United States Stove Company HB1520 Le manuel du propriétaire

- Catégorie

- Poêles

- Taper

- Le manuel du propriétaire

* All Pictures In This Manual Are For Illustrative Purposes Only. Actual Product May Vary.

© 2023 United States Stove Company, 227 Industrial Park Rd., South Pittsburg, TN 37380 Ph. 800-750-2723

THIS MANUAL IS SUBJECT TO CHANGE WITHOUT NOTICE.

Owner’s Instruction and Operation Manual

SAFETY NOTICE: If this unit is not properly installed, a fire may result. For your

safety, follow the installation instructions. Never use make-shift compromises during

the installation of this unit. Contact local building or fire ocials about permits,

restrictions and installation requirements in your area.

CAUTION! Please read this entire manual before you install or use this unit. Failure

to follow instructions may result in property damage, bodily injury, or even death.

Improper Installation Will Void Your Warranty!

Save These Instructions In A Safe Place For Future Reference.

CALIFORNIA PROPOSITION 65 WARNING:

This product can expose you to chemicals including carbon

monoxide, which is known to the State of California to cause

cancer, birth defects, and/or other reproductive harm. For

more information, go to www.P65warnings.ca.gov

U.S. Environmental Protection Agency

Certified to comply with 2020 particulate

emission standards

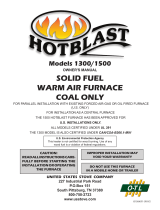

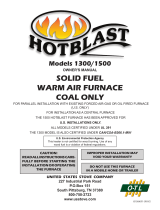

HB1520

Model Number:

Wood Only Central Furnace

R

Certified to UL-391-2006 (R2019), Certified

to: CSA B366.1-11 (R2020), and CSA B415.1:22

Report Number: 22-808

853966D- 0406M

2

© 2023 United States Stove Company

INTRODUCTION

For Customer Service, please call:

1-800-750-2723 Ext 5050 or;

Text to 423-301-5624 or;

Email us at:

customerservice@usstove.com

Note: Register your product online at

www.usstove.com or download the free

app today. This app is available only

on the App Store for iPhone and iPad.

Search US Stove. Save your receipt with

your records for any claims.

CAUTIONS:

• HOT WHILE IN OPERATION. KEEP CHILDREN, CLOTHING AND FURNITURE AWAY. CONTACT MAY CAUSE

SKIN BURNS.

• DO NOT USE CHEMICALS OR FLUIDS TO IGNITE THE FIRE.

• DO NOT LEAVE THE STOVE UNATTENDED WHEN THE DOOR IS SLIGHTLY OPENED.

• DO NOT BURN GARBAGE, FLAMMABLE FLUID SUCH AS GASOLINE, NAPHTHA OR MOTOR OIL.

• DO NOT CONNECT TO ANY AIR DISTRIBUTION DUCT OR SYSTEM.

• ALWAYS CLOSE THE DOOR AFTER THE IGNITION.

• YOUR CHIMNEY MUST BE INSPECTED PRIOR TO THE INSTALLATION OF YOUR NEW WOOD STOVE.

IN ADDITION, YOU SHOULD HAVE YOUR CHIMNEY INSPECTED FOR CREOSOTE DEPOSTS MONTHLY

DURING THE HEATING SEASON AND ANNUALLY INSPECTED AND CLEANED.

This manual describes the installation and operation of the Hotblast, HB1520 wood furnace. This furnace meets the

2020 U.S. Environmental Protection Agency’s emission limits for wood furnaces. Under specific EPA test conditions

this furnace has been shown to deliver heat at a rate of 15,997 – 53,042 BTU/hr. This furnace achieved a particulate

emissions rate of 0.13 lb/mmBtu when tested to method CSA B415.1-10 (*and an overall eciency of 70%). The

maximum overall heat output of this furnace was tested to be 65,258 Btu/hr.

Combustible: Wood

Flue Pipe Diameter: 6” (153cm)

Flue Pipe Type: (Standard, Single Wall, or

Double Wall): Black or Blued Steel 2100°F (650°C) Class “A”

Minimum Chimney Height: 12 ft (3.65 m)

Maximum Log Length: 23” (585 mm)

Electrical: 120 Volts, 60 Hz, 6.0 Amps

Dimensions

Assembled Height x Width x Depth: 45” (1143 mm) x 25-3/8” (645 mm) x 54-3/4” (1391 mm)

Combustion Chamber:

Width x Depth: 13.75” (350 mm) x 24” (610 mm)

Volume:

Cubic Feet: 3.95 Cu Ft.

Door Opening: Width x Height: 14” (356 mm) x 13.89” (353 mm)

© 2023 United States Stove Company

3

INSTALLATION CHECKLIST

Your Wood Stove should be installed by a qualified installer only. An NFI qualified Installer can be found at;

www.nficertified.org/public/find-an-nfi-pro/

CUSTOMER SERVICE

1-800-750-2723 ext 5050

Text to 423-301-5624

Email to: Customerservice@usstove.com

COMMISSIONING CHECKLIST

This checklist is to be completed in full by the qualified person who installs this unit. Keep this page for future reference.

Failure to install and commission according to the manufacturer’s instructions and complete this checklist will

invalidate the warranty.

Please Print

Customer Name: Telephone Number:

Address:

Model:

Serial Number:

Installation Company Name: Phone Number:

Installation Technician’s Name: License Number:

DESCRIPTION OF WORK

Location of installed appliance: __________________________________________________________________________________

Chimney System: New Chimney System Yes No If yes, Brand _________________________________________

If no, Date of inspection of the existing chimney system: __________________________________________________________

COMMISSIONING

Confirm Hearth Pad Installation as per Installation Instructions ...................................................................................................

Confirm proper placement of internal parts ..........................................................................................................................................

Check soundness of door gasket and door seals .................................................................................................................................

Confirm clearances to combustibles as per installation instructions in this manual ..............................................................

Check the operations of the air controls .................................................................................................................................................

Confirm all flue pipe and chimney system are secure and sealed ..................................................................................................

Confirm the stove properly drafts when fired .......................................................................................................................................

Check to ensure a CO alarm is installed as per local building codes and is functional ............................................................

Explain the safe operation, proper fuel usage, cleaning and routine maintenance requirements ........................................

Declaration of Completion: As the qualified person responsible for the work described above, I confirm that the appliance

as associated work has been installed as per manufacturer’s instructions and following any applicable building and

installation codes.

Signed: ______________________________________ Print Name: __________________________________Date: ______________

Home Owner: RETAIN THIS INFORMATION FOR FUTURE REFERENCE

4

© 2023 United States Stove Company

ASSEMBLY INSTRUCTIONS

TOOLS AND MATERIALS

The following is a list of tools and materials needed to

install your furnace.

• Safety glasses and gloves

• Various Hand Tools for component assembly. (Power

tools preferably)

• All Chimney and Chimney Connector materials required

for your particular installation.

• Electrical wiring tools and supplies

• All materials needed for Ductwork Installation (Supply

and return air) (Return Air Box is supplied with the unit)

UNPACKING

1. Remove all packaging from the furnace.

2. Remove the supplied parts from the furnace.

FIREBRICK CONFIGURATION

Inspect for any damage. Ensure that the bricks and

ash plug are positioned correctly and not broken (see

illustration for proper brick arrangement). NOTE: The

firebricks are silicone into place to prevent damage from

shipping. Attempting to remove the firebricks before

operation could result in damage.

CERAMIC FIBER BOARD CONFIGURATION

Inspect for any damage. Ensure the fiber board is

positioned correctly and not broken (see illustration for

proper fiber board arrangement). NOTE: The ceramic

fiber boards are silicone into place to prevent damage

from shipping. Attempting to remove the ceramic fiber

board before operation could result in damage.

ASSEMBLY OF FURNACE

Your furnace requires the following items to be assembled

or installed by the service person:

• Smoke Curtain

• Feed Door Handle & Latch

• Front Cover/Hood

• Distribution Blowers With Gaskets

• Junction Box Bracket

• Junction Box and Fan Center

• Draft Blower

• Honeywell Probe

• Filter Box

• Electrical Connections

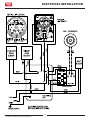

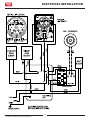

JUNCTION

BOX

DISTRIBUTION

BLOWERS

HONEYWELL

LIMIT SWITCH

DRAFT

BLOWER

FOR CUSTOMER SERVICE CALL: 8007502723 EXT 5050

© 2023 United States Stove Company

5

SMOKE CURTAIN

Using two (2) 1/4-20 x 1-1/4” Carriage bolts, two (2)

smoke curtain clips, and two (2) nuts, attach the smoke

curtain in place above the fuel feed door as shown. After

installation, the smoke curtain should swing freely back

into the furnace.

OUTSIDE VIEW OF THE UNIT

INSIDE VIEW OF THE UNIT

FEED DOOR HANDLE & LATCH

Use the included one (1) nut and one (1) washer to secure

the handle to the stove as shown. Note: Adjust the handle

as needed to ensure a proper seal.

Use two (2) 1/4-20 x 3/4 bolts and two (2) washers to

secure the latch assembly to the unit.

ASSEMBLY INSTRUCTIONS

6

© 2023 United States Stove Company

ASSEMBLY INSTRUCTIONS

Use three (3) 1/4-20 x 3/4 bolts, three (3) washers, and

three (3) 1/4-20 kep nuts to secure the latch top to the

latch bottom.

FRONT COVER/HOOD

Use the four (4) provided #10A x 1/2 screws to secure

the front cover hood to the unit as shown.

DISTRIBUTION BLOWERS WITH GASKETS

Secure the two blowers and gaskets to the unit using the

eight (8) provided 1/4-20 x 3/4 bolts.

JUNCTION BOX BRACKET

Secure the junction box bracket to the unit using the four

(4) provided #10A x 1/2 screws.

JUNCTION BOX & FAN CENTER

Secure the junction box to the junction box bracket using

the two (2) provided #10A x 1/2 screws as shown.

© 2023 United States Stove Company

7

Secure the fan center to the junction box using the two

(2) provided screws as shown.

DRAFT BLOWER

Secure the draft blower to the back upper left-hand side

of the unit using the four (4) provided 10-24 kep nuts.

HONEYWELL PROBE

Install the Honeywell probe into the ducktwork above the

unit. NOTE: The conduit is supplied at a predetermined

length of approximately 3 feet

FILTER BOX

The filter box is made up of 4 parts, plus all hardware

necessary for assembly.

Assemble the filter box sides, top, and bottom using

twenty (20) #10 A x 1/2 HX screws.

If your BX Cables will not match up to the previously

matched arrangement on the top, carefully measure

and custom notch to accommodate your particular

arrangement of BX Cables. There are several dierent

configurations.

Secure the filter box to the unit using a total of ten (10)

#10 A x 1/2 HX screws, five (5) on each side.

ASSEMBLY INSTRUCTIONS

8

© 2023 United States Stove Company

AIR FILTER REPLACEMENT

Insert one 16 x 24 x 1 air filter (not included).

ASSEMBLY INSTRUCTIONS

© 2023 United States Stove Company

9

INSTALLATION

ATTENTION:

• FAILURE TO FOLLOW THE INFORMATION IN

THIS MANUAL WILL CAUSE A HAZARD THAT

COULD RESULT IN DEATH, SERIOUS BODILY

INJURY, AND/OR PROPERTY DAMAGE.

• CHECK YOUR LOCAL CODES. THE INSTALL ATION

MUST COMPLY WITH THEIR RULINGS.

• ALWAYS CONNECT THIS FURNACE TO A

CHIMNEY AND VENT TO THE OUTSIDE. NEVER

VENT TO ANOTHER ROOM OR INSIDE A

BUILDING.

• DO NOT CONNECT THIS FURNACE TO AN

ALUMINUM TYPE B GAS VENT. THIS IS NOT

SAFE AND IS PROHIBITED BY THE NATIONAL

FIRE PROTECTION ASSOCIATION CODE. THIS

FURNACE REQUIRES A MASONRY OR LISTED

FACTORY BUILT CHIMNEY FOR RESIDENTIAL

TYPE OR BUILDING HEATING APPLIANCE

CHIMNEY. USE A 6" DIAMETER CHIMNEY OR

LARGER, THAT IS HIGH ENOUGH TO GIVE A

GOOD DRAFT.

• INSPECT CHIMNEY CONNECTOR AND

CHIMNEY BEFORE AND FREQUENTLY DURING

THE HEATING SEASON FOR ANY DEPOSIT

OF CREOSOTE OR SOOT WHICH MUST BE

REMOVED.

• PROVIDE AIR FOR COMBUSTION INTO THE

ROOM WHERE THE FURNACE IS LOCATED. IF

THE INTAKE IS NOT IN THE SAME ROOM, AIR

MUST HAVE FREE ACCESS TO THE ROOM.

• CAST IRON PARTS MUST BE "SEASONED" TO

AVOID CRACKING, BUILD ONLY SMALL FIRES

ON FIRST USE.

• TO PREVENT INJURY, DO NOT ALLOW ANYONE

TO USE THIS FURNACE WHO IS UNFAMILIAR

WITH THE CORRECT OPERATION OF THE

FURNACE.

CAUTION

GASES THAT ARE DRIVEN FROM FRESH WOOD

MUST BE BURNED OR THEY WILL ACCUMULATE

AND EXPLODE. NEVER SMOTHER A FIRE WHEN

ADDING FRESH WOOD.

DANGER: RISK OF FIRE OR EXPLOSION.

DO NOT BURN GARBAGE, GASOLINE, DRAIN OIL,

OR OTHER FLAMMABLE LIQUIDS.

WARNING: FIRE HAZARD.

• DO NOT OPERATE WITH FIRE DRAFT

EXCEEDING 0.06" W.C.

• DO NOT STORE FUELS, PAINTS, THINNERS,

FLAMMABLE LIQUIDS, OR OTHER HIGHLY

VOLATILE SUBSTANCES IN THE FURNACE

ROOM.

CAUTION!

CLEANOUT OF THE COMBUSTION CHAMBER,

FLUE PIPE, AND CHIMNEY IS ESPECIALLY

IMPORTANT AT THE END OF THE HEATING

SEASON TO MINIMIZE CORROSION DURING

THE SUMMER MONTHS CAUSED BY MOISTURE

ACCUMULATING IN LEFT-OVER ASH.

CAUTION!

INSPECT FLUE PIPES, FLUE PIPE JOINTS AND

FLUE PIPE SEALS REGULARLY TO ENSURE THAT

SMOKE AND FLUE GASES ARE NOT DRAWN INTO,

AND CIRCULATED BY, THE AIR CIRCULATION

SYSTEM.

SAFETY NOTICE:

IF THIS FURNACE IS NOT PROPERLY INSTALLED,

A HOUSE FIRE MAY RESULT. FOR YOUR SAFETY,

FOLLOW THE INSTALLATION DIRECTIONS.

CONTACT LOCAL BUILDING OR FIRE OFFICIALS

ABOUT RESTRICTIONS AND INSTALLATION

INSPECTION REQUIREMENTS IN YOUR AREA.

IF NOT ALREADY INSTALLED, WE RECOMMEND

THAT SMOKE DETECTORS BE INSTALLED.

CAUTION:

HOT SURFACES! KEEP CHILDREN AWAY. DO NOT

TOUCH DURING OPERATION.

10

© 2023 United States Stove Company

US Stove highly recommends your stove be installed by a

qualified NFI (US) or WETT (Canada) technician. To find

the nearest qualified installer, go to:

https://nficertified.org,

https://www.wettinc.ca/

FLOOR PROTECTOR

The furnace must be placed on solid concrete, solid

masonry, or when installed on a combustible floor, on a

floor protector. The floor protector is required to provide

heat, live ember, and ash protection and must be of a non-

combustible, continuous solid surface to protect against

infiltration of live embers and ash. Floor protection must

have and R-Value of at least 1.4. Refer to floor protector

manufacturer’s instructions for installation directions.

The floor protector or non combustible floor must extend

under the furnace and beyond each side as shown below.

Dimension Inch mm

AFront 24 609.6

B Flue Rear 2 50.8

C Side 8 203.2

A

C

C

B

FLUE

CLEARANCES TO COMBUSTIBLES

The installation of this furnace includes supplying

electrical power, return air ductwork, and supply air

ductwork. This furnace may be installed as a stand alone

wood furnace only. See installation section in this manual

to ensure proper assembly, installation and operation

of your new furnace. If installing in an area with a fan it

should not be allowed to create negative pressure in the

room where the furnace is installed. When locating your

furnace ensure the required maintenance clearances are

maintained. Your furnace must be installed as shown in

this manual and in compliance with all local and national

codes. It is of the utmost importance that the clearances

to combustible materials be strictly adhered to during

installation of the furnace. Refer to the table and diagrams

below for minimum required clearances.

Dimension Inch mm

D Backwall To Furnace 26 661

E Sidewall To Furnace 16 407

F Sidewall To Flue 25 635

G Backwall To Flue 18 458

H Supply Duct (first 6 feet) 6 153

J Supply Duct (after first 6 feet) 2 51

K Minimum Duct Height 8 204

L Top Of Door To Ceiling 48 1220

M Minimum Ceiling Height 75 1905

Back wall

Side wall

Side wall

F

E

D

Ceiling

Floor Protector

H (First 6ft)

J

K

L

M

G

INSTALLATION

FOR CUSTOMER SERVICE CALL: 8007502723 EXT 5050FOR CUSTOMER SERVICE CALL: 8007502723 EXT 5050

© 2023 United States Stove Company

11

DUCT WORK

We strongly recommend that the hot air ductwork

be installed by a home heating specialist. If doing

the installation yourself, consult a qualified heating

technician and follow his recommendations as to the

safest and most ecient method of installation.

SUPPLY AIR

The supply air duct shall be constructed of metal in

accordance with NFPA 90B, 2-1.1. The plenums installed

to the furnace shall be constructed of metal in accordance

with NFPA 90B, 2-1.3. When installing this furnace the

supply air plenum is to have a minimum height of 24”

(610mm) if the top of the first vertical section is not flush

with the top of the first horizontal section of ductwork.

If the top of the plenum is flush with the top of the first

horizontal section of ductwork then the minium height is

15” (381mm).

RETURN AIR

The return air intake on the furnace is on the rear of the

unit. The ductwork must be mechanically attached to the

unit or blower box with sheet metal screws to ensure a

proper operation.

STAND ALONE INSTALLATION

When installing this stand alone furnace, ensure all local

codes and all instructions in this manual are followed,

including clearance to combustibles, floor protector

specifications and safety warnings.

20.5

28.5

Supply Air Duct Work Outlet Size

LISTED FACTORY BUILT CHIMNEY

Your wood furnace may be hooked up with a factory

built or masonry chimney, matching the diameter of the

exhaust. If you are using a factory built chimney, it must

comply with UL 103 or CSA-B365 standard; therefore it

must be a Type HT (2100°F). It is extremely important

that it be installed according to the manufacturer’s

specifications.

If you are using a masonry chimney, it is important

that it be built in compliance with the specifications of

the National Building Code. It must be lined with fire

clay bricks, metal or clay tiles sealed together with fire

cement. (Round flues are the most ecient).

The interior diameter of the chimney flue must be

identical to the furnace smoke exhaust. A flue which is

too small may cause draft problems, while a large flue

favors rapid cooling of the gas, and hence the build-up

of creosote and the risk of chimney fires. Note that it is

the chimney and not the furnace which creates the draft

eect; your furnace’s performance is directly dependent

on an adequate draft from your chimney.

Do not connect this unit to a chimney flue serving another

appliance.

The following recommendations may be useful for the

installation of your chimney:

• It must rise above the roof at least 3’ (0.9m) from the

uppermost point of contact.

• The exterior portion should be double or triple wall pipe

to ensure proper draft.

• The chimney must exceed any part of the building or

other obstruction within a 10’ (3.04m) distance by a

height of 2’ (0.6m).

• Installation of an interior chimney is always preferable

to an exterior chimney. The interior chimney will be

hotter than an exterior chimney that is being cooled

by the ambient air outside the house. Therefore the

gas which circulates will cool slower, thus reducing the

build-up of creosote and the risk of chimney fires.

• The draft caused by the tendency for hot air to rise will

be increased with an interior chimney.

• Using a fire screen at the extremity of the chimney

requires regular inspection in order to ensure that it is

not obstructed thus blocking the draft, and it should be

cleaned when used regularly.

IMPORTANCE OF PROPER DRAFT

Draft is the force which moves air from the appliance

up through the chimney. The amount of draft in your

chimney depends on the length of the chimney, local

geography, nearby obstructions and other factors. Too

INSTALLATION

12

© 2023 United States Stove Company

INSTALLATION

much draft may cause excessive temperatures in the

appliance. Inadequate draft may cause back pung into

the room and ‘plugging’ of the chimney. Inadequate draft

will cause the appliance to leak smoke into the room

through appliance and chimney connector joints. An

uncontrollable burn or excessive temperature indicates

excessive draft. Do not operate with the flue draft

exceeding .06 water column/14.93 Pascals. The draft

can be checked with a draft gauge or manometer. Take

into account the chimney’s location to ensure it is not

too close to neighbors or in a valley which may cause

unhealthy or nuisance conditions.

MASONRY CHIMNEY

Sheathing

Airtight

Cleanout

Door

Floor

Protector

Thimble

12” of Brick

Combustible Wall

1” Clearance

with Firestop

Rafter

Concrete Cap

Flashing

To Stove

1” Clearance

Eave

Flashing

Fireclay Flue

Liner With

Airspace

CAUTION:

BE SURE THAT IF A MASONRY CHIMNEY IS

USED, IT IS SAFELY CONSTRUCTED AND IN GOOD

REPAIR. HAVE THE CHIMNEY INSPECTED BY THE

FIRE DEPARTMENT OR AN INSPECTOR.

Ensure that a masonry chimney meets the minimum

standards of the National Fire Protection Association

(NFPA) by having it inspected by a professional. Make

sure there are no cracks, loose mortar or other signs of

deterioration and blockage. Have the chimney cleaned

before the furnace is installed and operated. When

connecting the furnace through a combustible wall to

a masonry chimney, special methods are needed as

explained in the “Combustible Wall Chimney Connector

Pass-Throughs” Section.

WARNING:

DO NOT CONNECT THIS FURNACE TO A CHIMNEY

FLUE SERVING ANOTHER APPLIANCE.

COMBUSTIBLE WALL CHIMNEY

CONNECTOR PASSTHROUGHS

METHOD A - 12” (304.8 mm) Clearance to Combustible

Wall Member: Using a minimum thickness 3.5” (89 mm)

brick and a 5/8” (15.9 mm) minimum wall thickness clay

liner, construct a wall pass-through. The clay liner must

conform to ASTM C315 (Standard Specification for

Clay Fire Linings) or its equivalent. Keep a minimum of

12” (304.8 mm) of brick masonry between the clay liner

and wall combustibles. The clay liner shall run from the

brick masonry outer surface to the inner surface of the

chimney flue liner but not past the inner surface. Firmly

grout or cement the clay liner in place to the chimney flue

liner.

METHOD B - 9” (228.6 mm) Clearance to Combustible

Wall Member: Using a 6” (152.4 mm) inside diameter,

listed, factory-built Solid-Pak chimney section with

insulation of 1” (25.4 mm) or more, build a wall pass-

through with a minimum 9” (228.6 mm) air space

between the outer wall of the chimney length and wall

combustibles. Use sheet metal supports fastened

securely to wall surfaces on all sides, to maintain the

9” (228.6 mm) air space. When fastening supports to

chimney length, do not penetrate the chimney liner (the

inside wall of the Solid-Pak chimney). The inner end of

the Solid-Pak chimney section shall be flush with the

inside of the masonry chimney flue, and sealed with a

non-water soluble refractory cement. Use this cement to

also seal to the brick masonry penetration.

© 2023 United States Stove Company

13

METHOD C - 6” (152.4 mm) Clearance to Combustible

Wall Member: Starting with a minimum 24 gage (.024”

[.61 mm]) 6” (152.4 mm) metal chimney connector, and

a minimum 24 gage ventilated wall thimble which has

two air channels of 1” (25.4 mm) each, construct a wall

pass-through. There shall be a minimum 6” (152.4 mm)

separation area containing fiberglass insulation, from the

outer surface of the wall thimble to wall combustibles.

Support the wall thimble, and cover its opening with a

24-gage minimum sheet metal support. Maintain the 6”

(152.4 mm) space. There should also be a support sized

to fit and hold the metal chimney connector. See that

the supports are fastened securely to wall surfaces on

all sides. Make sure fasteners used to secure the metal

chimney connector do not penetrate chimney flue liner.

METHOD D - 2” (50.8 mm) Clearance to Combustible

Wall Member: Start with a solid-pak listed factory

built chimney section at least 12” (304 mm) long, with

insulation of 1” (25.4 mm) or more, and an inside diameter

of 8” (2 inches [51 mm] larger than the 6” [152.4 mm]

chimney connector). Use this as a pass-through for a

minimum 24-gauge single wall steel chimney connector.

Keep solid-pak section concentric with and spaced 1”

(25.4 mm) o the chimney connector by way of sheet

metal support plates at both ends of chimney section.

Cover opening with and support chimney section on both

sides with 24 gage minimum sheet metal supports. See

that the supports are fastened securely to wall surfaces

on all sides. Make sure fasteners used to secure chimney

flue line do not penetrate the inner liner.

NOTES:

• Connectors to a masonry chimney, excepting method

B, shall extend in one continuous section through the

wall pass-through system and the chimney wall, to but

not past the inner flue liner face.

• A chimney connector shall not pass through an attic or

roof space, closet or similar concealed space, or a floor,

or ceiling.

CHIMNEY CONNECTOR

3 screws

Flow

Direction

of Flue

Gases

Install

crimped

end

towards

stove.

Male Part Downwards

1/4” slope per foot

Your chimney connector and chimney must have the

same diameter as the furnace outlet. If this is not the

case, we recommend you contact your dealer in order to

ensure there will be no problem with the draft.

The furnace pipe must be made of aluminized or cold roll

steel with a minimum thickness of 0.021” or 0.53 mm. It

is strictly forbidden to use galvanized steel.

Your connector should be assembled in such a way that

the male section (crimped end) of the pipe faces down.

Attach each of the sections to one another with three

equidistant metal screws. Seal the joints with furnace

cement.

INSTALLATION

14

© 2023 United States Stove Company

INSTALLATION

The pipe must be short and straight. All sections installed

horizontally must slope at least 1/4 inch per foot, with

the upper end of the section toward the chimney. Any

installation with a horizontal run of furnace pipe must

conform to NFPA 211. You may contact NFPA (National

Fire Protection Association) and request the latest

edition of the NFPA Standard 211.

To ensure a good draft, the total length of the furnace

pipe should never exceed 8’ to 10’ (2.4m to 3.04 m).

(Except for cases of vertical installation, cathedral-roof

style where the smoke exhaust system can be much

longer and connected without problem to the chimney at

the ceiling of the room).

There should never be more than two 90 degrees elbows

in the smoke exhaust system.

Installation of a “barometric draft stabilizer” (fireplace

register) on a smoke exhaust system is prohibited.

Do not use with a flue damper. With a controlled

combustion wood furnaces the draft is regulated upon

intake of the combustion air in the furnace and not at the

exhaust.

FACTORY BUILT CHIMNEY

When a metal prefabricated chimney is used, the

manufacturer’s installation instructions must be

followed. You must also purchase (from the same

manufacturer) and install the ceiling support package

or wall pass-through and “T” section package, firestops

(where needed), insulation shield, roof flashing, chimney

cap, etc. Maintain proper clearance to the structure as

recommended by the manufacturer. The chimney must be

the required height above the roof or other obstructions

for safety and proper draft operation.

Listed Cap

Maintain 2”

Clearance

Listed

Chimney

Ceiling

Support

Ceiling

Support

Chimney

Connector

** Refer to Clearance

to Combustibles

Combustible Wall

Floor

Protector

To Stove

Storm Collar

Flashing

Listed

Chimney Attic

Insulation

Sheild

Specified

Clearance

Chimney

Connector

Combustible

Ceiling Joists

To Stove

© 2023 United States Stove Company

15

OPERATION

NEVER OPERATE THIS PRODUCT WHILE UNATTENDED

CAUTIONS: HOUSE FIRE HAZARDS

• DO NOT STORE WOOD ON FLOOR PROTECTOR,

UNDERNEATH STOVEPIPE(S) OR ANYWHERE

WITHIN CLEARANCES TO COMBUSTIBLE

SURFACES SPECIFIED FOR THIS APPLIANCE.

• NEVER OPERATE WITH SECONDARY TUBES,

FIBERBOARD, OR INSULATION REMOVED.

OPERATING SAFETY PRECAUTIONS

• NEVER OVERFIRE THIS APPLIANCE BY

BUILDING EXCESSIVELY HOT FIRES AS A

HOUSE/BUILDING FIRE MAY RESULT. YOU ARE

OVERFIRING THE APPLIANCE IF IT BEGINS TO

GLOW OR TURN RED.

• NEVER BUILD EXCESSIVELY LARGE FIRES IN

THIS TYPE OF APPLIANCE AS DAMAGE TO THE

FIREBOX OR SMOKE LEAKAGE MAY RESULT.

• DO NOT BUILD FIRE TOO CLOSE TO THE GLASS.

• HOT WHILE IN OPERATION. KEEP CHILDREN,

CLOTHING, AND FURNITURE AWAY. CONTACT

MAY CAUSE SKIN BURNS. DO NOT TOUCH THE

APPLIANCE UNTIL IT HAS COOLED.

• PROVIDE ADEQUATE AIR FOR COMBUSTION

TO THE ROOM WHERE THE APPLIANCE IS

INSTALLED.

• INSPECT CHIMNEY LINER EVERY 60 DAYS.

REPLACE LINER IMMEDIATELY IF IT IS RUSTING

OR LEAKING SMOKE INTO THE ROOM.

• ATTEMPTS TO ACHIEVE HEAT OUTPUT

RATES THAT EXCEED FURNACE DESIGN

SPECIFICATIONS CAN RESULT IN PERMANENT

DAMAGE TO THE FURNACE.

WARNING: EXPLOSION HAZARD

• NEVER USE CHEMICALS, GASOLINE, GASOLINE-

TYPE LANTERN FUEL, KEROSENE, CHARCOAL

LIGHTER FLUID, OR SIMILAR FLAMMABLE

LIQUIDS TO START OR “FRESHEN UP” A FIRE IN

THE APPLIANCE.

• KEEP ALL FLAMMABLE LIQUIDS, ESPECIALLY

GASOLINE, OUT OF THE VICINITY OF THE

APPLIANCE - WHETHER IN USE OR IN STORAGE.

Your heating appliance was designed to burn well

seasoned natural wood only; no other materials should

be burned. Any type of well seasoned natural wood

may be used in your stove, but specific varieties have

better energy yields than others. Higher eciencies and

lower emissions generally result when burning air dried

seasoned hardwoods, as compared to softwoods or too

green or freshly cut hardwoods. The following resources

can assist in learning the burn characteristics of various

species of wood:

http://firewoodresource.com/firewood-btu-ratings/; or

https://forestry.usu.edu/forest-products/wood-heating

The operation of this wood furnace in a manner

inconsistent with the owner’s manual will void your

warranty and is also against federal regulations. Waste

and other flammable materials should not be burned in

your stove. DO NOT BURN:

1. Garbage;

2. Lawn clippings or yard waste;

3. Materials containing rubber, including tires;

4. Materials containing plastic;

5. Waste petroleum products, paints or paint thinners,

or asphalt products;

6. Materials containing asbestos;

7. Construction or demolition debris;

8. Railroad ties or pressure-treated wood;

9. Manure or animal remains;

10. Saltwater driftwood or other previously salt water-

saturated materials;

11. Unseasoned wood; or

12. Paper products, cardboard, plywood, or particleboard.

The prohibition against burning these materials does

not prohibit the use of fire starters made from paper,

cardboard, sawdust, wax, and similar substances to

start a fire in an aected wood furnace.

Burning these materials may result in the release of toxic

fumes or render the furnace ineective and cause smoke.

Deadwood lying on the forest floor should be considered

wet and requires full seasoning time. Standing deadwood

can usually be considered to be about 2/3 seasoned.

Smaller pieces of wood will dry faster. All logs exceeding

6” in diameter should be split. The wood should not be

stored directly on the ground. Air should circulate through

the logs. A 24” to 48” air space should be left between

each row of logs, which should be placed in the sunniest

location possible. The upper layer of wood should be

protected from the element but not the sides. A good

indicator of if the wood is ready to burn is to check the

16

© 2023 United States Stove Company

piece ends. If cracks are radiating in all directions from

the center then the wood should be dry enough to burn.

If your wood sizzles in the fire, even though the surface

is dry, it may not be fully cured and should be seasoned

longer. It is EXTREMELY IMPORTANT that you use DRY

WOOD only in your wood stove. The wood should have

dried for 9 to 15 months, such that the humidity content

(in weight) is reduced below 20% of the weight of the log.

It is very important to keep in mind that even if the wood

has been cut for one, two, or even more years, it is not

necessarily dry, if it has been stored in poor conditions.

Under extreme conditions, it may rot instead of drying.

This point cannot be overstressed; the vast majority of

the problems related to the operation of a wood stove is

caused by the fact that the wood used was too damp or

had dried in poor conditions. These problems can be:

• ignition problems

• creosote build-up causing chimney fires

• low energy yield

• blackened windows

• incomplete log combustion

Do not burn manufactured logs made of wax

impregnated sawdust or logs with any chemical

additives.

TESTING YOUR WOOD

• When the furnace is thoroughly warmed, place one

piece of split wood (about five inches in diameter)

parallel to the door on the bed of red embers.

• Adjust all air controls to there maximum settings and

close the door. If ignition of the piece is accomplished

within 90 seconds from the time if was placed in the

furnace, your wood is correctly dried. If ignition takes

longer, your wood is damp.

If your wood hisses and water or vapor escapes at

the ends of the piece, your wood is soaked or freshly

cut (green). Do not use this wood in your stove. Large

amounts of creosote could be deposited in your chimney,

creating potential conditions for a chimney fire.

POWER FAILURE

DO NOT add additional fuel after a power failure, remove

all air filters and reduce combustion air to a minimum.

Observe furnace closely until power is restored.

TAMPER WARNING

This wood furnace has a manufacturer-set minimum low

burn rate that must not be altered. It is against federal

regulations to alter this setting or otherwise operate this

wood furnace in a manner inconsistent with operating

instructions in this manual.

EFFICIENCIES

Eciencies can be based on either the lower heating

value (LHV) or the higher heating value (HHV) of the

fuel. The lower heating value is when water leaves the

combustion process as a vapor, in the case of woodstoves

the moisture in the wood being burned leaves the stove

as a vapor. The higher heating value is when water leaves

the combustion process completely condensed. In the

case of woodstoves this would assume the exhaust gases

are room temperature when leaving the system, and

therefore calculations using this heating value consider

the heat going up the chimney as lost energy. Therefore,

eciency calculated using the lower heating value of

wood will be higher than eciency calculated using the

higher heating value. The best way to achieve optimum

eciencies is to learn the burn characteristic of you

appliance and burn well-seasoned wood. Higher burn

rates are not always the best heating burn rates; after a

good fire is established a lower burn rate may be a better

option for ecient heating. A lower burn rate slows the

flow of usable heat out of the home through the chimney,

and it also consumes less wood.

NOTICE INITIAL BURNS TO CURE PAINT

BECAUSE OF THE HIGH OPERATING TEMPERATURES,

THIS APPLIANCE IS COATED WITH A SPECIAL HIGH

TEMP PAINT WHICH REQUIRES A SERIES OF LOW TO

MEDIUM BURNS TO FULLY CURE FOR DURABILITY

AND A LIFETIME OF SERVICE.

Proper curing of the high-temp paint requires a series of

three initial burns. The appliance should be allowed to

cool o between each burn. The first two burns should

be small fires and low temperatures (250°F) for a

duration of 20 minutes each. The third fire should be at

a temperature of approximately 500°F for 20 minutes.

Provide adequate cross ventilation to clear any smoke or

odor caused by initial firings.

Notice: Use solid wood fuel only! Do not burn garbage,

or flammable fluids. Do not use coal. This appliance

is not designed to accommodate the air flow (draft)

required to properly burn coal or coal products. Do

not elevate the fire using grates or irons. Build the fire

directly on the firebrick.

FUELING INSTRUCTIONS

To ensure this unit produces the optimal minimum

emissions it is critical that only well-seasoned cordwood

is burned. Burning unseasoned wet wood only hurts

OPERATION

© 2023 United States Stove Company

17

your stoves eciency and leads to accelerated

creosote buildup in your chimney. Be considerate of the

environment and only burn dry wood.

CAUTION:

DO NOT LEAVE APPLIANCE UNATTENDED WITH

THE DOOR OPEN.

WARNINGS:

• NEVER OVERFIRE YOUR STOVE. IF ANY PART

OF THE STOVE STARTS TO GLOW RED, OVER

FIRING IS HAPPENING. READJUST THE AIR

INTAKE CONTROL AT A LOWER SETTING.

• THE INSTALLATION OF A LOG CRADLE OR

GRATES IS NOT RECOMMENDED IN YOUR WOOD

STOVE. BUILD FIRE DIRECTLY ON FIREBRICK.

• NEVER PUT WOOD ABOVE THE FIREBRICK

LINING OF THE FIREBOX.

• ATTEMPTS TO ACHIEVE HEAT OUTPUT

RATES THAT EXCEED FURNACE DESIGN

SPECIFICATIONS CAN RESULT IN PERMANENT

DAMAGE TO THE FURNACE.

GENERAL FURNACE OPERATION

Honeywell Limit Control

This device, mounted in the ductwork, just above the air

discharge atop the furnace, works in conjunction with

a wall thermostat, operating the distribution blowers

and the combustion fan on the rear of the furnace. The

factory settings are 100/150/200. The wall thermostat

setting operates the ON time of the combustion fan. If the

temperature is below the setting on the wall thermostat,

the combustion fan will come ON. (Recommended

setting at 5 to 10 degrees higher than other heating

thermostats.) The first two set points on the limit control

operates the distribution blowers. When the furnace

plenum temperature reaches the second set point on the

limit control, the distribution blowers will come on. If the

temperature falls to the first set point, the distribution

blower will shut-o. When the furnace reaches the

third set point on the limit control, the combustion fan

will shut-o. Once the temperature falls below that set

point and the wall thermostat is still calling for heat, the

combustion fan will turn back ON. The 200° is a Factory

Preset Limit for the combustion fan and should never

be changed. Doing so could result in excessive firebox

temperatures and could permanently damage your

firebox.

FURNACE LOADING PROCEDURE

Starting your Furnace

• When lighting the furnace, the wall thermostat should

be set to its MAX setting so that the combustion fan is

ON. Start the fire with approximately 12 lbs. of kindling,

which will be several small strips of wood, 1-1/2 to

2-1/2 inches wide, approximately 12 to 15 inches deep

in the bottom of the firebox. Leave the fuel loading door

slightly open to ensure good ignition of the kindling.

Make sure the combustion fan is ON and its damper is

closed, then pull the knob/loop on the front of the unit

to prop open the barometric dampers.

• Once the kindling is fully ignited, add another 12 to 15

lbs. of kindling, which will be around the same amount

as the initial load.

• Leave the door slightly open for three to five minutes

(3-5 min) to ensure full ignition of the second kindling

load.

• After the second load of kindling is fully ignited, you

can close the door and push the knob/loop on the front

of the unit back in to allow the barometric dampers to

function freely. After 15 minutes, fully open the damper

on the combustion fan.

• Once the kindling burns down to about 8 lbs., which

should be to the point that the kindling will break up

into a full bed of coals, the preload can be added into

the firebox. The preload should consist of around 40

pounds of properly seasoned cord wood, which should

be about 6 to 8 pieces of wood.

• After loading the preload, close the door, and make

certain the combustion fan is ON.

• Allow about one hour (1hr) for the preload to burn down

to around 10-12 lbs. or when all the preload wood will

break up into coals. You should now have a coal bed

that is several inches deep in the bottom of the firebox.

• The purpose of the preload burn is to establish a proper

coal bed prior to inserting the main load of wood. Having

a proper coal bed is the key to a complete ignition of

the main wood load and to maintain the correct firebox

temperatures to get the best emissions and eciency

output of the furnace.

• After you have completed the preload burn, you may

insert your main firewood load.

• The main load should be the same size or amount as

the preload, approximately 40 pounds of cord wood, 6

to 8 pieces.

• Try to keep gaps between the pieces of wood to help

with the ignition and maintain a good fire.

OPERATION

18

© 2023 United States Stove Company

MAIN FIREWOOD LOAD

• Ensure that the combustion fan is ON, and open the

feed door to insert the main firewood load.

• After loading, leave the feed door slightly open for five

minutes (5 min) to ensure proper ignition, then close

the door.

• The damper on the combustion fan should be open.

• Depending on the temperature at which the wall

thermostat is set, this will determine the burn duration

of the main load. A lower setting on the thermostat

should result in a longer burn time as this would allow

the combustion fan to remain OFF for longer periods.

A higher thermostat setting will cycle the combustion

blower ON/OFF more often, resulting in a hotter, but

shorter duration burn time of course. However, colder

outside temperatures and your home’s construction

(insulation) will play a big factor in how well the

thermostat can maintain it’s set temperature.

VISIBLE SMOKE

The amount of visible smoke being produced can be

an eective method of determining how eciently the

combustion process is taking place at the given settings.

Visible smoke consist of unburned fuel and moisture

leaving your stove. Learn to adjust the air settings of your

specific unit to produce the smallest amount of visible

smoke. Wood that has not been seasoned properly and

has a high wood moisture content will produce excess

visible smoke and burn poorly. Use the included moisture

meter to ensure your wood has a 20% or less moisture

content.

AIR TUBES

The air tubes assembled in this unit are designed to

provide an accurate mix of secondary air to ensure the

highest eciency. Any damage or deterioration of these

tubes may reduce the eciency of combustion. The air

tubes are held in position by screws or snap pins. Locate

these to either side of the tube and remove it to allow the

tube to be removed and replaced.

OPERATION

© 2023 United States Stove Company

19

MAINTENANCE

CAUTION:

DO NOT OVERFIRE APPLIANCE. YOU ARE

OVERFIRING IF ANY PART OF THE APPLIANCE

GLOWS RED. CLOSE THE DOOR AND SHUT DAMPER

IMMEDIATELY TO REDUCE THE AIR SUPPLY AND

SLOW DOWN THE FIRE.

CAUTION:

SLOW BURNING FIRES FOR EXTENDED USE OR

BURNING GREEN WOOD MAY CAUSE EXCESSIVE

CREOSOTE BUILD-UP. IGNITION OF CREOSOTE

OR OVERFIRING COULD CAUSE A CHIMNEY

FIRE. CHIMNEY FIRES BURN EXTREMELY HOT

AND MAY IGNITE SURROUNDING COMBUSTIBLE

MATERIALS. IN CASE OF A CHIMNEY FIRE, CALL

THE FIRE DEPARTMENT IMMEDIATELY!

CREOSOTE & SOOT FORMATION & NEED

FOR REMOVAL

When wood is burned slowly, the products of combustion

combine with moisture to form a soot residue which

accumulates on the flue lining. When ignited, this soot

makes an extremely hot fire. The chimney should be

inspected at least twice monthly during the heating

season to determine if a creosote or soot build up

has occurred. If creosote or soot has accumulated, it

should be removed to reduce the risk of a chimney fire.

Chimney fires burn very hot. If the chimney catches fire,

immediately call the fire department, then reduce the fire

by closing the inlet air control. Pour a large quantity of

coarse salt, baking soda or cool ashes on top of the fire in

the firebox.

CREOSOTE ACCUMULATION CAUSES CHIMNEY

FIRES. YOU SHOULD CHECK (OR HAVE CHECKED BY

A QUALIFIED CHIMNEY SWEEP) YOUR CHIMNEY FOR

CREOSOTE DEPOSITS AT LEAST MONTHLY DURING

THE HEATING SEASON. ANY ACCUMULATIONS

SHOULD BE REMOVED. COMPLETE CHIMNEY

INSPECTIONS AND CLEANING SHOULD BE

CONDUCTED ANNUALLY; TYPICALLY, THIS TASK

SHOULD BE PERFORMED PRIOR TO EACH HEATING

SEASON. IF USING AN EXISTING CHIMNEY, IT MUST

BE INSPECTED PRIOR TO THE INSTALLATION OF

YOUR NEW WOOD STOVE.

CAUTION

A CHIMNEY FIRE MAY CAUSE IGNITION OF WALL

STUDS OR RAFTERS WHICH YOU THOUGHT WERE

A SAFE DISTANCE FROM THE CHIMNEY. IF YOU

HAVE A CHIMNEY FIRE, HAVE YOUR CHIMNEY

INSPECTED BY A QUALIFIED PERSON BEFORE

USING AGAIN.

ATTENTION:

THIS FURNACE NEEDS PERIODIC INSPECTION AND

REPAIR FOR PROPER OPERATION. IT IS AGAINST

FEDERAL REGULATIONS TO OPERATE THIS

FURNACE IN A MANNER INCONSISTENT WITH

OPERATING INSTRUCTIONS IN THIS MANUAL.

TO PREVENT CREOSOTE BUILD UP

• Always burn dry wood. This allows clean burns and

higher chimney temperatures, therefore less creosote

deposit.

• Always check for creosote deposit once every two

months and have your chimney cleaned at least once

a year.

• If a chimney or creosote fire occurs, close all dampers

immediately. Wait for the fire to go out and the furnace

to cool, then inspect the chimney for damage. If no

damage results, perform a chimney cleaning to ensure

no more creosote deposits is remaining in the chimney.

CAUTION:

A CHIMNEY FIRE MAY CAUSE IGNITION OF WALL

STUDS OR RAFTERS WHICH WERE ASSUMED TO

BE A SAFE DISTANCE AWAY FROM THE CHIMNEY.

IF A CHIMNEY FIRE OCCURS, HAVE YOUR

CHIMNEY INSPECTED BY A QUALIFIED EXPERT

BEFORE USING AGAIN.

NEVER OPERATE THIS PRODUCT WHILE UNATTENDED

20

© 2023 United States Stove Company

ASH REMOVAL & DISPOSAL

Never let your ashes get any higher than the pilot air hole.

Remove ashes as needed leaving at least 2 inches of ash

in the bottom of the firebox. Ashes should be placed in

a metal container with a tight-fitting lid. The closed

container of ashes should be placed on a noncombustible

floor or on the ground, away from all combustible

materials, pending final disposal. The ashes should be

retained in the closed container until all cinders have

thoroughly cooled.

PILOT AIR

OPENINGS

CAUTIONS:

• ASHES COULD CONTAIN HOT EMBERS EVEN

AFTER TWO DAYS WITHOUT OPERATING THE

STOVE.

• THE ASH PAN CAN BECOME VERY HOT. WEAR

GLOVES TO PREVENT INJURY.

• NEVER BURN THE STOVE WITH THE ASH TRAP

OPEN. THIS WOULD RESULT IN OVER FIRING

THE STOVE. DAMAGE TO THE STOVE AND EVEN

HOUSE FIRE MAY RESULT.

SMOKE & CO MONITORS

Burning wood naturally produces smoke and carbon

monoxide(CO) emissions. CO is a poisonous gas when

exposed to elevated concentrations for extended periods

of time. While the modern combustion systems in

furnaces drastically reduce the amount of CO emitted

out the chimney, exposure to the gases in closed or

confined areas can be dangerous. Make sure you stove

gaskets and chimney joints are in good working order

and sealing properly to ensure unintended exposure. It is

recommended that you use both smoke and CO monitors

in areas having the potential to generate CO.

GASKET CARE

WARNING:

NEVER OPERATE THE STOVE WITHOUT GASKETS

OR WITH BROKEN GASKETS. DAMAGE TO THE

STOVE OR EVEN HOUSE FIRE MAY RESULT.

It is recommended that you change the door gasket

(which makes your furnace door air tight) once a year,

in order to ensure good control over the combustion,

maximum eciency and security. To change the door

gasket, simply remove the damaged one. Carefully clean

the available gasket groove, apply a high temperature

silicone sold for this purpose and install the new gasket.

You may light up your furnace again approximately 24

hours after having completed this operation. This unit’s

feed door uses a 5/8” diameter rope gasket. The door

glass on this unit uses a 1 x 1/8 gasket.

ATTENTION:

THIS WOOD FURNACE NEEDS PERIODIC

INSPECTION AND REPAIR FOR PROPER

OPERATION. IT IS AGAINST FEDERAL

REGULATIONS TO OPERATE THIS WOOD FURNACE

IN A MANNER INCONSISTENT WITH OPERATING

INSTRUCTIONS IN THIS MANUAL.

SERVICE HINTS

Do not expect a furnace to draw. It is the chimney that

creates the draft. Smoke spillage into the house or

excessive build-up of water or creosote in the chimney

are warnings that the chimney is not functioning properly.

Correct the problem before using furnace. Possible

causes are:

1. The connector pipe may be pushed into the chimney

too far, stopping the draft.

2. Do not connect two furnaces or a stove and furnace

into the same chimney flue.

3. The chimney used for a furnace must not be used to

ventilate the cellar or basement. If there is a cleanout

opening at the base of the chimney, it must be closed

tightly.

4. If the chimney is operating too cool, water will

condense in the chimney and run back into the

furnace. Creosote formation will be rapid and may

block the chimney. Operate the furnace at a high

enough fire to keep the chimney warm, preventing

this condensation.

MAINTENANCE

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

United States Stove Company HB1520 Le manuel du propriétaire

- Catégorie

- Poêles

- Taper

- Le manuel du propriétaire

dans d''autres langues

Documents connexes

-

Ashley Hearth Products AF1300E Le manuel du propriétaire

-

Ashley Hearth Products AF1600E Le manuel du propriétaire

-

Ashley AF1500E Le manuel du propriétaire

-

United States Stove VG900 Le manuel du propriétaire

-

Hotblast 1500 Le manuel du propriétaire

Hotblast 1500 Le manuel du propriétaire

-

United States Stove 2016EB Le manuel du propriétaire

-

United States Stove 2469E Le manuel du propriétaire

-

USSC TR001B Le manuel du propriétaire

-

United States Stove B2941E Le manuel du propriétaire