Delta 37-071 Manuel utilisateur

- Catégorie

- Outils électroportatifs

- Taper

- Manuel utilisateur

Ce manuel convient également à

Canteador de banco

de 152 mm (6 pulg.)

Dégauchisseuse d’établi

de 152 mm (6 po)

Instruction Manual

Manuel d’utilisation

Manual de instrucciones

Français (20)

Español (38)

INSTRUCTIVO DE OPERACIÓN, CENTROS

DE SERVICIO Y PÓLIZA DE GARANTÍA.

LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

www.DeltaMachinery.com

6 IN. BENCH JOINTER

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ...................................2

SAFETY GUIDELINES - DEFINITIONS ....................................3

GENERAL SAFETY RULES ......................................................3

ADDITIONAL SPECIFIC SAFETY RULES ...............................4

POWER CONNECTIONS ..........................................................6

MOTOR SPECIFICATIONS .......................................................6

GROUNDING INSTRUCTIONS ................................................6

EXTENSION CORDS ................................................................7

KEY FEATURES AND COMPONENTS ....................................7

FUNCTIO

NAL DESCRIPTION ..................................................7

PRODUCT SPECIFICATIONS ...................................................8

UNPACKING ..............................................................................8

ASSEMBLY .................................................................................9

Fence Assembly ..............................................................................................9

Fence Angle Lock Assembly ...................................................................10

Align Cutterhead to Outfeed Table .....................................................10

Connecting to Dust Collector.................................................................11

OPERATION .............................................................................12

Starting and Stopping the Jointer ........................................................12

Locking the Jointer Using the

Safety Ke

y ..........................................12

Adjusting Fence Position..........................................................................12

Feeding Stock ...............................................................................................13

Jointing Beveled Stock ..............................................................................13

Calibrating the 45°/90°/135° Stops ......................................................14

Depth Adjustment ......................................................................................15

MAINTENANCE ......................................................................16

Changing the Cutter Knives ....................................................................16

OTHER RECOMMENDED MAINTENANCE ..........................16

ACCESSORIES ........................................................................17

WARRANTY .............................................................................17

REPLACEMENT PARTS ..........................................................18

SERVICE AND REPAIRS .........................................................18

FRANÇAIS ......

.......

...................................................................20

ESPAÑOL .................................................................................38

IMPORTANT SAFETY INSTRUCTIONS

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING

THIS EQUIPMENT. Failure to follow all instructions listed below, may result in electric shock, fire,

and/or serious personal injury or property damage.

Woodworking can be dangerous if safe and proper operating procedures are not followed. As with all

machinery, there are certain hazards involved with the operation of the product. Using the machine with

respect and caution will considerably lessen the possibility of personal injury. However, if normal safety

precautions are overlooked or ignored, personal injury to the operator may result. Safety equipment such

as guards, push sticks, hold-downs, featherboards, goggles, dust masks and hearing protection can reduce your

potential for injury. But even the best guard won’t make up for poor judgment, carelessness or inattention. Always

use common sense and exercise caution in the workshop. If a procedure feels dangerous, don’t try it. Figure out

an alternative procedure that feels safer. REMEMBER: Your personal safety is your responsibility. For additional

information please visit our website www.DeltaMachinery.com.

This machine was designed for certain applications only. DELTA

®

Power Equipment Corporation

strongly recommends that this machine not be modified and/or used for any application other than

that for which it was designed. If you have any questions relative to a particular application, DO NOT use the

machine until you have first contacted DELTA

®

to determine if it can or should be performed on the product.

If you have any questions relative to its application DO NOT use the product until you have written DELTA

®

Power

Equipment Corporation and we have advised you. Contact us online at www.DeltaMachinery.com or by mail at

Technical Service Manager, DELTA

®

Power Equipment Corporation, 2651 New Cut Road, Spartanburg, SC 29303.

Information regarding the safe a

nd proper operation of this tool is available from the following sources:

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851or online at www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• U.S. Department of Labor regulations www.osha.gov

2

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to

protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we

use the symbols below. Please read the manual and pay attention to these sections.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided,

may result in property damage.

GENERAL SAFETY RULES

WARNING FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY.

•

FOR YOUR OWN SAFETY, READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE OPERATING THE

UNIT.

Learn the unit’s application and limitations as well as the specific hazards peculiar to it.

•

KEEP WORK AREA CLEAN.

Cluttered areas and benches invite accidents.

•

DON’T USE IN DANGEROUS ENVIRONMENT.

Don’t use this unit in damp or wet locations, or expose it to rain.

Keep work area well-lighted.

•

KEEP CHILDREN AND VISITORS AWAY.

All children and visitors should be kept a safe distance from work area.

•

DISCONNECT UNIT

before servicing.

•

CHECK DAMAGED PARTS.

Before further use of the unit, properly repair or replace any part that is damaged.

1. Read and understand the warnings posted on the

machine and in this manual. Failure to comply with

all of these warnings may cause serious injury.

2. Replace the warning labels if they become

obscured or removed.

3. This machine is designed and intended for use by

properly trained and experienced personnel only.

If you are not familiar with the proper and safe

operation of a band saw, do not use until proper

training and knowledge have been obtained.

4. Do not use this machine for other than its intended

use. If used for other purposes, DELTA

®

Power

Equipment Corporation disclaims any real or

implied warranty and holds itself harmless from any

injury that may result from that use.

5. Always wear approved safety glasses/face shields

while using this grinder.

6. operating this grinder, remove tie, rings, watches

and other jewelry, and roll sleeves up past the

elbows. Remove all loose clothing and confine long

hair. Non-slip footwear or anti-skid floor strips are

recommended. Do not wear gloves.

7. Wear ear protectors (plugs or muffs) during

extended periods of operation.

8. Some dust created by power sanding, sawing,

grinding, drilling and other construction activities

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS INJURY.

contain chemicals known to cause cancer,

birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other

masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk of exposure varies, depending on how often

you do this type of work. To reduce your exposure to

these chemicals, work in a well-ventilated area and

work with approved safety equipment, such as face or

dust masks that are specifically designed to filter out

microscopic particles.

9. Do not operate this machine while tired or under

the influence of drugs, alcohol or any medication.

10. Make certain the switch is in the OFF position

before connecting the machine to the power

source.

11. Make certain the machine is properly grounded.

12. Make all machine adjustments or maintenance with

the machine unplugged from the power source.

13. Form a habit of checking to see that all extra

continued on page 4

3

5. Always wear approved safety glasses/face shields

while using this tool.

6. Before operating this tool, remove tie, rings,

watches and other jewelry, and roll sleeves up past

the elbows. Remove all loose clothing and confine

long hair. Non-slip footwear or anti-skid floor strips

are recommended. Do not wear gloves.

equipment such as adjusting keys, wrenches,

scrap, stock, and cleaning rags are removed away

from the machine before turning on.

14. Keep safety guards in place at all times when the

machine is in use. If removed for maintenance

purposes, use extreme caution and replace the

guards immediately when maintenance is complete.

15. Make sure the tool is firmly secured to a stable work

surface before use.

16. Check damaged parts. Before further use of the

machine, a guard or other part that is damaged

should be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced.

17. Provide for adequate space surrounding work area

and non-glare, overhead lighting.

18. Keep the floor around the machine clean and free of

scrap material, oil and grease.

19. Keep visitors a safe distance from the work area.

Keep children away.

20. Make your workshop child proof with padlocks,

master switches or by removing starter keys.

21. Give your work undivided attention. Looking

around, carrying on a conversation and “horse-

play" are careless acts that can result in serious

injury.

22. Maintain a balanced stance at all times so that you

do not fall or lean against the tool or its moving

parts. Do not overreach or use excessive force to

perform any machine operation.

23. Use the right tool at the correct speed and feed

rate. Do not force a tool or attachment to do a job

for which it was not designed. The right tool will do

the job better and safer.

24. Use recommended accessories; improper

accessories may be hazardous.

25. Maintain machinery with care. Follow instructions

for lubricating and changing accessories.

26. Turn off the machine before cleaning. Use a brush

or compressed air to remove dust or debris — do

not use your hands.

27. Do not stand on the machine. Serious injury could

occur if the machine tips over.

28. Never leave the machine running unattended. Turn

the power off and do not leave the machine until it

comes to a complete stop.

29. At all times, hold the stock firmly.

30. Do not use this tool for other than it intended use. If

used for other purposes, DELTA

®

Power Equipment

Corporation disclaims any real or implied warranty

and holds itself harmless for any injury or damage

which may result from that use.

Familiarize yourself with the following safety notices

used in this manual:

This means that if precautions are not heeded, it may

result in minor injury and/or possible machine damage.

This means that if precautions are not heeded, it may

result in serious injury or possibly even death.

4

ADDITIONAL SPECIFIC SAFETY RULES

1. DO NOT OPERATE THIS MACHINE until it is

completely assembled and installed according to

the instructions. A machine incorrectly assembled

can cause serious injury.

2. OBTAIN ADVICE from your supervisor, instructor, or

another qualified person if you are not thoroughly

familiar with the operation of this machine.

Knowledge is safety.

3. FOLLOW ALL WIRING CODES and recommended

electrical connections to prevent shock or

electrocution.

4. KEEP KNIVES SHARP and free from rust and pitch.

Dull or rusted knives work harder and can cause

kickback.

5. TIGHTEN THE INFEED/OUTFEED TABLES

before starting the machine. Loss of control of the

workpiece can cause serious injury.

6. PROPERLY SECURE THE BLADES IN THE

CUTTERHEAD before turning the power “ON”.

Loose blades may be thrown out at high speeds.

7. NEVER TURN THE MACHINE “ON” before clearing

the table of all objects (tools, scraps of wood, etc.).

Flying debris can cause serious injury.

8. NEVER TURN THE MACHINE “ON” with the

workpiece contacting the cutterhead. Kickback can

occur.

9. AVOID AWKWARD OPERATIONS AND HAND

POSITIONS. A sudden slip could cause a hand to

move into the cutterhead.

10. KEEP ARMS, HANDS, AND FINGERS away from

the cutterhead to prevent severe injury.

11. NEVER MAKE CUTS deeper than 1/8" (3.2mm) to

prevent kickback.

Failure to follow these rules may result in serious personal injury.

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

5

12. NEVER JOINT OR PLANE A WORKPIECE that

is shorter than 10" (254mm), narrower than 3/4"

(19.0MM), or less than 1/2" (12.7mm) thick. Jointing

smaller workpieces can place your hand in the

cutterhead causing severe injury.

13. USE HOLD-DOWN/PUSH BLOCKS for jointing

or planing any workpiece lower than the fence.

Jointing or planing small workpieces can result in

kickback and severe injury.

14. HOLD THE WORKPIECE FIRMLY against the table

and fence. Loss of control of the workpiece can

cause kickback and result in serious injury.

15. NEVER PERFORM “FREE-HAND” OPERATIONS.

Use the fence to position and guide the workpiece.

Loss of control of the workpiece can cause serious

injury.

16. DO NOT attempt to perform an abnormal or little-

used operation without study and the use of

adequate hold-down/push blocks, jigs, fixtures,

stops, etc.

17. DO NOT FEED A WORKPIECE into the outfeed end

of the machine. The workpiece will be thrown out of

the opposite end at high speeds.

18. DO NOT FEED A WORKPIECE that is warped,

contains knots, or is embedded with foreign objects

(nails, staples, etc.) to prevent kickback.

19. MAINTAIN THE PROPER RELATIONSHIP OF

INFEED AND OUTFEED TABLE SURFACES

and cutterhead knife path. Loss of control of the

workpiece can cause serious injury.

20. PROPERLY SUPPORT LONG OR WIDE

WORKPIECES. Loss of control of the workpiece

can cause injury.

21. NEVER PERFORM LAYOUT, ASSEMBLY, OR

SETUP WORK on the table/work area when the

machine is running. A sudden slip could cause a

hand to move into the cutterhead. Severe injury can

result.

22. TURN THE MACHINE “OFF”, disconnect the

machine from the power source, and clean the

table/work area before leaving the machine. LOCK

THE SWITCH IN THE “OFF” POSITION to prevent

unauthorized use. Someone else might accidentally

start the machine and cause injury to themselves.

23. ADDITIONAL INFORMATION regarding the safe

and proper operation of power tools (i.e. a safety

video) is available from the Power Tool Institute,

1300 Sumner Avenue, Cleveland, OH 44115-2851

(www.powertoolinstitute.com). Information is also

available from the National Safety Council, 1121

Spring Lake Drive, Itasca, IL 60143-3201. Please

refer to the American National Standards Institute

ANSI 01.1 Safety Requirements for Woodworking

Machines and the U.S. Department of Labor OSHA

1910.213 Regulations.

ADDITIONAL SPECIFIC SAFETY RULES

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock. The conductor with

insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor.

If repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor

to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood,

or if in doubt as to whether the machine is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding type plugs and matching 3-conductor receptacles that

accept the machine’s plug, as shown in Fig. A.

Repair or replace damaged or worn cord immediately.

IN ALL CASES, MAKE CERTAIN THE RECEPTACLE IN QUESTION IS PROPERLY GROUNDED.

IF YOU ARE NOT SURE, HAVE A QUALIFIED ELECTRICIAN CHECK THE RECEPTACLE.

GROUNDING INSTRUCTIONS

THIS MACHINE MUST BE GROUNDED WHILE IN USE TO PROTECT THE OPERATOR FROM

ELECTRIC SHOCK.

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and

should be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords

which have 3-prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before

connecting the machine to the power line, make sure the switch (s) is in the "OFF" position and be sure that the

electric current is of the same characteristics as indicated on the machine. All line connections should make good

contact. Running on low voltage will damage the machine.

DO NOT EXPOSE THE MACHINE TO RAIN OR OPERATE THE MACHINE IN DAMP LOCATIONS.

FIG. A FIG. B

GROUNDED

OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

GROUNDED OUTLET BOX

GROUNDING

MEANS

ADAPTER

POWER CONNECTIONS

6

MOTOR SPECIFICATIONS

Your machine is wired for 110 volts, 60 HZ alternating current. Before connecting the machine to the power source,

make sure the switch is in the “OFF” position.

EXTENSION CORDS

Use proper extension cords. Make

sure your extension cord is in good

condition and is a 3-wire extension cord which has

a 3-prong grounding type plug and matching

receptacle which will accept the machine’s plug.

When using an extension cord, be sure to use one

heavy enough to carry the current of the machine.

An undersized cord will cause a drop in line

voltage, resulting in loss of power and overheating.

The table shows the correct gauge to use

depending on the cord length. If in doubt, use the

next heavier gauge. The smaller the gauge number,

the heavier the cord.

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere

Rating

Volts Total Length

of Cord in

Feet

Gauge of Extension

Cord

0-6

0-6

0-6

0-6

120

120

120

120

up to 25

25-50

50-100

100-150

18 AWG

16 AWG

16 AWG

14 AWG

6-10

6-10

6-10

6-10

120

120

120

120

up to 25

25-50

50-100

100-150

18 AWG

16 AWG

14 AWG

12 AWG

10-12

10-12

10-12

10-12

120

120

120

120

up to 25

25-50

50-100

100-150

16 AWG

16 AWG

14 AWG

12 AWG

12-16

12-16

12-16

120

120

120

up to 25

25-50

14 AWG

12 AWG

GREATER THAN 50 FEET NOT RECOMMENDED

7

KEY FEATURES AND COMPONENTS

A. Infeed/outfeed table

B. Depth of cut adjustment

C. On/Off switch

D. Cutterhead (not visible)

E. Cutter guard

F. Fence angle lock

G. 45° bevel stop

H. Rear fence

FUNCTIONAL DESCRIPTION

The DELTA

®

37-071 is a 6" Bench Jointer with designed cutting capacity of 6" (152mm) width and 1/8" (3.2mm)

depth. It features a 110-volt, 10,000 RPM motor, an in-and-out, tilting center-mounted fence, and a two-knife

cutterhead.

NOTE: Located within the fence

mount is a red sliding guard.

Please insure guard moves freely

with fence.

8

Compare all parts to the list below and check that all parts are present and in good condition. Report any missing

or damaged parts to your distributor or dealer. Prior to tool assembly and use, read this manual thoroughly to

familiarize yourself with proper assembly, maintenance and safety procedures.

PRODUCT SPECIFICATIONS

UNPACKING

DESCRIPTION (QUANTITY)

1. 37-071 6” Jointer (1)

2. Fence

3. Rear Fence Support (1)

4. Rear Fence Bracket (1)

5. Dovetail Clamp (1)

6. Indexing Handle (1)

7. Fence Mounting Plate (1)

8. Fence Angle Lock (1)

9. 45°/90° Angle Stop (1)

10. Hardware Package (1)

11. 4 mm Hex Wrench (1)

12. 6 mm Hex Wrench (1)

13. Push Blocks (2)

14. Dust Chute (1)

15. Operator’s Manual (not shown)

CONTENTS OF

HARDWARE PACK

• M8 x 16mm Hex Head Screws (4)

• M8 x 20mm Hex Head Screws (2)

• 8mm Lock Washers (6)

Weight 76 lbs

Overall Dimensions (L x W x H) 26 x 8 x 10 in.

Table Dimensions (L x W) 28-1/2 in. x 6-¼ in.

Motor

12 amps

120V

Single-Phase

60 Hz

Maximum Width of Cut 6 in.

Maximum Depth of Cut 1/8 in.

Number of Knives 2

Cuts per Minute 20,000

Fence Length 22-7/8 in.

Fence Height 4-5/16 in.

Fence Angle 45°, 90° and 135°

Cutterhead Diameter 1-7/8 in.

Cutterhead Speed 10,000 RPM

9

UNPACKING

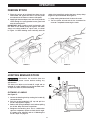

FENCE ASSEMBLY

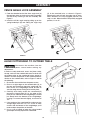

1. Attach the fence support bracket (A) to the tool

frame using two M8 x 25mm socket head screws

(B), each fitted with an 8mm lock washer. See

Figure 1. Ensure that the top surface of the bracket

is flush with the top of the table.

2. Referring to Figure 2, slide the dovetail clamp (C)

onto the fence support (D) ensuring the tops of both

bottom pins in the clamp are flush with the bottom

surface of the fence support bracket. Loosely

secure the dovetail clamp to the fence support with

the indexing lock handle (E).

3. Attach the fence mounting plate (A) to the fence

(B) using four M8 x 25mm socket head screws and

8mm lock washers. See Figure 3.

4. Slide assembled fence (A) over the fence support

bracket (B). The left edge of the fence assembly

should be aligned with the left edge of the

bracket. The dovetail edge on the right side must

be engaged with the dovetail clamp. Tighten the

indexing lock handle to firmly secure and square the

assembly. Insure that the red sliding guard moves

freely and attaches to the magnets on the rear side

of the fence. See Figure 4.

FIGURE 1

ASSEMBLY

FIGURE 2

Remove any protective materials and coatings from all of the parts and the tool. The protective coatings can be

removed by spraying WD-40 on them and wiping it off with a soft cloth. This may need redone several times before

all of the protective coatings are removed completely.

If any parts are missing, do not attempt to plug in the power cord and turn “ON” the machine. The

machine should only be turned “ON” after all the parts have been obtained and installed correctly.

FIGURE 3

FIGURE 4

10

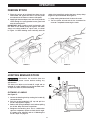

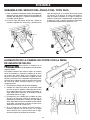

FENCE ANGLE LOCK ASSEMBLY

ALIGN CUTTERHEAD TO OUTFEED TABLE

ASSEMBLY

FIGURE 5 FIGURE 6

FIGURE 7

1. Feed the threaded end of the fence angle lock (A)

through both holes in the fence mounting assembly

and secure by screwing it into the assembly. See

Figure 5.

2. Install the 45°/90° angle stop by pulling up on the

spring-loaded pin (B) and sliding the angle stop

Disconnect the machine from the

power source before making any

adjustments!

In order to safely feed stock across the jointer safely,

the top surface of the outfeed table must be level with

the highest point of the cutterhead knives during its

rotation. To check the position of the cutterhead knives

relative to the outfeed table, refer to Figure 7 and do

the following.

1. Disconnect the machine from the power source.

2. Place a straight edge on the outfeed table (A) so

that one end overhangs above the cutterhead. For

best results, the straightedge should be able to

stand on edge without having to be held in place.

3. Carefully and slowly rotate the cutterhead (B)

toward the infeed table (C). As the edge of the

knife passes underneath the straightedge, it should

just barely brush the bottom of the straightedge,

causing it to move forward slightly, no more than

1/8”.

4. If the rotation of the cutterhead lifts and moves the

straight edge more than 1/8” or if it fails to make

contact with the bottom of the straightedge, you’ll

need to adjust the position of the knife.

5. Use a scrap of wood to keep the spring-loaded

guard open and fully-expose the cutterhead.

(C) in the mortised hole, as shown in Figure 6.

Releasing the pin will lock the angle stop in place.

When locked in the fully-engaged position, the

stop is at 90°. When locked in the partially engaged

position, it is at 45°.

FIGURE 8

11

ASSEMBLY

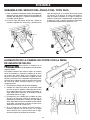

FIGURE 9

ALIGN CUTTERHEAD TO OUTFEED TABLE (continued)

FIGURE 10

6. Loosen the four screws securing the clamp bar to

the cutterhead. See Figure 8.

7. Locate the two adjustment screws on the exposed

knife. Refer to Figure 9.

8. Rotate the adjustment screws clockwise to lower

the knife or counterclockwise to raise it. Each screw

must be adjusted separately.

9. Re-check the position of the knife on either end

using the straightedge as in Step 3. Continue to

adjust the height of the knife until it brushes the

underside of the straightedge enough to move it

1/8”.

NOTE: Check both the left and right sides of the

cutterhead knife to ensure they are at the proper

height.

10. Replace the clamp bar and tighten the four screws

securing the clamp bar to the cutterhead. Slightly

tighten each of the clamp screws, making sure to

follow the sequence shown in Figure 10.

NOTE: Failure to follow the proper sequence for

tightening the clamp screws may result in the position

of the knife being altered which can affect the

performance of the tool.

CONNECTING TO DUST COLLECTOR

A jointer creates a large amount of fine particles while

in use. It is strongly recommended that you connect

the jointer to a dust collector. Your DELTA® Bench

Jointer is equipped with a 2-1/4” (OD) dust port which

is located underneath the outfeed table. This must

be connected to a dust collector hose to ensure safe

operation.

Do not attempt to operate this tool

without first connecting it to an

adequate dust collection system.

Always turn on the dust collector

before starting the jointer and always

stop the jointer before turning off the dust collector.

12

Make sure that the switch is in the

"OFF" position before plugging cord

into outlet. Do not touch the plug’s metal prongs when

unplugging or plugging in the cord.

In the event of a power outage (such

as a breaker or fuse trip), always move

the switch to the "OFF" position until the main power is

restored.

The On/Off switch (A), indicated in Figure 11, is located

on the front of the jointer cabinet. To turn the machine

“ON,” move the switch to the up position. To turn the

machine “OFF,” move the switch to the down position.

OPERATION

STARTING AND STOPPING THE JOINTER

FIGURE 11

LOCKING THE JOINTER USING THE SAFETY KEY

1. Your DELTA

®

6” Bench Jointer uses a safety key

that enables you to lock the tool in the “OFF”

position when not in use.

IMPORTANT: When the machine is not in use, the

switch should be locked in the "OFF" position to

prevent unauthorized use.

2. To lock the machine, remove the safety key by

pulling it straight out. With the safety key removed,

the switch will not operate.

3. Should the safety key be removed while the jointer

is running, the machine can be turned "OFF,"

but cannot be restarted unless the safety key is

re-inserted.

ADJUSTING FENCE POSITION

Disconnect the machine from the

power source before making any

adjustments!

See Figure 12.

Prior to performing any jointer operation, check to

make sure the fence position is approximately the

same as the width of the stock being jointed. For edge

jointing of thinner stock, it is recommended that you

occasionally reposition the fence to avoid dulling the

knives in one area.

1. To adjust the position of the fence, loosen the

indexing lock handle (A) by rotating it to left.

2. Move fence to proper position.

3. Retighten the indexing lock handle.

FIGURE 12

13

OPERATION

FEEDING STOCK

1. Place the surface to be jointed face down on the

infeed table and against the fence. Turn the jointer

on and wait for the motor to come to full speed.

2. Apply light downward pressure and slowly feed the

stock through the spring-loaded cutter guard and

over the cutting head.

IMPORTANT: When feeding stock horizontally, with

the width of the board laying flat against the table,

always use safety paddles or a push stick, as shown

in Figure 13. When feeding stock vertically, with the

FIGURE 13 FIGURE 14

width of the board flush against the fence, always keep

fingers on top of the board. See Figure 14.

3. Keep moving the board until it clears the cutter.

4. Turn the jointer off and wait for the cutterhead to

come to a stop before removing the stock.

JOINTING BEVELED STOCK

Disconnect the machine from the

power source before making any

adjustments!

The fence can adjust to an inward 45° angle and an

outward 45° angle, enabling you to joint beveled stock.

To adjust the fence tilt, do the following:

OUTWARD 45° ANGLE:

See Figure 15.

1. Loosen the beveling lock by rotating the handle (A)

counterclockwise.

2. Pull the spring-loaded pin (B) up and pull the

45°/90° Stop (C) back slightly.

3. Release the spring-loaded pin and continue pulling

the 45°/90° Stop until it locks in position.

4. Retighten the beveling lock. Use a combination

square or carpenters square to check the tilt angle.

If it needs to be adjusted, refer to “Calibrating the

45°/90° Stops” on page 14.

FIGURE 15

14

OPERATION

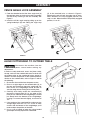

JOINTING BEVELED STOCK (continued)

FIGURE 16

INWARD 45° ANGLE:

See Figure 16.

1. Loosen the beveling lock (A) by rotating the handle

counterclockwise.

2. Tip the fence toward the table as far as it will go.

It will stop when the fence contacts the inward 45°

stop bolts.

3. Retighten the beveling lock. Use a combination

square or carpenters square to check the tilt angle.

If it needs to be adjusted, refer to “Calibrating the

45°/90° Stops” on page 14.

When jointing with the fence tilted

inward at 45° feed the stock carefully to

ensure that the workpiece does not become trapped

between the fence and table, which can create a

dangerous situation.

CALIBRATING THE 45°/90° STOPS

Disconnect the machine from the

power source before making any

adjustments!

To ensure precise and accurate results, the 45° and 90°

Stops must accurately position the fence in relation to

the table surface.

TO CALIBRATE THE 90° STOP:

1. Loosen the beveling lock by rotating the handle

counterclockwise.

2. Ensure the 45°/90° Stop is fully-engaged and locked

in position.

3. Using a carpenter’s square, with one edge flat on

the table and the other against the fence, check

to see if the fence and table are in square. If any

adjustment is needed, proceed to step #4.

4. Loosen the retaining nut located on the 90° Stop

rod.

5. Use a flat head screwdriver to adjust the position

of the Stop rod. Refer to Figure 17. Turning the rod

clockwise reduces the fence angle while rotating it

counterclockwise increases the fence angle.

6. Re-tighten the retaining nut and re-lock the beveling

lock. Then re-check the angle using the carpenter’s

square. Continue to adjust as needed.

FIGURE 17

15

FIGURE 18

TO CALIBRATE THE 45° INWARD AND OUTWARD STOPS:

OPERATION

1. Loosen the beveling lock by rotating the handle

counterclockwise.

2. Refer to Figure 18 and locate the two sets of 45°

Stop Bolts (A), there are two bolts that set the

position for the inward 45° Stop and two that set

the position for the outward 45° stop.

3. Loosen the two retaining nuts on the appropriate

set of Stop bolts and adjust the Stop bolts either in

or out.

NOTE: The heads of both Stop bolts must be flush

against the mount assembly.

4. Re-tighten the retaining nut and re-lock the

beveling lock. Then re-check the angle using the

carpenter’s square. Continue to adjust as needed.

DEPTH ADJUSTMENT

Disconnect the machine from the

power source before making any

adjustments!

The DELTA

®

37-071 Bench Jointer is designed to

remove no more than 1/8” of stock in a single pass. For

operations requiring the removal of more stock, make

several passes to achieve the desired dimensions.

1. To adjust the depth of cut, rotate the infeed table

height adjustment wheel. Turning the wheel

clockwise raises the table (reducing the depth of

cut) while rotating it counterclockwise lowers the

table (increasing the depth of cut).

16

MAINTENANCE

CHANGING CUTTERHEAD KNIVES

Disconnect the machine from the

power source before making any

adjustments!

Jointer knives are dangerously sharp.

Use extreme caution when inspecting,

removing, sharpening, or replacing knives into the

cutterhead. Failure to comply may cause serious injury.

The DELTA

®

37-071 6” Bench Jointer uses two

individual knives. Should you notice a significant

decrease in the performance of your jointer, it may be

necessary to replace the knives. To do this, follow these

steps:

1. Place a scrap piece of wood between the spring-

loaded cutter guard and fence in order to fully

expose the cutterhead.

2. Carefully and slowly rotate the cutterhead by hand

until the clamp bar and four clamp screws (A) are

accessible. See Figure 19.

3. Unscrew the clamp screws and remove the clamp

bar.

Cutterhead knives are sharp. Use

caution when handling cutterhead

knives. Use gloves to reduce the risk of injury.

4. Carefully lift the knife from the cutterhead, taking

care to note its proper orientation to the cutterhead.

5. Repeat Steps 2-4 for the second cutterhead knife.

6. Clean the cutterhead thoroughly before installing

new knives or re-installing sharpened knives.

7. Install the new or re-sharpened knife and the clamp

bar in the cutterhead. Slightly tighten each of the

clamp screws, making sure to follow the sequence

shown in Figure 20.

NOTE: Failure to follow the proper sequence for

tightening the clamp screws may result in the position

of the knife being altered which can affect the

performance of the tool.

8. Repeat Step 7 for the second cutterhead knife.

9. Check the alignment on the knives to the surface

of the outfeed table as described in the section

Align Cutterhead to Outfeed table, on page 10. If

necessary, rotate the two jack screws on either end

of the cutterhead knife in order to ensure the knife is

parallel to the outfeed table.

FIGURE 19

FIGURE 20

OTHER RECOMMENDED MAINTENANCE

1. Periodically blow out all air passages with dry

compressed air. All plastic parts should be cleaned

with a soft damp cloth. NEVER use solvents to

clean plastic parts. They could possibly dissolve or

otherwise damage the material.

2. Periodically check tightness on all other hardware

and listen for any unusual vibrations as you work as

these may be a sign of loose hardware.

10. Perform final tightening on each of the four clamp

screws uses the proscribed sequence in Figure 19.

11. Remove the scrap wood block and return the

cutterhead guard to original operating position.

Re-align the fence as needed and test the jointer

on a piece of scrap stock.

ACCESSORIES

A complete line of accessories is available from your DELTA

®

Supplier, DELTA

®

Factory Service Centers, and

DELTA

®

Factory Service Centers, and DELTA

®

Authorized Service Centers. Please visit our Web Site www.

DeltaMachinery.com for an online catalog or for the name or your nearest supplier.

Since accessories other than those offered by DELTA

®

have not been tested with this product,

use of such accessories could be hazardous. For safest operation, only DELTA

®

recommended

accessories should be used with this product.

Five Year Limited New Product Warranty

DELTA

®

will repair or replace, at its expense and at its option, any new DELTA

®

machine, machine part, or machine accessory which in normal

use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to a DELTA

®

factory service

center or authorized service station with proof of purchase of the product within five years and provides DELTA

®

with reasonable opportunity

to verify the alleged defect by inspection. For all refurbished DELTA

®

product, the warranty period is 180 days. DELTA

®

will not be responsible

for any asserted defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by anyone

other than an authorized DELTA

®

service facility or representative. Under no circumstances will DELTA

®

be liable for incidental or consequential

damages resulting from defective products. Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty is DELTA

®

’s sole warranty and sets forth the customer’s exclusive remedy,

with respect to defective products; all other warranties, express or implied, whether of merchantability, fitness for purpose, or otherwise, are

expressly disclaimed by DELTA

®

. For further detail of warranty coverage and warranty repair information, visit www.DeltaMachinery.com or call

1-800-223-7278. This warranty gives you specific legal rights and you may have other rights which vary in certain states or provinces.

WARRANTY

To register your tool for warranty service visit our website at www.DeltaMachinery.com.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America,

see country specific warranty information contained in the packaging, call the local company or see website for warranty

information.

17

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our website at www.DeltaMachinery.

com/service. You can also order parts from your nearest factory-owned branch, Authorized Warranty Service

Center or by calling Technical Service Manager at 1-800-223-7278 to receive personalized support from one of our

highly-trained representatives.

FREE WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call

1-800-223-7278

for a free replacement.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information

about DELTA

®

Power Equipment Corporation, its factory-owned branches, or to locate an

Authorized Warranty Service Center, visit our website at www.DeltaMachinery.com/service

or call our Customer Care Center at 1-800-223-7278. All repairs made by our service centers are fully

guaranteed against defective material and workmanship. We cannot guarantee repairs made or attempted by

others. By calling this number you can also find answers to most frequently asked questions.

You can also write to us for information at DELTA

®

Power Equipment Corporation, 2651 New Cut

Road, Spartanburg, SC 29303. - Attention: Technical Service Manager. Be sure to include all of the

information shown on the nameplate of your tool (model number, type, serial number, date code, etc.)

PARTS, SERVICE OR WARRANTY ASSISTANCE

All DELTA

®

machines and accessories are manufactured to high quality standards and are serviced by a network of

DELTA

®

Factory Service Centers and DELTA

®

Authorized Service Centers. To obtain additional information regarding

your DELTA

®

quality product or to obtain parts, service, warranty assistance, or the location of the nearest service

center, please call 1-800-223-7278.

18

19

20

CONSIGNES DE SÉCURITÉ IMPORTANTES

CONSIGNES DE SÉCURITÉ - DÉFINITIONS

ASSUREZ-VOUS D’AVOIR BIEN LU ET COMPRIS TOUTES LES MISES EN GARDE ET LES

CONSIGNES D’UTILISATION AVANT D’UTILISER CET ÉQUIPEMENT. Le fait de ne pas

respecter toutes les instructions ci-dessous pourrait causer une électrocution, des incendies, et/ou des blessures

personnelles ou des dommages matériels graves.

Le travail du bois peut être dangereux si des procédures d’utilisation sécuritaires et adéquates ne sont

pas respectées. Comme c’est le cas pour toute pièce de machinerie, l’utilisation de ce produit comporte

certains dangers. En utilisant cet appareil selon les directives et avec prudence, vous réduirez de façon

importante les risques de blessures corporelles. Cependant, si les précautions normales de sécurité

sont négligées ou ignorées, la personne qui utilise l’appareil pourrait être blessée. L’équipement de protection

comme les gardes, les poussoirs, les dispositifs de retenue, les planches de protection, les lunettes de sécurité,

les masques antipoussières et la protection pour l’ouïe peut réduire le risque de blessure. Cependant, même le

meilleur dispositif de protection ne peut compenser un mauvais jugement, un manque de prudence ou d'inattention.

Utilisez toujours le bon sens et soyez prudent dans l’atelier. Si une manœuvre a l’air dangereuse, ne l’effectuez

pas. Essayez plutôt de trouver un moyen plus facile. RAPPELEZ-VOUS : vous êtes responsable de votre sécurité

personnelle. Pour des renseignements complémentaires, rendez-vous sur notre site Web à l’adresse suivante

www.DeltaMachinery.com.

Cet appareil a été conçu seulement pour certaines utilisations. DELTA

MD

Power Equipment

Corporation recommande fortement que cet appareil ne soit pas modifié ni utilisé pour

toutes autres fins que celles pour lesquelles il a été conçu. Si vous avez des questions sur une utilisation en

particulier, N’UTILISEZ PAS l’appareil avant d’avoir d’abord communiqué avec DELTA

MD

pour déterminer si cette

utilisation peut ou si elle devrait être faite sur ce produit.

Si vous avez des questions relativement à son utilisation, N’UTILISEZ PAS le produit tant que vous n’aurez pas

communiqué par écrit avec DELTA

MD

Power Equipment Corporation et obtenu une réponse de sa part. Contactez-nous

en ligne à www.DeltaMachinery.com ou par courrier à l’adresse suivante : Responsable du service technique, DELTA

MD

Power Equipment Corporation, 2651 New Cut Road, Spartanburg, SC 29303.

Des renseignements au sujet de l’utilisation sécuritaire et appropriée de cet appareil sont disponibles auprès des

sources suivantes :

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851 ou en ligne sur www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• Réglementation du Département américain du travail (OSHA) à l’ad

resse www.osha.gov

Ce manuel contient des renseignements qu'il est important de connaître et de comprendre. Ces renseignements ont pour

but d’assurer VOTRE SÉCURITÉ et de PRÉVENIR LES PROBLÈMES D’ÉQUIPEMENT. Pour vous aider à reconnaître ces

renseignements, nous utilisons les symboles ci-dessous. Veuillez lire le manuel et prêter attention à ces sections.

Indique une situation extrêmement dangereuse qui, si elle n’est pas évitée, entraînera la mort ou une

blessure grave.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait

entraîner la mort ou une blessure grave.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, peut entraîner une

blessure mineure ou modérée.

Utilisé sans le symbole d’avertissement, indique une situation potentiellement dangereuse qui, si elle

n’est pas évitée, peut endommager l’appareil.

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

Delta 37-071 Manuel utilisateur

- Catégorie

- Outils électroportatifs

- Taper

- Manuel utilisateur

- Ce manuel convient également à

dans d''autres langues

- English: Delta 37-071 User manual

- español: Delta 37-071 Manual de usuario