RotoPol-31

RotoPol-35

Instruction Manual

Gebrauchsanweisung

Mode d’emploi

Manual No.: 15287001

Date of release: 22.08.2008

RotoPol-31/-35

Instruction Manual

Table of Contents Page

User’s Guide ..............................................................1

Reference Guide.......................................................13

Quick Reference Guide............................................31

Always state Serial No and Voltage/frequency if you have technical questions or when ordering spare parts.

You will find the Serial No. and Voltage on the type plate of the machine itself. We may also need the Date

and Article No of the manual. This information is found on the front cover.

The following restrictions should be observed, as violation of the restrictions may cause cancellation of

Struers legal obligations:

Instruction Manuals: Struers Instruction Manual may only be used in connection with Struers equipment

covered by the Instruction Manual.

Service Manuals: Struers Service Manual may only be used by a trained technician authorised by Struers.

The Service Manual may only be used in connection with Struers equipment covered by the Service Manual.

Struers assumes no responsibility for errors in the manual text/illustrations. The information in this manual is

subject to changes without notice. The manual may mention accessories or parts not included in the present

version of the equipment.

The contents of this manual is the property of Struers. Reproduction of any part of this manual without the

written permission of Struers is not allowed.

All rights reserved. © Struers 2008.

Struers A/S

Pederstrupvej 84

DK-2750 Ballerup

Denmark

Telephone +45 44 600 800

Fax +45 44 600 801

RotoPol-31/-35

Instruction Manual

RotoPol-31/-35

Safety Precaution Sheet

To be read carefully

before use

1. The operator(s) should be fully instructed in the use of the machine,

any connected equipment and accessories and the applied

consumables according to the relevant Instruction Manuals.

2. The machine must be placed on a safe and stable table with an

adequate working height. All functions on the machine and any

connected equipment must be in working order.

3. Operators should ensure that the actual voltage corresponds to the

voltage on the back of the machine. The machine must be earthed.

Follow the local regulations. Always turn the power off and remove the

plug or the cable before opening the machine.

4. Connect only to cold water. Make sure that the water connections are

leak-proof and that the water outlet is working.

5. Struers recommend that the mains water supply is shut off or

disconnected if the machine is to be left unattended.

6. Establish efficient exhaust from the working area if consumables

containing alcohol, e.g. blue DP-Lubricant, are being used.

7. Make sure that the grinding or polishing discs are correctly mounted,

the driving pins engaged with the holes in the turntable.

8. Keep clear of the rotational disc and the specimen mover during

operation. Make sure that any screws for clamping of specimens in

specimen holders protrude as little as possible. While grinding

manually, be careful not to touch the grinding paper. Do not drop the

specimen while grinding.

9. Do not lift the specimen mover while preparing individual specimens.

RotoForce-4 or Pedemat must be set to Auto.

10. If you observe malfunctions or hear unusual noises - stop the machine

and call technical service.

The equipment is designed for use with consumables supplied by Struers. If subjected to misuse, improper

installation, alteration, neglect, accident or improper repair, Struers will accept no responsibility for

damage(s) to the user or the equipment.

Dismantling of any part of the equipment, during service or repair, should always be performed by a qualified

technician (electromechanical, electronic, mechanical, pneumatic, etc.).

RotoPol-31/-35

Instruction Manual

Disposal

Equipment marked with a WEEE symbol contain electrical and

electronic components and must not be disposed of as general

waste.

Please contact your local authorities for information on the correct

method of disposal in accordance with national legislation.

RotoPol-31/-35

Instruction Manual

1

User’s Guide

Table of Contents Page

1. Getting Started

Checking the Contents of Packing................................................... 2

RotoPol-31 (ROT31) RotoPol-35 (ROT35) ................................ 2

Lid, Optional (ROTLI)............................................................... 2

Recirculation Cooling Unit, Optional (TRECI) ........................ 2

Recirculation Cooling Unit Connector, Optional (ROPRE).....2

Getting Acquainted with RotoPol-31/-35......................................... 3

Unpacking RotoPol-31/-35................................................................ 4

Placing RotoPol-31/-35...................................................................... 4

Supplying Power............................................................................... 4

RotoPol-31.................................................................................. 4

Direction of the Turntable on RotoPol-35 ................................ 4

RotoPol-35 Single-phase Versions ............................................ 4

RotoPol-35 Three-phase versions .............................................4

Supplying Water ............................................................................... 5

Connection to Water Mains ......................................................5

Connection to Water Outlet ...................................................... 5

Software Settings.............................................................................. 6

Setting the Language .......................................................................7

2. Basic Operation

Using the Controls............................................................................ 8

The Front Panel of RotoPol-31.................................................. 8

The Front Panel of RotoPol-35.................................................. 8

Front Panel Controls ........................................................................ 9

General Use of Keys ................................................................ 10

Acoustic Signals....................................................................... 10

Reading the Display ................................................................ 10

Routine Operations......................................................................... 11

Mounting a Disc....................................................................... 11

Starting the Disc...................................................................... 11

Stopping the Disc..................................................................... 11

Selecting Water and Speed ..................................................... 11

Settings with a RotoCom Memory Unit ................................. 12

RotoPol-31/-35

Instruction Manual

1. Getting Started

In the packing box you should find the following parts:

Checking the Contents of

Packing

1 RotoPol-31/-35

RotoPol-31 (ROT31)

RotoPol-35 (ROT35) 1 Pressure hose 3/4" x 2 m

1 Filter gasket

1 Gasket ø11/ø24 x 1.5 mm

1 Reduction ring with gasket

1 Drain hose, ø38 mm x 3 m

1 Drain elbow pipe

2 Hose clamps

1 Protection ring

1 Set of Instruction Manuals

1 Lid

Lid, Optional (ROTLI)

1 TRECI complete

Recirculation Cooling Unit,

Optional (TRECI) 1 Outlet angle

1 Funnel

2 Disposable plastic containers (TREPO)

1 Connection box

Recirculation Cooling Unit

Connector, Optional (ROPRE) 1 Hexagon nipple

1 Non-return valve with elbow and hexagon nipple

1 Reduction piece, large

1 Reduction piece, small

1 Hose clamp

1 Diagram

2

RotoPol-31/-35

Instruction Manual

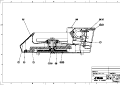

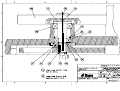

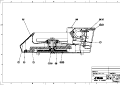

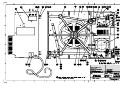

Take a moment to familiarise yourself with the location and

names of all the RotoPol components:

Getting Acquainted with

RotoPol-31/-35

RotoPol (RotoPol-31)

A Front panel controls

B Main switch

C Water tap with sprinkler tube

D Turntable

Back of RotoPol (RotoPol-31)

c Water inlet tube

d Water outlet tube

e Valve for disc cooling

f Socket for recirculation cooling unit connection

g Socket for specimen mover

h Fuse

3

RotoPol-31/-35

Instruction Manual

Detach RotoPol-31/-35 from the bottom of the packing case by

removing the four screws from below.

Unpacking RotoPol-31/-35

Place RotoPol-31/-35 on a steady table with an adequate working

height. The machine must be close to the power supply, water

mains and water outlet facilities. If water recirculation is used,

there must be room under the table for the Recirculation Cooling

Unit (TRECI).

Placing RotoPol-31/-35

RotoPol-31/-35 is factory mounted with electric cable.

Supplying Power

IMPORTANT

Check that the mains voltage corresponds to the voltage stated on the type

plate on the back of the machine.

Mount a plug on the cable or connect to mains:

RotoPol-31

Yellow-green or just green: earth

Other colours: phase

Check that the turntable rotates in the direction indicated by a

label on the turntable (anti-clockwise). If the direction of rotation

is incorrect, switch two of the phases.

Direction of the Turntable

on RotoPol-31

Mount a plug on the cable or connect to mains:

RotoPol-35

Single-phase Versions

Yellow-green: earth

Blue or white: neutral

Other colours: phase

Mount a plug on the cable or connect to mains:

RotoPol-35

Three-phase versions

Yellow-green or just green: earth

Other colours: phase

DANGER!

The machine must be earthed

4

RotoPol-31/-35

Instruction Manual

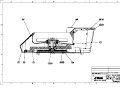

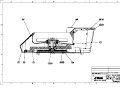

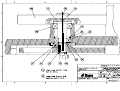

Water for wet grinding and disc cooling may be supplied from the

water mains or a Recirculation Cooling Unit.

Supplying Water

RotoPol (RotoPol-31)

c Water inlet tube

d Water outlet tube

Mount the straight end of the pressure hose onto the water

inlet tube (upper) in the hose box on the back of

RotoPol-31/ -35:

Connection to Water Mains

− Insert the filter gasket in the coupling nut with the flat

side against the pressure hose.

− Tighten the coupling nut completely.

Mount the other end of the pressure hose on the water mains

tap for cold water:

− Mount the reduction ring with gasket on the water mains

tap, if necessary.

− Introduce the gasket and tighten the coupling nut

completely.

IMPORTANT

Only connect to cold water.

Determine the best arrangement for the outlet. If the drain

hose is directed parallel to the machine, the drain elbow pipe

should be mounted on the water outlet tube (lower) in the

hose box on the back of RotoPol-31/-35.

Connection to Water Outlet

5

RotoPol-31/-35

Instruction Manual

Locate the end of the drain hose where a short length of the

steel reinforcement has been stripped away. Mount the

stripped end of the hose onto the water outlet tube, or onto

the drain elbow pipe if such is mounted. Use hose clamp for

fastening.

Lead the other end of the drain hose to the water outlet.

Arrange the tube so that it slopes throughout its length.

Shorten the hose, if necessary. The drain hose should be

attached to the water outlet system if possible.

REMEMBER

Avoid sharp bends in the drain hose and make sure that the hose slopes

throughout its length.

Switch on the power at the main switch. The following display

will appear briefly:

Software Settings

- ROTOPOL-31 -

VERSION X.Y

- ROTOPOL-35 -

VERSION X.Y

When the operation menu appears, you are ready to choose

the language you prefer in the display.

6

RotoPol-31/-35

Instruction Manual

7

WATER OFF 150RPM Example screen

D

m The MENU m key activates the set-

up menu.

D

DISC COOLING

WHEN WATER OFF

D

m Press MENU m again. The language

screen appears.

D

LANGUAGE

ENGLISH

D

L Press SELECT L to choose between

English, German, French or Japanese

D

SPRACHE

DEUTSCH

D

L Press SELECT

L until you reach the

language you prefer.

D

LANGUE

FRANCAIS

D

Press STOP o to accept the choice.

o The Operation Menu will re-appear in

the language you have chosen.

D

EAU OFF 150 T/M

Setting the Language

Remember

to set the same language on all connected RotoSystem modules. Setting

the Communication and Disc Cooling: see Advanced Operation Section.

RotoPol-31/-35

Instruction Manual

2. Basic Operation

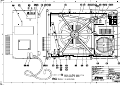

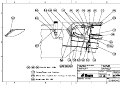

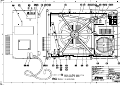

Using the Controls

The Front Panel of RotoPol-31

The Front Panel of RotoPol-35

8

c Main Switch: figure A

5 Water Tap with Sprinkler Tube: figure B

RotoPol-31/-35

Instruction Manual

Communication is set to STANDARD mode

Name Key Function Name Key Function

c

MAIN

SWITCH

The main switch is located to the

right of the cabinet. Turn clock-

wise to switch on the power. k

SPEED

300 RPM

d

300

Select 300 RPM.

(RotoPol-31)

d

POWER

INDICATOR

Power Lights up when the main power

is on. l

SPEED

150 RPM

d

150

Select 150 RPM.

(RotoPol-31)

e

START s Starts the disc and any con-

nected RotoSystem equipment

set in Auto mode. 1

MENU m

Activates the set-up menu or

moves down in the menu

structure.

f

STOP o Stops the disc and any con-

nected RotoSystem equipment

set in Auto mode.

Exits the set-up menu.

2

SELECT L

Changes values in the set-up

menu.

g

DISC AO Scrolls up in the operation menu. 3

SPEED dOIncreases the speed.

(RotoPol-35)

h

DISC AN Scrolls down in the operation

menu. 4

SPEED dNDecreases the speed.

(RotoPol-35)

i

WATER ON w Select WATER ON: press the

key briefly.

Manual Dosing: keep pressing

the key. Release the key to stop

the water.

5

WATER

TAP Adjust the water on the tap.

j

WATER

OFF

W Select WATER OFF.

Front Panel Controls

9

RotoPol-31/-35

Instruction Manual

WATER ON w, WATER OFF W and SPEED d can only be

selected freely at User Select.

General Use of Keys

MENU m, SELECT L and DISC A can only be activated

when the machine has been stopped.

SELECT L can only be activated when MENU m is selected.

When pressing a key, a short beep indicates that the com-

mand has been accepted, whereas a long beep indicates that

the key cannot be activated at the moment.

A

coustic Signals

10

WATER ON 300RPM

GRINDING

- The first line on the screen shows the

setting of parameters WATER and SPEED.

- The second line, if any, shows a selected

pre-set mode (GRINDING or POLISHING).

Reading the Display

RotoPol-31/-35

Instruction Manual

Place the disc on the turntable and turn it until the three

driving pins engage with the holes in the turntable.

Routine Operations

Mounting a Disc

Press START s. The disc starts rotating. Selected functions

are executed and connected RotoSystem modules start

operating.

Starting the Disc

Press STOP o. The disc stops rotating. Selected functions

and connected RotoSystem modules stop.

Stopping the Disc

You can either select water and speed yourself or press DISC AN

to select one of the pre-set GRINDING and POLISHING modes.

Selecting Water and Speed

Setting to User Select WATER OFF 150RPM

The User Select screen has an empty line

at the bottom.

D U- Press w or W to select WATER ON or

WATER OFF.

- Press SPEED

d 150 or d 300 to

select the speed. (RotoPol-31)

- Press SPEED dN or dO to adjust the

speed. (RotoPol-35)

AN AO Press

DISC AN or AO to change

between the settin

g

s.

D U

Setting to GRINDING WATER ON 300RPM

GRINDING

The standard setting GRINDING is pre-

set to WATER ON and 300RPM.

D U

AN AO Press DISC AN or AO to change

between the settin

g

s.

D U

Setting to POLISHING WATER OFF 150RPM

POLISHING

The standard setting POLISHING is pre-

set to WATER OFF and 150RPM.

11

RotoPol-31/-35

Instruction Manual

If RotoPol is connected to RotoCom and communication is in

ROTOCOM mode, the following screen will appear:

Settings with a

RotoCom Memory Unit

WATER ON 300RPM

PG-Paper #120

- The first line on the screen shows the

settings of parameters for WATER and

(Example screen) SPEED.

- The second line shows the surface to be

used, according to the preparation pro-

gram selected on RotoCom.

DISC AN and AO toggles between the various surfaces defined

in RotoCom.

STRUERS CONSUMABLES

Struers offers a wide range of:

- Consumables for both plane and fine grinding.

- Polishing cloths, diamond and oxide abrasive materials.

12

RotoPol-31/-35

Instruction Manual

13

Reference Guide

Table of Contents Page

1. Advanced Operations

Selection of Disc.............................................................................. 14

Disc Cooling ....................................................................................14

Setting the Disc Cooling.......................................................... 14

Adjustment of Water Flow at Disc Cooling ................................... 15

Mounting of Specimen Mover (Optional)....................................... 16

RotoForce-3/4 ........................................................................... 16

Pedemat/Pedemax-S................................................................ 16

Adjusting Pedemat .................................................................. 17

Mounting of Multidoser (optional)................................................. 18

RotoCom Memory Unit (optional).................................................. 18

Setting the Communication ........................................................... 18

Recirculation Cooling Unit (Optional)........................................... 19

Struers Metalog Guide™................................................................ 20

Oxide Polishing............................................................................... 21

2. Overview of Menu Screens

in the Set-up Menu ..................................................................... 22

3. Accessories and Connected Equipment........................... 23

4. Trouble-shooting.................................................................... 24

5. Maintenance

Daily Service ................................................................................... 26

Weekly Service................................................................................ 26

Replacing the Cooling Water.......................................................... 26

Checking the Recirculation Cooling Unit...................................... 26

Replacing the Swivel for Disc Cooling ........................................... 27

6. Technical Data........................................................................ 28

RotoPol-31/-35

Instruction Manual

1. Advanced Operations

RotoPol-31/35 is designed for MD-Discs of 300 mm dia., wet

grinding discs of 305 mm dia. and polishing discs of 300 mm dia.

However, the whole range of Struers discs can be mounted.

Selection of Disc

For automatic preparation of specimen holders mounted in

specimen movers, only aluminium discs should be used. See

the instructions for RotoForce-3 or RotoForce-4.

When disc cooling is selected, only aluminium discs should be

used.

Disc cooling should be selected in the setting whenever

RotoPol-31/-35 is used intensively for:

Disc Cooling

Preparation of specimen holders.

Polishing time longer than 5 minutes.

Successive preparation of several specimen holders on the

same disc.

Important

The set-up menu setting can only be implemented

when the machine has been stopped.

Press MENU m to move from one screen to another.

Setting the Disc Cooling

When in the DISC COOLING menu, press SELECT L:

14

Press STOP o when the desired setting appears, or press

MENU m repeatedly until the operation menu appears again.

WHEN WATER OFF should normally be selected when disc

cooling is applicable.

ALWAYS ON should only be selected for special applications.

DISC COOLING

WHEN WATER OFF

DISC COOLING

WHEN WATER OFF

D

U

L DISC COOLING

ALWAYS ON

L DISC COOLING

ALWAYS OFF

L

RotoPol-31/-35

Instruction Manual

ALWAYS OFF should be selected if disc cooling is not

relevant for the application.

Disc cooling will automatically start and stop with

RotoPol-31/-35.

IMPORTANT

- Disc cooling will only be active at rotational speeds up to 300 RPM.

- Disc cooling is only efficient when aluminium discs are being used.

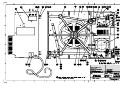

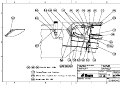

Select mode WHEN WATER OFF or ALWAYS ON in the disc

cooling menu.

Adjustment of Water Flow at

Disc Cooling

Select WATER OFF W and SPEED d 150, and start RotoPol-

31/-35 without a preparation disc.

Adjust the flow using the valve at the rear of the cabinet so

that the cooling water flows from the hole in the centre of the

turntable at a height of about 2 mm. This will result in a

water flow of about 250 ml/min which will generally be

adequate.

RotoPol (RotoPol-31)

e Valve for Disc Cooling

Disc cooling works with both tap water or by means of

recirculation. The cooling capability for Recirculation Cooling

Unit (TRECI) will be sufficient for most situations. If, however,

the equipment is used very intensively, using recirculation, the

temperature of the cooling water may vary too much during

working time to be adequate for disc cooling. In this situation, a

separate cooling system (available from most laboratory

suppliers) should be connected to the Recirculation Cooling Unit.

15

RotoPol-31/-35

Instruction Manual

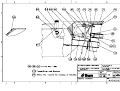

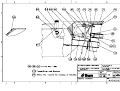

Mounting of

Specimen Mover (Optional)

RotoPol-31/-35 can be equipped with a RotoForce-3 or a

RotoForce-4 specimen mover. To mount the specimen mover, see

the Instruction Manual of the specimen mover.

RotoForce-3/4

Older versions of the specimen movers: Pedemat (PEDRO) or

Pedemax-S (PEDSO) can be mounted on RotoPol-31/-35, operating

with automatic start and stop. In such a configuration, however, a

RotoCom unit cannot be connected.

Pedemat/Pedemax-S

c Fastening screws.

d Support hole.

Remove the cap covering the support hole placed on the top of

the RotoPol-31/-35 cabinet by lifting it with a knife.

Remove the two caps covering the fastening screws on the

left- hand side of the RotoPol-31/-35 cabinet by lifting them

with a knife.

Remove the black plastic ring from the supporting column of

Pedemat/Pedemax-S.

Lead the supporting column of the specimen mover down into

the support hole in RotoPol-31/-35. Turn the column until the

cross pin in the bottom of the column gets caught by the

guiding slots inside RotoPol-31/-35.

Tighten the two fastening screws on the left-hand side of the

RotoPol-31/-35 cabinet by means of the hexagon key included

in the packing case, and mount the two caps again.

16

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

dans d''autres langues

- English: Struers RotoPol-31 User manual

- Deutsch: Struers RotoPol-31 Benutzerhandbuch

Documents connexes

-

Struers RotoPol-11 Manuel utilisateur

Struers RotoPol-11 Manuel utilisateur

-

Struers RotoPol-21 Manuel utilisateur

Struers RotoPol-21 Manuel utilisateur

-

Struers RotoForce-1 Manuel utilisateur

Struers RotoForce-1 Manuel utilisateur

-

Struers RotoForce-4 Manuel utilisateur

Struers RotoForce-4 Manuel utilisateur

-

Struers PDM-Force-20 Manuel utilisateur

Struers PDM-Force-20 Manuel utilisateur

-

Struers MAPS Manuel utilisateur

Struers MAPS Manuel utilisateur

-

Struers Metason Manuel utilisateur

Struers Metason Manuel utilisateur

-

Struers Abramin Manuel utilisateur

Struers Abramin Manuel utilisateur

-

Struers ProntoPress-10 Manuel utilisateur

Struers ProntoPress-10 Manuel utilisateur

-

Struers Prepamatic-2 Manuel utilisateur

Struers Prepamatic-2 Manuel utilisateur