.

Piccole parti

Questo kit comprende delle parti di piccole dimensioni e non lo si può lasciare incustodito se c’è la presenza di bambini

che li possono inghiottire e rimanere soffocati o intossicati.

RACCOMANDAZIONI PER OPERARE IN SICUREZZA

• Controllare attentamente il modello prima di ogni volo per accertarsi che sia idoneo.

• Essere consapevoli che un altro utente della frequenza in uso, potrebbe procurare delle interferenze.

• Essere sempre cortesi e rispettosi nei confronti degli altri utilizzatori dell’area in cui ci si trova.

• Scegliere un’area libera da ostacoli e abbastanza ampia da permettere lo svolgimento del volo in sicurezza.

• Prima del volo verifi care che l’area sia libera da amici e spettatori.

• Stare attenti alle altre attività che si svolgono in vicinanza della vostra traiettoria di volo, per evitare possibili confl itti.

• Pianifi care attentamente il volo prima di lanciare il modello.

• Rispettare sempre scrupolosamente le regole stabilite dall’associazione locale.

PRIMA DI INIZIARE IL MONTAGGIO

• Togliere tutti i pezzi dalla scatola.

• Verifi care che la fusoliera, l’ala e i piani di coda non siano danneggiati.

• Se si trovano parti danneggiate, contattare il negozio da cui è stato acquistato.

• Caricare il trasmettitore e la batteria di volo.

• Centrare stick e trim sul trasmettitore.

• Con una radio computerizzata creare una nuova memoria per questo modello.

• Facendo riferimento alle istruzioni del radiocomando, connettere (bind) trasmettitore e ricevitore.

IMPORTANTE: Ripetere la procedura di connessione una volta regolate le corse, per evitare che i servi vadano a fi ne

corsa. Garantirà anche che le impostazioni di inversione del servo vengano salvate nel sistema radio.

PRECAUZIONI PER LA COSTRUZIONE

Durante l’assemblaggio noi consigliamo di appoggiare le varie parti su di una superfi cie morbida come un

asciugamano di spugna per evitare ammaccature al rivestimento.

10

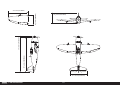

TRANSPORTATION AND STORAGE

Use the 3-view drawing at the back of this manual to

determine the amount of space required to transport and

store your model. The model can be disassembled, so the

amount of room necessary can vary. We recommend the

use of a wing bag to help protect these surfaces during

transport and storage. The control horns and linkages can

also cause damage to nearby surfaces even when placed

in storage bags. Always place surfaces so the tops are

together to prevent damage from the control horns and

linkages.

PRINTED COVERING NOTES

• The covering used on your model has the coloring and

markings printed directly on the covering.

• The covering has a self-adhesive backing, and it is

not recommended to use heat as it may damage the

covering.

• Use only mild cleaning agents on the printed fi nish.

Denatured alcohol is the most aggressive agent we

recommend, but test on an inconspicuous area fi rst.

Prolonged use will remove the paint.

• Use tape with care. Anything other than low-tack tape

can remove the fi nish, particularly on edges.

• Avoid contact with raw fuel, especially alcohol-based

fuels containing nitro methane.

• Remove exhaust residue as soon as practical to avoid

staining or damaging of the fi nish.

There are two areas on your aircraft that will receive wear

under normal use. The fi rst area is where the cowling fi ts

over the fuselage hatch, and where the wing fi ts into the

fuselage. Placing a piece of clear tape on the wing where

it fi ts into the fuselage, and on the hatch underneath the

cowling, will reduce the wear on the covering in these

areas. Sanding the inside of the cowling smooth will also

help in preventing wear of the covering under the cowling.

TRANSPORT UND LAGERUNG

Mit der Zeichnung aus drei Ansichten am Ende des

Handbuchs lässt sich ermitteln, wie viel Platz zum

Transport und zur Lagerung des Modells benötigt

wird. Das Modell kann demontiert werden, daher ist

der erforderliche Platz variabel. Die Empfehlung einer

Flügeltasche wird empfohlen, um diese Oberfl ächen bei

Transport und Lagerung zu schützen. Die Steuerhörner

und Gestänge können zudem Schäden an benachbarten

Oberfl ächen verursachen, auch wenn sie in Taschen

gelagert sind. Oberfl ächen stets so platzieren, dass

die Oberseiten aneinander liegen, um Schäden durch

Steuerhörner und Gestänge zu vermeiden.

HINWEISE ZUR BESPANNUNG

• Bei der bei diesem Modell verwendeten Abdeckung

sind Farben und Markierungen direkt auf die

Abdeckung gedruckt.

• Die Abdeckung ist selbstklebend, und ein Erwärmen

wird nicht empfohlen, da die Wärme die Abdeckung

beschädigen könnte.

• Verwenden Sie nur milde Reiniger für die bedruckte

Folie. Als aggressiver Reiniger der noch zu empfehlen

ist, empfehlen wir denaturierten Alkohol. Prüfen

Sie vorher unbedingt an unauffälliger Stelle die

Verträglichkeit. Wiederholte / verlängerte Anwendung

entfernt die Farbe.

• Verwenden Sie Klebeband nur mit äußerster Vorsicht.

Bis auf Kreppband entfernt alle Klebebänder die Farbe.

Dieses gilt insbesondere für die Kanten.

• Vermeiden Sie den Kontakt mit Kraftstoff, insbesondere

Alkohol-basierte Kraftstoffe mit Nitromethan.

• Entfernen Sie Abgasrückstände schnellstmöglich um

ein Verfärben oder Beschädigen der Bespannung zu

vermeiden.

Zwei Stellen Ihres Modells sind bei normalem Gebrauch

Verschleiß ausgesetzt. Bei der ersten Stelle handelt es

sich um den Bereich, in dem die Motorhaube auf der

Rumpfabdeckung sitzt und in dem die Tragfl äche in den

Rumpf führt. Indem Sie die Tragfl äche dort, wo sie in den

Rumpf führt, sowie an der Abdeckung unter der Motorhaube

mit einem Stück transparentem Klebeband versehen,

können Sie den Verschleiß der Abdeckung reduzieren.

Außerdem vermindern Sie den Verschleiß der Abdeckung

unter der Motorhaube, wenn Sie die Innenseite der

Motorhaube mit Sandpapier glattschmirgeln.

TRANSPORT ET STOCKAGE

Utilisez le schéma à 3 vues à l’arrière de ce manuel

pour déterminer l’espace nécessaire pour transporter

et stocker votre maquette. La maquette peut être

démontée, l’espace nécessaire peut donc varier. Nous

vous conseillons d’utiliser un sac à ailes pour protéger ces

surfaces lors du transport et du stockage. Les renvois de

commande et tringleries peuvent également endommager

les surfaces proches même si rangés dans des sacs de

rangement. Placez toujours ces surfaces de manière à

ce que les sommets soient ensemble pour prévenir tout

dommage causé par les renvois de commande et les

tringleries.

REMARQUES RELATIVES À L’ENTOILAGE

IMPRIMÉ

• L’entoilage utilisé sur votre maquette a les couleurs et

les marquages imprimés directement sur l’entoilage.

• L’entoilage a un endos autocollant, et il n’est pas

recommandé d’utiliser de la chaleur car cela peut

endommager l’entoilage.

• Utilisez uniquement des produits de nettoyage doux

sur la surface du fi lm. L’alcool dénaturé est le produit le

plus agressif que vous pouvez utiliser, mais nous vous

conseillons de procéder d’abord à un essai sur une

partie de surface non visible. Une utilisation fréquente

endommagera la peinture présente sur le fi lm.

• Utilisez du ruban adhésif avec précautions. Tout autre

adhésif que de l’adhésif de masquage endommagera la

décoration, surtout au niveau des angles.

• Evitez le contact avec du carburant brut, surtout les

carburants à base d’alcool contenant du nitrométhane.

• Essuyez les résidus de carburant immédiatement après

le vol afi n d’éviter d’endommager la fi nition.

In condizioni di utilizzo normali, sono due le parti

dell’aeromodello soggette a usura. La prima è la giuntura

tra la cappottatura e il portello della fusoliera, l’altra è il

punto di inserimento delle ali nella fusoliera. Applicando

del nastro trasparente sull’ala nel punto di inserimento

nella fusoliera e sul portello al di sotto della cappottatura

è possibile ridurre l’usura in queste zone del rivestimento.

Inoltre, carteggiare l’interno della cappottatura aiuta a

prevenire l’usura di questa parte di rivestimento.

TRASPORTO E DEPOSITO

Fare riferimento al trittico riportato sul retro di questo

manuale per determinare lo spazio necessario al

trasporto e all’immagazzinaggio del modello. Il modello

può essere smontato e, di conseguenza, lo spazio

necessario può variare. È consigliabile usare delle borse

alari per proteggere queste superfi ci durante il trasporto

e l’immagazzinaggio. Squadrette e rinvii possono

danneggiare le superfi ci circostanti anche all’interno delle

borse. Per prevenire questo problema, sistemare sempre

le superfi ci facendo combaciare le superfi ci superiori.

NOTE SUL RIVESTIMENTO STAMPATO

• Colori e marcature di questo modello sono stampati

direttamente sul rivestimento.

• Il retro del rivestimento è autoadesivo e non è quindi

consigliabile avvicinarvi fonti di calore che potrebbero

danneggiarlo.

• Usare solo detergenti delicati sulla fi nitura stampata.

L’alcol denaturato è il detergente più aggressivo che noi

consigliamo, però conviene sempre provarlo prima su

di un’area del rivestimento che è poco visibile. Un uso

prolungato potrebbe rimuovere la vernice.

• Usare il nastro adesivo con attenzione. Qualsiasi cosa

che sia di più di un nastro a bassa adesività, potrebbe

staccare la fi nitura specialmente sui bordi.

• Evitare il contatto con del combustibile, specialmente

se a base di alcol e contenente nitrometano.

• Togliere i residui dello scarico appena possibile per

evitare la formazione di macchie o il danneggiamento

della fi nitura.

En utilisation normale, votre appareil s’endommagera à

deux endroits. Premièrement, à l’endroit où le capot est

inséré au-dessus de la trappe du fuselage, puis à l’endroit

où les ailes s’intègrent au fuselage. Placer du ruban

adhésif transparent sur l’aile, à l’endroit où elle s’insère

dans le fuselage, mais aussi sur la trappe, en-dessous du

capot, permet de réduire l’usure du revêtement de ces

zones. Poncer l’intérieur du capot lisse permet également

d’empêcher l’usure du revêtement sous le capot.

11 EN

P-47D Thunderbolt 20cc

FLAP INSTALLATION

1. Use a piece of low-tack tape to hold the aileron in

position. This will keep the aileron in position while

aligning the fl ap.

1.

2.

3.

4.

5.

2. Locate the two fl ap control horns. When installed,

the concaved portion of the horn (as indicated in the

drawing) will face toward the top of the fl aps.

3. Use a pin vise and 1/16-inch (1.5mm) drill bit to remove

the paint from the hole in the fl ap control horn for the

clevis. Prepare all the control horns at this time.

4. Use medium-grit sandpaper to remove the paint from

the fl ap control horn where it fi ts into the fl ap. Clean the

sanded area using a paper towel and isopropyl alcohol to

remove any debris or oils. Removing the paint provides

the surface texture necessary for the epoxy to bond to.

5. Remove the fl ap from the wing. Run your fi nger down

the leading edge of the fl ap to locate the area for the fl ap

control horn. Use a hobby knife and #11 blade to remove

the covering, exposing the slot for the control horn. Use

15-minute epoxy to glue the fl ap control horn in position.

Remove any excess epoxy using a paper towel and

isopropyl alcohol.

6.

7.

6. Run your fi nger down the lower surface leading edge

of the fl ap to locate the areas for the fl ap hinges. Use

a hobby knife and #11 blade to remove the covering,

exposing the holes for the fl ap hinges. Test fi t the hinges

to the fl ap. Do not use any adhesives now. Slide the

hinge into position. Position as shown, checking to make

sure it can move freely.

7. Run your fi nger down the lower surface trailing edge

of the wing to locate the areas for the fl ap hinges. Use

a hobby knife and #11 blade to remove the covering,

exposing the holes for the fl ap hinges. Check the fi t of

the fl ap to the wing. The top of the fl ap will align to the

top of the wing. It will also line up with the aileron. The

fl ex point of the hinges will align with the hinge line of

the fl aps when installed properly. Test the operation of

the fl ap to make sure the hinges are properly aligned and

the fl ap movies freely.

8. Apply a small amount of petroleum jelly to the fl ex point

of the hinge to prevent epoxy from entering the hinge.

Î Use care to only apply the petroleum jelly to the flex

point. If applied to the hinge portion, it could cause the epoxy

not to adhere to the hinge, resulting in a poor glue joint.

Î The flaps must be positioned to the wing before the

epoxy begins to cure. Make sure to read through all the

steps before mixing any epoxy. Glue only one flap at a time

to allow enough working time to properly install the hinges.

Î Use 15-minute or 30-minute epoxy to allow

enough working time during the hinge installation.

9. Remove the fl ap from the wing and remove the hinges.

Apply epoxy into each of the holes in the fl ap.

Î Do not use an excessive amount of epoxy

when gluing the hinges so that it expels from the

hinge. Also make sure to use enough epoxy so it

securely adheres the hinge to the surfaces.

9.

8.

12EN

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

10. Apply epoxy to each hinge where it will be inserted into

the fl ap. Insert the hinges as shown in Step 6.

AILERON INSTALLATION

15. Remove the tape and aileron from the wing panel.

11. Apply epoxy to each hinge where it will be inserted into

the wing.

16. Use a pin vise and 1/16-inch (1.5mm) drill bit to drill a

hole in the center of each hinge slot. Drill the hole 1/4-

inch (6mm) deep into the wood. Drill holes in both the

wing and aileron hinges slots now.

12. Apply epoxy into each of the holes in the wing. 17. Check the gap between the wing tip and aileron.

13. Fit the fl ap to the wing as shown in Step 7. Check that

the fl ap can move freely and the hinges are all aligned

properly. Use low-tack tape to hold the fl ap in position

until the epoxy fully cures.

18. Check the gap between the fl ap and aileron. The gaps

in Steps 16 and 17 must be equal before applying CA to

the hinges.

Î When the flap is lowered and the aileron is in the

full down position, there may be some interference

between the flap and aileron. In flight, the aileron will

not drop down far enough to interfere with the flap.

14. Use a paper towel and isopropyl alcohol to remove any

excess epoxy before it can fully cure. Use care not to get

epoxy in the moving part of the hinge or between the fl ap

and wing. Continue once the epoxy has fully cured for

both sets of fl ap hinges.

Î Repeat this section for the remaining flap installation.

19. Apply thin CA to the top of each of the hinges. Make sure

to fully soak the hinges so the CA can wick into the hinge

and bond to the surrounding wood.

Î Use thin CA so it wicks into the hinge. A thicker CA

will not wick into the hinge properly. Do not to allow the

CA to run over the covering on the wing and aileron.

13 EN

P-47D Thunderbolt 20cc

20.

21.

22.

23.

24.

15/16 inch

(24mm)

25.

26.

27.

28.

29.

20. Allow the CA to cure for 10 to 15 minutes. Gently pull on

the fi xed surface and control surface to make sure the

hinges are glued securely. If not, apply additional CA to

secure each of the hinges.

25. Apply epoxy to the area of the control horns that fi ts into

the slots. Use enough epoxy so the control horns will be

fully bonded to the fi xed surfaces.

22. Check both the up and down movement of the hinges

before proceeding.

27. Before the epoxy fully cures, remove the tape from

around the control horn. This will allow the epoxy to fl ow

around the control horn, creating a small fi llet between

the control horn and surface for a fi nished look and

secure bond.

Î Repeat this section for the

remaining aileron installation.

21. Move the aileron through its range of throw to break in

the hinges.

26. Remove the control horns from the control surfaces.

Apply epoxy to the slot in the aileron and fl ap. Make sure

the epoxy gets into the slot for a good bond between the

surfaces and control horn.

23. Run your fi nger along the bottom of the aileron to locate

the area for the fl ap control horn. Use a hobby knife and

#11 blade to remove the covering, exposing the slot for

the control horn. Place tape around the slot in the aileron

for the aileron control horn.

24. Locate the two silver aileron control horns. Use medium-

grit sandpaper to remove the paint from the bottom of

the control horn where it fi ts into the aileron.

AILERON SERVO INSTALLATION

28. Use a hobby knife or other sharp tool to puncture the

covering at the screw holes that will secure the cover to

the wing. Also remove the covering for the aileron servo

arm in the cover.

29. Place the cover back into position. Use a pin vise and

1/16-inch (1.5mm) drill bit to drill the mounts for the

servo covers. Use care not to drill through the covering

on the top of the wing.

14EN

35.

36.

37.

38.

39.

30.

31.

32.

33.

34.

30. Thread an M2 x 10 sheet metal screw into each hole

using a #1 Phillips screwdriver. Remove the screws

before proceeding.

31. Apply a small amount of thin CA to harden the threads

made in the previous step. Allow the CA to fully cure

before installing the aileron servo cover.

Î Prepare the flap servo covers at this time as well.

32. Check that the vertical servo mount is glued securely to

the servo cover. If the mount is not secure, use a small

amount of medium CA or epoxy to securely adhere the

servo mount to the cover.

33. Use a pin vise and 5/32-inch (2mm) drill bit to drill the

holes for the servo mounting screws. Make sure to

harden the holes using the technique outlined in Steps

30 and 31. Use the screws provided with the servo and a

#1 Phillips screwdriver when installing the screws.

34. Secure the servo to the cover using a #1 Phillips

screwdriver and the screws provided with the servo.

Center the servos, then secure the servo arm so it is

perpendicular to the servo centerline. Use side cutters to

remove any arms that do not protrude to the outside of

the cover.

35. Secure a 12-inch (300mm) servo extension to the servo

using a commercially available fastener (SPMA3054).

36. Tie or tape the string located inside the wing to the end

of the servo lead.

37. Use the string to pull the servo lead through the wing and

out at the root.

38. Secure the servo to the wing using four M2 x 10 sheet

metal screws. Use a #1 Phillips screwdriver to tighten

the screws.

39. Slide a silicone tube on the clevis. Thread the clevis on

the 4

7

/

8

inch (124mm) pushrod. Allow 1/16 inch (1.5mm)

of the threads on the pushrod protrude between the forks

of the clevis.

15 EN

P-47D Thunderbolt 20cc

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

40. Attach the clevis to the inside hole on the aileron control

horn.

41. Center the aileron servo using the radio system. With

the aileron centered, use a felt-tipped pen to mark the

pushrod where it crosses the outer hole of the servo arm.

42. Remove the clevis from the control horn. Use pliers to

bend the pushrod at the mark made in the previous step.

43. Insert the pushrod into the outer hole on the servo arm.

It may be necessary to enlarge the hole using a pin vise

and 5/64-inch (2mm) drill bit. Reattach the clevis to the

control horn.

44. Slide the pushrod keeper on the pushrod wire.

45. Slide the keeper tightly against the servo arm. Use pliers

to snap the keeper on the pushrod wire.

46. Use side cutters to trim the pushrod wire 1/16 inch

(1.5mm) from the pushrod keeper.

47. Check the operation of the aileron using the radio

system. Trim the servo cover if the keeper or pushrod

wire hits the cover during the operation of the aileron.

Slide the clevis retainer over the forks of the clevis. Apply

a drop of threadlock on the threads near the clevis, then

tighten the nut against the clevis using pliers.

Î Repeat this section for the remaining

aileron servo installation.

FLAP SERVO INSTALLATION

48. Slide a silicone tube on the clevis. Thread the clevis on

the 4

7

/

8

inch (124mm) pushrod. Allow 1/16 inch (1.5mm)

of the threads on the pushrod protrude between the forks

of the clevis.

49. Attach the clevis to the fl ap control horn.

16EN

54.

55.

56.

57.

58.

50.

51.

52.

53.

50. Secure an 3-inch (75mm) servo extension to the servo

using a commercially available fastener (SPMA3054).

Secure the servo in the wing using a #1 Phillips

screwdriver and the screws provided with the servo.

Make sure the servo output faces toward the leading

edge of the wing. Pull the fl ap servo extension through

the wing so it exits near the aileron servo lead.

Î The servo arm for the flap servos

will point toward the right wing tip.

51. Center the fl ap servo using the radio system. Attach the

servo arm to the servo using the hardware included with

the servo. Remove any arms that may interfere with the

operation of the servo.

52. Use a pin vise and 5/64-inch (2mm) drill bit to enlarge

the hole in the servo arm that is 1/2-inch (12mm).

53. Place the fl ap in the UP fl ap position. We recommend

using low-tack tape to keep the fl ap in position during

the next few steps.

54. Use the radio system to move the servo to the UP fl ap

position. Use a felt-tipped pen to mark the pushrod

where it crosses the outer hole in the servo arm.

55. Remove any tape holding the fl ap in position. Connect

the linkage to the servo arm using a pushrod keeper. Use

the radio system to center the fl ap servo.

Î Remove the screw securing the servo arm to

make adjustments to the linkage in the next step.

56. Make sure the fl ap is in the MID fl ap position according

to the control throws in this manual. Adjust the linkage

as necessary to set the throw.

57. Move the servo to the FULL fl ap position using the radio

system. Adjust the throws in the radio system to obtain

the measurements listed in the manual for the full fl ap

position.

58. Move the servo to the UP fl ap position using the radio

system. Adjust the throws at the radio system to bring

the fl ap in alignment with the trailing edge of the wing.

17 EN

P-47D Thunderbolt 20cc

59.

60.

61.

62.

63.

64.

65.

66.

67.

68.

59. Secure the servo arm to the servo. Secure the clevis to

the control horn following the same procedures as the

aileron linkage. Always use threadlock on metal-to-metal

fasteners. Secure the fl ap servo cover in position using

four 2mm x 10mm sheet metal screws.

60. Use canopy glue to glue the navigation lights in position

at the wing tips. The left navigation light is red, the right

is green.

Î Do not use CA when attaching the navigation

lights and covers as it will fog the covers as it cures.

61. Use canopy glue to glue the covers to the wing tips. Use

low-tack tape to hold the covers in position until the

adhesive fully cures.

Î Repeat this section for the

remaining flap servo installation.

FIXED GEAR INSTALLATION

Î Skip this section of the manual if you

are installing the optional retracts.

62. Use a fl at fi le to make a 1/2-inch long fl at area on the

strut. The setscrew from the mount will tighten on the

fl at, preventing the gear from rotating.

63. Attach the landing gear strut in the mount. Use

threadlock on the setscrew before tightening it on the fl at

area on the strut. Use a 2mm hex wrench to tighten the

setscrew.

64. Use a hobby knife and #11 blade to remove the covering

from the mounting rails in the wing. Trim the covering

inside the opening.

65. Attach the strut mount to the wing using four M3 x 25

socket head cap screws, four M3 washers and four

M3 lock washers. Place a drop of threadlock on each

screw before installing them. Tighten the screws using a

2.5mm hex wrench.

66. Place the landing gear door mount near in the opening

in the landing gear door. Use a felt-tipped pen to transfer

the locations for the mounting screws on the gear door.

67. Use a drill and 1/8-inch (3mm) drill bit to drill the

locations for the gear door mounting screws.

68. Slide the landing gear door mounts on the landing gear

struts. The position of the mounts will be adjusted during

the landing gear door installation.

18EN

69.

70.

74.

69. Slide the M5 washer on the M5 x 45 socket head cap

screw. Slide the screw into the wheel. Make sure the

wheel rotates freely on the screw. If not, use a hobby

knife with a #11 blade or 5mm drill bit to remove any

fl ashing that may be interfering with the rotation of the

wheel on the screw.

70. Slide the M5 plastic spacer on the screw.

71. Thread the screw into the landing gear strut. Make sure

the wheel can rotate freely on the screw. Tighten the

setscrew using a 2mm hex wrench to secure the screw.

Î Always use threadlock on metal-to-metal fasteners.

Î It may be necessary to add an additional

washer to provide clearance between the wheel

and strut if the wheel rubs against the strut.

72. Position the gear door mounts so there will be a 1/8-inch

(3mm) gap between the gear door and wing. Use four M3

x 6 button head screws to attach the gear doors to the

gear door mounts.

73. Check that there is a slight amount of toe-in (roughly

1-degree). Adjustments can be made by loosening the

two setscrews on the strut near the mount using a

1.5mm hex wrench.

Î The amount of toe-in shown has been

exaggerated so it can be seen clearly in the photo.

Î Always use threadlock on metal-to-metal fasteners.

Î Repeat this section for the

remaining fixed gear installation.

RETRACT INSTALLATION

Î Skip this section of the manual if the fixed

gear has been installed on your model.

74. Use a hobby knife and #11 blade to remove the covering

from the retract openings in the wing. Trim the covering

inside the opening.

75. Place the landing gear door mount near in the opening

in the landing gear door. Use a felt-tipped pen to transfer

the locations for the mounting screws on the gear door.

76. Use a drill and 1/8-inch (3mm) drill bit to drill the

locations for the gear door mounting screws.

78. Secure a 9-inch (230mm) servo extension to the lead on

the retract.

71.

72.

73.

75.

76.

77.

78.

77. Slide the gear door mounts on the retract strut. Insert the

retract strut into the retract frame. Secure the strut by

tightening the two setscrews using a 2mm hex wrench.

Î The gear door mount positions will be

adjusted later in this section of the manual.

19 EN

P-47D Thunderbolt 20cc

84.

85.

86.

87.

79.

80.

81.

82.

83.

79. Fit the retract frame to the wing. Guide the servo

extension through the wing, exiting the same location as

the fl ap and aileron servo leads.

Î Make sure to mark each servo lead so they can be

identified easily when connection them to the receiver.

80. Secure the retract in the wing using the hardware

included with the retract.

Î Always use threadlock on metal-to-metal fasteners.

Î It may be necessary to use the spacers included

with the retracts to make sure there is no torsional stress

on retract frame when tightened into position. Torsional

stress can cause intermittent operation of the retract unit.

81. Use a fl at fi le to make a 1/4 inch (6mm) wide fl at area on

the retract axle.

82. Slide the axle into the wheel. Make sure the wheel

rotates freely on the axle. If not, use a hobby knife with

a #11 blade or 5mm drill bit to remove any fl ashing that

may be interfering with the rotation of the wheel on the

axle.

83. Place a nylon spacer on the axle.

84. Slide the axle into the retract strut. Tighten the setscrew

to secure the axle to the strut. Make sure the wheel can

rotate freely on the axle.

Î Always use threadlock on metal-to-metal fasteners.

85. Check the operation of the retract using the radio system.

The wheel must be centered in the opening. If not, loosen

the mounting screws and adjust as necessary.

Î Spacers have been included with the retracts.

Use these to adjust the positioning of the retract

to allow the wheel to retract without interfering

with the wheel well. Once adjusted, check that

there is no torsional stress on retract frame.

86. Attach the landing gear doors to the gear door mounts

using the hardware included with the retracts. The

mounts should be easily moved so the gear door can be

positioned in the following step.

87. Use the radio system to cycle the retracts. Position the

gear doors so they align with the recess in the wing.

It may be necessary to cycle the gear a few times to

correctly position the gear doors. Make sure there is no

binding during the operation of the retract, which could

cause it to stop during its operation. Tighten all the

hardware to complete the retract installation.

20EN

88. 92.

93.

94.

95.

96.

AA

A=A

88. Check that there is a slight amount of toe-in (roughly

1-degree). Adjustments can be made by loosening the

setscrews on the retract frame. After adjusting the toe

in, check the alignment of the wheel as it retracts into

the wheel well to verify that it is not binding in the up

position.

Î The amount of toe-in shown has been

exaggerated so it can be seen clearly in the photo.

Î Always use threadlock on metal-to-metal fasteners.

Î Repeat this section for the

remaining retract installation.

STABILIZER AND RUDDER INSTALLATION

89. Move the canopy latch toward the front of the fuselage.

90. Lift the canopy hatch from the fuselage at the rear. Slide

the hatch back and remove it from the fuselage. Set it

aside in a safe location.

91. Slide the wing tube into the wing tube socket.

92. Slide the wing panel into position. Guide the fl ap and

aileron leads into the fuselage.

93. Secure the wing to the fuselage using the 1/4-20 x 2

nylon wing bolt.

94. Use a razor saw to remove the tail post at the rear of the

fuselage. Use medium grit sandpaper to sand the area

fl at so the stabilizer will fi t into the opening.

95. Place the stabilizer in position. The black stripe on the

stabilizer will face toward the top of the fuselage.

96. Center the stabilizer on the fuselage.

89.

90.

91.

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

Hangar 9 HAN2990 Le manuel du propriétaire

- Catégorie

- Jouets télécommandés

- Taper

- Le manuel du propriétaire

dans d''autres langues

- italiano: Hangar 9 HAN2990 Manuale del proprietario

- English: Hangar 9 HAN2990 Owner's manual

- Deutsch: Hangar 9 HAN2990 Bedienungsanleitung

Documents connexes

-

Hangar 9 HAN2765 Le manuel du propriétaire

Hangar 9 HAN2765 Le manuel du propriétaire

-

Hangar 9 HAN3390 Manuel utilisateur

Hangar 9 HAN3390 Manuel utilisateur

-

Hangar 9 HAN2820 Le manuel du propriétaire

Hangar 9 HAN2820 Le manuel du propriétaire

-

Hangar 9 HAN4670 Le manuel du propriétaire

Hangar 9 HAN4670 Le manuel du propriétaire

-

Hangar 9 HAN4720 Le manuel du propriétaire

Hangar 9 HAN4720 Le manuel du propriétaire

-

Hangar 9 HAN2345 Le manuel du propriétaire

Hangar 9 HAN2345 Le manuel du propriétaire

-

Hangar 9 HAN5260 Le manuel du propriétaire

Hangar 9 HAN5260 Le manuel du propriétaire

-

Hangar 9 HAN5080 Le manuel du propriétaire

Hangar 9 HAN5080 Le manuel du propriétaire

-

Hangar 9 HAN4885 Le manuel du propriétaire

Hangar 9 HAN4885 Le manuel du propriétaire

-

Hangar 9 HAN5065 Le manuel du propriétaire

Hangar 9 HAN5065 Le manuel du propriétaire

Autres documents

-

E-flite EFLG725 Mode d'emploi

-

E-flite EFLG115 Le manuel du propriétaire

-

E-flite EFLG500 Le manuel du propriétaire

-

E-flite EFLG520 Le manuel du propriétaire

-

E-flite Beast 60e ARF Manuel utilisateur

-

E-flite EFLG625SP Le manuel du propriétaire

-

E-flite EFLG120 Le manuel du propriétaire

-

FMD Furniture Variant 7 205-007 Assembly Instructions

-

Greenlee Model 508S Wire Finder Manuel utilisateur

-

Tamiya 300061123 Mode d'emploi