La page est en cours de chargement...

TABLE OF CONTENTS

QUICK START GUIDE 4

TECHNICAL SPECIFICATIONS 6

SAFETY GUIDELINES 7

KEY PARTS DIAGRAM 12

IMPORTANT INFORMATION 13

ASSEMBLY INSTRUCTIONS 14

OPERATION 16

MAINTENANCE 19

TROUBLESHOOTING GUIDE 21

EXPLODED VIEW AND PARTS LIST 24

WARRANTY 29

2

TABLE OF CONTENTS

model no. 058-9317-8 | contact us 1-888-670-6682

model no. 058-9317-8 | contact us 1-888-670-6682

4

QUICK START GUIDE

Fix the wheels (1) to the tank using the

bolts and nuts. Place the compressor

(2) on the floor or a hard, level surface

in a clean, well-ventilated area.

See step 4 referenced below.

1

Connect the air hose (1)

between the air line outlet (2)

and air tool (3). See page 15,

step 4.

2

Make sure the AUTO/OFF switch

(1) is in OFF position and the drain

valve at the bottom of tank is

closed. See page 16, steps 1-2.

3

2

1

1

2

3

1

1

1

3

2

2

2

1

1

2

3

1

1

1

3

2

2

2

1

1

2

3

1

1

1

3

2

2

5

TM

QUICK START GUIDE

Adjust the hose pressure

gradually with respect to the

operating pressure of the air

tool by turning the pressure

regulator knob (1) clockwise.

See page 17, step 6.

5

Turn the pressure regulator knob (1)

counter-clockwise completely. Plug

in the power cord (2) into electrical

outlet. Turn the AUTO/ OFF switch

(3) to the AUTO position.

See pages 16-17, steps 3-5.

4

2

1

1

2

3

1

1

1

3

2

2

2

1

1

2

3

1

1

1

3

2

2

model no. 058-9317-8 | contact us 1-888-670-6682

6

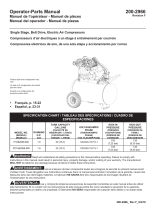

TECHNICAL SPECIFICATIONS

COMPRESSOR TYPE Oil-less, single stage, direct drive

RUNNING HORSEPOWER 1.5

POWER 120 V, 60 Hz 15A

DUTY CYCLE 50%

TANK SIZE 15 U.S. GALLONS (56.8 L)

MOTOR TYPE Heavy-duty induction motor

CUT-IN PRESSURE 160 PSI (1.10 MPa)

CUT-OFF PRESSURE 200 PSI (1.38 MPa)

COMPRESSOR CAPACITY 5 CFM* @ 40 PSI

4 CFM* @ 90 PSI

PACKAGING WEIGHT 92 lb (41.7 kg)

TECHNICAL SPECIFICATIONS

*CFM: Cubic feet per minute

7

TM

SAFETY GUIDELINES

FPO

FPO

SAFETY GUIDLINES

This manual contains information that relates to PROTECTING PERSONAL SAFETY and

PREVENTING EQUIPMENT PROBLEMS. It is very important to read this manual carefully

and understand it thoroughly before using the product. The symbols listed below are

used to indicate this information.

DANGER!

Potential hazard that will result in serious injury or loss

of life.

FPO

WARNING!

Potential hazard that could result in serious injury or loss

of life.

CAUTION!

Potential hazard that may result in moderate injury or

damage to equipment.

SAFETY RECOMMENDATIONS

These precautions are intended for the personal safety of the user and others working

with the user. Failure to follow these instructions may result in a permanent loss of

vision, serious personal or even fatal injury, property damage, and/or tool damage.

Please take the time to read and understand them.

DANGER!

Potential hazard that will result in serious injury or loss of life.

• Keep bystanders, children, and visitors away from the work area while operating

the compressor. Do not allow children to handle the compressor. Distractions can

affect the control over compressor.

• Never direct compressed air, dust, or dirt toward yourself, other people or animals

to reduce the risk of serious injury.

• Wear a face or dust mask or use a respirator in dusty environments or when

spraying paint.

• Never remove the pressure switch housing at anytime.

• Never use the compressor in a combustible environment or in the presence of

combustible materials, such as flammable chemicals, adhesives, gasoline or

solvents, as the internal combustion produces hot exhaust gases that may ignite

flammable materials. Failure to observe this warning can cause explosion and

serious personal injury or death.

• Risk of inhalation. Operate the compressor in an open area at a minimum of

12” (30 cm) away from any wall or object that could restrict the flow of fresh

air to ventilation openings. Do not use the compressor to spray chemicals, as

doing so may affect your lungs by inhaling toxic fumes. Use a respirator in dusty

environments or when spraying paint.

8

model no. 058-9317-8 | contact us 1-888-670-6682

SAFETY GUIDELINES

• Risk of bursting. Do not adjust the pressure regulator knob to increase the output

pressure to greater than the maximum rated pressure of the air tool attached to the

compressor.

WARNING!

Potential hazard that could result in serious injury or loss of life.

• Do not allow inexperienced or untrained individuals to operate the compressor.

• Before servicing the compressor, always disconnect the power supply and open the

drain valve to decompress the air tank. Make sure water is drained. Wait until the

compressor becomes cool.

• Turn the pressure regulator knob fully clockwise after shutting off the compressor,

to avoid accidental rise in pressure when starting the compressor.

• Use head protection accessory such as hard hat, if required. It must conform to

American National Standards Institute (ANSI Z89.1) requirements.

CAUTION!

Potential hazard that may result in moderate injury or damage to equipment.

• Do not wear watches, rings, bracelets, or loose clothing when using the compressor.

Keep your hair, clothing, and gloves away from moving parts.

• Use the compressor only for its intended purpose. Do not alter or modify the

compressor from its original design or function.

• Do not use a compressor that is malfunctioning or with loose, missing or damaged

parts, or that requires repairs. Verify that all screws are securely tightened.

• Keep the compressor and work area clean and well lit. A cluttered or dirty place

may lead to an accident. Floors should be kept clear.

• Do not misuse the power cord. Never use the cord to carry the compressor. Always

use grip handle to move it. Remove the power plug from the power supply outlet

after use.

• Do not operate the compressor if it does not contain a legible warning label.

• Never use the compressor when there is air or water leakage.

• Store the compressor in a dry location, out of reach of children and other untrained

persons.

FPO

CAUTION!

Potential hazard that may result in moderate injury or

damage to equipment.

FPO

WARNING!

Potential hazard that could result in serious injury or loss

of life.

9

TM

SAFETY GUIDELINES

• Always maintain the compressor the compressor properly to avoid internal

corrosion and possible failure.

• Release all pressure within the compressor slowly, as the dust and debris is harmful

and affect human health.

• Keep the exterior of the compressor dry, clean, and free from oil and grease.

Always use a clean cloth for cleaning. Never use brake fluids, gasoline, petroleum-

based products, or any strong solvents to clean the compressor to reduce the risk of

deterioration of the plastic enclosure.

• When servicing the compressor, use only replacement parts of same specification

to avoid risk of injury and equipment damage.

• Drain out the moisture from the tank completely after each day’s use to prevent

corrosion on the inside of the tank.

• Before using the compressor, check for damaged parts, misalignment or binding

of moving parts, broken parts, and any other condition that affects the operation.

The damaged parts should be properly repaired or replaced only by a qualified

electrician. The repaired part should be checked carefully to ensure that it operates

properly and performs its intended function.

• Use the proper extension cord. Make sure to use an extension cord that is suitable

to carry the current required by the air tool. A wire of 12 gauge size is recommended

for an extension cord of length 50’ (15 m) or less. It is not recommended to use a

cord exceeding 100’ (30 m). If in doubt, use the next heavier gauge. An undersized

cord will cause a drop in line voltage, resulting in loss of power and overheating of

the air tool.

• Ensure compressor is plugged into a circuit protected by a fuse or breaker.

• Inspect the air tank yearly for rust, pin holes, or other imperfections. Never weld or

drill holes in the air tank.

• Use safety glasses and ear protection. Wear safety glasses with side shields when

operating the tool and verify that others in the work area are also wearing safety

glasses. Safety glasses must conform to American National Standards Institute

(ANSI Z87.1) requirements and must provide protection from flying particles from

the front and the sides. Compressors are loud and the sound can cause hearing

damage. Always wear ear protection to help prevent hearing damage and loss.

Failure to comply may result in moderate injury.

10

model no. 058-9317-8 | contact us 1-888-670-6682

SAFETY GUIDELINES

SAFETY INSTRUCTIONS FOR USING AIR TOOL

• The air tool is not a toy. Careless and improper use of the tool may result in serious

accident.

• Never leave or store the tool with air hose attached to avoid accidental start of the

tool and serious personal injury.

• Protect air hose from damage or puncture. Keep the air hose away from sharp

objects, chemical spills, oil, solvents, and wet floors.

• Make sure the hose is free of obstructions or snags. Entangled or snarled hoses can

cause loss of balance or footing and may become damaged.

• Inspect the power cord of the tool and air hose before each use. Ensure that all

connections are secure. Do not use a damaged hose. Have a qualified electrician to

repair or replace the damaged part.

• Stay alert, and use common sense when operating the tool. Do not use the tool

when you are tired or under the influence of drugs, alcohol, or medication.

• Do not overreach. Keep proper footing and balance at all times to enable better

control of the tool in unexpected situations.

• For personal safety, use an extension cord marked as “W-A” or “W” while operating

the tool outdoors.

• Maintain the tool with care.

• Make sure the tool is serviced only by a qualified technician.

• Store idle tools out of reach of children and other untrained persons.

• Always wear eye protection when using the tool. If required, use a dust mask, non-

skid safety footwear, a hard hat or hearing protection.

WARNING!

This manual contains important safety and operating

instructions for your air compressor. Before using the

compressor, read all instructions and warnings in the Safety

Guidlines.

FPO

11

TM

SAFETY GUIDELINES

FPO

ELECTRICAL SAFETY

Grounding instructions: In the event of a malfunction

or breakdown, grounding provides the path of least

resistance for electrical current in order to reduce the risk

of electric shock. This tool is equipped with an electric

cord that has a grounding wire and a grounding plug (1).

The plug must be plugged into a matching power supply

outlet (2) that is properly installed and grounded in

accordance with all local codes and ordinances or grounded wall socket for optimum

performance. The grounding plug has two flat blade terminals and grounding pin. If

the grounding plug does not fit into the outlet, do not try to modify it. Have a qualified

electrician to install the proper type of electrical outlet. If the compressor electrical

cord requires repair or replacement, have this done by an authorized, qualified service

technician.

Guidelines for using extension cords.

• Use only 3-wired extension cord that have 3-prong grounding plug that fits into a

3-slot receptacle.

• Never use an electrical adaptor with the grounding plug.

• Ensure the extension cord is properly wired and in good condition. Always replace a

damaged extension cord immediately or have it repaired by a qualified technician.

• The length of the extension cord should not exceed 50’ (15 m). The minimum wire

size of the extension cord is 12 gauge (AWG).

• Protect the extension cords from sharp objects, excess heat and damp or wet areas.

• Using extension cords with inadequately-sized wires will cause a serious drop in

voltage, resulting in loss of power and tool damage. The smaller the gauge number,

the heavier the extension cord. If in doubt, select the next heavier gauge.

NOTE: Do not use an extension cord unless it is necessary. It is better to

use a longer air hose that reaches the work area where air is needed.

NOTE: Recycle unwanted materials rather than disposing of them as

waste. Sort the tools and their components in specific categories and take

to the local recycling centre or dispose of them in an environmentally-safe

way.

2

1

model no. 058-9317-8 | contact us 1-888-670-6682

12

KEY PARTS DIAGRAM

No. Description

1 Motor

2 Air filter cap

3 Tank pressure gauge

4 Pressure relief valve

5 Pressure switch

6 Power cord

7 Air tank

No. Description

8 Wheel

9 Check valve

10 AUTO/OFF switch

11 Pressure regulator knob

12 Air line outlet

13 Regulated pressure gauge

14 Handle

9

11

12

3

4

5

6

7

13

2

1

14

10

8

WARNING!

• Remove the compressor and any accessories from the

package. Make sure that all items listed in the packing list

are included.

• Inspect the compressor carefully to make sure no

breakage or damage occurred during shipping.

• Do not discard the carton or any packaging material until

all parts have been examined.

FPO

13

TM

IMPORTANT INFORMATION

GENERAL USE

This Maximum

®

Workshop Air Compressor is designed to be compact and portable and

used for air tool applications, inflation and nailing tasks, and heavy DIY automotive

applications. This compressor is equipped with pressure switch, air tank, pump and

motor with automatic reset thermal overload protector. The compressor is factory

lubricated and does not require any oil.

AIR COMPRESSOR COMPONENTS

AIR FILTER

• The air filter is a porous element contained within a metal or plastic housing. The filter is

attached to the compressor cylinder head for removing impurities from the air intake of the

compressor.

AIR TANK

• This air tank is a cylindrical component which is used to store the compressed air.

CHECK VALVE

• This valve prevents backflow of compressed air from air tank to the compressor pump.

MOTOR

• The motor provides rotational force necessary to operate the compressor pump.

PRESSURE REGULATOR KNOB

• The knob can be adjusted to regulate the pressure at the air line outlet of the compressor. Turn

the knob clockwise to increase pressure and counter-clockwise to decrease pressure.

PRESSURE SWITCH

• The switch automatically controls the on/off cycling of the compressor. It stops the

compressor when the air pressure in the air tank reaches the cut-off pressure, and restarts the

compressor automatically when the air pressure drops below the cut-in pressure.

Cut-in pressure: The low pressure (160 PSI) at which the motor will automatically restart.

Cut-off pressure: The high pressure (200 PSI) at which the motor will automatically shut off.

PUMP

• The pump is used to compress the air and discharge the compressed air into the air tank via

the reciprocating piston contained within the cylinder.

REGULATED PRESSURE GAUGE

• The gauge is used to measure the regulated pressure at the air line outlet.

PRESSURE RELIEF VALVE

• This valve will activate automatically if the pressure switch does not shut down the motor in

case of abnormally high pressure in the air tank. To operate manually, pull the relief valve ring

to relieve air pressure in the tank.

TANK PRESSURE GAUGE

• The gauge indicates the pressure level of stored air in the air tank. It is not adjustable by the

operator.

THERMAL OVERLOAD PROTECTOR

• This protector will automatically turn off the compressor if the temperature of the electric

motor exceeds a predetermined limit. If the thermal overload protector is actuated, the motor

must be allowed to cool down before restarting.

AUTO/OFF SWITCH

• This switch is operated manually to turn ON/OFF the compressor. In the AUTO position of

the lever, the compressor shuts down or starts up automatically based on air pressure level in

the air tank. Always set this lever to OFF position when the compressor is not being used and

before unplugging the compressor. To reset the motor overload condition, toggle the AUTO/

OFF lever to OFF position and unplug the compressor from the power outlet. Allow the motor

to cool for 10 minutes. Then plug in the compressor and restart it.

model no. 058-9317-8 | contact us 1-888-670-6682

14

BEFORE ASSEMBLY

• Unpack the carton and remove the compressor. Make sure all parts are present.

Inspect the unit for damage.

• If any part is missing or damaged, do not attempt to assemble the product.

Contact customer service for replacement parts.

• Claim for replacement parts immediately as there is time limitation.

• Check the compressor’s serial label to ensure that the correct model has been

received, and that it has the required pressure rating (160/200 PSI)

for its intended use.

ASSEMBLY

1. Align the holes on the wheels (1) with

corresponding holes on both sides at

bottom of the tank (2). Insert bolts (3)

through the holes and tighten them

using washers (4) and nuts (5)

(FIG. A).

2. Place the compressor (1) on the floor

or a hard, level surface in a clean, well-

ventilated area to ensure sufficient

air flow and cooling. Make sure the

compressor is placed at least 12”

(30 cm) from any wall or obstruction

(FIG. B).

3

1

4

5

2

1

12”(30 cm)

3

1

4

5

2

1

12”(30 cm)

CAUTION!

• Potential hazard that may result in moderate injury or

damage to equipment.

• Do not use compressor in areas containing dust particles

to avoid damage to the motor.

FPO

ASSEMBLY INSTRUCTIONS

15

TM

2

1

3

2

2

1

3

2

NOTE: During cold weather or in cold temperature environments,

store the compressor in a warm area when not in use. This will

improve performance and reduce starting problems.

NOTE: The compressor must be placed on a flat surface to ensure

proper drainage of the moisture in the tank.

ASSEMBLY INSTRUCTIONS

3. Locate the compressor near a

grounded electrical outlet (2)

(FIG. C).

4. Connect an air hose (1) to the air line

outlet (2). Then connect the air hose

to an air tool (3) e.g. air-powered

spray gun (FIG. D).

16

model no. 058-9317-8 | contact us 1-888-670-6682

OPERATION

FPO

STARTING THE COMPRESSOR

1. Make sure the AUTO/OFF lever (1) is in

OFF position (FIG. E).

2. Make sure the drain valve (1) at the

bottom of the tank is closed (FIG. F).

3. Turn the pressure regulator knob (1)

counter-clockwise completely, before

starting the compressor (FIG. G).

1

1

WARNING!

• Potential hazard that could result in serious injury

or loss of life.

• Do not touch the compressor while operating, as the motor

will be very hot. Allow the compressor to cool before handling

or servicing it to avoid skin burns or other injuries.

• Do not use any storage cover to cover the compressor

during operation.

• Do not move the compressor when the air tank is under

pressure. Never use air hose or power cord to pull or move

the compressor. If required use the grip handle to move it.

• Never direct air stream towards yourself or other people

standing nearby.

FPO

1

1

1

17

TM

OPERATION

NOTE: Do not exceed the operating pressure of the air tool.

The regulated pressure gauge measures the hose pressure.

1

2

1

1

4. Plug in the power cord (1) of the

compressor to the electrical outlet

(2). Turn ON the power supply to the

compressor (FIG. H).

5. Turn the AUTO/OFF switch (1) to AUTO

position. Let the motor run (FIG. I).

6. Adjust the hose pressure gradually with

respect to the operating pressure of the

air tool by turning the pressure regulator

knob (1) clockwise (FIG. J).

18

model no. 058-9317-8 | contact us 1-888-670-6682

SHUTTING DOWN THE COMPRESSOR

1. Turn the AUTO/OFF switch (1) to the

OFF position. Turn OFF the power

supply and unplug the power cord (2)

from the electrical outlet (FIG. K).

2. Pull the pressure relief valve ring (1)

and keep the relief valve open to

release the pressure in the tank

(FIG. L).

3. Open the drain valve (1) by turning

counter-clockwise to release water in

the tank (FIG. M).

1

1

1

CAUTION!

• Potential hazard that may result in moderate injury or

damage to equipment.

• Wear safety glasses when opening the drain valve, as the

air and moisture being released from the tank can propel

debris that may cause eye injury.

FPO

OPERATION

19

TM

MAINTENANCE

GENERAL MAINTENANCE

Regular and periodic maintenance of the compressor ensures trouble-free operation.

The compressor components should be inspected on a regular basis.

FPO

WARNING!

• Potential hazard that could result in serious injury or loss of life.

• To avoid personal injury, always shut off and unplug the

compressor from the power supply outlet and relieve all air

pressure from the air supply system before performing any

service on the air compressor.

• Do not use damaged tool. If abnormal noise or vibration occurs,

rectify the problem before use.

FPO

NOTE: During cold temperatures, drain the air tank after each use to

reduce freezing problems.

DRAINING THE AIR TANK

1. Turn OFF the power supply to the pump. Release air pressure in tank by pulling the

relief valve ring.

2. Turn the drain valve counter-clockwise to open it and tilt the tank to drain out water

completely.

DESCRIPTION COMPONENTS Daily Weekly Monthly

Drain moisture Air tank X

Check proper operation Pressure relief valve, air filter X X

Check air leaks, abnormal

noise, or vibration

Worn or broken parts X X

MAXIMUM SERVICE INTERVAL

20

model no. 058-9317-8 | contact us 1-888-670-6682

MAINTENANCE

• Potential hazard that could result in serious injury or

loss of life.

• Make sure the tank is drained every day to prevent

corrosion of tank.

FPO

FPO

WARNING!

CAUTION!

• Potential hazard that may result in moderate injury or

damage to equipment.

• Wear safety glasses when opening the drain valve, as

the air and moisture releases out from the tank can

propel debris that may cause eye injury.

CHECKING THE PRESSURE RELIEF VALVE

1. Turn OFF the power supply to the pump.

2. Pull the relief valve ring to check whether it s operating properly and to clear

possible obstructions of the valve.

CHANGING THE AIR FILTER

After continuous use of the compressor, the air filter may get clogged. This will reduce

the air intake capability of the compressor. Therefore it is necessary to replace the air

filter.

1. Turn OFF the power supply to the pump.

2. Open the air filter cap (1) and remove the old

air filter (2) (FIG. N).

3. Place a new air filter and close the filter cap.

NO

OFF

1

2

TESTING FOR LEAKS

Check whether all connections are tight. To find leakage

in hose, transfer tube, or pipe connection, spray a small

amount of soapy water around the damaged area with

a spray bottle. If bubbles appear around the area, repair

or replace the faulty component. Do not overtighten any

connections.

STORAGE

Before storing the compressor for a prolonged period, follow the below steps correctly.

• Disconnect the power cord and coil it up on the handle.

• Clean all dust and debris from the compressor using an air blow gun.

• Pull the relief valve ring to release all pressure from the tank.

• Drain all moisture from the air tank.

• Cover the compressor to protect it from moisture and dust.

FIG. N

1/61