Laguna Tools F3 Fusion Le manuel du propriétaire

- Taper

- Le manuel du propriétaire

OWNERS’S MANUAL

Fusion

3

Table

Saw

36” & 52” Fence

LagunaTools.com

Thank you for investing in a Fusion Saw by Laguna Tools. This table saw is one of a family

of unique machines proudly offered by Laguna Tools. Every Laguna machine is engineered

for years of dependable service. Please feel free to contact Laguna Tools if you have a

question or suggestion. We appreciate working with you and your choice of a Laguna Tools

machine for your shop.

Regards,

Torben Helshoj

President & Founder Laguna Tools

Laguna takes pride in our products and stands behind them with continuing service and support for our customers. Your

Laguna machine was designed to bring a new dimension of productivity to your shop.

Before using your machine for the first time, learn how to use it. This manual covers a step-by-step process of assembly

and machine operation. If you have any questions, this manual will provide answers.

We do our best to thoroughly document every product that we sell for customer reference. Several files are compiled to

cover all components of a machine.

Several machines may be covered by one manual.

Many machines sold by Laguna include components with independent owners’ manuals.

The information contained in this publication was correct at the time of print. In the interest of continuous innovation, we

reserve the right to change specifications, design or included equipment without notice or obligation. No part of this

publication may be reproduced, transmitted, or translated into any language in any form by any means without our written

permission. Errors and omissions may be current.

Laguna Tools, Inc. LAGUNA® and the LAGUNA Logo® are the registered trademarks of Laguna Tools, Inc. All rights

reserved. 04/01/2019

LAGUNA AMERICAN HEADQUARTERS

Texas: 744 Refuge Way Suite 200, Grand Prairie, Texas 75050, U.S.A. Phone: +1-800-332-4094

Huntington Beach: 7291 Heil Ave Huntington Beach, CA 92647, U.S.A. Phone: +1-949-474-1200

South Carolina: 825 Bistline Dr. Ste 101, West Columbia, SC 29172, U.S.A. Phone: +1-800-234-1976

Minnesota: 5250 West 74th St, Edina, MN 55439, U.S.A Phone: +1-949-474-1200

lagunatools.com

supermaxtools.com

lagunacleanair.com

lagunalathe.com

LAGUNA

EUROPE

Walker Rd, Bardon Hill, Coalville LE67 1TU, United Kingdom. Phone: +44-1530-516921

lagunatools.uk

DAKE

CORPORATION

724 Robbins Road, Grand Haven, MI 49417, United States +1-800-937-3253

dakecorp.com

Fusion 3 Table Saw

© 2020 Laguna Tools

Table

of

Contents

Safety

......................................................................................

4

Electrical Saftey .......................................................................

9

Safety (FRENCH) .................................................................. 13

Setup

.................................................................................... 16

Inventory

List

.................................................................. 17

Unboxing

........................................................................ 21

Front

Rail

........................................................................

24

Rear

Rail ......................................................................... 28

Right Extension Table ..................................................... 32

Rear

Extension

Table

...................................................... 34

Front Rail Pt. 2 & Control Switch ......................................

37

Accessory

Installation

.................................................... 41

Maintenance

......................................................................... 49

Troubleshooting

.................................................................... 52

Specifications

....................................................................... 53

Wiring

Diagram

..................................................................... 59

Parts Diagram........................................................................

60

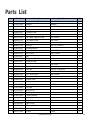

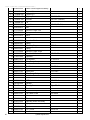

Parts List................................................................................ 65

Warranty

............................................................................... 76

Fusion 3 Table Saw \ Safety \

4

© 2020 Laguna Tools

Safety

Read and understand all warnings and operation instructions before using any tool or equipment. Always follow basic

safety precautions to reduce the risk of personal injury. Improper operation, maintenance or modification of tools or

equipment could result in serious injury and property damage. There are certain applications for which tools and equipment

are designed. This product should NOT be modified and/or used for any application other than for which it was designed.

It is important for you to read and understand this manual. The information it contains relates to protecting your safety and

preventing problems.

Safety Guidelines - Definitions

This manual contains information this is vital to protecting your safety and preventing equipment problems. To help you

recognize this information, we use the symbols below. Please read the manual and pay attention to these sections.

Safety

Call-outs

An imminently hazardous situation which, if not avoided, will result in death or serious injury.

Sometimes displayed as

A potentially hazardous situation which, if not avoided, could result in death or serious injury.

Sometimes displayed as

A potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Sometimes displayed as

A helpful tip from our technical staff. Sometimes displayed as NOTICE!

Safety

Symbols

Disconnect from power before proceeding.

Wear

ear

protection.

Be aware of possible laceration danger.

Wear Eye Protection.

Be aware of possible crushing danger. Wear a full face shield.

Be aware of possible crushing danger. Wear lung protection.

Electrical

Hazard.

..

X

Requires

X

People

Fusion 3 Table Saw \ Safety \

© 2020 Laguna Tools

5

Important

Safety

Instructions

Read and understand all warnings and operating instructions before using this equipment.

Failure to follow all instructions listed below, may result in electric shock, fire, and/or serious personal injury or property

damage.

Woodworking can be dangerous if safe and proper operating procedures are not followed. As with all machinery, there are

certain hazards involved with the operation of the product. Using the machine with respect and caution will considerably

lessen the possibility of personal injury. However, if normal safety precautions are overlooked or ignored, personal injury to

the operator may result. Safety equipment such as guards, push sticks, hold-downs, feather boards, goggles, dust masks

and hearing protection can reduce your potential for injury. But even the best guard won’t make up for poor judgment,

carelessness or inattention. Always use common sense and exercise caution in the workshop. If a procedure feels

dangerous, don’t try it. Figure out an alternative procedure that feels safer. REMEMBER: Your personal safety is your

responsibility.

This machine was designed for certain applications only. We strongly recommend that this machine not be modified

and/or used for any application other than that for which it was designed. If you have any questions relative to a particular

application, do not use the machine until you have first contacted the manufacturer to determine if it can or should be

performed on the product.

If you have any questions relative to its application do not use the product until you have contacted the manufacturer and

we have advised you.

General

Safety

Rules

FAILURE

TO

FOLLOW

THESE

RULES

MAY

RESULT

IN

SERIOUS

PERSONAL

INJURY.

FOR

YOUR

OWN

SAFETY,

READ

AND

UNDERSTAND

THE

INSTRUCTION

MANUAL

BEFORE

OPERATING

THE

MACHINE.

Learn the unit’s application and limitations as well as the specific hazards peculiar to it.

KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use this unit in damp or wet locations or expose it to rain. Keep work

area well-lighted.

KEEP CHILDREN AND VISITORS AWAY. All children and visitors should be kept a safe distance from work area.

DISCONNECT UNIT before servicing.

CHECK DAMAGED PARTS. Before further use of the unit, properly repair or replace any part that is damaged.

CSA

Required

Safety

Information:

Table

Saws

For Your Own Safety Read Instruction Manual before Operating Tablesaw.

a) Never place your hands in the vicinity or in line with the saw blade.

b) "Wear eye protection" or the sign M004 of ISO 7010.

c) Always use a properly functioning saw-blade guard, riving knife and anti-kickback device for every

operation for which it can be used, including all through sawing.

d) Use a push-stick or push-block when required.

e) Do not perform any operation freehand.

f)

Pay particular attention to instructions on reducing risk of kickback.

g) Never reach around or over saw blade.

h)

Turn off tool and wait for saw blade to stop before moving workpiece or changing settings.

i)

Never stand directly in line with the saw blade. Always position your body on the same side of the saw

blade as the fence.

In addition, use hearing protection and wear gloves when handling saw blades.

Fusion 3 Table Saw \ Safety \

6

© 2020 Laguna Tools

Guarding

Related

Warnings

a) Keep guards in place. Guards must be in working order and be properly mounted. A guard that

is loose, damaged, or is not functioning correctly must be repaired or replaced.

b)

Always use saw blade guard, riving knife and anti-kickback device for every through-cutting operation. For through-

cutting operations where the saw blade cuts completely through the thickness of the workpiece, the guard and other

safety devices help reduce the risk of injury.

c) Immediately reattach the guarding system after completing an operation (such as rabbeting, dadoing or resawing cuts)

which requires removal of the guard, riving knife and/or anti-kickback device. The guard, riving knife, and anti-kickback

device help to reduce the risk of injury.

d)

Make sure the saw blade is not contacting the guard, riving knife or the workpiece before the switch is turned on.

Inadvertent contact of these items with the saw blade could cause a hazardous condition.

e)

Adjust the riving knife as described in this instruction manual. Incorrect spacing, positioning and alignment can make

the riving knife ineffective in reducing the likelihood of kickback.

f)

For the riving knife and anti-kickback device to work, they must be engaged in the workpiece. The riving knife and anti-

kickback device are ineffective when cutting workpieces that are too short to be engaged with the riving knife and anti-

kickback device. Under these conditions a kickback cannot be prevented by the riving knife and antikickback device.

g)

Use the appropriate saw blade for the riving knife. For the riving knife to function properly, the saw blade diameter must

match the appropriate riving knife and the body of the saw blade must be thinner than the thickness of the riving knife

and the cutting width of the saw blade must be wider than the thickness of the riving knife.

Cutting

Procedures

Warnings

a) Never place your fingers or hands in the vicinity or in line with the saw blade. A

moment of inattention or a slip could direct your hand towards the saw blade and result in serious personal injury.

b)

Feed the workpiece into the saw blade or cutter only against the direction of rotation. Feeding the workpiece in the same

direction that the saw blade is rotating above the table may result in the workpiece, and your hand, being pulled into the

saw blade.

c) Never use the miter gauge to feed the workpiece when ripping and do not use the rip fence as a length stop when cross

cutting with the miter gauge. Guiding the workpiece with the rip fence and the miter gauge at the same time increases

the likelihood of saw blade binding and kickback.

d) When ripping, always apply the workpiece feeding force between the fence and the saw blade. Use a push stick when

the distance between the fence and the saw blade is less than 150 mm and use a push block when this distance is

less than 50 mm. "Work helping" devices will keep your hand at a safe distance from the saw blade.

e)

Use only the push stick provided by the manufacturer or constructed in accordance with the instructions. This push

stick provides sufficient distance of the hand from the saw blade.

f) Never use a damaged or cut push stick. A damaged push stick may break causing your hand to slip into the saw blade.

g)

Do not perform any operation "freehand". Always use either the rip fence or the miter gauge to position and guide the

workpiece. "Freehand" means using your hands to support or guide the workpiece, in lieu of a rip fence or miter gauge.

Freehand sawing leads to misalignment, binding and kickback.

h) Never reach around or over a rotating saw blade. Reaching for a workpiece may lead to accidental contact with the

moving saw blade.

i)

Provide auxiliary workpiece support to the rear and/or sides of the saw table for long and/or wide workpieces to keep

them level. A long and/or wide workpiece has a tendency to pivot on the table’s edge, causing loss of control, saw blade

binding and kickback.

j)

Feed workpiece at an even pace. Do not bend or twist the workpiece. If jamming occurs, turn the tool off immediately,

unplug the tool then clear the jam. Jamming the saw blade by the workpiece can cause kickback or stall the motor.

Fusion 3 Table Saw \ Safety \

© 2020 Laguna Tools

7

k)

Do not remove pieces of cut-off material while the saw is running. The material may become trapped between the

fence or inside the saw blade guard and the saw blade pulling your fingers into the saw blade. Turn the saw off and wait

until the saw blade stops before removing material.

l)

Use an auxiliary fence in contact with the tabletop when ripping workpieces less than 2 mm thick. A thin workpiece may

wedge under the rip fence and create a kickback.

Kickback Causes and Related Warnings

Statistics show that most common accidents among table saw users can be linked to kickback.

Kickback is a sudden reaction of the workpiece due to a pinched, jammed saw blade or misaligned line of cut in the

workpiece with respect to the saw blade or when a part of the workpiece binds between the saw blade and the rip fence or

other fixed object.

Most frequently during kickback, the workpiece is lifted from the table by the rear portion of the saw blade and is propelled

towards the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or conditions and can be avoided by taking

proper precautions as given below:

a)

Never stand directly in line with the saw blade. Always position your body on the same side of the saw

blade as the fence. Kickback may propel the workpiece at high velocity towards anyone standing in front and in line with

the saw blade.

b)

Never reach over or in back of the saw blade to pull or to support the workpiece. Accidental contact with

the saw blade may occur or kickback may drag your fingers into the saw blade.

c)

Never hold and press the workpiece that is being cut off against the rotating saw blade. Pressing the

workpiece being cut off against the saw blade will create a binding condition and kickback.

d)

Align the fence to be parallel with the saw blade. A misaligned fence will pinch the workpiece against the saw blade and

create kickback.

e) Use a feather-board to guide the workpiece against the table and fence when making non-through cuts such as

rabbeting, dadoing or resawing cuts. A feather-board helps to control the workpiece in the event of a kickback.

f) Use extra caution when making a cut into blind areas of assembled workpieces. The protruding saw blade may cut

objects that can cause kickback.

g) Support large panels to minimize the risk of saw blade pinching and kickback. Large panels tend to sag under their own

weight. Support(s) must be placed under all portions of the panel overhanging the table top.

h)

Use extra caution when cutting a workpiece that is twisted, knotted, warped or does not have a straight edge to guide it

with a miter gauge or along the fence. A warped, knotted, or twisted workpiece is unstable and causes misalignment of

the kerf with the saw blade, binding and kickback.

i) Never cut more than one workpiece, stacked vertically or horizontally. The saw blade could pick up one or more pieces

and cause kickback.

j)

When restarting the saw with the saw blade in the workpiece, center the saw blade in the kerf so that the saw teeth are

not engaged in the material. If the saw blade binds, it may lift up the workpiece and cause kickback when the saw is

restarted.

k) Keep saw blades clean, sharp, and with sufficient set. Never use warped saw blades or saw blades with cracked or

broken teeth. Sharp and properly set saw blades minimize binding, stalling and kickback.

Fusion 3 Table Saw \ Safety \

8

© 2020 Laguna Tools

Table

Saw

Operating

Procedure

Warnings

1.

Turn off the table saw and disconnect the power cord when removing the table insert,

changing the saw blade or making adjustments to the riving knife, anti-kickback device or saw blade guard, and when

the machine is left unattended. Precautionary measures will avoid accidents.

2.

Never leave the table saw running unattended. Turn it off and don’t leave the tool until it comes to a complete stop. An

unattended running saw is an uncontrolled hazard.

3.

Locate the table saw in a well-lit and level area where you can maintain good footing and balance. It should be installed

in an area that provides enough room to easily handle the size of your workpiece. Cramped, dark areas, and uneven,

slippery floors invite accidents.

4.

Frequently clean and remove sawdust from under the saw table and/or the dust collection device. Accumulated

sawdust is combustible and may self-ignite.

5.

The table saw must be secured. A table saw that is not properly secured may move or tip over.

6.

Remove tools, wood scraps, etc. from the table before the table saw is turned on. Distraction or a potential jam can be

dangerous.

7.

Always use saw blades with correct size and shape (diamond versus round) of arbor holes. Saw blades that do not

match the mounting hardware of the saw will run off-center, causing loss of control.

8.

Never use damaged or incorrect saw blade mounting means such as flanges, saw blade washers, bolts or nuts. These

mounting means were specially designed for your saw, for safe operation and optimum performance.

9.

Never stand on the table saw, do not use it as a stepping stool. Serious injury could occur if the tool is tipped or if the

cutting tool is accidentally contacted.

10.

Make sure that the saw blade is installed to rotate in the proper direction. Do not use grinding wheels, wire brushes, or

abrasive wheels on a table saw. Improper saw blade installation or use of accessories not recommended may cause

serious injury.

Fusion 3 Table Saw \ Electrical Safety \

© 2020 Laguna Tools

9

Electrical

Safety

Power

Connections

A separate electrical circuit should be used for your machines. This circuit should not be less than the wiring listed below

and should be protected with an appropriate circuit breaker based on the total running and start-up amperage's (listed

below). If an extension cord is used, use only 3-wire extension cords which have 3-prong grounding type plugs and

matching receptacle which will accept the machine’s plug.

Before connecting the machine to the power source, make sure the switch is in the “OFF”

position.

MTSF3362203-0130-36

VOLTAGE

220V

PHASE

1PH

HERTZ

60Hz

FULL LOAD AMPERAGE

14.8A

Below are RECOMMENDATIONS to be used for this machine based on the above

information. Variables outside of our control are:

Actual voltage supplied to the machine

Electrical code that must be met in your local province.

An

electrician

will

verify

that

all

the

demands

are

met

to

properly

wire

the

machine.

If

you

have

absolutely any doubt when wiring this machine - please consult with a qualified electrician.

PLUG/RECEPTACLE

6-15

WIRING (Gauge)

14 Ga. (minimum)

CIRCUIT BREAKER / (Fuse)

20AMP / (20 AMP Slow Blow)

MTSF3362203-0130-52

VOLTAGE

220V

PHASE

1PH

HERTZ

60Hz

FULL LOAD AMPERAGE

14.8A

Below are RECOMMENDATIONS to be used for this machine based on the above

information. Variables outside of our control are:

Actual voltage supplied to the machine

Electrical code that must be met in your local province.

An

electrician

will

verify

that

all

the

demands

are

met

to

properly

wire

the

machine.

If

you

have

absolutely any doubt when wiring this machine - please consult with a qualified electrician.

PLUG/RECEPTACLE

6-15

WIRING (Gauge)

14 Ga. (minimum)

CIRCUIT BREAKER / (Fuse)

20AMP / (20 AMP Slow Blow)

Fusion 3 Table Saw \ Electrical Safety \

10

© 2020 Laguna Tools

52

If this information is different than what is stated on the Motor Specification Plate - omit this

information. It is possible that the documentation is outdated to a machine change - such as a

different motor.

Always

check

the

motor

plate

prior

to any

wiring.

If

any

doubts, please consult a

certified electrician.

Know when to use a time delay fuse! AKA Slow blow fuse.

Generally, if the motor uses a start capacitor, a time delay fuse is required. This type of fuse

(circuit breaker) will not trip with the initial amperage needed to start the machine, which is typically double that of the

running amperage.

Most woodworking machines use this type of fuse.

Running on Low voltage will damage the machine. Never run the machine in wet or damp

conditions.

For a detailed wiring diagram please see the Wiring Diagram

section at the end of this

manual.

Fusion 3 Table Saw \ Electrical Safety \

© 2020 Laguna Tools

11

Grounding

Methods

This machine must be grounded while in use to protect the operator from electric shock.

In all cases, make certain that the receptacle in question is properly grounded. If you are not

sure, have a qualified electrician check the receptacle.

Grounding Methods Provided by CSA Group. (A) Receptacle with nominal rating less than 150 volts. (B) 150

volt receptacle without grounding pin fitted with adapter.

1.

All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the

risk of electric shock. This machine is equipped with an electric cord having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into a matching outlet that is properly installed and grounded in accordance with

all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock. The conductor with

insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in

doubt as to whether the machine is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding type plugs and matching 3-conductor receptacles that accept

the machine’s plug, as shown in Fig. A. Repair or replace damaged or worn cord immediately.

2.

Grounded, cord-connected machines intended for use on a supply circuit having a nominal rating less than 150 volts:

If the machine is intended for use on a circuit that has an outlet that looks like the one illustrated in Fig. A, the machine will

have a grounding plug that looks like the plug illustrated in Fig. A. A temporary adapter, which looks like the adapter

illustrated in Fig. B, may be used to connect this plug to a matching 2-conductor receptacle as shown in Fig. B if a properly

grounded outlet is not available. The temporary adapter should be used only until a properly grounded outlet can be installed

by a qualified electrician. The green-colored rigid ear, lug, and the like, extending from the adapter is used, it must be held in

a place with a metal screw. NOTE: In Canada, the use of a temporary adapter is not permitted by the Canadian Electric

Code.

Fusion 3 Table Saw \ Electrical Safety \

12

© 2020 Laguna Tools

Extension

Cords

Use proper extension cords. Make sure your extension cord is in good condition and is a 3-wire extension cord

which has a 3-prong grounding type plug and matching receptacle which will accept the machine’s plug. When using an

extension cord, be sure to use one heavy enough to carry the current of the machine. An undersized cord will cause a drop

in line voltage, resulting in loss of power and overheating. Fig. D.1 or D.2, shows the correct gauge to use depending on the

cord length. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

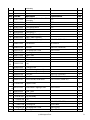

MINIMUM GAUGE EXTENSION CORD 120V

RECOMMENDED

SIZES

FOR

USE

WITH

STATIONARY

ELECTRIC

MACHINES

Ampere

Rating

Volts

Total Length of

Cord in Feet

Gauge of Extension

Cord

0-

6

0-

6

0-

6

0-

6

120

120

120

120

up to 25

25-

50

50-

100

100-

150

18 AWG

16 AWG

16 AWG

14 AWG

6-

10

6-

10

6-

10

6-

10

120

120

120

120

up to 25

25-

50

50-

100

100-

150

18 AWG

16 AWG

14 AWG

12 AWG

10-

12

10-

12

10-

12

10-

12

120

120

120

120

up to 25

25-

50

50-

100

100-

150

16 AWG

16 AWG

14 AWG

12 AWG

12-

16

12-

16

12-

16

120

120

120

up to 25

25-

50

14 AWG

12 AWG

GREATER THAN 50 FEET NOT

RECOMMENDED

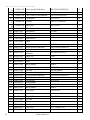

MINIMUM GAUGE EXTENSION CORD 240V

RECOMMENDED

SIZES

FOR

USE

WITH

STATIONARY

ELECTRIC

MACHINES

Ampere

Rating

Volts

Total Length of

Cord in Feet

Gauge of Extension

Cord

0-

6

240

up to 50

18 AWG

0-

6

240

50-

100

16 AWG

0-

6

240

100-

200

16 AWG

0-

6

240

200-

300

14 AWG

6-

10

240

up to 50

18 AWG

6-

10

240

50-

100

16 AWG

6-

10

240

100-

200

14 AWG

6-

10

240

200-

300

12 AWG

10-

12

240

up to 50

16 AWG

10-

12

240

50-

100

16 AWG

10-

12

240

100-

200

14 AWG

10-

12

240

200-

300

12 AWG

12-

16

12-

16

12-

16

240

240

240

up to 50

50-

100

14 AWG

12 AWG

GREATER THAN 100 FEET NOT

RECOMMENDED

Fusion 3 Table Saw \ Safety (FRENCH) \

© 2020 Laguna Tools

13

Safety

(FRENCH)

AVERTISSEMENT!

Pour votre propre sécurité, lisez le manuel d'instructions avant d'utiliser la scie à table.

(a) DANGER - Ne placez jamais vos mains à proximité ou en ligne avec la lame de scie.

(b) AVERTISSEMENT - "Porter une protection oculaire" ou le signe M004 de la norme ISO 7010.

(c) AVERTISSEMENT - Toujours utiliser un protecteur de lame de scie, un couteau diviseur et un dispositif anti-retour pour

chaque opération pour laquelle il peut être utilisé, y compris tout au long du sciage.

(d) AVERTISSEMENT - Utiliser un bâton-poussoir ou un bloc-poussoir au besoin.

(e) AVERTISSEMENT - N'effectuez aucune opération à main levée.

(f) AVERTISSEMENT - Porter une attention particulière aux instructions sur la réduction du risque de rebond. (ou "Savoir

comment réduire les risques de pots-de-vin.")

(g) AVERTISSEMENT - Ne jamais tendre la main autour ou au-dessus de la lame de scie. (ou "Ne jamais tendre la main à

l'arrière ou au-dessus de la lame de scie").

(H) AVERTISSEMENT - Éteindre l'outil et attendre que la lame de scie s'arrête avant de déplacer la pièce ou de changer les

réglages.

(I) AVERTISSEMENT - Ne jamais se tenir directement en ligne avec la lame de scie. Placez toujours votre corps du même

côté de la lame de scie que la clôture.

De plus, utilisez une protection auditive et portez des gants pour manipuler les lames de scie.

Avertissements relatifs à la protection

Laisser les protecteurs en place. Les protecteurs doivent être en état de fonctionnement et montés correctement. Un

protecteur mal fixé, endommagé ou ne fonctionnant pas correctement doit être réparé ou remplacé.

Toujours utiliser un protecteur de lames, un couteau diviseur et un appareil antirecul pour toute opération de coupe

traversante. Pour les opérations de coupe traversante où la lame traverse complètement l'épaisseur de la pièce, le

protecteur et les autres appareils de sécurité contribuent à limiter le risque de blessure.

Fixer de nouveau immédiatement le protecteur après l'exécution d'une opération (telle que le refeuillement, l'engravure ou la

refente) qui nécessite l'enlèvement du protecteur, du couteau diviseur et/ou de l'appareil anti-recul. Le protecteur, le

couteau diviseur et l'appareil anti-recul contribuent à limiter le risque de blessure.

Veiller à ce que la lame n'entre pas en contact avec le protecteur, le couteau diviseur ou la pièce avant le déclenchement du

commutateur. Un contact involontaire de ces éléments avec la lame pourrait entraîner un fonctionnement dangereux.

Ajuster le couteau diviseur comme décrit dans la notice d'utilisation. Un espacement, un positionnement et un alignement

incorrects peuvent empêcher le couteau diviseur de limiter le risque de recul.

Pour que le couteau diviseur et l'appareil anti-recul fonctionnent, ils doivent être engagés dans la pièce. Le couteau diviseur

et l'appareil anti-recul sont inefficaces lorsque l'on coupe des pièces trop courtes pour que le couteau diviseur et l'appareil

antirecul puissent s'y engager. Dans ces conditions, le couteau diviseur et l'appareil anti-recul ne peuvent pas empêcher un

recul de se produire.

Utiliser la lame appropriée au couteau diviseur. Pour que le couteau diviseur fonctionne correctement, le diamètre de la

lame doit correspondre au couteau diviseur approprié, l'épaisseur de la lame de scie doit être plus mince que celle du

couteau diviseur et la largeur de coupe de la lame de scie doit être supérieure à l'épaisseur du couteau diviseur.

Avertissements relatifs aux modes opératoires de coupe

DANGER: Ne jamais mettre les doigts ou les mains à proximité ou dans l'alignement de la lame. Votre main pourrait glisser

ou se diriger vers la lame dans un moment d'inattention et entraîner une blessure grave.

Avancer la pièce en direction de la lame ou du couteau uniquement dans le sens inverse de rotation. L'avance de la pièce

dans le même sens que le sens de rotation de la lame au-dessus de la table peut entraîner la pièce et la main dans la lame.

Ne jamais utiliser le guide inclinable pour avancer la pièce lors d'un sciage en long et ne pas utiliser le guide longitudinal

comme butée longitudinale lors d'un sciage en travers à l'aide du guide inclinable. Le guidage de la pièce en utilisant en

même temps le guide longitudinal et le guide inclinable augmente le risque de blocage de la lame et de recul.

Fusion 3 Table Saw \ Safety (FRENCH) \

14

© 2020 Laguna Tools

Lors d'un sciage en long, toujours appliquer la force d'alimentation de la pièce entre le guide et la lame. Utiliser un poussoir

lorsque la distance entre le guide et la lame est inférieure à 150 mm et utiliser un bloc-poussoir lorsque cette distance est

inférieure à 50 mm. Des appareils d'aide à l'utilisation maintiendront la main à une distance sans risque de la lame.

Utiliser seulement le poussoir fourni par le fabricant ou construit conformément aux instructions. Ce poussoir permet de

garder une distance suffisante entre la main et la lame.

Ne jamais utiliser un poussoir endommagé ou coupé. Un poussoir endommagé peut faire glisser votre main dans la lame.

Ne jamais effectuer une opération "à main levée". Toujours utiliser le guide longitudinal ou le guide inclinable pour

positionner et guider la pièce. “A main levée" signifie utiliser ses mains pour soutenir ou guider la pièce, au lieu d'un guide

longitudinal ou inclinable. Une coupe à main levée entraîne un mauvais alignement, un blocage et un recul.

Ne jamais tendre le bras autour ou au-dessus de la lame rotative. Le fait d'étendre le bras pour atteindre une pièce peut

entraîner un contact accidentel avec la lame rotative.

Prévoir un support supplémentaire de la pièce à l'arrière et/ou sur les côtés de la scie circulaire pour des pièces longues

et/ou larges afin de les maintenir à plat. Une pièce longue et/ou large a tendance à pivoter sur le bord de la table, entraînant

une perte de contrôle, un blocage de la lame et un recul.

Avancer la pièce à un rythme régulier. Ne pas plier ou tordre la pièce. En cas de coincement de la lame, arrêter l'outil

immédiatement, le débrancher et décoincer la lame. Un coincement de la lame par la pièce peut provoquer un recul ou faire

caler le moteur.

Ne pas enlever des morceaux de matériau coupé lors du fonctionnement de la lame. Le matériau peut être emprisonné

entre le guide ou à l'intérieur du protecteur de lame et la lame, entraînant vos doigts dans la lame. Stopper le

fonctionnement de la scie et attendre l'arrêt de la scie avant de retirer le matériau.

Utiliser un guide auxiliaire en contact avec le plateau de la table lors d'un sciage en long de pièces d'épaisseur inférieure à 2

mm. Une pièce mince peut se coincer sous le guide longitudinal et provoquer un recul.

Causes de recul et avertissements associés

Le recul est une réaction soudaine de la pièce due à une lame pincée, bloquée ou une ligne de coupe mal alignée dans la

pièce par rapport à la position de la lame ou lorsqu'une partie de la pièce se bloque entre la lame et le guide longitudinal ou

un autre objet fixe.

Le plus souvent lors d'un recul, la pièce est soulevée de la table par la partie arrière de la lame et est projetée en direction de

l'opérateur.

Le recul résulte d'une mauvaise utilisation de la scie et/ou de modes opératoires ou de conditions de fonctionnement

incorrects et peut être évité en prenant les précautions nécessaires telles qu'indiquées ci-dessous.

Ne jamais se tenir dans l'alignement direct de la lame. Toujours se tenir du même côté de la lame que le guide. Un recul

peut propulser la pièce à une vitesse rapide vers quiconque se trouvant devant et dans l'alignement de la lame.

Ne jamais tendre le bras au-dessus ou à l'arrière de la lame pour retirer ou soutenir la pièce. Un contact accidentel avec la

lame peut se produire ou un recul peut entraîner vos doigts dans la lame.

Ne jamais maintenir et presser la pièce contre la lame rotative. Presser la pièce contre la lame rotative provoquera un

blocage de la lame et un recul.

Aligner le guide parallèlement à la lame. Un mauvais alignement du guide entraînera un pincement de la pièce contre la

lame et un recul.

Utiliser un peigne anti-recul pour guider la pièce contre la table et le guide lors des coupes non traversantes tels que le

refeuillement, l'engravure ou la refente. Un peigne anti-recul aide à contrôler la pièce en cas de recul.

User de précautions supplémentaires lors d'une coupe dans des zones non visibles de pièces assemblées. La partie de

lame qui dépasse peut couper des objets qui peuvent provoquer un recul.

Soutenir les grands panneaux pour limiter le risque d'un blocage de la lame et d'un recul. Les grands panneaux ont tendance

à s'affaisser sous leur propre poids. Un (des) support(s) doi(ven)t être placé(s) sous toutes les portions du panneau par-

dessus la table.

User de précautions supplémentaires lors de la coupe d'une pièce torsadée, gauchie ou comportant des noeuds, qui n'a pas

un bord droit pour le guider à l'aide d'un guide inclinable ou le long du guide. Une pièce torsadée, gauchie ou comportant des

noeuds est instable et provoquer un mauvais alignement du trait de scie avec la lame, un blocage de la lame et un recul.

Fusion 3 Table Saw \ Safety (FRENCH) \

© 2020 Laguna Tools

15

Ne jamais couper plusieurs pièces empilées verticalement ou horizontalement. La lame pourrait attraper plusieurs pièces et

provoquer un recul.

Lors d'un redémarrage d'une scie avec une lame de scie dans la pièce, centrer la lame dans le trait de scie de sorte que les

dents ne pénètrent pas dans le matériau. Si la lame se bloque, elle peut soulever la pièce et provoquer un recul lors du

redémarrage de la scie.

Maintenir les lames propres, bien aiguisées et avec un écart latéral suffisant. Ne jamais utiliser des lames gauchies ou des

lames dont les dents sont fissurées ou cassées. Des lames bien aiguisées et ayant un bon écart latéral limitent le risque

de blocage, de calage et de recul.

Avertissements relatifs au mode opératoire de fonctionnement de la scie circulaire à table

Arrêter le fonctionnement de la scie circulaire et débrancher le cordon d'alimentation lors de l'enlèvement de la plaque

amovible, du remplacement de la lame de scie ou des réglages du couteau diviseur, de l'appareil anti-recul ou du protecteur

de lame, et lorsque la machine est laissée sans surveillance. Ces mesures de précaution éviteront les accidents.

Ne jamais laisser la scie circulaire à table fonctionner sans surveillance. Arrêter le fonctionnement et ne pas quitter l'outil

tant qu'il n'a pas cessé de fonctionner. Une scie fonctionnant sans surveillance est un danger incontrôlé.

Placer la scie circulaire à table dans un endroit bien éclairé et sur une surface plane où elle peut être maintenue bien en

appui et en équilibre. Il convient de l'installer dans un endroit qui prévoit une place suffisante pour pouvoir manipuler

facilement la pièce quelle que soit sa taille. Des endroits exigus, sombres et des sols inégaux et glissants sont

susceptibles de provoquer des accidents.

Nettoyer fréquemment et enlever la sciure accumulée sous la scie circulaire à table et/ou sous l'appareil de dépoussiérage.

La sciure accumulée est combustible et peut s'enflammer.

La scie circulaire à table doit être immobilisée. Une scie circulaire à table mal immobilisée peut bouger ou basculer.

Enlever les outils, copeaux de bois, etc. de la table avant de faire fonctionner la scie. Un moment d'inattention ou un

coincement éventuel peut être dangereux.

Toujours utiliser des lames de scie de dimensions et de forme appropriées des alésages centraux (lame de scie au

diamant contre lame de scie ronde). Des lames qui ne sont pas conformes aux matériels de montage de la scie seront

excentrées, provoquant une perte de contrôle.

Ne jamais utiliser des appareils de montage, tels que des flasques, des rondelles de lame, des boulons ou écrous,

endommagés ou inadaptés. Ces appareils de montage ont été spécialement conçus pour être utilisés avec votre scie, à

des fins de fonctionnement sûr et de performance optimale.

Ne jamais se tenir sur la scie circulaire à table, ne pas l'utiliser comme tabouret. Des blessures sérieuses peuvent survenir

si l'outil bascule ou en cas de contact accidentel avec l'outil de coupe.

Veiller à ce que la scie circulaire à table soit installée de façon à tourner dans la bonne direction. Ne pas utiliser des

meules, des brosses métalliques ou des disques abrasifs sur une scie circulaire à table. Une installation incorrecte de la

lame ou l'utilisation d'accessoires non recommandés peut entraîner de graves blessures.

Fusion 3 Table Saw \ Setup \

16

© 2020 Laguna Tools

17

24

28

9

Setup

Expand any section above to view help sections created. If you are reading this manual or viewing an electronic PDF

version, You may want to check out our interactive manual available here:

https://lagunatools.com/classic/tablesaws/f3/manual

All videos and sections will be current on this website.

Setup Overview (MUST READ)

When setting up your Fusion F3 Table saw, please take a moment to read this overview prior to starting.

1.

Carefully un-box the saw.

2.

Gather all loose parts and organize them first. Keep all hardware close to the installation location and be sure not to mix

the hardware up after removing it from the packaging. A detailed Inventory list

section has be made to aid

organization and simplify set up.

3.

Level the saw to the ground first. If you begin to the level the saw to a non level ground, everything will be off. Start from

the ground up. The saw can easily be leveled to the floor with the integrated foot pads on the right side of the base.

4.

After leveling the base to the foundation, begin to follow the Front Rail

Section.

5.

After the Front Rail is attached, follow the Rear Rail

Section.

6.

After both rails are installed begin to install the Right Extension Table 32 , and then the Rear Extension Table 34 . Be sure

to level all the rails and tables to the cabinet (which is level to the floor).

7.

Once all the tables and rails are installed, finish setup by installing the Front Rail and the Control Switch 37 .

8.

Now that the Setup is complete, all that is left is to plug it in.

Fusion table saws all have magnetic

switches, but make certain the blade is tight and nothing is in the way of the blade prior to turning on the machine.

Be sure wiring is correct according to local electric code. All needed electrical information can be found in

the Electrical Safety

Section.

After Setup, there may be a few adjustment to be made. All of these adjustments are done prior to shipping the saw, but if

one is found to need adjustment please follow the adjustment guides.

Fusion 3 Table Saw \ Setup \ Inventory List

© 2020 Laguna Tools

17

Inventory

List

Your F3 Fusion table saw will likely be delivered by a third-party delivery service. Before unpacking your new machine, first

inspect the packaging, the invoice, and the shipping documents supplied by the driver. When unpacking your table saw,

separate all enclosed items from the packing materials and inspect them for damages. Ensure that there is no visible

damage to either the packaging or the machine BEFORE the driver leaves. Save all packaging materials until you are

satisfied with the machine and/or have resolved any issues concerning any missing or damaged items.

NOTICE! All shipping damage must be noted upon delivery and signed by the owner and the delivery driver. If you find any

damaged items in your package, you must contact Laguna Tools to file a complaint. In order to return damaged goods

under the limited warranty to Laguna Tools, Inc., you MUST have the original packaging. All claims of loss or damaged

goods must be reported to Laguna Tools within 24 HOURS of delivery. Please contact the Laguna Tools, Inc. Customer

Service Department to make claims for any damaged items/parts.

Loose Parts Inventory

The following depicts items shipped with your machine. Before assembling your saw, ensure that you have received all

parts shown below. Machine parts should arrive sealed in plastic bags. Remove parts from plastic bags before laying them

out to inventory them.

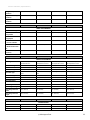

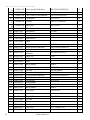

REF

Description

Q

PACKAGING

F3

Table

1

Wooden Crate

Right Extension Table

1

Boxed Individually

Right Extension Legs

2

Boxed with Outboard Table

Rear

Extension

Table

1

Boxed Individually

Rear Extension Table Legs

2

Each

leg

Boxed

individually

Miter Gauge

1

Boxed Individually

Dust Collection Hose

1

Plastic Wrapped Individually

Blade

Guard Assembly

1

Boxed Individually

Fence

Assembly

1

Boxed Individually

Fence Lock Knob

1

Boxed w/ Fence Assembly

Push Stick

1

Boxed w/ Fence Assembly

Fusion 3 Table Saw \ Setup \ Inventory List

18

© 2020 Laguna Tools

REF

Description

Q

PACKAGING

Left Side Front Rail

1

Boxed w/ Fence Assembly

Front Rail Assembly

1

Boxed Individually

Rear Rail Assembly

1

Boxed with Steel Rail

Control

Switch

1

Attached to table

Dust Collector Hose

1

Boxed Individually

Hardware

Inventory

Listed below are all the hardware required for assembly of the Fusion F3 table saws. The hardware below has been

included in the Fusion F3’s packaging. As you inventory the other parts shipped with your machine, be sure to inventory and

familiarize yourself with the hardware listed below.

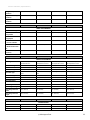

Ref.

Description

Q

Installation

A

Counter-Sunk Alan Head

Screws (25mm)

use with hex nuts(F), flat

washers(H)

7

Front Rail Assembly, F3 Table

Also used to fasten Right

Extension Table

B

Socket head Button Screw w/

Lock Washer (28mm)

use with hex nuts(F), flat

washers(H)

4

Rear Rail Assembly, F3 Table

Dust collector hose support,

F3 Table

C

Hex Cap Screw w/ Flat Washer

(longer)

5

Rear Extension Table, F3 Table

Control Switch, Left Front Rail

D

Socket Head Cap Screw (no

washer) (28mm)

use with use with hex nuts(F),

lock washers (E)

5

Rear Rail

Assembly,

F3 Table

E

Hex Cap Bolt (30mm)

use with hex nuts(F), lock

washers (E)

2

Left Side Front Rail Assembly,

F3 Table

F

Hex Nuts (13mm)

20

Multiple

G

Flat Washers (8mm)

17

Multiple

Fusion 3 Table Saw \ Setup \ Inventory List

© 2020 Laguna Tools

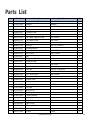

19

Ref.

Description

Q

Installation

H

Lock Washers (8mm)

8

Multiple

I

Hex Cap Bolt (51mm)

use with Nylon Lock Nuts(H)

4

Rear Extension Table Legs,

Rear Extension table

J

Nylon Lock Nuts (16mm)

4

Rear Extension Table Legs,

Rear Extension table

K

Rubber

Feet

2

F3 Table (Bottom)

L

Hex Cap Screw w/ Flat Washer

(shorter)

9

Front Body to Front Rail (left &

right side)

Fusion 3 Table Saw \ Setup \ Inventory List

20

© 2020 Laguna Tools

Accessory Hardware & Tools

NOTICE! The hardware and tools listed below come individually wrapped in plastic bags.

General Tools: dual-sided wrench and Allen

wrenches.

Band clamp with hex bolt, flat washer, and hex nut.

Fence hooks and hex bolts with flat washers.

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

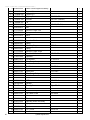

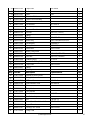

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

Laguna Tools F3 Fusion Le manuel du propriétaire

- Taper

- Le manuel du propriétaire

dans d''autres langues

Documents connexes

Autres documents

-

Delta 36-5000T2 Le manuel du propriétaire

-

Delta 36-725 Le manuel du propriétaire

-

Delta 36-5000 Le manuel du propriétaire

-

Delta 36-5000T2 Manuel utilisateur

-

Delta 36-6013 Le manuel du propriétaire

-

Delta 36-6023 Manuel utilisateur

-

Delta 36-L552D Manuel utilisateur

-

Delta 36-L500 Manuel utilisateur

-

Delta 36-6023 Le manuel du propriétaire

-

Delta S36-300T2 Le manuel du propriétaire