Fire Magic A660I6LAPW Guide d'installation

- Catégorie

- Barbecues

- Taper

- Guide d'installation

Ce manuel convient également à

1

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY BEFORE STARTING INSTALLATION OR USE.

BUILT-IN OUTDOOR GAS GRILLS

DANGER:

IF YOU SMELL GAS:

1. Shut off the gas to the appliance.

2. Extinguish any open fl ame.

3. Open lid.

4. If odor continues, keep away from the

appliance and immediately call your

gas supplier or the fi re department.

WARNING:

1. Do not store or use gasoline or other

fl ammable vapors and liquids in the

vicinity of this or any other appliance.

2. An LP cylinder not connected for use

shall not be stored in the vicinity of this

or any other appliance.

CODE AND SUPPLY REQUIREMENTS: This

grill must be installed in accordance with local

codes and ordinances, or, in the absence of local

codes, with the latest National Fuel Gas Code

(ANSI Z223.1/NFPA 54), or Natural Gas and

Propane Storage and Handling Installation Code

(CSA-B149.1).

This appliance and its dedicated manual shutoff

valve must be disconnected from the gas-supply

piping system when testing the system at pressures

in excess of ½ psig (3.5 kPa).

This appliance must be isolated from the gas-

supply piping system by closing its dedicated

manual shutoff valve during any pressure testing

of the gas-supply system at pressures up to and

including ½ psig (3.5 kPa).

All electrical outlets in the vicinity of the grill must

be properly grounded in accordance with local

codes, or, in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70, or the

Canadian Electrical Code, CSA C22.1, whichever

is applicable.

Keep all electrical-supply cords and fuel-supply

hoses away from any heated surface.

Robert H. Peterson Co. • 14724 East Proctor Avenue • City of Industry, CA 91746

INSTALLATION

INSTRUCTIONS AND

OWNER’S MANUAL

INSTALLER: Leave these instructions with consumer.

CONSUMER: Retain for future reference.

WARNING:

Improper installation, adjustment, alteration,

service, or maintenance can cause injury

or property damage. For proper installation,

refer to the installation instructions. For

assistance or additional information, consult

a qualifi ed professional service technician,

service agency, or the gas supplier.

WARNINGS AND SAFETY CODES

Proper operation of your grill

requires prompt and periodic

maintenance. See the CARE &

CLEANING section for details.

Certifi ed to: ANSI Z21.58-2015

CSA 1.6-2015

11-093

US

®

C

REV 1 - 1603010800

L-C2-434

A790i w/ analog thermometer shown

A430i, A530i, A540i, A660i, & A790i

2

IMPORTANT: LISEZ CES INSTRUCTIONS SOIGNEUSEMENT AVANT DE COMMENCER L’INSTALLATION OU L’UTILISATION

GRIL EXTÉRIEUR DE GAZ DU BUILT-IN

DANGER:

SI VOUS SENTEZ LE GAZ :

1. Coupez le gaz à l’appareil.

2. Éteignez-vous n’importe quelle fl amme nue.

3. Ouvrez le couvercle.

4. Si l’odeur continue, gardez loin de

l’appareil et appelez immédiatement

votre département de fournisseur ou de

feu de gaz.

AVERTISSEMENT:

1. Ne stockez pas ou n’employez pas

l’essence ou d’autres vapeurs et liquides

infl ammables à proximité de ceci ou

d’aucun autre appareil.

2. Un cylindre de propane non relié pour

l’usage ne sera pas stocké à proximité

de ceci ou d’aucun autre appareil.

CONDITIONS DE CODE ET D’APPROVISIONNEMENT:

Ce gril doit être installé selon des codes et des ordonnances

locaux, ou, en l’absence des codes locaux, avec l’un ou l’autre

le plus défunt Code national de gaz de carburant (norme ANSI

Z223.1/NFPA 54), et Stockage de gaz naturel et de propane

et manipulation du code d’installation (CSA-B149.1).

Cet appareil et ses différents robinets d’isolement doivent être

démontés du gaz-fournissent le système siffl ant en examinant

le système aux pressions au-dessus du ½ psig (kPa 3.5).

Cet appareil doit être isolé dans gaz-fournissent le système

siffl ant par fermeture que ses différents robinets d’isolement

manuels pendant tous les essais sous pression du gaz-

fournissent le système aux pressions jusques et y compris

le ½ psig (kPa 3.5).

Toutes les sorties électriques à proximité du gril doivent être

correctement fondues selon des codes locaux, ou en l’absence

de local code, avec le code électrique national, ANSI/NFPA

70, ou le code électrique canadien, CSA C22.1, celui qui est

applicable.

Maintenez tout électrique-fournissent des cordes et carburant-

fournissent des tuyaux partis de n’importe quelle surface de

chauffage.

INSTALLATEUR : Laissez ces instructions avec le consommateur.

CONSOMMATEUR : Maintenez pour la future référence.

AVERTISSEMENT:

L’installation inexacte, l’ajustement, le

changement, le service, ou l’entretien

peuvent causer des dommages ou des

dégats matériels. Référez-vous à ce manuel.

Pour de l'aide ou des renseignements

supplémentaires, consulter un technicien

professionnel qualifié de service, une

agence de service ou le fournisseur de gaz.

SÛRETÉ ET CODES D’AVERTISSEMENT

• Ce gril est pour ultilisation à l’extérieur seulement.

Si l’appareil est entreposé à l’intérieur, enlever les

bouteilles et les laisser à l’extérieur.

• Ne pas ranger le gril immédiatement aprés l’avoir utilisé.

le laisser refroidir avant de le déplacer ou de la ranger.

Le non respect de cette mesure de sécurité pourrait

entraîner un incendie causant des dommages à la

propriété, des blessures ou la mort.

• Ne pas utiliser cet appareil sous une surface combustible.

• Ne pas utiliser cet appareil sous un auvent. Le non

respect de cette mesure de sécurité pourrait entraîner

un incendie ou des blessures.

• Dégagement minimal entre les parois latérales et l’arriére

de l’appareil et la construction combustible (45.7 cm à

partir des parois latérales et 45.7cm à partir de l’arriére).

• Le régulareur de pression de gaz prévu avec cet appareil

de cuisson à gaz pour l’extérieur doit être utilisé. Ce

régulateur est réglé pour une pression de sortie de 5

pouces de colonne de l’eau pour le gaz naturel, et 10

pouces pour le propane.

• LE RÉGULATEUR INCLUS D’APPAREILS EST ÉVALUÉ

POUR LE MAXIMUM DE 1/2 (LIVRES PAR POUCE

CARRÉ). SI VOTRE OFFRE DE GAZ EST 1/2 PLUS

GRAND QUE (LIVRES PAR POUCE CARRÉ), UN

RÉGULATEUR ADDITIONNEL DOIT ÊTRE INSTALLÉ

AVANT LE GRIL. VOIR LA SECTION DE CONDITIONS

D’OFFRE DE GAZ POUR LA PRESSION APPROPRIÉE

D’OFFRE DE GAZ.

• Ne couvrez jamais la surface entière de cuisine ou de

gril de gauffreuses ou de casseroles. La surchauffe se

produira et les brûleurs ne seront pas très performants

quand la chaleur de combustion est emprisonnée au-

dessous de la surface à cuire.

• Ne pulvérisez jamais l’eau sur une unité chaude de gaz,

comme ceci peut endommager des composants de

porcelaine ou de fer de fonte.

• Une fuite de GPL peut causer une incendie ou une

explosion si enflammée entraînant des blessures

corporelles graves ou la mort.

• Communiquez avec le fournisseur de GPL pour les

réparations ou pour disposer de qules bouteille ou du

GPL non utilisé.

INSTALLATION INSTRUCTIONS ET MANUEL DU PROPRIÉTAIRE

Certifi é à la norme: ANSI Z21.58-2015 / CSA 1.6-2015

REV 1 - 1603010800

L-C2-434

3

CONTENTS

REV 1 - 1603010800

L-C2-434

GETTING STARTED

REPLACEMENT PARTS LIST .......................................4

MODEL SPECIFICATIONS ............................................ 6

BUILT-IN GRILL DIMENSIONS TABLE.........................6

COUNTERTOP OVERHANG ....................................... 6

SUBSTRATE .............................................................7

BUILT-IN GRILL DIMENSIONS TABLE.........................7

BUILT-IN GRILL WIRING DIAGRAM ...........................8

GRILL MAINTENANCE AND SAFETY INFORMATION

......................................................................................9

ELECTRICAL CONNECTIONS ....................................9

LIGHT SWITCH ........................................................ 9

INSTALLATION REQUIREMENTS .............................10

OVERHEAD CONSTRUCTION REQUIREMENTS

(IF APPLICABLE)

...................................................10

SIDE AND REAR WALL CLEARANCES .......................10

BACKSPLASH CLEARANCE (IF APPLICABLE) ...........10

ENSURE PROPER COMBUSTION AIR AND COOLING

AIRFLOW

.............................................................. 11

EXHAUST REMOVAL ..............................................11

GAS-SUPPLY PLUMBING REQUIREMENTS ...............11

ENCLOSURE REQUIREMENTS ..................................12

VENTILATION (ALL ENCLOSURES) ..........................12

WHEN A PROPANE (L.P.) CYLINDER IS USED IN THE

ENCLOSURE

.........................................................12

PROPANE SAFETY INFORMATION ...........................13

WARNING ............................................................. 13

INSTALLATION SAFETY GUIDELINES.......................13

OPERATING THE UNIT SAFELY AND CORRECTLY .13

SAFE USE & MAINTENANCE OF

PROPANE GAS CYLINDERS ......................................15

INSTALLATION

INSTALLATION ..........................................................16

COUNTER PREPARATION .......................................16

CONNECT THE GAS SUPPLY ...................................16

INSTALL THE FLAVOR GRIDS .................................. 17

ELECTRICAL INSTALLATION ...................................18

ELECTRICAL SAFETY ............................................18

IDENTIFICATION OF GRILL CONTROLS ..................19

USE, CARE, & SERVICE

LIGHTING (IGNITION) INSTRUCTIONS ....................21

ELECTRONIC LIGHTING ........................................21

MANUAL LIGHTING ...............................................21

SHUTTING OFF THE UNIT ...................................... 21

OPTIONAL DIGITAL THERMOMETER ......................22

OPTIONAL ROTISSERIE ............................................25

OPTIONAL INFRARED BURNER OPERATION ..........26

ACCESSORIES ............................................................ 27

FIRE MAGIC

®

DRIP TRAY .........................................28

CARE & CLEANING ...................................................29

REPLACING HALOGEN BULBS ................................30

CONVERT GAS TYPE / CHECK BURNER ORIFICES . 31

BURNER AIR SHUTTER ADJUSTMENT ....................33

CONTROL PANEL REMOVAL ....................................35

NOTES PAGE ..............................................................36

TROUBLESHOOTING ................................................. 37

WARRANTY ...............................................................38

4

To order replacement

parts, contact your

local Fire Magic

®

dealer.

REPLACEMENT PARTS LIST

REV 1 - 1603010800

L-C2-434

1

2

3

6

9

10

11

12

16

19

23

21

26

8

20

18

17

7

25

14

13

22

42

27

24

15

5

4

Some items shown

are optional, or are not

available for certain

models. Your model

may vary, refer to parts

table.

38

37

GETTING STARTED

5

REPLACEMENT PARTS LIST (cont.)

REV 1 - 1603010800

L-C2-434

A430i A530i A540i A660i A790i

Item Description

Part No. Qty. Part No. Qty. Part No. Qty. Part No. Qty. Part No. Qty.

1. Stainless cooking grid (set of 2 or 3) 23542-S-2 1 23539-S-2 1 23543-S-3 1 23544-S-3 1 23539-S-3 1

2. Flavor grid (set of 2 or 3) 3063-S-2 1 3056-S-2 1 3064-S-3 1 3057-S-3 1 3056-S-3 1

3. Main burner 3042-50 2 3041-50 2 3042-50 3 3041-50 3 3041-50 3

4. Heatshield kit 24177-05 2 24177-05 2 24177-05 3 24177-05 3 24177-05 3

5. Silicone gasket 24177-06 2 24177-06 2 24177-06 3 24177-06 3 24177-06 3

6. Infrared burner * 3060 1 3050 1 3060 1 3050 1 3050 1

7. Oven lid 23729-53 1 23736-53 1 23733-53 1 23738-52 1 23745-52 1

or Oven lid w/ oven thermometer 23729-55 1 23736-55 1 23733-55 1 23738-55 1 23745-55 1

or Oven lid w/ window † N/A N/A N/A 24170-54 1 24180-54 1

8. Warming rack 3672S-M 1 3672S-M 1 3673S-M 1 3673S-M 1 3675S-M 1

9. Back burner* 24130-11H 1 24130-11H 1 24170-11H 1 24170-11H 1 24180-11H 1

10. Back burner cover* 24148-010 1 24148-010 1 24739-010 1 24739-010 1 24745-010 1

11. Rotisserie motor* 3600-02 1 3600-02 1 3600-02 1 3600-02 1 3600-02 1

12. Heavy-duty motor*† N/A N/A 3600-05 1 3600-05 1 3600-05 1

13. Rotisserie rod* 3603-30 1 3603-30 1 3606-30 1 3606-30 1 N/A

14. Heavy duty rod*† N/A N/A 3606-40 1 3606-40 1 3609-40 1

15. Rotisserie knob* 24187-16 1 24187-16 1 24187-16 1 24187-16 1 24187-16 1

16. Meat holder (pair)* 3613 1 3613 1 3613 1 3613 1 3613 1

17. Counterbalance* 3620E 1 3620E 1 3620E 1 3620E 1 3620E 1

18. Grid lifter 3519 1 3519 1 3519 1 3519 1 3519 1

19. Convertible regulator PR-4 1 PR-4 1 PR-4 1 PR-4 1 PR-4 1

20. Valve manifold w/ back burner 24130-22 1 24130-22 1 24170-22 1 24170-22 1 24180-22 1

or valve manifold w/o back burner 24130-28 1 24130-28 1 24170-28 1 24170-28 1 N/A

21. Control panel w/ back burner, w/ digital thermo. 24130-45 1 24130-45 1 24170-45 1 24170-45 1 24180-45 1

or Control panel w/ back burner, w/o digital thermo. 24130-47 1 24130-47 1 24170-47 1 24170-47 1 24180-47 1

or Control panel w/o back burner, w/ digital thermo. 24130-46 1 24130-46 1 24170-46 1 24170-46 1 N/A

or Control panel w/o back burner, w/o digital thermo. 24130-48 1 24130-48 1 24170-48 1 24170-48 1 24180-48 1

22. Small knob* 3016 1 3016 1 3016 1 3016 1 3016 1

23. Large knob 3015 2 3015 2 3015 3 3015 3 3015 3

24. Digital thermometer 24180-12H 1 24180-12H 1 24180-12H 1 24180-12H 1 24180-12H 1

or Oven hood thermometer ‡ 23305 1 23305 1 23305 1 23305 1 23305 1

or Grill top thermometer (window models) ‡ 3573 1 3573 1 3573 1 3573 1 3573 1

25. Meat probe * 24187-14S 1 24187-14S 1 24187-14S 1 24187-14S 1 24187-14S 1

26. Drip tray 3084 1 3084 1 3084 1 3084 1 3084 1

27. Drip tray liner (set of 4) 3557 1 3557 1 3557 1 3557 1 3557 1

28. Wire harness assembly‡ 24177-28 1 24177-28 1 24177-28 1 24177-28 1 24177-28 1

29. Back burner electrode*‡ 4199-52 1 4199-52 1 4199-52 1 4199-52 1 4199-52 1

30. Main burner electrode‡ 3199-72 2 3199-72 2 3199-72 3 3199-72 3 3199-72 3

31. Natural gas orifi ce(s)‡ 3001-42-2 1 3001-40-2 1 3001-44-3 1 3001-42-3 1 3001-38-3 1

32. Natural back burner gas orifi ce(s)‡ 3001-52-1 1 3001-52-1 1 3001-48-1 1 3001-48-1 1 3001-45-1 1

33. Propane gas orifi ce(s)‡ 3001-54-2 1 3001-53-2 1 3001-55-3 1 3001-54-3 1 3001-53-3 1

34. Propane back burner gas orifi ce(s)‡ 3001-59-1 1 3001-59-1 1 3001-56-1 1 3001-56-1 1 3001-55-1 1

35. Fire Magic

®

cookbook‡ 3595 1 3595 1 3595 1 3595 1 3595 1

36. Thermometer wire harness *‡ 24177-25 1 24177-25 1 24177-25 1 24177-25 1 24177-25 1

37. Power supply w/ connector 24177-12 1 24177-12 1 24177-12 1 24177-12 1 24177-12 1

38. Wire harness extension 24182-53 1 24182-53 1 24182-53 1 24182-53 1 24182-53 1

39. 12V / 10 watt halogen light bulb ‡ 24187-15 2 24187-15 2 24187-15 2 24187-15 2 24187-15 2

40. Light lens ‡ 24187-26 2 24187-26 2 24187-26 2 24187-26 2 24187-26 2

41. Lamp assembly ‡ 24187-28 2 24187-28 2 24187-28 2 24187-28 2 24187-28 2

42. Light switch 24182-46 1 24182-46 1 24182-46 1 24182-46 1 24182-46 1

43. Magic View window (only) *‡ N/A N/A N/A 24187-45 1 24187-45 1

44. Flash tube (left) ‡ 24187-29 1 24187-29 1 24187-29 1 24187-29 1 24187-29 1

45. Flash tube (right) ‡ 24187-35 1 24187-35 1 24187-35 2 24187-35 2 24187-35 2

46. Backburner fl ex connector *‡ 3030-01 1 3030-08 1 3030-01 1 3030-08 1 3030-08 1

* If equipped

† Not available on A430i or A530i models

‡ Not shown

6

COUNTERTOP OVERHANG

The control panel is designed to sit fl ush against the enclosure front wall. If the non-combustible enclosure countertop extends beyond

the front wall, creating a countertop overhang, it must be cut fl ush with the front wall for the width of the control panel or a gap will be

created exposing the forward portions of the left and right side grill fi re walls. See illustrations above.

Important: FOR YOUR SAFETY, you must provide openings in the island enclosure for drainage, replacement air, and

cross-ventilation of any storage area exposed to possible leakage from gas connections, the unit, or propane

bottles. See the ENCLOSURE REQUIREMENTS section for details.

TOP VIEW

Countertop

Lower support

Countertop

overhang

Control panel

NON-COMBUSTIBLE

ENCLOSURE CUT-OUT

DIMENSIONS

Fig. 6-1

FRONT VIEW

B

C

D

See next page

for substrate

considerations

Countertop

overhang

X

TOP VIEW

SIDE VIEW

Countertop

overhang

(Control

panel)

(Countertop)

Y

1

/

4

"

Clearance

(Overhang)

X= D-B

÷

2

Y= Total

Countertop

Overhang

A

Control

panel

Check clearance for

control panel removal

MODEL SPECIFICATIONS

REV 1 - 1603010800

L-C2-434

MODEL SPECIFICATIONS TABLE

Table 1

A430i A530i A540i A660i A790i

Main burner quantity

N/P orifi ce drill size

2

#42 / #54

2

#40 / #53

3

#44 / #55

3

#42 / #54

3

#38 / #53

Backburner

▲

N/P orifi ce drill size

#52 / #59 #52 / #59 #48 / #56 #48 / #56 #45 / #55

Infrared searing burner

▲

N/P orifi ce drill size

#49 / #56 #45 / #55 #49 / #56 #45 / #55 #45 / #55

Aurora insulating liner model # (not included)* 23130-50 23125-50 23150-50 3176-50 3186-50

Input electrical requirements

120VAC / 15 AMP minimum / 60 Hz / GFCI outlet

Oven lights rating 12V / 10 watt halogen bulb

A Countertop to unit bottom cut-out* 12" 12" 12" 12" 12"

B Side to side non-combustible cut-out* 25-

1

/

2

" 25-

1

/

2

" 32" 32" 37-

3

/

4

"

C Front to back non-combustible cut-out*† 19-

1

/

2

" 23-

1

/

2

" 19-

1

/

2

" 23-

1

/

2

" 23-

1

/

2

"

D Control panel width non-combustible cut-out‡ 27" 27" 33" 33" 38-

3

/

4

"

▲

If equipped

*Note: If installing this grill in a combustible enclosure, the correct insulating liner must be used. Consult liner instructions for counter

cut-out dimensions and installation.

†

Includes any substrate at front wall of enclosure (in the area the rear of the control panel is to sit fl ush against). See SUBSTRATE

section on next page.

‡

Only applicable for non-combustible enclosures that have countertops with an overhang (see illustration and section below).

7

MODEL SPECIFICATIONS (cont.)

SUBSTRATE

When adding any substrate to the enclosure front wall (including tiles, stone, etc.), consider the following:

Substrate Behind Control Panel

Substrate Alongside Control Panel

C

C

Flush

(Control panel)

(Countertop)

(Countertop)

(Control panel)

Substrate

(includes tiles,

etc. at front of

enclosure)

Countertop

overhang

(if applicable)

Flush

Grill liner

Grill liner

Substrate

(includes tiles,

etc. at front of

enclosure)

1

/4"

Clearance

Any additional substrate alongside the control panel

does not need to be considered in Dim. C (see previous

page), however a

1

/4" clearance on each side (same as

overhang) and below is required.

Substrate

+

countertop "front to back" cutout

must equate to Dim. C (see previous page)

when the substrate sits fl ush behind the

control panel.

Fig. 7-1 Fig. 7-2

Countertop

overhang

(if applicable)

TOP VIEW TOP VIEW

1

/4"

Clearance

REV 1 - 1603010800

L-C2-434

Model

Height Width Depth

(Top to bottom) (Left to right) (Front to

back)

Upper hanger to top

(with oven)

Hanger to

hanger

(G)

Control

panel

width

(H)

Maximum

depth

(I)

Open

(E)

Closed

(F)

A430i

20

1

/4" 13

1

/4" 30" 26

1

/2" 26

3

/4"

A530i

23

5

/8" 15" 30" 26

1

/2" 29

3

/4"

A540i

20

1

/4" 13

1

/4" 36

1

/2" 32

1

/2" 26

3

/4"

A660i

23

5

/8" 15" 36

1

/2" 32

1

/2" 29

3

/4"

A790i

23

5

/8" 15" 42

1

/4" 38

1

/4" 29

3

/4"

I

F

E

G

H

Fig. 7-3

BUILT-IN GRILL DIMENSIONS TABLE

8

REV 1 - 1603010800

L-C2-434

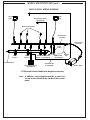

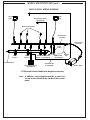

Note: In addition, a wire diagram specifi c to your unit

can be found affi xed to the inside of the control

panel.

Power supply

Wire harness

extension

Wire harness

assembly

Valve manifold

Ground

wire

Main burner igniters

BUILT-IN GRILL WIRING DIAGRAM

Back burner igniter

(if equipped)

Oven

light

Oven

light

Digital thermometer

(if equipped)

Light

switch

Thermocouple

(if equipped)

Back burner

(if equipped)

Main

burner 1

Main

burner 2

Main

burner 3

*

A790i model shown. Model wire diagrams may vary.

MODEL SPECIFICATIONS (cont.)

*

Meat probe

(if equipped)

9

1. The outdoor grill and surrounding area MUST

remain clear of fl ammable substances such as

gasoline, yard debris, wood, etc.

2. The airfl ow through the vent space located below

the control panel must remain unobstructed.

3. When using propane gas:

a. The required ventilation openings in the

enclosure must be clear of debris. See

the PROPANE SAFETY INFORMATION

section.

b. The propane cylinder, regulator, and

rubber hose must be in a location not

subject to temperature above 125° F (51°

C).

4. The fl ames on each burner burn evenly along

the entire burner with a steady fl ame (mostly

blue). If burner fl ames are not normal, check

and clean the orifi ce and burner/venturi tubes

for insects and insect nests. A clogged tube can

lead to a fi re beneath the grill. A proper fl ame

pattern will ensure safe operation and optimal

performance. Adjust the air shutter as needed

(see AIR SHUTTER ADJUSTMENT).

5. The in-line gas valve or gas cylinder valve must

always be shut OFF when the grill is not in use.

6. The drip collector holes must be clear and

unobstructed. Excessive grease deposits can

result in a grease fi re.

7. The backburner or IR burner cover must be

removed before using the burner.

8. Whenever reconnecting any wires, apply a

small amount of dielectric grease to the male

connector, then make the connection. This will

ensure conductivity and prevent moisture from

affecting the contact.

WARNING: NEVER cover the entire cooking or grill surface with griddles or pans. Overheating will occur, and

burners will not perform properly when combustion heat is trapped below the cooking surface.

CAUTION: NEVER spray water on a hot gas unit.

The grill serial identifi cation number is located on the underside of the drip tray handle. It

is recommended that the drip tray fi rst be removed and cleaned / emptied of its contents,

then turned over to view. The unit rating label is located on the inside of the control panel.

GRILL MAINTENANCE AND SAFETY INFORMATION

REV 1 - 1603010800

L-C2-434

ELECTRICAL CONNECTIONS

A 120VAC (15 AMP minimum) Ground Fault

Circuit Interrupter (GFCI) GROUNDED 3-wire

receptacle (not included) is required within the

vicinity of the grill to provide power to the unit.

• Observe all local codes.

• Verify proper polarity of the receptacle.

• If an extension cord is used, ensure it is a 3-wire

GROUNDED cord that is rated for the power of

the equipment, and is approved for outdoor

use with a W-A marking. DO NOT use 2-prong

adapters.

• DO NOT TAMPER WITH THE EXTENSION CORD

OR THE UNIT POWER-SUPPLY CORD.

Important: ONLY REPLACE THE OVEN LIGHTS

WITH 12V / 10 WATT HALOGEN

BULB(S).

LIGHT SWITCH

The light switch is push button operated, and is

located on the right side of the control panel (see

Fig. 9-1). It controls the power to all lights.

Light

switch

Fig. 9-1

Meat probe

(if equipped)

10

Installation must be performed by a qualifi ed professional service

technician.

This grill is designed for outdoor use only. DO NOT use this grill inside

a building, garage, enclosed area, or under overhead combustible

construction.

See below and the EXHAUST REMOVAL section on the following

page for details on installing under non-combustible overhead

construction.

DO NOT use this grill in or on a recreational vehicle or boat.

Important: If installing this grill in a combustible surround, the correct

RHP insulating liner must be used.

Important: Refer to the information below to ensure all required

clearances are met.

The grill must have a minimum clearance of 18" from combustible

materials/items AT ALL TIMES.

OVERHEAD CONSTRUCTION REQUIREMENTS

(IF APPLICABLE)

This outdoor cooking gas appliance shall not be used under

overhead combustible construction.

A minimum clearance of 5 feet is required between the countertop

and the non-combustible construction above (Fig. 10-1).

SIDE AND REAR WALL CLEARANCES

For the minimum clearances between the grill and any side or rear

walls, your setup must fall within one (or more) of the following:

A. Clearance between grill and strictly non-combustible wall

(i.e. brick wall, see Fig. 10-2)

• The grill must have a minimum of 4" right, left, and rear

clearance from any non-combustible wall.

(To allow for proper ventilation and prevent dangerous

overheating.)

B. Clearance between grill and a protected combustible wall

(i.e. a non-combustible wall in front of a combustible wall to serve

as a barrier. This can be accomplished by brick, or a metal stud

fi nished with non-combustible substrate, see Fig. 10-3)

• The grill must have a minimum of 14" right, left, and rear

clearance from the protected combustible wall.

(The 4" non-combustible material plus an additional 10"

clearance between the grill and protected wall.)

C. Clearance between grill and combustible wall

• The grill must have a minimum of 18" right, left, and rear

clearance from any combustible wall (see Fig. 10-4).

BACKSPLASH CLEARANCE (IF APPLICABLE)

If a non-combustible backsplash exists, it must have a minimum of a

4" clearance from the rear of the grill (to allow for proper ventilation

and prevent dangerous overheating). See Fig. 10-5.

Important: This 4" backsplash clearance must fi rst be met prior to

any non-combustible walls beginning behind it.

Fig. 10-2 Clearance 'A' Diagram

Fig. 10-3 Clearance 'B' Diagram

Fig. 10-4 Clearance 'C' Diagram

Non-combustible

Min.

4"

Min.

14"

Non-combustible

substrate

Non-combustible 4"

Combustible

Min.

18"

(Clearance required for

right, left, and rear)

Fig. 10-5 Backsplash clearance

Non-combustible

Backsplash

Min.

4"

Com-

bustible

(Clearance required for

right, left, and rear)

(Clearance required for

right, left, and rear)

Fig. 10-1 Overhead requirements

Min.

5'

INSTALLATION REQUIREMENTS

NON-COMBUSTIBLE

CONSTRUCTION ONLY

REV 1 - 1603010800

L-C2-434

11

INSTALLATION REQUIREMENTS (Cont.)

The control panel MUST remain removable for servicing

(see PARTS LIST).

ENSURE PROPER COMBUSTION AIR AND

COOLING AIRFLOW

Proper airfl ow (Fig. 11-1) MUST be maintained for the

grill to perform as it was designed. If airfl ow is blocked,

overheating and poor combustion will result. Do not

block the 1" (2.5 cm) front air inlet along the bottom of

the control panel or more than 75% of the cooking grid

surface with pans or

griddles.

Note: The 1" (2.5 cm)

front air space

also allows

access to the

drip tray.

EXHAUST REMOVAL

If the grill is installed under an overhead structure, it

must be constructed of non-combustible material. An

exhaust hood is recommended. See below.

When using an exhaust hood:

The cooking grid area must be covered by an exhaust

hood (with a vent) larger than the cooking surface. Refer

to manufacturer specifi cations. An exhaust fan with a

rating of 1,000 CFM (cubic feet per minute) (472 liters

per second) or more may be necessary to effectively

remove smoke and other cooking by-products from the

area under the hood. RHP Vent Hoods are available,

contact your local dealer.

THIS UNIT MUST NOT BE LOCATED IN A FULLY

ENCLOSED AREA OF ANY KIND.

GAS-SUPPLY PLUMBING REQUIREMENTS

For natural gas or a household propane system, rigid

1

/

2

"

(1.3 cm) or

3

/

4

" (1.9 cm) black steel pipe or local code-

approved pipe is required to conduct the gas supply to

the unit. Contact your local gas supplier. Connect this

pipe to the required C.S.A.-approved stainless-steel fl ex

connector (attached). An NPT adapter has been provided

for

1

/

2

" pipe. DO NOT use a rubber hose within the grill

enclosure. Apply only joint compounds that are resistant

to all gasses to all male pipe fi ttings except fl are fi ttings.

Make sure to tighten every joint securely.

Note: If

1

/

2

" (1.3 cm) pipe is used with natural gas,

it should be no longer than 20' (6.1 meters).

Important: A shut-off valve (not included) in

the gas line is required. It provides

for safety when the unit is not in use

and for convenient maintenance and

repair. It must be installed within 6 feet

of the unit. Use a pipe joint compound

resistant to all gasses on all male

fi ttings except fl are fi ttings.

CAUTION: Wind blowing into or across the rear

oven lid vent (Fig. 11-2) can cause

poor performance and/or dangerous

overheating. Orient the grill so that the

prevailing wind blows toward the front of

the grill (Fig. 11-3).

GAS SUPPLY AND MANIFOLD PRESSURES:

For natural gas - normal 7" (17.78 cm) water column

(w.c.), minimum 5" (12.7 cm), maximum 10

1

/

2

" (26.7

cm). For propane gas - normal 11" w.c., minimum 10"

(25.4 cm), maximum 13" (33 cm).

REV 1 - 1603010800

L-C2-434

Fig. 11-1 - Ventilation diagram

Left-side

hanger

Fig. 11-4

Flex connector

Left-side

support wall

Orient grill

so prevailing

wind blows

this way.

Fig. 11-3

CORRECT

G

c

PLACE GRILL SO PREVAILING

WIND BLOWS TOWARD FRONT

OF GRILL

YOU MUST PROTECT

REAR OVEN VENT FROM

PREVAILING WIND

Rear oven lid vent

INCORRECT

Fig. 11-2

12

Adapter

Grill

C.S.A. listed

stainless steel

fl ex connector

Non-combustible

heatshield

Regulator/

hose

assembly

L.P.

cylinder

Fig. 12-2 Propane cylinder orientation

ENCLOSURE REQUIREMENTS

VENTILATION (ALL ENCLOSURES)

For All Piping Systems and All Gas Types:

(Natural Gas, Household Propane, L.P. Cylinder)

FOR YOUR SAFETY, you must provide the openings listed

below for replacement air and cross-ventilation of the

unit enclosure.

One side of the enclosure shall be left completely open to

the outside; OR 4 (minimum) ventilation openings MUST

be created (reference Fig. 12-1):

Each opening must have a minimum of 10 sq. in. of

free area. The openings must be equally sized and

unobstructed.

Two openings must be in the side walls of the enclosure, at

the top level, and spaced at 180 degrees. The openings must

begin 1" or less below the countertop level and end no more

than 5" below the countertop level.

Two openings must be in the side walls of the enclosure, at

the fl oor level, and spaced at 180 degrees. The openings must

begin 1" or less above the fl oor level and end no more than

5" above the fl oor level.

To achieve the proper ventilation, you may use RHP venting

panels (PN 5510-01) as shown. Contact your dealer.

KEEP THE VENT OPENINGS AND SURROUNDING

AREA OF THE ENCLOSURE CLEAN AND FREE OF

OBSTRUCTIONS AT ALL TIMES.

WARNING: Ventilation openings in side walls shall not

communicate directly with other enclosures of

the outdoor cooking gas appliance.

WHEN A PROPANE (L.P.) CYLINDER IS USED IN

THE ENCLOSURE

When a propane (L.P.) cylinder is installed inside of the

enclosure, the guidelines below MUST be followed. FAILURE

TO DO SO MAY CAUSE DAMAGE TO YOUR UNIT AND/OR

PERSONAL INJURY. Reference Fig. 12-2 for an example.

• Only a C.S.A. listed stainless steel connector can be

connected to the grill.

• The regulator/hose assembly coming from the propane

cylinder can only be connected to the above mentioned

grill fl ex connector. DO NOT connect the regulator/

hose assembly directly to the grill. An adapter will

be required.

• A non-combustible heatshield must be installed to protect

the regulator/hose assembly and propane cylinder valve.

• RHP offers propane tank door with tank tray models

and a propane tank heatshield that rest directly on

the tank to meet the cylinder install requirements.

Propane tank door with tank tray shown in Fig. 12-3.

Contact your dealer for ordering information.

Fig. 12-1 Ventilation detail

Fig. 12-3 Optional RHP door w/ tank tray

Cylinder & regulator/hose assembly

protected by heatshield

Additional adapters may be required

for your setup (not included)

Equipped with adapter

for hose assembly.

Flex connector not

included.

Ventilation Requirements:

• Minimum 4 openings

(2 per side wall - spaced at 180 degrees)

• Top openings: within 5" of countertop (see below)

• Bottom openings: within 5" of fl oor (see below)

1"

max.

Keep surrounding area

and vent openings clear

for proper venting

5"

max.

1"

max.

5"

max.

33820-TSL

model shown

Vent openings (4)

10 sq. in. of free

area min. (ea.)

3" min.

REV 1 - 1603010800

L-C2-434

13

PROPANE SAFETY INFORMATION

WHEN OPERATING THIS APPLIANCE WITH PROPANE, ALL INSTRUCTIONS AND

WARNINGS MUST BE OBSERVED. FAILURE TO DO SO MAY RESULT IN A FIRE OR

EXPLOSION CAUSING SERIOUS INJURY OR DEATH.

WARNING

This gas appliance, its enclosure, and the propane cylinder enclosure, if any, MUST be plumbed and

vented in accordance with local building and safety codes and should be approved by local code

enforcement offi cials. This appliance MUST be installed and operated according to the information

below.

FAILURE TO PROPERLY VENT THE ENCLOSURE MAY RESULT IN A FIRE OR EXPLOSION CAUSING

SERIOUS INJURY OR DEATH.

When using propane gas:

• Propane gas (also known as L.P. gas) is heavier than air and will accumulate or pool in an inadequately

vented enclosure or recessed area.

• A leaking gas connection or valve unintentionally left open will create a hazard.

• If a pool of propane gas is ignited, an explosion will occur. Adequate venting at the fl oor level, or the

lowest point where gas could accumulate, will eliminate this danger.

Refer to the ENCLOSURE REQUIREMENTS section.

Observe all local codes.

• DO NOT store a spare propane-gas cylinder under or near the enclosure.

INSTALLATION SAFETY GUIDELINES

THIS UNIT MUST BE INSTALLED IN SUCH A MANNER THAT ALL REQUIRED VENT OPENINGS ON THE

UNIT ENCLOSURE REMAIN CLEAR AND FREE OF ALL OBSTRUCTIONS AT ALL TIMES AND DURING

ALL WEATHER CONDITIONS. See the ENCLOSURE REQUIREMENTS section for details.

Important: FOR YOUR SAFETY, you must provide openings in the enclosure for replacement air and

cross-ventilation (in case of possible leakage from gas connections or propane cylinders).

See the ENCLOSURE REQUIREMENTS section for details.

The gas cylinder, regulator, and rubber hose must be in a location not subject to temps. above 125° F

(51° C).

WHEN A PROPANE CYLINDER IS INSTALLED INSIDE OF THE ENCLOSURE, THE GUIDELINES FOUND

IN THE ENCLOSURE REQUIREMENTS SECTION MUST BE FOLLOWED.

Every time you use the unit, make sure that:

1. The area around the enclosure is clear and free from combustible materials, gasoline and fl ammable vapors/

liquids.

2. There is no blockage of the airfl ow through the vent openings located on the enclosure.

3. The hose is inspected (if applicable). See SAFE USE & MAINTENANCE OF PROPANE-GAS CYLINDERS section.

DO NOT store any combustible materials, gasoline, and any other fl ammable vapors/liquids in the vicinity of the

unit. Provide adequate clearance for servicing and operation.

OPERATING THE UNIT SAFELY AND CORRECTLY

REV 1 - 1603010800

L-C2-434

14

U

L

Fig. 14-1 type coupleur rapide de fi l de point culminant d’I

Valve

de

décompression

QCC

Type 1

Valve

Ajustage de précision

en laiton de fi l de

point culminant

Indicateur

de niveau

de liquide

(facultatif)

Écrou de main avec le

fi l de point culminant.

Régulateur

Passage

Tuyau

Volant de commande

main dans le sens des aiguilles d’une montre pour engager les

fi ls et pour serrer jusqu’à ce que douillettement. L’utilisation des

pinces ou de la clé ne devrait pas être nécessaire. Seulement

le propane marqué par cylindres doit être employé.

Pour débrancher: Tournez l’écrou de main dans le sens

contraire des aiguilles d’une montre jusqu’à isolé (fi g. 14-1).

Important: Avant d’employer le gril, et ensuite chaque

fois que le cylindre est enlevé et rattaché,

examinez tous les raccordements pour déceler

les fuites. Arrêtez les valves de gril et ouvrez

la valve principale de cylindre, puis vérifi ez

les raccordements avec de l’eau savonneux.

Réparez toutes les fuites avant d’allumer le gril.

ATTENTION: Tournez toujours la valve principale de cylindre

de propane au loin après chaque utilisation,

et avant de déplacer le gril et le cylindre, ou

débrancher l’accouplement. Cette valve doit

rester fermée et le cylindre a débranché alors

que l’appareil n’est pas en service, quoique

l’écoulement de gaz soit arrêté par un dispositif

de sûreté quand le coupleur est débranché.

Inspectez soigneusement l’ensemble de tuyau chaque fois

avant que le gaz soit allumé. Un tuyau fi ssuré ou effi loché doit

être immédiatement remplacé.

Si l'appareil est stocké à l'intérieur, le cylindre doit être disconnected

et a enlevé. Des cylindres Disconnected doivent être stockés

dehors, hors de la portée des enfants, avec les prises de valve

fi letées étroitement installées, et ne doivent pas être stockés dans

un bâtiment, le garage, ou n'importe quel autre secteur inclus.

POUR VOTRE SÛRETÉ

a. Ne stockez pas un cylindre de gaz disponible de propane

dessous ou ne vous approchez pas de cet appareil.

b. Ne remplissez jamais cylindre au delà de 80 pour cent de

plein.

c. SI L’INFORMATION DANS “A” ET “B” N’EST PAS SUIVIE

EXACTEMENT, UN FEU CAUSANT LA MORT OU DES

DOMMAGES SÉRIEUX PEUT SE PRODUIRE.

IMPORTANT POUR VOTRE SÛRETÉ

LISEZ ET SUIVEZ TOUS LES AVERTISSEMENTS ÉQUIPÉS DE VOTRE CYLINDRE DE GAZ DE PROPANE.

En actionnant cet appareil avec un cylindre de gaz de propane ON DOIT observer ces instructions et avertissements.

LE MANQUE DE FAIRE AINSI PEUT AVOIR COMME CONSÉQUENCE UNE INCENDIE OU UNE EXPLOSION SÉRIEUSE.

CYLINDRE ET CONDITIONS ET

CARACTÉRISTIQUES DE CONNECTEUR

a. Des cylindres et les valves de gaz de propane doivent être

maintenus en bon état et doivent être remplacés s’il y a

des dommages évidents au cylindre ou à la valve.

b. Ce gril, une fois utilisé avec un cylindre, devrait être relié à

un gallon de la norme 5 (20lb.) cylindre de gaz de propane

équipé d’un OPD (remplissez au-dessus du niveau le

dispositif d’empêchement). L’OPD a été exigé sur tous les

cylindres vendus depuis octobre 1.1998 pour empêcher le

remplissage excessif.

c. Les dimensions de cylindre devraient être approximativement

12"(30.5cm) de diamètre et 18" (45.7cm) hauts. Des

cylindres doivent être construits et marqués selon les

caractéristiques pour des cylindres de gaz de propane du

département des ETATS-UNIS du transport (D.O.T.) ou

le niveau national du Canada, du CAN/CSA-B339, des

cylindres, des sphères et des tubes pour le transport des

marchandises dangereuses.

d. Le cylindre doit inclure un collier pour protéger la valve

de cylindre et le circuit d’alimentation de cylindre doit être

assuré le retrait de vapeur.

e. Le montage du régulateur de pression et le fl exible (Fig. 14-1)

fourni avec cet appareil au gaz en plein air (modèles au

propane seulement) doit être utilisé. Assemblées d'origine et

régulateur de pression et le tuyau de remplacement doivent

être ceux spécifi és par le fabricant pour le raccordement d'un

dispositif de cylindre de liaison identifi ée comme de type I par

le 21.58-2005/CGA ANSI Z 1.6 à 2005 (voir liste des pièces

pour les informations de commande).

f. La valve de cylindre de gaz de propane doit être équipée

d’un dispositif d’accouplement de raccordement de

cylindre, décrit comme type I dans la norme défi nie dans le

e. de paragraphe ci-dessus. Ce dispositif est généralement

décrit comme coupleur rapide de fi l de point culminant.

g. Si votre cylindre de gaz de propane vient avec une prise

de la poussière, placez le bouchon anti-poussière sur la

sortie de valve de cylindre toutes les fois que le cylindre

n’est pas en service.

OPÉRATION DE COUPLEUR RAPIDE

Pour relier le regulator/hose à l’ajustage de précision de

valve de cylindre de gaz de propane: Serrez l’écrou de main

sur le régulateur au-dessus de l’ajustage de précision de fi l

de point culminant sur la valve de cylindre. Tournez l’écrou de

1

2

3

4

e. Le régulateur de pression et l’ensemble de tuyau utilisé

doivent assortir les spécifi cations pour le type I par ANSI

Z 21.58-2005/CGA 1.6-2005 (voir la fi gue. 14-1).

Pour la ventilation de propane, voir la section sur les exigences de boîtier.

UTILISATION SÛRE ET ENTRETIEN DES CYLINDRES DE GAZ DE PROPANE

15

U

L

Fig. 15-1 Type I Acme thread quick coupler

Pressure

relief

valve

QCC

Type 1

valve

Brass Acme

thread fi tting

Liquid level

indicator

(optional)

Hand nut with Acme

thread

Regulator

Vent

Hose

Hand wheel

The use of pliers or a wrench should not be necessary. Only

cylinders marked “propane” may be used.

To disconnect: Turn the hand nut counterclockwise until

detached (Fig. 15-1).

Important: Before using the unit, and after each time the

cylinder is removed and reattached, check

the hose for wear (see a.) and check all

connections for leaks. Turn off the unit valves

and open the main cylinder valve, then check

connections with soapy water. Repair any

leaks before lighting the unit.

CAUTION: Always turn the propane cylinder main valve

off after each use, and before moving the unit

and cylinder or disconnecting the coupling.

This valve must remain closed and the

cylinder disconnected while the appliance

is not in use, even though the gas fl ow is

stopped by a safety feature when the coupler

is disconnected.

Carefully inspect the hose assembly each time before the

gas is turned on. A cracked or frayed hose must be replaced

immediately.

If the appliance is stored indoors, the cylinder must be

disconnected and removed. Disconnected

cylinders must be

stored outdoors, out of the reach of children, with threaded

valve plugs tightly installed, and must not be stored in a

building, garage, or any other enclosed area.

FOR YOUR SAFETY

a. DO NOT store a spare propane-gas cylinder under or

near this appliance.

b. NEVER fi ll the cylinder beyond 80-percent full.

c. IF THE INFORMATION IN a. AND b. IS NOT FOLLOWED

EXACTLY, A FIRE CAUSING DEATH OR SERIOUS

INJURY MAY OCCUR.

IMPORTANT FOR YOUR SAFETY

READ AND FOLLOW ALL WARNINGS PROVIDED WITH THE PROPANE-GAS CYLINDER.

When operating this appliance with a propane-gas cylinder, these instructions and warnings MUST be observed.

FAILURE TO DO SO MAY RESULT IN A SERIOUS FIRE OR EXPLOSION.

CYLINDER/CONNECTOR REQUIREMENTS

a. Propane-gas cylinders, valves, and hoses must be

maintained in good condition and must be replaced if

there is visible damage to either the cylinder or valve. If the

hose is cut or shows excessive abrasion or wear, it must

be replaced before using the gas appliance (see e.).

b. This unit, when used with a cylinder, should be connected

to a standard 5-gallon (20 lb.) propane-gas cylinder

equipped with an OPD (Overfi ll Prevention Device).

The OPD has been required on all cylinders sold since

October 1,1998, to prevent overfi lling.

c. Cylinder dimensions should be approximately 12" (30.5

cm) in diameter and 18" (45.7 cm) high. Cylinders must

be constructed and marked in accordance with the

Specifi cations for Propane Gas Cylinders of the U.S.

Department of Transportation (D.O.T.) or the National

Standard of Canada, CAN/CSA-B339, Cylinders,

Spheres, and Tubes for Transportation of Dangerous

Goods.

d. The cylinder used must include a collar to protect the

cylinder valve, and the cylinder supply system must be

arranged for vapor withdrawal.

e. The pressure regulator and hose assembly (Fig. 15-1)

supplied with this outdoor gas appliance (L.P. models

only) must be used. Original and replacement pressure

regulator and hose assemblies must be those specifi ed

by the manufacturer for connection with a cylinder

connecting device identifi ed as Type I by the ANSI Z

21.58-2005/CGA 1.6-2005 (see PARTS LIST for ordering

information).

f. The propane-gas cylinder valve must be equipped with a

cylinder connection coupling device, described as Type I

in the standard defi ned in paragraph e. above. This device

is commonly described as an Acme thread quick coupler.

g. If the propane-gas cylinder comes with a dust plug, place

the dust cap on the cylinder valve outlet whenever the

cylinder is not in use.

QUICK COUPLER OPERATION

To connect the regulator/hose assembly to the propane-

gas cylinder valve fi tting: Press the hand nut on the regulator

over the Acme thread fi tting on the cylinder valve. Turn the hand

nut clockwise to engage the threads and tighten until snug.

e. The pressure regulator and hose assembly used must

match the specifi cation for Type I by ANSI Z 21.58-2005/

CGA 1.6-2005 (see Fig. 15-1).

For propane ventilation requirements, see the ENCLOSURE REQUIREMENTS section.

SAFE USE & MAINTENANCE OF PROPANE GAS CYLINDERS

16

COUNTER PREPARATION

Consult Table 1 for non-combustible enclosure cut-out

dimensions. An RHP insulating liner must be used if any

supporting construction is combustible. Consult the instructions

that come with the liner for dimensions and additional installation

information before beginning the installation.

This outdoor built-in grill must be supported by the stainless-

steel hanger extending from the upper portion of the grill. The

hanger rests on the left, right, and back of the countertop and on

the two front structural supports with attached adjustable screws

located below the control panel on the left and right sides.

The control panel is designed to sit fl ush against the enclosure

front wall (see Fig. 16-2). If the non-combustible enclosure

countertop extends beyond the front wall, creating a countertop

overhang (see Fig. 16-1), it must be cut fl ush with the front

wall for the width of the control panel or a gap will be created

exposing the forward portions of the left and right side grill fi re

walls. Reference the MODEL SPECIFICATIONS section.

Note: It is not necessary to remove the control panel or

knobs to install this unit.

CONNECT THE GAS SUPPLY

For propane cylinders:

For connecting a propane unit to a portable propane tank,

read the safety warnings and follow the instructions in the

section SAFE USE AND MAINTENANCE OF PROPANE GAS

CYLINDERS.

Note: When a propane cylinder is installed inside of the

enclosure, the guidelines found in the ENCLOSURE

REQUIREMENTS section MUST be followed.

For household propane or natural gas units:

CAUTION: Use only C.S.A. listed stainless-steel flex

connectors within the enclosure.

WARNING

A rubber or plastic connector will rupture or leak, resulting

in an explosion or serious injury if used inside the appliance

enclosure.

1. Run the attached fl ex connector routed under the left side

of the grill to the gas stub.

2. Turn OFF the gas supply at the source.

3. A shut-off valve is required within 6 feet of the unit.

If shut-off valve is connected to end of gas supply stub:

• Connect the fl ex connector to the shut-off valve (see

Fig. 16-3). Tighten securely.

If shut-off valve is installed in-line:

• Install the supplied fl are adapter to the gas supply using

a pipe joint compound resistant to all gasses (see Fig.

16-3). Tighten securely.

• Connect the fl ex connector to the fl are adapter (see Fig.

16-3). Tighten securely.

GAP CREATED

IDEAL

Flush-mounted

control panel

Proposed cut-

out in overhang

Countertop

Countertop

Overhang

Control panel

stops here

INSTALLATION

Fig. 16-3 Connecting to a gas line

Gas supply

Flare adaptor

(use on gas

supply stub only

if shut-off valve

installed in-line)

Flex connector

(coming from unit)

Shut-off valve

(required, not

included, must be

installed within 6

feet of the unit)

INCORRECT

Fig. 16-1 Countertop overhang - incorrect cutout

Fig. 16-2 Countertop overhang - correct cutout

CORRECT

Fig. 16-4 Household propane & natural gas diagram

OFF

Shut-off valve (shown in-line)

must be within 6 feet of the unit

To gas

system

(Cut-out)

Pipe

adapter

fitting

(Countertop)

Gas inlet pipe

Flex

connector

Hanger

INSTALLATION

17

4. Turn all burner control knobs to the OFF position.

Turn the gas supply on. Then carefully check all gas

connections for leaks with a brush and half-soap/

half-water solution before lighting. NEVER USE A

MATCH OR OPEN FLAME TO TEST FOR LEAKS.

5. Close the shut-off valve, then slide the grill into

place. Do not to pinch, kink, or damage the gas

connector line.

6. Rotate the adjustable support screws to the left to

raise and to the right to lower the respective side

of the appliance grill. Use a

7

/16" open-end wrench

as needed. See Fig. 17-1.

Important: Do not extend the support screws so

far that any part of the hanger is raised

off the counter top.

INSTALL THE FLAVOR GRIDS

Place the fl avor grids directly onto the studs on the burners.

See Fig. 17-2. The fl avor grids allow heat from the burners

to be evenly distributed throughout the cooking area. They

are stainless steel and will heat and cool quickly, making

your grill very responsive to the changes you specify in grill

temperature. They are rust resistant and may be cleaned

with standard oven cleaners. Some discoloring will be

seen with use. This is normal for stainless steel and does

not affect the function.

INSTALLATION (Cont.)

Fig. 17-2 Install fl avor grids

Fig. 17-1 Adjust support screws

Place onto studs

Adjustable

support

screw

Bottom of

control panel

Bottom of

cut-out opening

18

POWER SUPPLY HOOKUP

CAUTION: IMPROPERLY CONNECTED WIRES WILL

CAUSE DAMAGE TO THE GRILL AND MAY

RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

This grill includes a power supply box. When installing the

power supply box:

• It MUST be located at least 12 inches below the bottom

of the grill (see Fig. 18-3).

• The wire extension that exits from the control panel

MUST be routed directly downward. This will prevent

overheating. DO NOT route the wire extension below

the grill (see Fig. 18-3).

Note: For enclosures with a solid area beneath the grill,

a cutout must me made near the wire extension

to allow for the above requirement. If an insulating

liner is installed, route the wire down through the

nearest hole possible.

• DO NOT block the vent holes found on the box.

Fasten the power supply box to the inside of the enclosure

using appropriate hardware for your enclosure.

The electrical connections from the power supply box to the

grill electrical systems come pre-connected.

WARNING: Electrical Grounding Instructions - This

appliance is equipped with a three-pronged

(grounding) plug for your protection against

shock hazard and should be plugged

directly into a properly grounded three-

prong receptacle. Do not cut or remove the

grounding prong from this plug.

CONNECT THE POWER SUPPLY TO LINE

POWER

Connect the cord coming from the unit's power supply to

a 120VAC (15 AMP minimum) GFCI GROUNDED 3-wire

receptacle.

ELECTRICAL SAFETY

To protect against electric shock, do not immerse cord or plugs in water or other liquid.

Unplug from the outlet when not in use and before cleaning. Allow to cool before putting on or taking off parts.

Do not operate any outdoor cooking gas appliance with a damaged cord, plug, or after the appliance malfunctions

or has been damaged in any manner. Contact the manufacturer for repair.

Do not let the cord hang over the edge of a table or touch hot surfaces.

Do not use an outdoor cooking gas appliance for purposes other than intended.

When connecting, fi rst connect plug to the outdoor cooking gas appliance then plug appliance into the outlet.

Use only a properly wired and inspected 120VAC (15 AMP minimum) GFCI

GROUNDED 3-wire receptacle

with this outdoor cooking gas appliance.

Never remove the grounding plug or use with an adapter of 2 prongs.

Use only extension cords with a 3 prong grounding plug, rated for the power of the equipment, and approved for

outdoor use with a W-A marking.

Grounded

plug

Required

GFI electrical

receptacle

(not included)

Grounded

plug

Required 120VAC (15 AMP minimum) GFCI

GROUNDED 3-wire receptacle (not included)

12"

Min.

Fig. 18-3 Power supply clearance

Fig. 18-2 Wire connections

Fig. 18-1 Power supply detail

Route wires

directly downward

(to prevent

overheating)

ELECTRICAL INSTALLATION

19

Fig. 19-1

Left

main burner

control knob

Right

main burner

control knob

Backburner

control knob

(if equipped)

Digital

Thermometer

(if equipped)

Center main burner

control knob

Fig. 19-2

Left

main burner

control knob

Right

main burner

control knob

Backburner

control knob

(if equipped)

Digital

thermometer

(if equipped)

Drip

tray

A430i and A530i controls

A540i, A660i, and A790i controls

Control panel

screw(s)

Control panel

screw(s)

Meat probe

(if equipped)

Meat probe

(if equipped)

Light switch

Drip

tray

Light switch

IDENTIFICATION OF GRILL CONTROLS

USE

,

CARE

,

&

SERVICE

20

ARRÊT DU UNITÉ

Pour couper le unité, diminuez chaque bouton de commande

de valve et tout en pressant tour il dans le sens des aiguilles

d’une montre à la position de repos.

Fermez toujours la valve de la fourniture de gaz après chaque

utilisation du unité.

ÉCLAIRAGE ÉLECTRONIQUE

Note: L’éclairage électronique exige une batterie installée

de 9 volts avec une bonne charge.

1. Ouvrez les couvercles ou enlevez les couvertures des brûleurs

pour être Lit.

2. Tournez tous les boutons de commande de gaz à leurs

positions de repos.

3. Allumez le gaz à sa source.

Note: N’ouvrez

pas plus d’une

valve à la fois

pour l’éclairage

électronique ou

manuel.

4. Diminuez le bouton de commande désiré pendant 5

secondes, puis, et tout en pressant le tour il dans le sens

contraire des aiguilles d’une montre dans la position

LÉGÈRE de HI. Une fois que le brûleur s’allume, libérez

le bouton.

ATTENTION : Si un brûleur ne s’allume pas dans cinq

(5) secondes d’allumer le bouton de

commande, enfoncez le bouton et tournez-

le à la position de repos. ATTENDEZ CINQ

(5) MINUTES avant de répéter l’étape 4. Si

vous sentez le gaz, suivez les instructions

sur la couverture de ce manuel. Si les

brûleurs ne s’allument toujours pas après

que plusieurs tentatives, se rapportent aux

instructions pour l’éclairage manuel.

5. Répétez l’étape 4 pour que chaque brûleur additionnel soit Lit.

EN EMPLOYANT UN RÉSERVOIR DE PROPANE PORTATIF

Des réservoirs de propane sont équipés d’un dispositif

d’arrêt de sûreté qui peut ne pas causer le bas ou aucunes

pression de gaz/fl amme aux brûleurs si le fonctionnement

et l’allumage des instructions ne sont pas suivis exactement

(voir la note importante dans la section de dépannage pour

plus de détails.)

ÉCLAIRAGE MANUEL

ATTENTION: Attendez toujours cinq (5) minutes le gaz

pour se dégager après que n’importe quelle

tentative non réussie d’éclairage.

1. Suivez les étapes 1 à 3 (à gauche).

2. Passez un allumeur brûlant de butane de long-baril ou

une allumette brûlante de long-tige dans la grille à cuire

s’ouvrant au dessus du tube d’éclairage. (Fig. 20-2). Pour

des backburners, tenez la fl amme contre le surface du

backburner. Pour des sideburners, tenez la fl amme contre

le brûleur.

3. Vieux match / fl amme d’un briquet à la partie supérieure

du tube d’éclairage pendant 5 secondes, ou, à côté de la

brûleur latéral / veilleuse. Puis appuyer sur le bouton de

contrôle approprié et en appuyant tourner dans le sens

antihoraire à la position HI LIGHT. Retirez le briquet ou

des allumettes quand le brûleur s’allume, puis relâchez

le bouton de commande.

4. Si le brûleur ne se allume pas dans les cinq (5)

secondes de tourner le bouton de commande, enfoncez

immédiatement le bouton et tournez la valve à AU LOIN.

ATTENDEZ CINQ (5) MINUTES avant de répéter les

étapes 2 à 4 des instructions manuelles d’éclairage.

Lisez toutes les instructions avant l’allumage, et suivez ces instructions chaque fois vous lumière le unité.

Fig. 20-2 - Éclairage manuel

Plus léger

Tube

d’éclairage

Fig. 20-1 - bouton de commande

OFF

HI

LIGHT

LOW

TO

TURN OFF

TO TURN ON

Read setting

here

HIGH to

LIGHT

Lisez l’établissement ici

(OUTRE de montrer)

OUTRE DE

SUR

Utilisation

SALUT

(haute)

à la lu-

mière

Enfoncez

le bouton

pour

tourner

3. Maintenez le match / fl amme d’un briquet à la partie

supérieure du tube d’éclairage pendant 5 secondes, ou,

à côté de la veilleuse. Puis appuyer sur le bouton de

contrôle approprié et en appuyant tourner dans le sens

antihoraire à la position HI LIGHT. Retirez le briquet ou

des allumettes quand le brûleur s’allume, puis relâchez

le bouton de commande.

Note: Le unité doit être relié à la puissance 120VAC pour

l’éclairage électronique.

ALLUMAGE DES INSTRUCTIONS (D’ALLUMAGE)

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

Fire Magic A660I6LAPW Guide d'installation

- Catégorie

- Barbecues

- Taper

- Guide d'installation

- Ce manuel convient également à

dans d''autres langues

Documents connexes

-

Fire Magic C540I1T1P Guide d'installation

-

Fire Magic A430i Le manuel du propriétaire

-

Fire Magic Gourmet Single and Double Searing Station Manuel utilisateur

-

Fire Magic Aurora Built-In Grill Manuel utilisateur

-

Fire Magic E1060I4A1P Le manuel du propriétaire

-

Fire Magic Aurora Portable Grill Manuel utilisateur

-

Fire Magic E1060i Le manuel du propriétaire

-

Fire Magic Electric Grill App Setup and Operation Manuel utilisateur

-

Fire Magic 42VH6 Manuel utilisateur

-

Fire Magic E1060S4EAP71 Guide d'installation

Autres documents

-

FireMagic 32874-1(P) Installation And Operating Insctruction Manual

-

Jackson Grills 2017/18 LUX 550 BI Manuel utilisateur

-

Jackson Grills SUPREME BUILT INS Le manuel du propriétaire

-

media-tech MT6208 Manuel utilisateur

-

FireMagic Aurora A540s Installation Instructions And Owner's Manual

-

Coleman LG39611SB Le manuel du propriétaire

-

Coleman LG200 Le manuel du propriétaire

-

Hasbro LITE BRITE CUBE Le manuel du propriétaire