Unitronics IO-PT400 I-O Expansion Modules Mode d'emploi

- Taper

- Mode d'emploi

Unitronics

1

IO-PT400, IO-PT4K User Guide

I/O Expansion Modules 4 RTD Inputs

IO-PT400 and IO-PT4K are I/O Expansion

Modules that can be used in conjunction with

specific Unitronics OPLC controllers.

This module is offered in two models.

Each module offers 4 RTD inputs for

temperature measurement:

1 4

2

3

5

Part No.

RTD Type

I/O-PT400

PT100, NI100, NI1201

I/O-PT4K

PT1000, NI1000

The interface between the module and the

OPLC is provided by an adapter.

The module may either be snap-mounted on

a DIN rail, or screw-mounted onto a

mounting plate.

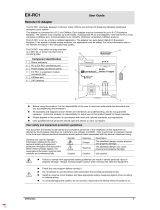

Component identification*

1

Module-to-module connector

2

Status indicators

3

Input connection points, CH2 & CH3

4

Module-to-module connector port

5

Input connection points, CH0 & CH1

*Note that the model shown represents all models.

◼ Before using this product, it is the responsibility of the user to read and understand this document and

any accompanying documentation.

◼ All examples and diagrams shown herein are intended to aid understanding, and do not guarantee

operation. Unitronics accepts no responsibility for actual use of this product based on these examples.

◼ Please dispose of this product in accordance with local and national standards and regulations.

◼ Only qualified service personnel should open this device or carry out repairs.

User safety and equipment protection guidelines

This document is intended to aid trained and competent personnel in the installation of this equipment as

defined by the European directives for machinery, low voltage, and EMC. Only a technician or engineer trained

in the local and national electrical standards should perform tasks associated with the device’s electrical wiring.

Symbols are used to highlight

information relating to the user’s

personal safety and equipment

protection throughout this document.

When these symbols appear, the

associated information must be read

carefully and understood fully.

Symbol

Meaning

Description

Danger

The identified danger causes physical

and property damage.

Warning

The identified danger can cause

physical and property damage.

Caution

Caution

Use caution.

◼ Failure to comply with appropriate safety guidelines can result in severe personal injury or

property damage. Always exercise proper caution when working with electrical equipment.

1

Note that the temperature range for NI120 is not standard: -50° to 172°C (-58° to 341°F).

UG_IO-PT400-4K I/O Expansion Modules

2

Unitronics

◼ Check the user program before running it.

◼ Do not attempt to use this device with parameters that exceed permissible levels.

◼ Install an external circuit breaker and take appropriate safety measures against short-circuiting

in external wiring.

◼ To avoid damaging the system, do not connect / disconnect the device when the power is on.

Environmental Considerations

◼ Do not install in areas with: excessive or conductive dust, corrosive or flammable gas,

moisture or rain, excessive heat, regular impact shocks or excessive vibration.

◼ Leave a minimum of 10mm space for ventilation between the top and bottom edges of the

device and the enclosure walls.

◼ Do not place in water or let water leak onto the unit.

◼ Do not allow debris to fall inside the unit during installation.

Mounting the Module

DIN-rail mounting

Snap the device onto the DIN rail as shown below; the module will be squarely situated on the DIN rail.

60mm

(2.362")

3.5mm

(0.137")

14mm

(0.55")

80mm

(3.15")

93mm

(3.66")

44.5mm

(1.75")

UG_IO-PT400-4K I/O Expansion Modules

Unitronics

3

Screw-Mounting

The figure below is not drawn to scale. It may be used as a guide for screw-mounting the module.

Mounting screw type: either M3 or NC6-32.

4mm

5.8mm

(0.228")

85mm

(3.346")

80mm

(3.15")

68.4mm

(2.693")

93mm

(3.66")

4mm (x2)

(0.16")

(0.16")

UG_IO-PT400-4K I/O Expansion Modules

4

Unitronics

Connecting Expansion Modules

An adapter provides the interface between the OPLC and an expansion module. To connect the I/O module to

the adapter or to another module:

1. Push the module-to-module connector into the port located on the right side of the device.

Note that there is a protective cap provided with the adapter. This cap covers the port of the final

I/O module in the system.

◼ To avoid damaging the system, do not connect or disconnect the device when the

power is on.

1 2

Component identification

1

Module-to-module

connector

2

Protective cap

Wiring

◼ Do not touch live wires.

◼ Unused pins should not be connected. Ignoring this directive may damage the device.

◼ Double-check all wiring before turning on the power supply.

Wiring Procedures

Use crimp terminals for wiring; use 26-14 AWG wire (0.13 mm 2–3.31 mm2) for all wiring purposes.

1. Strip the wire to a length of 7±0.5mm (0.250–0.300 inches).

2. Unscrew the terminal to its widest position before inserting a wire.

3. Insert the wire completely into the terminal to ensure that a proper connection can be made.

4. Tighten enough to keep the wire from pulling free.

◼ To avoid damaging the wire, do not exceed a maximum torque of 0.5 N·m (5 kgf·cm).

◼ Do not use tin, solder, or any other substance on stripped wire that might cause the wire strand to break.

◼ Install at maximum distance from high-voltage cables and power equipment.

UG_IO-PT400-4K I/O Expansion Modules

Unitronics

5

I/O Wiring—General

◼ Input or output cables should not be run through the same multi-core cable or share the same wire.

◼ Allow for voltage drop and noise interference with input lines used over an extended distance. Use wire

that is properly sized for the load.

Analog Inputs

◼ Shields should be connected at the signal source.

PT1000/NI1000*

2 wire connection

4 wire connection

RTD

RTD

3 wire connection

RTD

* RTD input types PT1000/NI1000 support a two-wire connection, because the high resistance (1000 ohm)

of the sensor element compensates for voltage drop.

IO-PT400, IO-PT4K Technical Specifications

Max. current consumption

35mA maximum from the adapter’s 5VDC

UG_IO-PT400-4K I/O Expansion Modules

6

Unitronics

Typical power consumption

0.09W @ 5VDC

Status indicator

(RUN)

Green LED:

—Lit when a communication link is established between module and OPLC.

—Blinks when the communication link fails.

Analog Inputs

Number of inputs

4

Model number

I/O-PT400

I/O-PT4K

RTD type

PT100, NI100, NI120

PT1000, NI1000

Temperature coefficient

PT: 385/392, NI100: 618, NI120: 672

PT: 385/392, NI: 618

See Note 1

Temperature unit

°C and °F

Temperature range

PT100/1000

-50° to 460°C (-58° to 860°F)

NI100/1000

-50° to 232°C (-58° to 449°F)

NI120

-50° to 172°C (-58° to 341°F)

Isolation

None

Resolution

12-bit (4096 units)

Measurement resolution

±0.1°C (0.1°F). See Note 2.

Conversion method

Successive approximation

Conversion time

40msec

Input impedance

10MΩ minimum

Auxiliary current

PT100/NI100/NI120

1.9mA

PT1000/NI1000

0.19mA

Linearity error

I/O-PT400

I/O-PT4K

±0.3°C (0.6°F) (±0.05%)

±0.4°C (0.8°F) (±0.06%)

Temperature accuracy

±0.4°C (0.8°F)

Status indicators

(OUT OF RANGE)

Red LEDs—Lit when the corresponding input measures an analog value

(temperature) outside of the permissible range. See Note 3.

Connection options

2, 3 or 4 wires

Environmental

IP20 / NEMA1

Operating temperature

0 to 50C (32 to 122° F)

Storage temperature

-20 to 60C (-4 to 140° F)

Relative Humidity (RH)

10% to 95% (non-condensing)

Dimensions (WxHxD)

80 x 93 x 60mm (3.15 x 3.66 x 2.362”)

Weight

140.3g (4.94oz.)

Mounting

Either onto a 35mm DIN-rail or screw-mounted.

UG_IO-PT400-4K I/O Expansion Modules

Unitronics

7

Notes:

1. Alpha () type is selected in software. The PT default setting is 385.

2. The input analog value represents the temperature value as follows:

Analog value-262 Actual measured temperature: 26.2C

3. The temperature values can also indicate certain faults as shown in the following table.

Value

Possible Cause

-10000 (-1000°)

◼ Input temperature is out of the permissible range

(under -50°C)

◼ -I signal is not connected

◼ Sensor is short-circuited

10000 (1000°)

◼ Input temperature is out of the permissible range

(PT: over 460°C) (NI: over 232° C) (NI120: over 172C)

◼ Sensor is not connected to input

◼ +I or +V signals are not connected

◼ -I and –V signals are not connected

Addressing I/Os on Expansion Modules

Inputs and outputs located on I/O expansion modules that are connected to an OPLC are assigned

addresses that comprise a letter and a number. The letter indicates whether the I/O is an input (I) or an

output (O). The number indicates the I/O’s location in the system. This number relates to both the position

of the expansion module in the system, and to the position of the I/O on that module.

Expansion modules are numbered from 0-72 as shown in the figure below.

0 1 2 3 4 5 6 7 Expansion module

identification number

Adapter

The formula below is used to assign addresses for I/O modules used in conjunction with the OPLC.

X is the number representing a specific module’s location (0-7). Y is the number of the input or output on that

specific module (0-15).

The number that represents the I/O’s location is equal to:

32 + x • 16 + y

Examples

◼ Input #3, located on expansion module #2 in the system, will be addressed as I 67,

67 = 32 + 2 • 16 + 3

◼ Output #4, located on expansion module #3 in the system, will be addressed as O 84,

84 = 32 + 3 • 16 + 4.

UG_IO-PT400-4K I/O Expansion Modules

8

Unitronics

UL Compliance

The products listed above may be used with compatible Unitronics PLCs.

Detailed Installation Guides containing the I/O wiring diagrams for these models, technical specifications, and

additional documentation are located in the Technical Library in the Unitronics website:

https://unitronicsplc.com/support-technical-library/

The following section is relevant to Unitronics’ products that are listed with the UL.

The following models: IO-AI4-AO2, IO-AO6X, IO-ATC8, IO-DI16, IO-DI16-L, IO-DI8-RO4,

IO-DI8-RO4-L, IO-DI8-TO8, IO-DI8-TO8-L, IO-RO16, IO-RO16-L, IO-RO8, IO-RO8L, IO-TO16,

EX-A2X are UL listed for Hazardous Locations.

The following models: EX-D16A3-RO8, EX-D16A3-RO8L, EX-D16A3-TO16, EX-D16A3-TO16L,

IO-AI1X-AO3X, IO-AI4-AO2, IO-AI4-AO2-B, IO-AI8, IO-AI8Y, IO-AO6X, IO-ATC8, IO-D16A3-RO16,

IO-D16A3-RO16L, IO-D16A3-TO16, IO-D16A3-TO16L, IO-DI16, IO-DI16-L, IO-DI8-RO4,

IO-DI8-RO4-L, IO-DI8-RO8, IO-DI8-RO8-L, IO-DI8-TO8, IO-DI8-TO8-L, IO-DI8ACH, IO-LC1, IO-LC3,

IO-PT4, IO-PT400, IO-PT4K, IO-RO16, IO-RO16-L, IO-RO8, IO-RO8L, IO-TO16, EX-A2X, EX-RC1 are

UL listed for Ordinary Location.

UL Ratings, Programmable Controllers for Use in Hazardous Locations,

Class I, Division 2, Groups A, B, C and D

These Release Notes relate to all Unitronics products that bear the UL symbols used to mark products that

have been approved for use in hazardous locations, Class I, Division 2, Groups A, B, C and D.

Caution

◼This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D, or Non-hazardous

locations only.

◼ Input and output wiring must be in accordance with Class I, Division 2 wiring methods and in

accordance with the authority having jurisdiction.

◼ WARNING—Explosion Hazard—substitution of components may impair suitability for Class I,

Division 2.

◼ WARNING – EXPLOSION HAZARD – Do not connect or disconnect equipment unless power has

been switched off or the area is known to be non-hazardous.

◼ WARNING – Exposure to some chemicals may degrade the sealing properties of material used in

Relays.

◼ This equipment must be installed using wiring methods as required for Class I, Division 2 as per

the NEC and/or CEC.

Relay Output Resistance Ratings

The products listed below contain relay outputs:

Input/Output expansion modules, Models: IO-DI8-RO4, IO-DI8-RO4-L, IO-RO8, IO-RO8L

◼ When these specific products are used in hazardous locations, they are rated at 3A res, when these specific

products are used in non-hazardous environmental conditions, they are rated at 5A res, as given in the

product’s specifications.

Certification UL des automates programmables, pour une utilisation en environnement à

risques, Class I, Division 2, Groups A, B, C et D.

Cette note fait référence à tous les produits Unitronics portant le symbole UL - produits qui ont été certifiés

pour une utilisation dans des endroits dangereux, Classe I, Division 2, Groupes A, B, C et D.

UG_IO-PT400-4K I/O Expansion Modules

Unitronics

9

Attention

◼ Cet équipement est adapté pour une utilisation en Classe I, Division 2, Groupes A, B, C et

D, ou dans Non-dangereux endroits seulement.

◼ Le câblage des entrées/sorties doit être en accord avec les méthodes

de câblage selon la Classe I, Division 2 et en accord avec l’autorité compétente.

◼ AVERTISSEMENT: Risque d’Explosion – Le remplacement de certains composants rend caduque

la certification du produit selon la Classe I, Division 2.

◼ AVERTISSEMENT - DANGER D'EXPLOSION - Ne connecter pas ou ne débranche pas

l'équipement sans avoir préalablement coupé l'alimentation électrique ou la zone est reconnue pour

être non dangereuse.

◼ AVERTISSEMENT - L'exposition à certains produits chimiques peut dégrader les propriétés des

matériaux utilisés pour l'étanchéité dans les relais.

◼ Cet équipement doit être installé utilisant des méthodes de câblage suivant la norme Class I,

Division 2 NEC et /ou CEC.

Certification de la résistance des sorties relais

Les produits énumérés ci-dessous contiennent des sorties relais:

◼ Modules d’Extensions d'E/S, modèles: IO-DI8-RO4, IO-DI8-RO4-L, IO-RO8, IO-RO8L.

◼ Lorsque ces produits spécifiques sont utilisés dans des endroits dangereux, ils supportent

un courant de 3A charge résistive, lorsque ces produits spécifiques sont utilisés dans un environnement non

dangereux, ils sont évalués à 5A res, comme indiqué dans les specifications du produit Plages de

températures.

The information in this document reflects products at the date of printing. Unitronics reserves the right, subject to all applicable laws, at any time, at its sole discretion, and without notice,

to discontinue or change the features, designs, materials and other specifications of its products, and to either permanently or temporarily withdraw any of the forgoing from the market.

All information in this document is provided "as is" without warranty of any kind, either expressed or implied, including but not limited to any implied warranties of merchantability, fitness

for a particular purpose, or non-infringement. Unitronics assumes no responsibility for errors or omissions in the information presented in this document. In no event shall Unitronics be

liable for any special, incidental, indirect or consequential damages of any kind, or any damages whatsoever arising out of or in connection with the use or performance of this

information.

The tradenames, trademarks, logos and service marks presented in this document, including their design, are the property of Unitronics (1989) (R"G) Ltd. or other third parties and you

are not permitted to use them without the prior written consent of Unitronics or such third party as may own them.

UG_IO-PT400-4K.pdf 11/22

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

Unitronics IO-PT400 I-O Expansion Modules Mode d'emploi

- Taper

- Mode d'emploi

dans d''autres langues

Documents connexes

-

Unitronics IO-ATC8 Manuel utilisateur

-

Unitronics EX-RC1 Remote I/O Adapter Mode d'emploi

Unitronics EX-RC1 Remote I/O Adapter Mode d'emploi

-

Unitronics IO-TO16 I/O Expansion Module Manuel utilisateur

Unitronics IO-TO16 I/O Expansion Module Manuel utilisateur

-

Unitronics EX-RC1 Remote Input or Output Adapter Mode d'emploi

Unitronics EX-RC1 Remote Input or Output Adapter Mode d'emploi

-

Unitronics V1210-T20BJ Mode d'emploi

-

Unitronics JZ20-R31 HMI Display Unit Mode d'emploi

-

Unitronics V120 Rugged Programmable Logic Controllers Mode d'emploi

Unitronics V120 Rugged Programmable Logic Controllers Mode d'emploi

Autres documents

-

red lion IAMS and AFCM Guide d'installation

-

CHAUVIN ARNOUX C.A3420 Manuel utilisateur

-

red lion IAMS 0001 Manuel utilisateur

-

red lion IAMS Manuel utilisateur

-

red lion PGMMODC1 Communication Enabler Manuel utilisateur

-

Eurotherm T2750 Mode d'emploi

-

SBC PCD3-Compact Le manuel du propriétaire

-

SBC PCD1.B1010-A20 L-Series RIO 24DI, 10Rel Fiche technique

-

SBC PCD3.W745 Universal temperature measurement Fiche technique