Regulatory RF Device Approvals: EU

Contains RF Cellular Module: Telit LE910-EU V2

Dual-Band GSM/GPRS/EDGE EGSM900/DCS1800

Dual-Band WCDMA/HSPA FDD I / FDD VIII

Penta-Band LTE FDD 1 / FDD 3 / FDD 7 / FDD 8 / FDD 20 wireless module

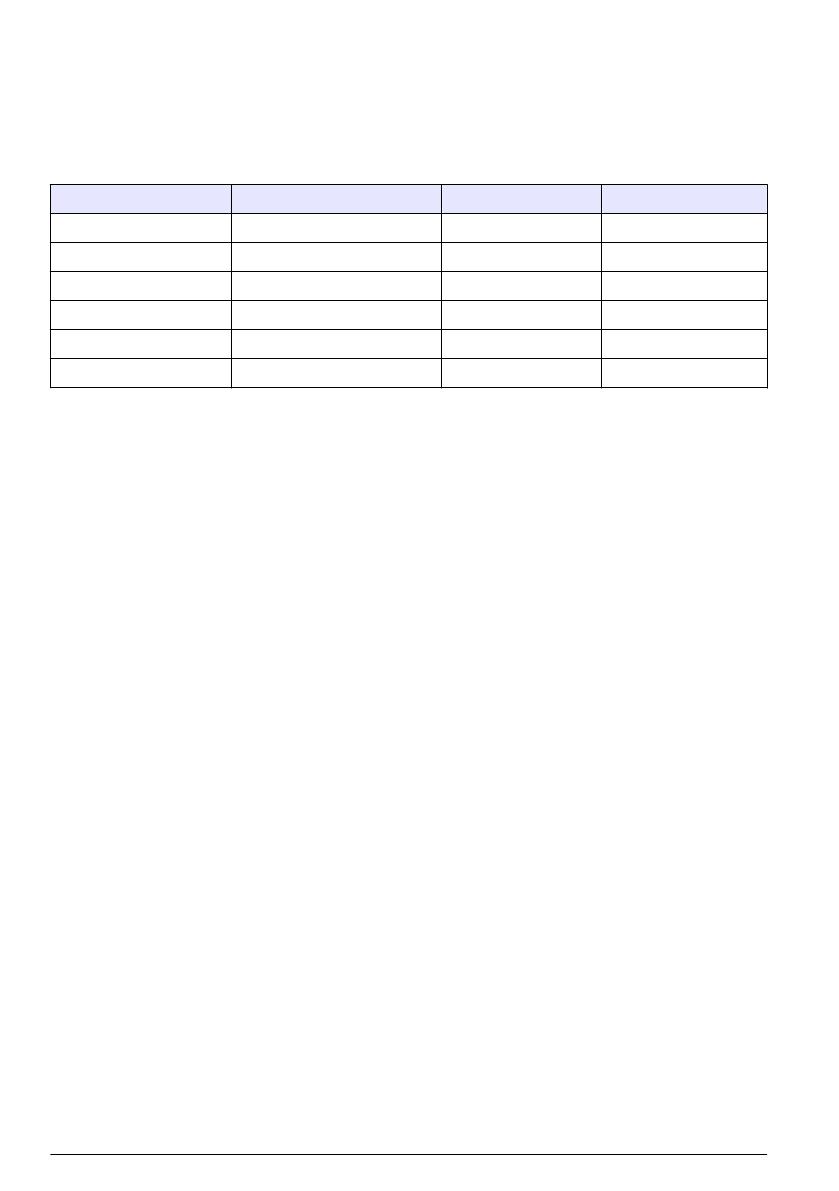

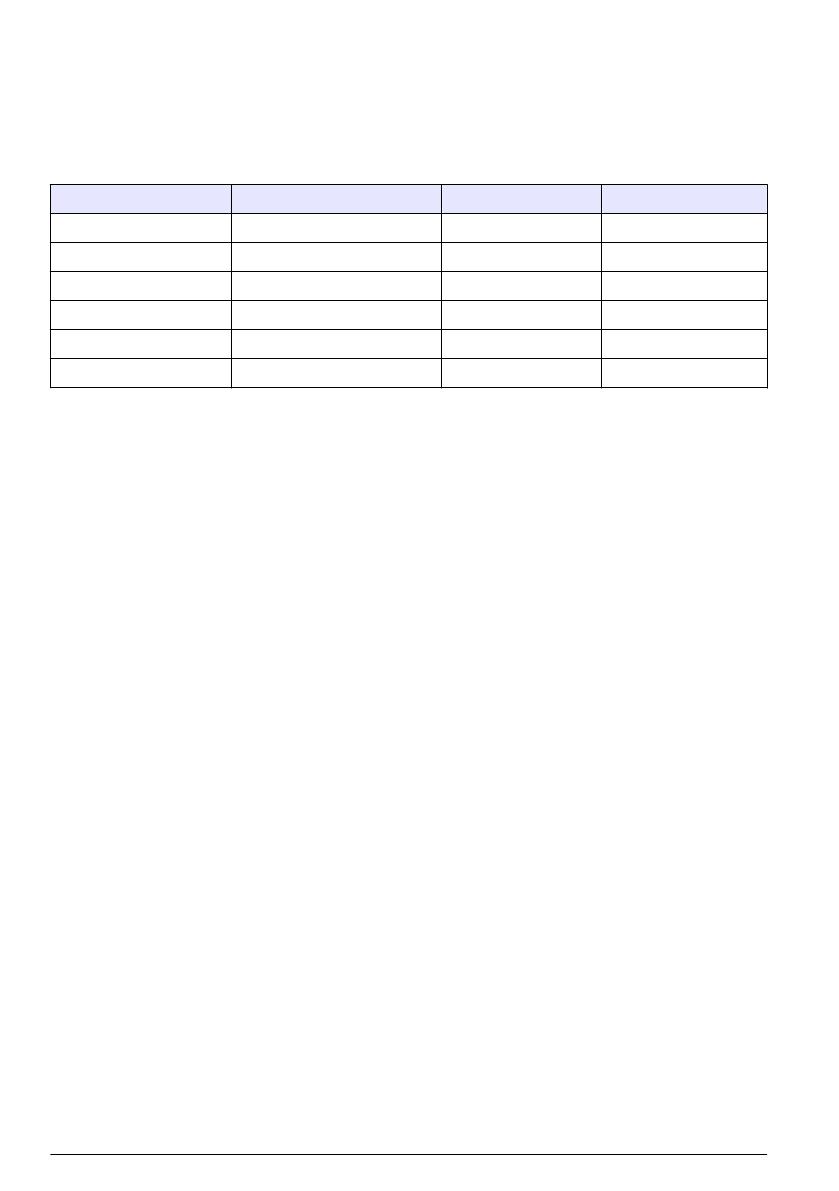

Table 2 Power for Cellular Modem: EU

Standard Operating frequency bands Output power [dBm] Output power (watts)

ETSI EN 301 908-1 (-13) E-GSM/GPRS 900 33.5 2.2

ETSI EN 301 908-1 (-13) EDGE 900 28 0.6

ETSI EN 301 908-1 (-13) DCS/GPRS 1800 30.5 1.1

ETSI EN 301 908-1 (-13) EDGE 1800 27 0.5

ETSI EN 301 908-1 (-13) WCDMA FDD I/VIII 24.5 0.3

ETSI EN 301 908-1 (-13) LTE 1/3/7/8/20 24 0.3

Canada (IC)

Contains RF module: IC : 5131A-LE910NAV2 or IC : 5131A-LE910SVV2

This class (A) digital apparatus complies with Canadian ICES-003. This device complies with

Industry Canada license exempt RSS standard(s). Operation is subject to the following two

conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause undesired

operation of the device.

Cet appareil numérique de la classe (A) respect toutes les exigences de la norme NMB-003 du

Canada. Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils

radio exempts de licence. L'exploitation est autorisée aux deux conditions suivantes:

(1) l'appareil ne doit pas produire de brouillage, et

(2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage

est susceptible d'en compromettre le fonctionnement.

United States (FCC)

Contains RF Module: FCC ID: RI7LE910NAV2 or FCC ID: RI7LE910SVV2

Modifications not expressly approved by this company could void the user's authority to operate this

equipment (FCC section 15.21).

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense (FCC section 15.105).

Telit RF Module FCC/IC Regulatory notices

Modification statement

Telit has not approved any changes or modifications to this device by the user. Any changes or

modifications could void the user's authority to operate the equipment.

Telit n'approuve aucune modification apportée à l'appareil par l'utilisateur, quelle qu'en soit la nature.

Tout changement ou modification peuvent annuler le droit d'utilisation de l'appareil par l'utilisateur.

Interference statement

This device complies with Part 15 of the FCC Rules and Industry Canada licence-exempt RSS

standard(s). Operation is subject to the following two conditions: (1) this device may not cause

6

English

Hach Polymentron 9500 Basic User Manual

Hach Polymentron 9500 Basic User Manual

Hach CD300 Manuel utilisateur

Hach CD300 Manuel utilisateur

Hach ORBISPHERE 410 Basic User Manual

Hach ORBISPHERE 410 Basic User Manual

Hach 9586sc Basic User Manual

Hach 9586sc Basic User Manual

Hach CD500 Manuel utilisateur

Hach CD500 Manuel utilisateur

Hach Polymetron 9523sc pH Basic User Manual

Hach Polymetron 9523sc pH Basic User Manual

Hach 9586sc Basic User Manual

Hach 9586sc Basic User Manual

Hach SC1500 Manuel utilisateur

Hach SC1500 Manuel utilisateur