Hayward RC9740WCCUB Le manuel du propriétaire

- Catégorie

- Accessoires de piscine hors terre

- Taper

- Le manuel du propriétaire

SharkVAC XL™ / e.VAC PRO™

by

Owner’s Manual

SharkVAC XL™ / e.VAC PRO™

par

Manuel du propriétaire

SharkVAC XL™ / e.VAC PRO™

de

Manual del propietario

ISRC9740XLN Rev C

2

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

SharkVAC XL™ / e.VAC PRO™

by

Owner’s Manual

IMPORTANT SAFETY INSTRUCTIONS

Basic safety precautions should always be followed, including the following: Failure to follow

instructions can cause severe injury and/or death.

This is the safety-alert symbol. When you see this symbol on your equipment or in this manual, look

for one of the following signal words and be alert to the potential for personal injury.

WARNING warns about hazards that could cause serious personal injury, death or major property

damage and if ignored presents a potential hazard.

CAUTION warns about hazards that will or can cause minor or moderate personal injury and/or

property damage and if ignored presents a potential hazard. It can also make consumers aware of

actions that are unpredictable and unsafe.

The NOTICE label indicates special instructions that are important but not related to hazards.

Hayward Pool Products

620 Division Street, Elizabeth, NJ 07207

Phone: (908) 351.5400

www.hayward.com

Contents

Warnings ........................... 3

Information ........................ 5

Operating Instructions ........... 7

Maintenance ....................... 11

Troubleshooting ................... 17

Warranty Registration .............. 22

3

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

WARNING – Read and follow all instructions in this owner’s manual and on the equipment. Failure to follow

instructions can cause severe injury and/or death.

WARNING – Suction Entrapment Hazard.

Suction in suction outlets and/or suction outlet covers which are, damaged, broken, cracked, missing, or unsecured can

cause severe injury and/or death due to the following entrapment hazards:

Hair Entrapment- Hair can become entangled in suction outlet cover.

Limb Entrapment- A limb inserted into an opening of a suction outlet sump or suction outlet cover that is damaged,

broken, cracked, missing, or not securely attached can result in a mechanical bind or swelling of the limb.

Body Suction Entrapment- A negative pressure applied to a large portion of the body or limbs can result in an entrapment.

Evisceration/ Disembowelment - A negative pressure applied directly to the intestines through an unprotected suction

outlet sump or suction outlet cover which is, damaged, broken, cracked, missing, or unsecured can result in evisceration/

disembowelment.

Mechanical Entrapment- There is potential for jewelry, swimsuit, hair decorations, finger, toe or knuckle to be caught in

an opening of a suction outlet cover resulting in mechanical entrapment.

WARNING – To Reduce the risk of Entrapment Hazards:

o When outlets are small enough to be blocked by a person, a minimum of two functioning suction outlets per

pump must be installed. Suction outlets in the same plane (i.e. floor or wall), must be installed a minimum of

three feet (3’) [1 meter] apart, as measured from near point to near point.

o Dual suction fittings shall be placed in such locations and distances to avoid “dual blockage” by a user.

o Dual suction fittings shall not be located on seating areas or on the backrest for such seating areas.

o The maximum system flow rate shall not exceed the flow rating of as listed on Table 1.

o Never use Pool or Spa if any suction outlet component is damaged, broken, cracked, missing, or not securely attached.

o Replace damaged, broken, cracked, missing, or not securely attached suction outlet components immediately.

o In addition two or more suction outlets per pump installed in accordance with latest ASME, APSP Standards and

CPSC guidelines, follow all National, State, and Local codes applicable.

o Installation of a vacuum release or vent system, which relieves entrapping suction, is recommended.

WARNING – Failure to remove pressure test plugs and/or plugs used in winterization of the pool/spa from the

suction outlets can result in an increase potential for suction entrapment as described above.

WARNING – Failure to keep suction outlet components clear of debris, such as leaves, dirt, hair, paper and

other material can result in an increase potential for suction entrapment as described above.

WARNING – Suction outlet components have a finite life, the cover/grate should be inspected frequently and

replaced at least every ten years or if found to be damaged, broken, cracked, missing, or not securely attached.

CAUTION – Components such as the filtration system, pumps and heater must be positioned so as to prevent

their being used as means of access to the pool by young children.

WARNING – Never operate or test the circulation system at more than 50 PSI.

WARNING – Never change the filter control valve position while the pump is running.

WARNING – To reduce risk of injury, do not permit children to use or climb on this product. Closely supervise

children at all times. Components such as the filtration system, pumps, and heaters must be positioned to prevent children

from using them as a means of access to the pool.

WARNING – Hazardous Pressure. Pool and spa water circulation systems operate under hazardous pressure during start

up, normal operation, and after pump shut off. Stand clear of circulation system equipment during pump start up. Failure to follow

safety and operation instructions could result in violent separation of the pump housing and cover, and/or filter housing and clamp

due to pressure in the system, which could cause property damage, severe personal injury, or death. Before servicing pool and spa

water circulation system, all system and pump controls must be in off position and filter manual air relief valve must be in open

position. Before starting system pump, all system valves must be set in a position to allow system water to return back to the pool.

Do not change filter control valve position while system pump is running. Before starting system pump, fully open filter manual air

relief valve. Do not close filter manual air relief valve until a steady stream of water (not air or air and water) is discharged.

WARNING – Separation Hazard. Failure to follow safety and operation instructions could result in violent

separation of pump and/or filter components. Strainer cover must be properly secured to pump housing with strainer cover

lock ring. Before servicing pool and spa circulation system, filters manual air relief valve must be in open position. Do not

operate pool and spa circulation system if a system component is not assembled properly, damaged, or missing. Do not

operate pool and spa circulation system unless filter manual air relief valve body is in locked position in filter upper body.

4

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

WARNING – Risk of Electric Shock. All electrical wiring MUST be in conformance with applicable local codes, regulations,

and the National Electric Code (NEC). Hazardous voltage can shock, burn, and cause death or serious property damage. To reduce

the risk of electric shock, do NOT use an extension cord to connect unit to electric supply. Provide a properly located electrical

receptacle. Before working on any electrical equipment, turn off power supply to the equipment.

WARNING – To reduce the risk of electric shock replace damaged wiring immediately. Locate conduit to prevent

abuse from lawn mowers, hedge trimmers and other equipment.

WARNING – Electrical ground all electrical equipment before connecting to electrical power supply. Failure to

ground all electrical equipment can cause serious or fatal electrical shock hazard.

WARNING – Do NOT ground to a gas supply line.

WARNING – To avoid dangerous or fatal electrical shock, turn OFF power to all electrical equipment before

working on electrical connections.

WARNING – Failure to bond all electrical equipment to pool structure will increase risk for electrocution and could result in

injury or death. To reduce the risk of electric shock, see installation instructions and consult a professional electrician on how to

bond all electrical equipment. Also, contact a licensed electrician for information on local electrical codes for bonding requirements.

Notes to electrician: Use a solid copper conductor, size 8 or larger. Run a continuous wire from external bonding lug to

reinforcing rod or mesh. Connect a No. 8 AWG (8.4 mm2) [No. 6 AWG (13.3 mm2) for Canada] solid copper bonding wire to

the pressure wire connector provided on the electrical equipment and to all metal parts of swimming pool, spa, or hot tub,

and metal piping (except gas piping), and conduit within 5 ft. (1.5 m) of inside walls of swimming pool, spa, or hot tub.

IMPORTANT - Reference NEC codes for all wiring standards including, but not limited to, grounding, bonding and other

general wiring procedures.

WARNING – Risk of Electric Shock. Connect only to a branch circuit protected by a ground-fault circuit-interrupter

(GFCI). Contact a qualified electrician if you cannot verify that the circuit is protected by a GFCI.

WARNING – Risk of Electric Shock. The electrical equipment must be connected only to a supply circuit that is

protected by a ground-fault circuit-interrupter (GFCI). Such a GFCI should be provided by the installer and should be tested on

a routine basis. To test the GFCI, push the test button. The GFCI should interrupt power. Push reset button. Power should be

restored. If the GFCI fails to operate in this manner, the GFCI is defective. If the GFCI interrupts power to the electrical

equipment without the test button being pushed, a ground current is flowing, indicating the possibility of an electrical shock.

Do not use this electrical equipment. Disconnect the electrical equipment and have the problem corrected by a qualified

service representative before using.

CAUTION – This pump is intended for use with permanently-installed pools and may be used with hot tubs and spas

if so marked. Do not use with storable pools. A permanently-installed pool is constructed in or on the ground or in a

building such that it cannot be readily disassembled for storage. A storable pool is constructed so that it is capable of being

readily disassembled for storage and reassembled to its original integrity.

SAVE THESE INSTRUCTIONS

Hayward® Pool Products Limited Warranty

To original purchasers of this equipment, Hayward Pool Products, Inc. warrants its cleaners to be free from defects in materials and workmanship

for a period of TWO (2) years from the date of purchase, when used in single family residential applications.

The limited warranty excludes damage from freezing, negligence, improper installation, improper use or care or any Acts of God. Parts that fail

or become defective during the warranty period shall be repaired or replaced, at our option, within 90 days of the receipt of defective product,

barring unforeseen delays, without charge.

Proof of purchase is required for warranty service. In the event proof of purchase is not available, the manufacturing date of the product will be

the sole determination of the purchase date.

To obtain warranty service, please contact the place of purchase or the nearest Hayward Authorized Service Center. For assistance on your

nearest Hayward Authorized Service Center please visit us at www.hayward.com.

Hayward shall not be responsible for cartage, removal, repair or installation labor or any other such costs incurred in obtaining warranty replacements or repair.

The Hayward Pool products warranty does not apply to components manufactured by others. For such products, the warranty established by the

respective manufacturer will apply.

The express limited warranty above constitutes the entire warranty of Hayward Pool Products with respect to its’ pool products and is in lieu of

all other warranties expressed or implied, including warranties of merchantability or fitness for a particular purpose. In no event shall Hayward

Pool products be responsible for any consequential, special or incidental damages of any nature.

Some states do not allow a limitation on how long an implied warranty lasts, or the exclusion of incidental or consequential damages, so the above

limitation may not apply to you. This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state.

Hayward Pool Products

620 Division Street

*Supersedes all previous publications. Elizabeth, NJ 07207

5

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

CONSUMER INFORMATION AND SAFETY

DANGER

Risk of electrical shock or electrocution

The electrical supply to this product must be installed in accordance with all applicable

local codes and ordinances. Improper installation will create an electrical hazard which

could result in death or serious injury to pool users or others due to electrical shock, and

may also cause damage to property.

WARNING

Do not play with cleaner or cable or apply to body. Can trap or tear hair or body parts.

Cable can trip or entangle swimmers, which could result in drowning.

CAUTION

Before installing the cleaner, understand cleaner coverage. The cleaner was not designed

to automatically clean steps or to work under a solar cover. It was also not designed to do

initial cleanup for a new pool installation.

OPERATING THE CLEANER

WARNING

A Ground Fault Current Interrupter (GFCI –USA) must be installed to protect your

electrical outlet and to prevent any possible electric shock. Failure to do so could create

an electrical hazard which could result in death or serious injury to pool users or others

due to electrical shock and may also cause damage to property.

CAUTION

DO NOT switch the pool cleaner to “ON” if it is not immersed in the water. Operating the

cleaner out of the water may cause severe damage and will result in loss of warranty.

Always remember to turn off the power supply “OFF” and unplug it from the power

outlet before removing the cleaner from the pool.

WARNING

It is mandatory to allow a safety distance between the power supply and the pool as

required by the current installation standard (11.5 feet minimum or 3.5 meters).

6

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Dear Hayward Robotic Cleaner Owner:

Thank you for choosing Hayward. In order to achieve optimal performance, please read and follow

these steps:

1. Cleaner filter cartridges should be thoroughly cleaned after each use or as often as needed to ensure

cleaner's optimal performance. (see the Maintenance section for filter cleaning instructions)

2. Before using your cleaner and especially when opening the pool for the first time remove larger

items such as toys, large leaves, or other debris from the pool that may diminish the cleaner's

performance. Clean filter frequently when pool is excessively dirty.

3. For the first use, run cleaner for the full cycle (3 hours) to ensure a clean pool and give you a full

understanding of the cleaner's capabilities.

4. Cleaner may periodically go to the wall but not necessarily climb to the vertical position. This is a

normal part of the programmed cycle.

5. Cleaner may stop in the middle of the pool and reverse during cleaning cycle. This is a normal part of

the programmed cycle.

6. DO NOT start cleaner out of the water. Power button should only be switched to "ON" position when

unit is fully submerged. The unit will automatically shut off, but it is best to put power switch in

"OFF" position when unit completes cleaning.

7. Only plug into a GFCI (Ground Fault Circuit Interrupter) protected 110-120 volt AC outlet.

8. Place the cleaner power supply so that it is at a minimum distance of 11.5 feet (3.5 meters) from the

pool edge. The length of the standard cleaner cable is 60 feet (18.29 meters).

9. Depending on the size and shape of your pool the entire length of the floating cable may not be

necessary. The floating cable should reach from the cleaner power supply to the furthest point in the

pool, plus the depth at the deep end of the pool. To reduce cable tangling any excess cable should

be coiled and placed next to the power supply.

WARNING - READ THESE IMPORTANT

OPERATING TIPS BEFORE USING YOUR UNIT!

7

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

GENERAL OPERATING INSTRUCTIONS

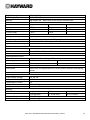

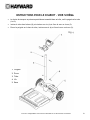

Take a moment to get familiar with the cleaner using the figure 3. Throughout this manual reference to this

figure is made when referring to different components of the cleaner.

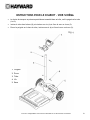

Remove the cleaner by placing the carton down and

removing it from the box as shown. On models which

include a caddy cart the cleaner and the Power Supply

are pre-mounted to the cart.

See the figure 4 for Caddy Cart.

1. Select the nearest GFCI (Ground Fault Circuit Interrupter) protected 110-120 volt AC outlet.

2. Place the cleaner power supply so that it is at a minimum distance of 11.5 feet (3.5 meters) from the

pool edge. The length of the standard cleaner cable is 60 feet (18.29 meters).

3. Stretch out the floating cable along the pool deck to remove any twisting the cord has from storage

and measure out the approximate amount of cleaner cord needed for pool coverage.

4. Connect the floating cable to the power supply. Use only the original Power Supply manufactured by

Hayward.

4. Place the cleaner in the pool. It will slowly sink to the bottom of the pool as the air inside is released.

5. Connect the power supply to the protected outlet and switch it on. The cleaner will perform a self-

diagnostics routine before starting the cleaning cycle for several minutes.

Notice: To reduce risk of injury and prevent damage to the cleaner the start up sequence the

cleaner has been equipped with an out of water sensor. Should the cleaner sense that it is not in

the water it will power itself down. To reset the cycle switch off the power supply for 10 seconds

and restart.

6. The cleaner will automatically shut off after 3 hours for a full cleaning cycle. If your pool is cleaned in

less time than 3 hours, you may shut the cleaner off manually by switching the power supply to the off

position. Should a second cleaning cycle be required, switch OFF the power supply for 10 seconds and

restart.

7. After the pool has been cleaned, switch OFF the power supply before removing the cleaner from the pool.

8

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

8. Remove the cleaner from the water at the shallow end of the pool by gently pulling the cable until

the cleaner reaches the surface. Then lift it out of the water using the handle, NOT the cable.

9. If the supply cord is damaged it must be replaced by the manufacturer, service agent, or similarly

qualified persons in order to avoid a hazard.

10. All electrical connections must be done by a qualified electrician according to local electrical

standard (see p16).

Operating the cleaner using an aftermarket timer

If you are using an aftermarket timer to turn your cleaner on please follow these instructions:

1. Plug the aftermarket timer into the nearest GFCI (Ground Fault Circuit Interrupter) protected 110-

120 volt AC outlet and then plug the power supply into the timer.

2. The cleaner operates on a 3 hour cycle so set the timer duration for 3 hours or more. If you set the

timer duration for less than 3 hours the cleaner will only operate for the period of time you set. If

you set the timer duration for longer than 3 hours the cleaner will stop automatically at the end of

its 3 hour cycle. Should a second cleaning cycle be required, switch OFF the power supply for 10

seconds and restart.

CAUTION: When removing cleaner from the pool do NOT reel it around your arm. The cleaner is heavy

and may cause someone to lose their balance and fall into the pool. To avoid falling into the pool, gently

reel the cable in hand-over-hand from the shallow end of the pool.

DO NOT ENTER THE SWIMMING POOL WHEN THE CLEANER IS OPERATING.

Optimum operating water temperature range for the cleaner is 50ºF - 100ºF (10ºC - 35ºC).

Remove the cleaner from the pool, empty the filter bucket and clean filters after each use. Keeping the

cleaner permanently in the pool may result in additional service requirements. (see maintenance section for

cleaning instructions)

Store the cleaner in a shaded area.

9

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

1. Power Supply

2. On/Off Switch

3. Floating Cable

4. Handle

5. Filter Cartridge

6. Filter Bucket

7. Filter Door

8. Dome Assembly

9. Side Panel

10. Wheel

11. Float Assembly

12. Sealed Motor Unit

13. Wheel Brush and Tube

14. Drive Track

10

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

CADDY CART INSTRUCTIONS - SEE DIAGRAM

Caddy Cart will come partially assembled in the carton less the handle & tube. (1 & 3)

Insert the tube into base (5) & insert the screw (4) securing it with the nut (2)

Insert the handle into the top of the tube & insert the screw (4) securing it with the nut (2)

11

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

MAINTENANCE

Clean the filter cartridge after each use:

1. Open the cleaner by pressing the lid button and lifting up the dome cover.

2. Remove the easy access filter bucket assembly by lifting it up out of the cleaner with both hands

from each side.

3. Flip the bucket assembly over to remove the debris and then rinse with a garden hose to remove

small particles.

4. Filter cartridges do not need to be removed to clean.

Fig. 6

12

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

5. Remove the filter cartridges:

a. Unsnap and lift up both filter door latches.

b. Pull out the filter cartridges. Using a garden hose with a spray nozzle, wash the filter

elements to remove debris. Hold the filter elements as shown to allow the debris to fall out.

Filter cleaning solution can be used to remove excessive dirt and/or sand. The cleaner your

filter is the more effective the cleaning will be.

Fig. 7

c. Wash the entire filter bucket assembly. (Previously shown).

d. Place the filter cartridges back into the filter bucket assembly with the center frame

reinforcements facing inward.

Fig. 8

e. Snap the filter door latches into place.

13

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

6. Return the filter bucket assembly into the cleaner using the diagram shown to determine the front

and back.

7. Close the dome and press the lid button to snap dome into place.

Periodic Cleaning of Moving Parts

WARNING: Disconnect the power supply from electrical outlet before cleaning moving parts.

Inspect the venturi to ensure that no debris or hair has clogged the impeller.

The impeller can be cleaned by spraying it with a garden hose.

Spray water using a garden hose around the float box assembly to remove any sand or debris to

ensure free movement when changing float position.

Remove any debris that has accumulated between the tracks and wheels.

Storage

When unit is out of the water, store the cleaner in a dry, shady location at temperatures between

40F - 115F (4°C-46°C).

Cable Care

With continued use, the cable may become coiled (like a telephone cord). To correct this, stretching the

cord out in the sun should remove any cord twists.

IMPORTANT: The cable should be checked periodically for any external damage.

14

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

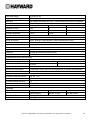

Back side wall

climbing

Float Position

WALL CLIMBING FEATURE

SharkVac-XL is equipped with patent pending “movable flotation technology”. Each float position (I,

II, and III) will provide different wall climbing action.

Float position “I” is the default position locating the float in the middle of the cleaner and will

provide the best cleaning behavior for most swimming pools.

Float position “II” will provide an additional angle in the movement where the cleaner will travel

along the water line or pool wall faster and benefit cleaning coverage.

Float position “III” will provides a reduced angle in the movement where the cleaner will spend more

time scrubbing the pool wall along the water line. This float position will aid the wall climbing

feature in pools with slick surfaces such as tile and fiberglass.

Method of selection: Position may be set while the cover is closed using the slide handle, or while

the cover is opened by moving the float box to the preferred location.

15

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

OUT OF WATER SENSOR

To better protect the cleaner from damage, it will sense when being asked to turn on when not safely in

water, or leaves the water during operation.

Out of water at start up

Out of water at start up means that the cleaner has been powered on, either by the user connecting the

power supply to the protected outlet and switching it on or by being connected to a timer that switches on

the power supply, before the cleaner has been placed in the water. If the cleaner senses that it is not in the

water the unit will power itself down. To reset the cycle, switch off the power supply for 10 seconds and

restart.

Out of water during operation

Out of water during operation refers to the cleaner leaving or being removed from the water while in

normal operation cycle. If the cleaner senses that it is no longer in the water, the unit will attempt to

re-enter the water by reversing its current direction. If the cleaner is not submerged within ninety (90)

seconds of leaving the water the unit will power itself down. To reset the cycle, switch off the power supply

for 10 seconds and restart.

16

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

IMPORTANT TIPS

Do not drop or throw the cleaner into pool. Place cleaner away from the pool wall but do not throw

the cleaner in the pool.

Cleaning the filter cartridges after every use maximizes the unit's performance.

Replace worn brushes and foam rollers.

To avoid clogging the cleaner's filter elements, be sure all chemical powders are fully dissolved

before operating the cleaner.

In a pool with high calcium content, more frequent cleaning of the filter cartridges is recommended.

Save the original carton for extended storage or shipping requirements should your cleaner require

dealer service.

The sealed Motor Unit and the Power Supply contain no user-serviceable parts. Opening them will

automatically VOID your warranty.

Remove items such as thermometer, toys and the like from the pool before operating the unit. Such

items can jam the cleaner and cause damage to the unit and/or your pool.

The filter bucket is designed to be cleaned with the filters installed for normal clean up. For deep

cleaning, the user can remove each filter cartridge and clean separately.

During the normal operating cycle of the cleaner, the handle side of the unit will rise from the pool

bottom to allow the unit to clear obstacles, such as elevated main drains and stair steps.

For cleaners used in areas that have a lot of sand the cleaner may need to be rinsed with water at all

flapper (filter bucket's flapper is at intake port) areas, and may need rinsing at the dome push button

to allow free operation.

17

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

TROUBLESHOOTING

If the cleaner fails to pick up fine or heavy debris:

It may be clogged. Clean the filter. A filter cleaning solution can be used to remove excessive

dirt and/or sand.

If the cleaner starts working momentarily but then stops working:

Impeller may be clogged or jammed with debris, check and clean if necessary following the

instructions in the maintenance section.

Brush roller or drive tracks may be stuck, check for debris and clean if necessary.

Cleaner performs by both timing and a pool wall detection sensor, whichever comes first.

There are 3 intake ports located at bottom of filter bucket and near the brush roller, check for

debris and clean if necessary.

Cleaner may get stuck if a high main drain is installed in the pool. Cleaner may remain lodged on the

drain for a short period of time, but will eventually free it's self by virtue of the cleaner's embedded

program.

Cleaner performance: Confusion may exist over the perception of how the cleaner operates at

different times during each cycle. It is important to judge the performance of the cleaner by

observing improved pool cleanliness after the cleaner has run a complete cleaning cycle.

If a cleaner has poor coverage of the pool in one cycle or only covers a small area, check the filter

and clean if necessary and make sure the unit is not getting caught on drains, in-floor cleaning heads

or toys. The user may try starting the cleaner in different locations to find the optimum cleaning

location.

If debris falls from cleaner while removing from pool, it may be caused by filter overload, increase

frequency of filter cleaning. Assure that there is no large debris blocking any of the three intakes.

Large debris must be removed from the pool before using machine. If drain flaps are out of place or

stuck by sand or leaves in the open position, the flaps can be snapped back into place, after cleaning

the area.

If the flotation cord gets twisted which can be caused by the cleaner getting stuck on large objects

such as rocks, toys or main drains, it can be straightened by laying the flotation cord at full length (if

possible) in the sun; heat from the sun will help reduce the twisting.

If a high level of debris is visible through the dome windows, remove cleaner quickly from the water

to reduce the chance of the debris escaping the filter bucket and reentering the pool.

If you observe the cleaner spending more than the preferred amount of time on the walls/tile line,

return the float position to position I (center/default position).

18

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

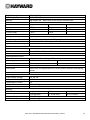

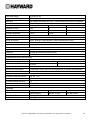

Weight (w/o cable)

23 lb (10.45 Kg)

Cable Length, Type

60 ft (18.29 m)

Materials

High Impact ABS - Metal Parts of Non-Ferrous Stainless Steel

Motor Unit

Pump

Drive

PCB

Speed (rpm)

2700

55

-

Voltage

24 VDC

22 VDC

5 VDC

Current (amp)

2.62 A

0.63 A

-

Waterproof Sealing

Triple Redundant Radial Shaft Seals & O-ring

Motor Housing

Sealed, Watertight, High Impact Polypropylene

Overload Protection

Electronic Overload Monitoring with auto-shutoff

Filter

Type

Removable, Re-Usable, Pleated Element Cartridge

Media

Pleated Cellulose/Polyester Blend

Cleaning Routine Control

Type

Adaptive Seek Control Logic (ASCL®) Microprocessor

Cleaning Cycle

Full Cycle

3 hours

Drive System

Direct Drive w/Polyurethane Drive Track & Acetal/Stainless Steel Bearing

System

Power Supply

Input Primary Voltage

110-120 VAC

Output Secondary Voltage

24 VDC

Rated Output Current

4 A

Weight

8.3 lbs (3.8 Kg)

Shipping

Carton Dimensions (mm)

Length

Width

Height

24 in (620 mm)

17 in (440 mm)

30 in (752 mm)

Shipping Weight with Caddy

49 lb (22.3 Kg)

without Caddy

43 lb (19.5 Kg)

19

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

IMPORTANT SAFETY INSTRUCTIONS

This robotic swimming pool cleaner has been manufactured with the highest degree of care and concern for

safety. We suggest the following safety precautions become part of your pool safety regulations:

SAVE THESE INSTRUCTIONS

1. ALWAYS PUT THE MACHINE INTO THE WATER BEFORE connecting it to the GFCI protected electrical

outlet.

2. IT IS IMPORTANT FOR SWIMMERS’ SAFETY TO REMOVE THE UNIT IMMEDIATELY FOLLOWING USE. THIS

CAN ALSO IMPROVE THE OPERATING LIFE OF YOUR CLEANER.

3. BE CERTAIN THE machine IS ONLY PLUGGED into a grounded electrical outlet equipped with an

approved and properly operating ground fault circuit interrupter (GFCI).

4. DO NOT HANDLE MACHINE WHILE IT IS PLUGGED INTO THE ELECTRICAL OUTLET.

5. DO NOT USE AN EXTENSION CORD. THIS COULD CREATE A SAFETY HAZARD AND/OR DAMAGE YOUR

CLEANER.

6. ALWAYS STAY OUT OF THE POOL WHILE CLEANER IS IN OPERATION.

7. NEVER ALLOW PLUG TO ENTER THE POOL.

8. DO NOT OPERATE THE MACHINE OUT OF WATER. THIS WILL DAMAGE THE MOTOR SEAL AND VOID THE

WARRANTY.

9. DO NOT DRAG THE MACHINE OUT OF THE POOL AGAINST THE SIDE WALL. THIS COULD DAMAGE UNIT

AND/OR YOUR POOL WALL.

10. DO NOT BURY CORD. DO NOT OPERATE CLEANER WITH DAMAGED CORD. REPLACE DAMAGED

CORDS IMMEDIATELY.

WARNING - TO REDUCE THE RISK OF INJURY; DO NOT PERMIT CHILDREN TO USE THIS

PRODUCT UNLESS THEY ARE CLOSELY SUPERVISED AT ALL TIMES.

11. If the supply cord is damaged it must be replaced by the manufacturer, service agent, or

similarly qualified persons in order to avoid a hazard.

While the cleaner has been made to operate as safely as possible, we suggest you exercise

reasonable care in the handling of the vacuum and inspect the electrical cord frequently for damage

or wear, as with any other electrical appliance. After use, remove the unit and rinse with fresh

water and remove any twists that may be present in the cord.

20

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

HAYWARD® LIMITED WARRANTY

All HAYWARD products are covered for manufacturing defects or material defects for a warranty period of 2

years as of date of purchases. Any warranty claim should be accompanied by evidence of purchase,

indicating date of purchase. We would therefore advise you to keep your invoice.

The HAYWARD warranty is limited to repair or replacement, as chosen by HAYWARD, of the faulty products,

provided that they have been subjected to normal use, in compliance with the guidelines given in their user

guides, provided that the products have not been altered in any way, and provided that they have been used

exclusively with HAYWARD parts and components. The warranty does not cover damage due to frost and to

chemicals. Any other costs (transport, labor, etc.) are excluded from the warranty.

HAYWARD may not be held liable for any direct or indirect damage resulting from incorrect installation,

incorrect connection, or incorrect operation of a product.

In order to claim on a warranty and in order to request repair or replacement of an article, please ask your dealer.

No equipment returned to our factory will be accepted without our prior written approval.

Wearing parts are not covered by the warranty.

EXCEPTIONS AND EXCLUSIONS FROM WARRANTY

The cleaner must be used with electrical requirements as indicated on the Power Supply. Otherwise

damage, defects, malfunctions or other failures of the cleaner arising from use on electrical supply not as

indicated are excepted and excluded from this warranty.

Defects, malfunctions, failure or damage of the cleaner caused by improper, unreasonable, or negligent use

or abuse by the consumer, are excluded from this warranty.

If any repair is made on your cleaner by anyone other than authorized personnel (designated to perform

such work) without first having obtained factory instructions, HAYWARD, at its sole option, may determine

that this warranty will not apply and that reimbursement for such repair will not be made because of failure

to comply with such factory specified instructions.

Filter cartridges are not covered by this warranty and will be replaced only with your prior approval of the

charges.

ELECTRIC STANDARD/COUNTRY

F

NF EN C 15-100

GB

BS7671:1992

D

DIN VDE 0100-702

EW

EVHS-HD 384-7-702

A

ÖVE 8001-4-702

H

MSZ 2364-702:1994 / MSZ 10-533 1/1990

E

UNE 20460-7-702 1993, REBT ITC-BT-31 2002

M

MSA HD 384-7-702.S2

IRL

Wiring Rules + IS HD 384-7-702

PL

PN-IEC 60364-7-702:1999

I

CEI 64-8/7

CZ

CSN 33 2000 7-702

LUX

384-7.702 S2

SK

STN 33 2000-7-702

NL

NEN 1010-7-702

SLO

SIST HD 384-7-702.S2

P

RSIUEE

TR

TS IEC 60364-7-702

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

Hayward RC9740WCCUB Le manuel du propriétaire

- Catégorie

- Accessoires de piscine hors terre

- Taper

- Le manuel du propriétaire

dans d''autres langues

- English: Hayward RC9740WCCUB Owner's manual