Ingersoll-Rand TS10A Operation and Maintenance Manual

- Catégorie

- Sèche-linge électriques

- Taper

- Operation and Maintenance Manual

Ensure that the operator reads and understands the

decals and consults the manuals before maintenance or

operation.

OPERATION AND MAINTENANCE MANUAL

C.C.N. : 80441223

DATE : JANUARY 2007

REV. : F

Ensure that maintenance personnel are adequately

trained, competent and have read the Maintenance

Manuals.

TS1A–13A

Ensure that the Operation and Maintenance manual is

not removed permanently from the machine.

ENGLISH

FRENCH

PORTUGUESE

SPANISH

PRINT LANGUAGE

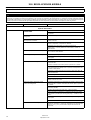

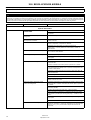

CONTENTS

TS1A–13A

http://air.irco.com

1

CONTENTS PAGE CONTENTS PAGE

1.0 CONTENTS 1

2.0 FOREWORD 2

3.0 ABBREVIATIONS &

SYMBOLS

3

4.0 PURCHASE ORDER

DETAILS

4

5.0 SAFETY 5

5.1 Safety instructions

5.2 Safety precautions

5.3

Text decals, North America

5.4 Decals, World wide – ISO

6.0 RECEIPT AND

HANDLING

10

6.1 Receipt

6.2 Unpacking and handling

7.0 INSTALLATION 11

7.1 Location in plant

7.2 Discharge and condensate

piping

7.3 Electrical

7.4 Outdoor sheltered

installation

7.5 Multiple Compressor /

Dryer Installations

8.0 GENERAL INFORMATION 14

8.1 Technical information

8.2 Installation drawing

8.3 Electrical schematic

8.4

Process and

instrumentation schematics

8.5 General description

9.0 OPERATING

INSTRUCTIONS

36

9.1 Basic operation

9.2 Intellisys controls

9.3 Display screen

9.4 Operator setpoints

9.5 Warnings

9.6 Service warnings

9.7 Alarms

10.0

START–UP PROCEDURE 42

10.1 Initial start–up

11.0 MAINTENANCE 43

11.1 Maintenance prompts

11.2 Maintenance chart

11.3 Maintenance procedures

11.4 Routine maintenance

12.0 FAULT FINDING 46

12.1

General faults

2.0 FOREWORD

TS1A–13A

http://air.irco.com

2

The contents of this manual are considered to be proprietary and

confidential to Ingersoll Rand and should not be reproduced without the

prior written permission of Ingersoll Rand.

Nothing contained in this document is intended to extend any promise,

warranty or representation, expressed or implied, regarding the

Ingersoll Rand products described herein. Any such warranties or

other terms and conditions of sale of products shall be in accordance

with the standard terms and conditions of sale for such products, which

are available upon request.

This manual contains instructions and technical data to cover all routine

operation and scheduled maintenance tasks by operation and

maintenance staff. Major overhauls are outside the scope of this

manual and should be referred to an authorized Ingersoll Rand

service department.

All components, accessories, pipes and connectors added to the

compressed air system should be:

. of good quality, procured from a reputable manufacturer and,

wherever possible, be of a type approved by Ingersoll Rand.

. clearly rated for a pressure at least equal to the machine maximum

allowable working pressure.

. compatible with the compressor lubricant/coolant.

. accompanied with instructions for safe installation, operation and

maintenance.

Ingersoll Rand reserves the right to make changes and improvements

to products without notice and without incurring any obligation to make

such changes or add such improvements to products sold previously.

Details of approved equipment are available from Ingersoll Rand

Service departments.

This machine has been designed and supplied for use only in the

following specified conditions and applications:

. Drying water vapor out of compressed air containing no known or

detectable additional gases, vapors or particles

. Operation within the ambient temperature range specified in the

GENERAL INFORMATION section of this manual.

IF IN DOUBT CONSULT SUPERVISION

.

The company accepts no responsibility for errors in translation of this

manual from the original English version.

SSR ULTRA COOLANT

R

is a registered trademark of

Ingersoll–Rand Company USA.

INTELLISYS

R

is a registered trademark of Ingersoll–Rand

Company USA.

COPYRIGHT 2007

INGERSOLL–RAND COMPANY LIMITED

WARNING

The use of the machine in any of the situation types listed in table

1:

a) Is not approved by Ingersoll Rand,

b) May impair the safety of users and other persons, and

c) May prejudice any claims made against Ingersoll Rand.

TABLE 1

WARNING – NOT PERMITTED

Use of the machine to condition compressed air for:

a) direct human consumption

b) indirect human consumption.

Use of the machine outside the ambient temperature range

specified in the GENERAL INFORMATION SECTION of this

manual.

Use of the machine where there is any actual or foreseeable risk

of hazardous levels of flammable gases or vapors.

THIS MACHINE IS NOT INTENDED AND MUST NOT BE

USED IN POTENTIALLY EXPLOSIVE ATMOSPHERES,

INCLUDING SITUATIONS WHERE FLAMMABLE GASES OR

VAPOURS MAY BE PRESENT.

Use of the machine fitted with non Ingersoll Rand approved

components.

Use of the machine with safety or control components missing or

disabled.

Connection to an electrical supply of incorrect voltage and/or

frequency.

WARNING

The use of repair parts other than those included within the

Ingersoll Rand approved parts list may create hazardous

conditions over which Ingersoll Rand has no control. Therefore

Ingersoll Rand cannot be held responsible for equipment in which

non–approved repair parts are installed.

WARNING

The dryer can contain pressurized air in the shutdown mode. Any

pressurized air must be relieved from the compressor air system

prior to breaching the dryer compressed air side.

NOTICE

The manual is intended for worldwide use and contains both

metric and imperial data where required.

3.0 ABBREVIATIONS & SYMBOLS

TS1A–13A

http://air.irco.com

3

#### Contact Ingersoll Rand for serial number

–>#### Up to Serial No.

####–> From Serial No.

* Not illustrated

† Option

NR Not required

AR As required

SM Sitemaster/Sitepack

HA High ambient machine

WC Watercooled machine

AC Aircooled machine

ERS Energy recovery system

T.E.F.C. Totally enclosed fan cooled motor (IP54)

O.D.P. Open drip proof (motor)

ppm parts per million

bg Bulgarian

cs Czech

da Danish

de German

el Greek

en English

es Spanish

et Estonian

fi Finnish

fr French

hu Hungarian

it Italian

lt Lithuanian

lv Latvian, Lettish

mt Maltese

nl Dutch

no Norwegian

pl Polish

pt Portuguese

ro Romanian

ru Russian

sk Slovak

sl Slovenian

sv Swedish

zh Chinese

4.0 PURCHASE ORDER DETAILS

TS1A–13A

http://air.irco.com

4

REFRIGERATED DRYER

This unit was purchased from

Ingersoll–Rand Company reserves the right to

make changes or add improvements without

notice and without incurring any obligation to

make such changes or add such improvements

to products sold previously.

No. of units on order:

Customer Order No:

Ingersoll–Rand Co. Order No.:

For ready reference:

Record the serial number and model number of

your unit here.

Serial Number:

Model Number:

5.0 SAFETY

TS1A–13A

http://air.irco.com

5

5.1 SAFETY INSTRUCTIONS

Safety instructions in the operators manual are bold–faced for

emphasis. The signal words DANGER, WARNING and CAUTION are

used to indicate hazard seriousness levels as follows.

Ensure that the operator reads and understands the decals and

consults the manuals before maintenance or operation.

Ensure that the Operation and Maintenance manual, and the manual

holder, are not permanently removed from the machine.

Ensure that maintenance personnel are adequately trained, competent

and have read the Maintenance Manuals.

DANGER

Indicates the presence of a hazard which WILL cause serious injury,

death or property damage, if ignored.

WARNING

Indicates the presence of a hazard which CAN cause serious injury,

death or property damage, if ignored.

CAUTION

Indicates the presence of a hazard which WILL or can cause injury or

property damage, if ignored.

NOTICE

Indicates important set–up, operating or maintenance information.

5.2 SAFETY PRECAUTIONS

General Information

Pressurized air, refrigerant and electricity can be dangerous. Before

undertaking any work on the dryer, ensure that the electrical supply

has been isolated, locked off, tagged and the dryer has been

relieved of all compressed air pressure.

Make sure that all protective covers are in place and that the

canopy/doors are closed during operation.

Installation of this dryer must be in accordance with recognized

electrical codes and any local Health and Safety Codes.

Use only safety solvent for cleaning the dryer and auxiliary equipment.

Compressed air

Ensure that the machine is operating at the rated pressure and that the

rated pressure is known to all relevant personnel.

All air pressure equipment installed in or connected to the machine

must have safe working pressure ratings of at least the machine rated

pressure.

If more than one dryer is connected to one common downstream plant,

effective check valves and isolation valves must be fitted and controlled

by work procedures, so that one machine cannot accidentally be

pressurized / over pressurized by another.

If a safety valve is installed between the isolation valve and the dryer,

it must have sufficient capacity to relieve the full capacity of the

compressor(s).

If the discharged air is to be ultimately released into a confined space,

adequate ventilation must be provided.

The use of plastic bowls on line filters without metal guards can be

hazardous. Their safety can be affected by either synthetic lubricants,

or the additives used in mineral oils. Metal bowls should be used on a

pressurized system.

When using compressed air, always use appropriate personal

protective equipment.

All pressure containing parts, especially flexible hoses and their

couplings, must be regularly inspected, be free from defects and be

replaced according to the Manual instructions.

Compressed air can be dangerous if incorrectly handled. Before doing

any work on the unit, ensure that all pressure is vented from the system

and that the machine cannot be started accidentally.

Avoid bodily contact with compressed air.

Refrigerant

Refrigeration pipes can be very hot or very cold depending on the

operating pressure and media phase. Avoid contact with these

components.

Only technicians trained on servicing refrigeration circuits may work on

refrigeration systems. Handling, recovery, and dispensing refrigerant

requires specific Local and National refrigerant certifications.

DANGER

BREATHING REFRIGERANT CAN CAUSE DEATH BY

SUFFOCATION. DO NOT BREATHE FUMES.

Materials

The following substances are used in the manufacture of this machine

and may be hazardous to health if used incorrectly:

. refrigerant

compressor oil

WARNING

AVOID INGESTION, SKIN CONTACT AND INHALATION OF

FUMES

For further information, request and consult the Refrigerant and Oil

Material Data Sheets. The sheets are designated as 80441231

refrigerant MSDS, 80441926 refrigerant oil MSDS and can be obtained

from your local IR office, Distributor or Air Center.

Consult a physician if the refrigerant is inhaled or the refrigerant oil is

ingested.

Transport

When loading or transporting machines ensure that the specified lifting

and tie down points are used.

It is recommended that the machine be moved using the fork lift slots

in the machine base.

Refer to section 8 for reference information.

5.0 SAFETY

TS1A–13A

http://air.irco.com

6

Electrical

The dryer has high and dangerous voltage in the motor starter and

control box. All installations must be in accordance with recognized

electrical codes. Before working on the electrical system, be sure to

remove voltage from the system by using a manual disconnect switch.

A circuit breaker or fuse safety switch must be provided in the electrical

supply line leading to the dryer.

Those responsible for installation of this equipment must provide

suitable grounds, maintenance clearance and lightning arrestors for all

electrical components in accordance with National and Local code

requirements.

Keep all parts of the body and any hand–held tools or other conductive

objects, away from exposed live parts of the dryer electrical system.

Maintain dry footing, stand on insulating surfaces and do not contact

any other portion of the dryer when making adjustments or repairs to

exposed live parts of the dryer electrical system.

Close all access doors when the dryer is left unattended.

Do not use extinguishers intended for Class A or Class B fires on

electrical fires. Use only extinguishers suitable for class BC or class

ABC fires.

Attempt repairs only in clean, dry, well lighted and ventilated areas.

Connect the dryer only to electrical systems that are compatible with

its electrical characteristics and that are within it’s rated capacity.

Condensate disposal

Condensate cannot be discharged into fresh/surface water drains. In

some regions compressor condensate containing ULTRA COOLANT

can be fed directly into a drainage system that has downstream

sewage treatment.

As waste water regulations vary by country and region it is the

responsibility of the user to establish the limitations and regulations in

their particular area. Ingersoll Rand and its associated distributors are

happy to advise and assist in these matters.

Refrigerant Oil

Steps to be taken in the case of spillage: Soak up with a suitable

absorbent material, then sweep into a plastic bag for disposal.

Burn in an approved incinerator, or according to local area or country

regulations.

For further information, consult Material Safety Data Sheets

WARNING

There is a high temperature shutdown feature built into each

dryer. Refer to maintenance section for service.

Failure to adhere to these recommendations can result in

mechanical failure, property damage and serious injury or death.

S All air and water inlet, and air and water discharge pipework to

and from the inlet and discharge port connections must take into

account vibration, pulsations, temperature, maximum pressure

applied, corrosion and chemical resistance. In addition, it should

be noted that lubricated compressors will discharge some oil into

the air stream; therefore, compatibility between discharge piping,

system accessories and software must be assured.

S For the foregoing reasons, the use of plastic piping, soldered

copper fittings and rubber hose as air piping is not recommended.

In addition, flexible joints and/or flex lines can only be considered

for such purposes if their specifications fit the operating

parameters of the system.

S It is the responsibility of the installer and owner to provide the

appropriate service pipework to and from the machine.

WARNING

“Ingersoll Rand air dryers are not designed, intended, or

approved for breathing air applications. Ingersoll Rand does not

approve specialized equipment for breathing air application and

assumes no responsibility or liability for dryers used for

breathing air services.”

WARNING

The specification of this machine is such that the machine is not

suitable for use in flammable gas risk areas.

WARNING

Vent compressed air system before opening.

5.0 SAFETY

TS1A–13A

http://air.irco.com

7

Read and understand safety and information decals thoroughly. Heed warnings and follow instructions. If you do not understand, inform

your supervisor.

5.3 TEXT DECALS, NORTH AMERICA

Read the Operation and Maintenance manual

before operation or maintenance of this

machine is undertaken.

Lifting point.

WARNING – Hot surface.

WARNING: Electrical shock risk. ROTATION

5.0 SAFETY

TS1A–13A

http://air.irco.com

8

5.3 TEXT DECALS, NORTH AMERICA

5.0 SAFETY

TS1A–13A

http://air.irco.com

9

5.4 DECALS, WORLD WIDE – ISO

WARNING – Do not undertake any

maintenance on this machine until the

electrical supply is disconnected and the air

pressure is totally relieved.

Read the Operation and Maintenance manual

before operation or maintenance of this

machine is undertaken.

WARNING – Hot surface.

Do not operate the machine without the guard

being fitted.

CONDENSATE DRAIN

POWER INLET (AC)

ROTATION

6.0 RECEIPT / HANDLING

10

TS1A–13A

http://air.irco.com

6.1 RECEIPT

When you receive the dryer please inspect it closely. Any indication of careless handling by the carrier should be noted on the delivery receipt especially

if the dryer will not be immediately unpacked. Obtaining the deIivery persons signed agreement to any noted damages will facilitate any future insurance

claims.

IMPORTANT

READ THIS

LOST OR DAMAGED GOODS

THOROUGHLY INSPECT THIS SHIPMENT IMMEDIATELY UPON ARRIVAL

OUR RESPONSIBILITY FOR THIS SHIPMENT CEASED WHEN THE CARRIER SIGNED

BILL OF LADING

If goods are received short or in damaged condition, it is important that you notify the carrier and insist on a

notation of the loss or damage across the face of the freight bill. Otherwise no claim can be enforced against the

transportation company.

If concealed loss or damage is discovered, notify your carrier at once and request an inspection. This is absolutely

necessary. Unless you do this the carrier will not entertain any claim for loss or damage. The agent will make an

inspection and grant a concealed damage notation. If you give the transportation company a clear receipt for

goods that have been damaged or lost in transit, you do so at your own risk and expense.

WE, AT lR, ARE WILLING TO ASSIST YOU IN EVERY POSSIBLE MANNER TO COLLECT CLAIMS FOR LOSS

OR DAMAGE, BUT THE WILLINGNESS ON OUR PART DOES NOT MAKE US RESPONSIBLE FOR

COLLECTION OF CLAIMS OR REPLACEMENT OF MATERIAL. THE ACTUAL FILING AND PROCESSING OF

THE CLAIM IS YOUR RESPONSIBILITY.

Ingersoll–Rand Company Limited

6.2 UNPACKING AND HANDLING

The dryer will normally be delivered with a cardboard box or other cover. If a knife has to be used to remove this cover, ensure that the exterior paintwork

of the dryer is not damaged.

Incorporated within the base of the dryer are slots to enable a fork lift truck to move the machine. Ensure truck forks are fully engaged on both sides.

Alternatively a special lifting frame can be utilized to enable a crane or hoist to move the dryer. Use only marked lifting points.

7.0 INSTALLATION

TS1A–13A

http://air.irco.com

11

For technical information see section 8.0.

7.1 LOCATION IN PLANT

KEY

1. Compressor

2. Air Receiver

3. Air Dryer

4. Compressed air filters

5. System demand points

6. Valve, vent

7. Valve, isolation

8. Valve, condensate

9. Valve, bypass

Ensure that the correct tie down points are used.

For major overhaul position the machine to obtain lifting access e.g.

fork lift truck.

Ambient temperatures higher than 46_C (115_F) must be avoided as

well as areas of high humidity.

Consider also the environment surrounding or near the dryer. The area

selected for the location of the dryer should be free of dust, chemicals,

metal filings, paint fumes and overspray.

Hard surfaces may reflect noise with an apparent increase in the

decibel level. When sound transmission is important, a sheet of rubber

or cork can be installed beneath the machine to reduce noise. Flexible

piping may be required.

It is recommended that provision be made for lifting heavy components

during major overhaul. Use only lifting points provided.

Minimum space in front of control panel door as required by National

or Local codes must be maintained.

The dryer can be installed on any level floor capable of supporting it.

A dry, well ventilated area where the atmosphere is as clean as

possible is recommended.

Sufficient space all around and above the dryer must be allowed, to

enable the effective removal of the cooling air which, in turn, will reduce

the risk of recirculating the cooling air back through the dryer.

CAUTION

A minimum of 1 m (3ft) all round the dryer is recommended. If

headroom is restricted, then the exhaust should be ducted or

deflected away from the machine.

7.0 INSTALLATION

TS1A–13A

http://air.irco.com

12

7.2 DISCHARGE AND CONDENSATE PIPING

KEY

1. Compressor

2. Air Receiver

3. Air Dryer

4. Compressed air filters

5. System demand points

6. Valve, vent

7. Valve, isolation

8. Valve, condensate

9. Valve, bypass

It is essential when installing a new dryer [3], to review the total air

system. This is to ensure a safe and effective total system. One item

which should be considered is liquid carryover. Installation of air dryers

[3] is always good practice since properly selected and installed they

can reduce any liquid carryover to zero.

Piping should be at least as large as the discharge connection of the

equipment. All piping and fittings should be suitably rated for the

operating pressure.

It is good practice to locate by–pass piping close to the dryer and to

install line filters [4].

IMPORTANT: The drain line must slope downward from the base to

work properly. For ease of inspection of the automatic drain trap

operation, the drain piping should include an open funnel.

CAUTION

The use of plastic bowls on line filters and other plastic air line

components without metal guards can be hazardous. Their safety

can be affected by either synthetic coolants or the additives used

in mineral oils. From a safety standpoint, metal bowls should be

used on any pressurized system.

NOTICE

Do not use the dryer to support the piping.

7.3 ELECTRICAL

CAUTION

This procedure should only be carried out by a qualified

electrician, electrical contractor or your local Ingersoll Rand

Distributor or Air Center.

The dryer should be properly grounded / earthed in accordance with

Local and National Code requirements..

Installation of this dryer must be in accordance with recognized

electrical codes and any local Health and Safety Codes.

The dryer must have its own isolator situated adjacent to it. The fuse

protecting the circuit and the dryer must be selected in accordance with

local and national code requirements on the basis of the data provided

in the general information section

Feeder cables should be sized by the customer/electrical contractor to

ensure that the circuit is balanced and not overloaded by other

electrical equipment. The length of wiring from a suitable electrical feed

point is critical as voltage drops may impair the performance of the

dryer.

Feeder cable connections to incoming terminals L1–L2–L3 should be

tight and clean.

The applied voltage must be compatible with the data plate ratings.

NOTICE

The control circuit transformer has different voltage tappings.

Ensure that these are set for the specific applied voltage prior to

starting.

A hole is provided for incoming power connection. If it is necessary to

make a hole in the control box in a different location, care should be

taken to not allow metal shavings to enter the starter and other electrical

components within the box. If another hole is used, the original hole

must be blocked off.

The feeder cable must be suitably glanded into the electrical box to

ensure that dirty air does not by–pass.

On completion of electrical installation, check that fan motor rotation is

correct. Cooling air must discharge upwards.

7.0 INSTALLATION

TS1A–13A

http://air.irco.com

13

7.4 OUTDOOR SHELTERED INSTALLATION

TS dryers are not suitable for outdoor installation.

Installing a TS dryer outside voids the warranty of the dryer.

7.5 MULTIPLE COMPRESSOR /DRYER INSTALLATIONS

KEY

A/C Air Compressor

D Air Dryer

CAUTION

Contact Ingersoll Rand for proper design and application.

Failure to do so may result in overloading of the dryer(s), dryer(s) shutdown, and water in the compressed air system.

8.0 GENERAL INFORMATION

TS1A–13A

http://air.irco.com

14

8.1 TECHNICAL INFORMATION

COMMON TECHNICAL DATA

General

Maximum ambient temperature _C (_F) 46 (115)

Minimum ambient temperature _C (_F) 2 (35)

Refrigerant type R404A

Refrigerant oil ISO 32 Polyolester (POE)

Maximum standard compressed air inlet pressure, barg (psig)

(4)

12.1 (175)

Control settings

Hot gas valve setting, barg (psig)

(5)

5.03 – 5.66 (73 – 82)

Thermal expansion valve superheat, _C (_F)

(6)

3.3 – 5.0 (6.0 – 9.0)

High refrigerant temperature switch setting _C 115 (240)

High pressure switch setting barg (psig) 29.3 (425)

Fan pressure switch setting on/off barg (psig) 16.5 / 13.1 (240 / 190)

Fan temp switch setting on/off _C (_F) 99 / 82 (210 / 180)

Low pressure switch setting barg (psig) 2.8 (40)

Performance

(1)(2)

Dew point temperature at rated conditions and flow, _C (_F)

(2)

3.8 (39)

Dew point temperature at rated conditions and flow, _C (_F)

(1)

3.0 (37.4)

Air Cooling System

Maximum ∆P across duct work, mm H

2

O (in. H

2

O) 1.0 (0.04)

(1)

All standard 230v/1/50Hz, 230v/1/60Hz, 400v/3/50Hz and 380v/3/60Hz machines: 25_C ambient, 7 barg inlet, 35_C inlet, 35_C dew point

inlet.

(2)

All standard 230v/3/60Hz, 460v/3/60Hz and 575v/3/60Hz machines: 85_F ambient, 125 psig inlet, 100_F inlet, 100_F dew point inlet.

(3)

Always apply local electrical codes for sizing cables and fusing. In absence of local codes, the minimum cable size should always be calculated

on basis of maximum package full load x1.25.

(4)

High pressure options allow machines to operate at high pressure ratings. See machine specification data decal for pressure ratings for these

machines.

(5)

The low side refrigerant pressure is factory set at 5.38 – 5.66 barg (78 – 82 psig). It may need to be adjusted at the hot gas valve periodically due

to local ambient and seasonal changes to avoid dryer freeze–up. See section 11.4 “Routine Maintenance” for the adjustment procedure.

(6)

Evaporator superheat is factory set and should not require adjustment unless it is measured out of specification when the dryer is operating at

its nominal load, and the discharge air pressure dewpoint is high.

See “Routine Maintenance” for the adjustment procedure.

8.0 GENERAL INFORMATION

TS1A–13A

http://air.irco.com

15

Model / Electrical Compressed Air,

m

3

/min (scfm) (1),

(2)

Dryer Pressure

Drop, bar (psi) (1),

(2), (3)

Cooling Air Flow,

m

3

/hr (cfm)

(1), (2), (3)

Nominal Package

Amps (1), (2), (3)

Maximum Package

Amps

TS–1A, 230/1/50 9.0 (319) 0.16 (2.3) 4,200 (2,470) 10.4 12.7

TS–1A, 230/1/60 9.0 (319) 0.16 (2.3) 4,800 (2,820) 10.2 11.8

TS–1A, 230/3/60 7.0 (250) 0.13 (1.8) 5,500 (3,230) 8.5

TS–1A, 460/3/60 7.0 (250) 0.13 (1.8) 3,200 (1,880) 4.4

TS–2A, 230/1/50 14.0 (494) 0.19 (2.8) 4,400 (2,580) 13.3 18.4

TS–2A, 230/1/60 14.0 (494) 0.19 (2.8) 3,700 (2,170) 10.9 17.0

TS–2A, 230/3/60 9.6 (340) 0.20 (2.8) 1,800 (1,050) 8.7

TS–2A, 400/3/50 14.0 (494) 0.19 (2.8) 3,400 (2,000) 4.9 6.9

TS–2A, 460/3/60 9.6 (340) 0.20 (2.8) 1,800 (1,050) 4.8

TS–3A, 230/3/60 13.0 (460) 0.23 (3.2) 5,500 (3,230) 12.5

TS–3A, 380/3/60 15.8 (560) 0.23 (3.4) 4,600 (2,700) 6.1 8.4

TS–3A, 400/3/50 15.8 (560) 0.23 (3.4) 5,400 (3,170) 5.8 8.2

TS–3A, 460/3/60 13.0 (460) 0.23 (3.2) 3,000 (1,760) 6.1

TS–4A, 230/3/60 16.4 (580) 0.24 (3.4) 5,100 (3,000) 13.2

TS–4A, 380/3/60 19.2 (676) 0.28 (4.0) 3,900 (2,290) 8.5 9.5

TS–4A, 400/3/50 19.2 (676) 0.28 (4.0) 6,000 (3,530) 8.0 9.7

TS–4A, 460/3/60 16.4 (580) 0.24 (3.4) 4,800 (2,820) 6.8

TS–5A, 230/3/60 19.2 (680) 0.21 (3.0) 6,200 (3,640) 15.3

TS–5A, 380/3/60 23.4 (827) 0.15 (2.2) 7,300 (4,290) 9.2 10.0

TS–5A, 400/3/50 23.4 (827) 0.15 (2.2) 6,000 (3,530) 8.6 10.9

TS–5A, 460/3/60 19.2 (680) 0.21 (3.0) 6,100 (3,590) 7.7

TS–6A, 380/3/60 28.0 (987) 0.25 (3.6) 7,600 (4,470) 9.8 11.9

TS–6A, 400/3/50 28.0 (987) 0.25 (3.6) 7,500 (4,410) 9.3 12.3

TS–6A, 460/3/60 25.4 (900) 0.18 (2.5) 7,600 (4,470) 10.1

TS–7A, 380/3/60 31.5 (1,113) 0.23 (3.4) 7,600 (4,470) 11.6 14.4

TS–7A, 400/3/50 31.5 (1,113) 0.23 (3.4) 7,500 (4,410) 11.3 14.0

TS–7A, 460/3/60 30.2 (1,070) 0.25 (3.6) 7,700 (4,530) 11.7

TS–8A, 380/3/60 40.2 (1,420) 0.26 (3.7) 10,900 (6,410) 14.5 17.6

TS–8A, 400/3/50 46.5 (1,643) 0.26 (3.7) 10,800 (6,350) 14.4 18.2

TS–8A, 460/3/60 35.6 (1,260) 0.25 (3.6) 14,000 (8,240) 14.5

TS–9A, 380/3/60 51.0 (1,800) 0.30 (4.3) 12,400 (7,290) 16.7 22.6

TS–9A, 400/3/50 51.0 (1,800) 0.30 (4.3) 14,600 (8,590) 15.6 20.0

TS–9A, 460/3/60 43.6 (1,540) 0.35 (5.0) 12,100 (7,120) 17.0

TS–10A, 460/3/60 49.5 (1,750) 0.40 (5.7) 14,900 (8,760) 18.8

TS–10A, 380/3/60 62.4 (2,203) 0.22 (3.2) 16,300 (9,590) 17.8 22.7

TS–10A, 400/3/50 62.4 (2,203) 0.22 (3.2) 18,200 (10,710) 17.2 23.2

TS–11A, 400/3/50 71.5 (2,527) 0.22 (3.2) 20,400 (12,000) 21.1 26.3

TS–11A, 460/3/60 56.6 (2,000) 0.42 (6.0) 17,000 (10,000) 22.7

TS–12A, 400/3/50 80.7 (2,850) 0.21 (3.1) 32,400 (19,060) 27.9 33.0

TS–12A, 460/3/60 63.7 (2,250) 0.43 (6.1) 19,600 (11,530) 23.2

TS–13A, 460/3/60 68.8 (2,430) 0.45 (6.5) 23,100 (13,590) 28.0

(1)

All standard 230v/1/50Hz, 230v/1/60Hz, 380v/3/60Hz, 400v/3/50Hz machines rated at 25_C ambient, 7 barg inlet, 35_C inlet, and 35_C pressure

dew point inlet.

(2)

All standard 230v/3/60Hz, 460v/3/60Hz, and 575v/3/60Hz machines rated at 85_F ambient, 125 psig, 100_F inlet, and 100_F pressure dew point

inlet.

(3)

Data reported at compressed air flow condition stated in table.

(4)

575v data is not specifically published since it is a 460v dryer shipped with a transformer.

8.0 GENERAL INFORMATION

TS1A–13A

http://air.irco.com

16

8.2 INSTALLATION DRAWING

TS–1A, 50/60Hz

KEY

A. Electrical conduit connection

B. Compressed air inlet

50Hz – 1 1/2” BSPT female

230v / 1 / 60Hz – 1 1/2” BSPT female

All other 60Hz – 1 1/2” NPT female

C. Compressed air discharge

50Hz – 1 1/2” BSPT female

230v / 1 / 60Hz – 1 1/2” BSPT female

All other 60Hz – 1 1/2” NPT female

D. Condensate drain

50Hz – 1/8” BSPT female

230v / 1 / 60Hz – 1/8” BSPT female

All other 60Hz – 1/8–27 NPTF female

NOTES:

1. Weight (approximate):207 kg (455 lb)

2. Refrigerant: R–404A

3. Tolerance on dimensions: 13mm (0.5”) unless otherwise

stated.

4. 305mm (12”) minimum electrical cable length allowance is

required between the electrical cable entry (A) and the mains

terminal block.

5. Recommended clearance on all sides 1 m (3 ft) front panel with

starter door may require more as defined by local and national

electrical codes.

6. External piping shall not exert any unresolved moments or

forces on it.

7. There should be no plastic piping, not approved by IR, attached

to this unit or used for any lines downstream.

8. Field installed ducting to and from the dryer can not add more

than 1.0mm (0.04) water air resistance.

8.0 GENERAL INFORMATION

TS1A–13A

http://air.irco.com

17

TS–2A, TS–3A & TS–4A, 50/60Hz

KEY

A. Electrical conduit connection

B. Compressed air inlet

50Hz – 2” BSPT female

230v / 1 / 60Hz – 2” BSPT female

380v / 3 / 60Hz – 2” BSPT female

All other 60Hz – 2” NPT female

C. Compressed air discharge

50Hz – 2” BSPT female

230v / 1 / 60Hz – 2” BSPT female

380v / 3 / 60Hz – 2” BSPT female

All other 60Hz – 2” NPT female

D. Condensate drain

50Hz – 1/8” BSPT female

230v / 1 / 60Hz – 1/8” BSPT female

380v / 3 / 60Hz – 1/8” BSPT female

All other 60Hz – 1/8–27 NPTF female

Model Dimension “X”

TS–2A 1408 mm

TS–3A 1396 mm

TS–4A 1410 mm

NOTES:

1. Weight (approximate):

TS–2A: 226 kg (497 lb)

TS–3A: 230 kg (506 lb)

TS–4A: 230 kg (506 lb)

2. Refrigerant: R–404A

3. Tolerance on dimensions: 13mm (0.5”) unless otherwise

stated.

4. 305mm (12”) minimum electrical cable length allowance is

required between the electrical cable entry (A) and the mains

terminal block.

5. Recommended clearance on all sides 1 m (3 ft) front panel with

starter door may require more as defined by local and national

electrical codes.

6. External piping shall not exert any unresolved moments or

forces on it.

7. There should be no plastic piping, not approved by IR, attached

to this unit or used for any lines downstream.

8. Field installed ducting to and from the dryer can not add more

than 1.0mm (0.04) water air resistance.

8.0 GENERAL INFORMATION

TS1A–13A

http://air.irco.com

18

TS–5A 50/60Hz

KEY

A. Electrical conduit connection

B. Compressed air inlet

50Hz: 3” BSP female

380v / 3 / 50Hz: 3” BSP female

All other 60Hz: 3” NPT female

C. Compressed air discharge

50Hz: 3” BSP female

380v / 3 / 50Hz: 3” BSP female

All other 60Hz: 3” NPT female

D. Condensate drain

50Hz: 1/4” BSP female

380v / 3 / 60Hz: 1/4” BSP female

All other 60Hz: 1/4” NPT female

NOTES:

1. Weight (approximate):

TS–5A: 429 kg (944 lb)

2. Refrigerant: R–404A

3. Tolerance on dimensions: 13mm (0.5”) unless otherwise

stated.

4. 305mm (12”) minimum electrical cable length allowance is

required between the electrical cable entry (A) and the mains

terminal block.

5. Recommended clearance on all sides 1m (3ft) front panel with

starter door may require more as defined by local and national

electrical codes.

6. External piping shall not exert any unresolved moments or

forces on it.

7. There should be no plastic piping, not approved by IR, attached

to this unit or used for any lines downstream.

8. Field installed ducting to and from the dryer can not add more

than 1.0mm (0.04) water air resistance.

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

-

157

157

-

158

158

-

159

159

-

160

160

-

161

161

-

162

162

-

163

163

-

164

164

-

165

165

-

166

166

-

167

167

-

168

168

-

169

169

-

170

170

-

171

171

-

172

172

-

173

173

-

174

174

-

175

175

-

176

176

-

177

177

-

178

178

-

179

179

-

180

180

-

181

181

-

182

182

-

183

183

-

184

184

-

185

185

-

186

186

-

187

187

-

188

188

-

189

189

-

190

190

-

191

191

-

192

192

-

193

193

-

194

194

-

195

195

-

196

196

-

197

197

-

198

198

-

199

199

-

200

200

-

201

201

-

202

202

-

203

203

-

204

204

Ingersoll-Rand TS10A Operation and Maintenance Manual

- Catégorie

- Sèche-linge électriques

- Taper

- Operation and Maintenance Manual

dans d''autres langues

- English: Ingersoll-Rand TS10A

- español: Ingersoll-Rand TS10A

- português: Ingersoll-Rand TS10A

Documents connexes

-

Ingersoll-Rand 2475N7.5-V Manuel utilisateur

-

Ingersoll-Rand 2000 Manuel utilisateur

-

Ingersoll-Rand P1.5IU-A9 Le manuel du propriétaire

-

Ingersoll-Rand UP6 15c Installation, Operation and Maintenance Manual

-

Ingersoll-Rand HF50–PE Manuel utilisateur

-

Ingersoll-Rand 400 Manuel utilisateur

-

Ingersoll-Rand D54IN Manuel utilisateur

-

Ingersoll-Rand UP6 30 Operation and Maintenance Manual

-

Ingersoll-Rand 2000 Manuel utilisateur

-

Ingersoll-Rand SSR UP6-7.5 Operation and Maintenance Manual

Autres documents

-

Ingersoll Rand 23231624 Manuel utilisateur

-

Ingersoll Rand 23231806 Manuel utilisateur

-

Industrial Air IAD20 Manuel utilisateur

-

HANKISON HPRP 150 Manuel utilisateur

HANKISON HPRP 150 Manuel utilisateur

-

Frigidaire FGVU17F8QF Information produit

-

Frigidaire FGVU17F8QF Information produit

-

Thermo King Magnum+ Manuel utilisateur

-

Hillsdale Furniture Rockdale Wood Bunk Bed Le manuel du propriétaire

-

EKOM DK50 DS Manuel utilisateur

EKOM DK50 DS Manuel utilisateur

-

Sigma HRD2250EM Manuel utilisateur