red lion DA 6UIN Module Manuel utilisateur

- Taper

- Manuel utilisateur

Installation DA6UIN-B

Drawing No. LP1122

Revised 03/2020

DA Series Universal Analog Input Module

With 6 Isolated Channels

Installation Guide

1

MODULE PACKAGE CHECKLIST

This product package should contain the items listed below. If

any items are missing or damaged, contact Red Lion immediately.

- DIN rail mount DA 6UIN Module

- Installation Guide

GENERAL DESCRIPTION

The DA 6UIN module is designed for use with the DA70

controllers, that can support up to 10 I/O modules simultaneously.

This module features 6 Universal Analog Inputs operating at

16-bit resolution, which makes it an ideal choice for a data-

acquisition application. The module can accept a wide range of

thermocouples and RTDs, as well as 0/4-20 mA and 0-10 V

Process signals. Each input has a dedicated alarm LED that

indicates a variety of conditions.

The modules connect and communicate via proprietary

backplane to the DA host device. The DA host device, equipped

with serial ports as well as Ethernet port(s), allows the system to

share data with PCs, PLCs, and SCADA systems.

Internal power management circuits allow the module to be

replaced while power is applied, which reduces downtime in the

event of a module failure. All configuration information is stored

locally within the module, as well as in the Host, so replacement

modules do not need to be configured.

CONFIGURATION

The DA 6UIN modules are configured with Windows

®

compatible Crimson

®

software. The software is an easy to use,

graphical interface which provides a means of configuration and

commissioning of new systems, as well as routine module

re-calibration.

ALARMS

There are a total of 6 red Alarm LEDs – one per Universal Input

channel. The 6UIN module Status LED shows general module

health status. Please reference the LED section for a list of LED

functions.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that

appear in this document or on equipment must be observed to

ensure personal safety and to prevent damage to either the

device or equipment connected to it.

Do not use these products to replace proper safety interlocking.

No software-based device (or any other solid-state device) should

ever be designed to be responsible for the maintenance of

personnel safety or consequential equipment not equipped with

safeguards. Red Lion disclaims any responsibility for damages,

either direct or consequential, that result from the use of this

equipment in a manner not specified.

CAUTION: Risk of Danger

Read complete instructions prior to installation and

operation of the unit.

ATTENTION : Risque de danger

Lire les instructions complètes avant l’installation et

l’utilisation de l’appareil.

WARNING - EXPLOSION HAZARD - SUBSTITUTION

OF COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIVISION 2

AVERTISSEMENT - DANGER D’EXPLOSION - LE

REMPLACEMENT DE COMPOSANTS PEUT NUIRE À

L’APTITUDE À LA CLASSE I, DIVISION 2

z Universal inputs accept TC, RTD, 0-5 V, 0-10 V, 0-20 mA,

4-20 mA, 0-50 mV signals

z Offers complete isolation; inputs, power and Controller

z Ideal for data acquisition applications

z Fully isolated design provides reliable operation

z Configured using Crimson

®

software (version 3.1 or later)

FOR USE IN HAZARDOUS LOCATIONS:

Class I, Division 2, Groups A, B, C, and D

T4

C

US

U

L

R

LISTED

IND.CONT. EQ.

E317425

0.49

(12.51)

0.45 (11.50)

4.53 (114.97)

6.22

(157.91)

1.91

(48.51)

1.35

(34.32)

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

09

08

07

06

05

04

03

02

01

6.00

(152.40)

DIMENSIONS In inches (mm)

II 3 G Ex ec IIC T4 Gc

DEMKO 20 ATEX 2268X

IECEx UL 20.0007X

2

Drawing No. LP1122 Revised 03 2020

SPECIFICATIONS

1. POWER: Power is supplied by the DA host device. Modules

may be hot-swapped (replaced while powered up) in non-

hazardous locations only.

6UIN Port-Isolated Max Power: 1 W

2. LEDs:

STS: RGB Status LED shows module condition

AL1 - 6: Alarm LEDs are lit during an internal alarm condition

3. MEMORY: Non-volatile memory retains all programmable

parameters.

4. INPUTS:

GENERAL:

Effective Resolution: Full 16-bit

Sample Time: 50 msec

Common Mode Rejection: >110 dB, 50/60 Hz

Normal Mode Rejection: >50 dB, 50/60 Hz

Temperature Coefficient: 0.01%/

°

C

Step Response Time: 100 msec typ., 200 msec max

THERMOCOUPLE INPUTS:

Types: T, E, J, K, R, S, B, N, C

Slope & Offset: Provides sensor error correction

Input Impedance: 20 M ohm

Lead Resistance Effect: 0.25 µV/ohm

Cold Junction Compensation: Less than ±1 °C typical (±1.5

°C max) over -40 to 75 °C ambient temperature

Resolution: 0.1

°

TYPE

MEASUREMENT

RANGE

WIRE COLOR

ANSI BS 1843

T

-200 to +400 °C

-328 to +752 °F

(+) Blue

(-) Red

(+) White

(-) Blue

E

-200 to +730 °C

-328 to +1346 °F

(+) Violet

(-) Red

(+) Brown

(-) Blue

J

-200 to +760 °C

-328 to +1400 °F

(+) White

(-) Red

(+) Yellow

(-) Blue

K

-200 to +1350 °C

-328 to +2462 °F

(+) Yellow

(-) Red

(+) Brown

(-) Blue

R

0 to +1768 °C

+32 to +3214 °F

No Standard

(+) White

(-) Blue

S

0 to +1768 °C

+32 to +3214 °F

No Standard

(+) White

(-) Blue

B

+149 to +1820 °C

+300 to +3308 °F

No Standard No Standard

N

-200 to +1300 °C

-328 to +2372 °F

(+) Orange

(-) Red

(+) Orange

(-) Blue

C W5/W6

0 to +2315 °C

+32 to +4199 °F

No Standard No Standard

mV 0 mV to 50 mV N/A N/A

Temperature Indication Accuracy: ± (0.3% of span, +1 °C).

Includes NIST conformity, cold junction effect, A/D

conversion errors, temperature coefficient and linearization

conformity at 23 °C after 20 minute warm up.

Probe Break Response: Upscale drive, Input Fault Alarm bit

set high, ALM LED illuminates.

RTD INPUTS:

Type: 2 or 3 wire

Excitation: 150 µA

Lead Resistance: 15 ohms Max

Resolution: 1 or 0.1°

TYPE INPUT TYPE RANGE

385 100 ohm platinum, Alpha = 0.00385

-200 to +600 °C

-328 to +1100 °F

392 100 ohm platinum, Alpha = 0.003919

-200 to +600 °C

-328 to +1100 °F

672 120 ohm nickel, Alpha = 0.00672

-80 to +215 °C

-112 to +419 °F

Slope & Offset: Provides sensor error correction

Temperature Indication Accuracy: Includes NIST conformity,

A/D conversion errors, temperature coefficient and

linearization conformity at 23 °C after 20 minute warm up.

Probe Break Response: If channel is enabled: upscale drive,

Input

Fault Alarm bit set high, ALM LED illuminates

5. CURRENT INPUTS:

Ranges: 0-20 mA or 4-20 mA

Programmable Scaling: ±30,000

Input Impedance: 10 Ohm

Max. Continuous Overload: 100 mA

Accuracy: ±0.1% of span

Input Fault Response: Upscale Drive, Input Fault Alarm bit set

high, ALx LED illuminates below -2 mA, and above 22 mA

for 0-20 mA range; below +2 mA and above 22 mA for 4-20

mA signals.

6. VOLTAGE INPUTS:

Ranges: 0-10 VDC, 0-5 V, 0-50 mV

Programmable Scaling: ±30,000

Input Impedance: 1 M Ohm

Max. Continuous Overload: 50 V

Accuracy: ±0.1% of span

Input Fault Response: Upscale Drive, Input Fault Alarm bit set

high, ALx LED illuminates below -0.5 or -10.5 VDC and

above +10.5 VDC.

7. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: -40 to 75 °C

Storage Temperature Range: -40 to +85 °C

Operating and Storage Humidity: 0 to 85% max. Relative

humidity, non-condensing.

Vibration to IEC 60068-2-6: Operational 5-500 Hz, 2 g

Shock to IEC 68-2-27: Operational 15 g

Altitude: Up to 2000 meters

Installation Category II, Pollution Degree 2 as defined in IEC/

EN 60664-1.

8. CERTIFICATIONS AND COMPLIANCES:

CE Approved

EN 61326-1 Immunity to Industrial Locations

Emission CISPR 11 Class A

IEC/EN 61010-1

RoHS Compliant

ATEX Approved

II 3 G Ex ec IIC T4 Gc

DEMKO 20 ATEX 2268X

IECEx Approved

IECEx UL 20.0007X

UL Hazardous: File #E317425

Rugged IP30 enclosure

9. CONSTRUCTION: Polycarbonate enclosure with IP30 rating.

For use only in approved enclosure.

10. CONNECTIONS: Removable wire clamp screw terminal

blocks

Wire Strip Length: 0.3" (7.5 mm)

Wire Gauge Capacity: 14 to 24 AWG (2.08 to 0.20 mm

2

)

copper wire only

Torque: 2 inch-lbs (0.23 N-m)

11. MOUNTING: Mounts onto standard DIN style top hat (T)

profile mounting rails according to EN50022 – 35 x 7.5 mm

and 35 x 15 mm.

12. WEIGHT: 10.2 oz (317.26 g)

This equipment is suitable for use in Class I, Division 2,

Groups A, B, C, D, or non-hazardous locations only.

Cet équipement est adapté à une utilisation dans des

endroits de classe I, Division 2, Groupes A, B, C, D, ou

dans des endroits non dangereux seulement.

WARNING - EXPLOSION HAZARD. NOT HOT

SWAPPABLE. DO NOT REMOVE OR REPLACE WHILE

CIRCUIT IS LIVE UNLESS THE AREA IS FREE OF

IGNITIBLE CONCENTRATIONS.

AVERTISSEMENT - RISQUE D’EXPLOSION. NON

ÉCHANGEABLE À CHAUD. NE PAS RETIRER OU

REMPLACER SOUS TENSION SAUF SI LA ZONE EST

EXEMPTE DE CONCENTRATIONS INFLAMMABLES.

3

Revised 03 2020 Drawing No. LP1122

EMC INSTALLATION GUIDELINES

Although Red Lion Controls’ products are designed with a high

degree of immunity to Electromagnetic Interference (EMI), proper

installation and wiring methods must be followed to ensure

compatibility in each application. The type of the electrical noise,

source or coupling method into a unit may be different for various

installations. Cable length, routing, and shield termination are

very important and can mean the difference between a successful

or troublesome installation. Listed are some EMI guidelines for a

successful installation in an industrial environment.

1. A unit should be mounted in a metal enclosure, which is

properly connected to protective earth.

2. Use shielded cables for all Signal and Control inputs. The

shield connection should be made as short as possible. The

connection point for the shield depends somewhat upon the

application. Listed below are the recommended methods of

connecting the shield, in order of their effectiveness.

a. Connect the shield to earth ground (protective earth) at one

end where the unit is mounted.

b. Connect the shield to earth ground at both ends of the cable,

usually when the noise source frequency is over 1 MHz.

3. Never run Signal or Control cables in the same conduit or

raceway with AC power lines, conductors, feeding motors,

solenoids, SCR controls, and heaters, etc. The cables should

be run through metal conduit that is properly grounded. This

is especially useful in applications where cable runs are long

and portable two-way radios are used in close proximity or if

the installation is near a commercial radio transmitter. Also,

Signal or Control cables within an enclosure should be routed

as far away as possible from contactors, control relays,

transformers, and other noisy components.

4. Long cable runs are more susceptible to EMI pickup than

short cable runs.

5. In extremely high EMI environments, the use of external EMI

suppression devices such as Ferrite Suppression Cores for

signal and control cables is effective. The following EMI

suppression devices (or equivalent) are recommended:

Fair-Rite part number 0443167251 (Red Lion Controls

#FCOR0000)

Line Filters for input power cables:

Schaffner # FN2010-1/07 (Red Lion Controls #LFIL0000)

6. To protect relay contacts that control inductive loads and to

minimize radiated and conducted noise (EMI), some type of

contact protection network is normally installed across the

load, the contacts or both. The most effective location is

across the load.

a. Using a snubber, which is a resistor-capacitor (RC) network or

metal oxide varistor (MOV) across an AC inductive load is very

effective at reducing EMI and increasing relay contact life.

b. If a DC inductive load (such as a DC relay coil) is controlled

by a transistor switch, care must be taken not to exceed the

breakdown voltage of the transistor when the load is

switched. One of the most effective ways is to place a

diode across the inductive load. Most Red Lion products

with solid state outputs have internal zener diode

protection. However external diode protection at the load is

always a good design practice to limit EMI. Although the

use of a snubber or varistor could be used.

Red Lion part numbers: Snubber: SNUB0000

Varistor: ILS11500 or ILS23000

7. Care should be taken when connecting input and output

devices to the instrument. When a separate input and output

common is provided, they should not be mixed. Therefore a

sensor common should NOT be connected to an output

common. This would cause EMI on the sensitive input

common, which could affect the instrument’s operation.

Visit http://www.redlion.net/emi for more information on EMI

guidelines, Safety and CE issues as they relate to Red Lion

products.

HARDWARE INSTALLATION

Removing Module From Cradle

To remove the module from the cradle, push in the module

release button at the top of the cradle and pull the module out of

the cradle.

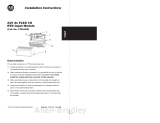

Attaching the Module/Cradle to the DIN Rail

The DIN rail should be mounted

horizontally so that the unit’s

ventilation holes are vertical in

relation to installation orientation.

A minimum clearance of 1 inch

(25.4 mm) should be maintained

above and below the unit to

ensure proper thermal regulation.

The cradle can be installed on

the DIN rail with or without the

module attached. Ensure the DIN

rail lock latch is in the outward

most position (unlocked). Hook

the top back of the cradle DIN

rail clip over the DIN rail. Press

the cradle until flush with the rail

and push the DIN rail lock latch to the latched (in) position.

For hazardous location installation, the following shall be taken

into consideration:

— The equipment shall only be used in an area of at least

pollution degree 2, as defined in EN/IEC 60664-1.

— The equipment shall be installed in an enclosure that provides

a minimum ingress protection of IP54 in accordance with EN/

IEC 60079-0. The enclosure shall be accessible only with the

use of a tool.

— Transient protection shall be provided that is set at a level not

exceeding 140% of the peak rated voltage value at the supply

terminals to the equipment.

Installing Module into Cradle

Push module into cradle until you hear an audible click

indicating it is properly latched.

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

09

08

07

06

05

04

03

02

01

MODULE

1

CRADLE

2

DIN RAIL LOCK LATCH

3

Unlock Lock

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

09

08

07

06

05

04

03

02

01

MODULE CRADLE

4

DIN

rail

4

Drawing No. LP1122 Revised 03 2020

MODULE HOT SWAPPING

If the area is known to be non-hazardous (free of ignitable

concentrations), then a module can be removed and/or installed

into a cradle attached to the controller while power is applied.

However, it is NOT recommended to connect to or remove from

the controller, a module/cradle pair or group of modules/cradles,

while power is applied. The power should be turned off anytime

a cradle or group of cradles (with or without modules) is plugged

into or removed from the controller.

BLOCK DIAGRAM

A

POWER

SUPPLY

+

-

VDC

DA SERIES HOST

DA 6UIN MODULE

E

ISOLATED

POWER

SUPPLY

INPUT 4

F

ISOLATED

INPUT 5

G

ISOLATED

INPUT 6

D

ISOLATED

INPUT 3

C

ISOLATED

INPUT 2

B

ISOLATED

INPUT 1

WIRING

WIRING CONNECTIONS

All power and input wiring must be in accordance with Class I,

Division 2 wiring methods and in accordance with the authority

having jurisdiction.

All conductors should meet voltage and current ratings for each

terminal. When wiring the module, use the numbers on the label

to identify the position number with the proper function. Strip

the wire, leaving approximately 0.3" (7.5 mm) of bare wire

exposed. Insert the wire into the terminal, and tighten.

INPUT CONNECTIONS

THERMOCOUPLE VOLTAGE

RTD CURRENT

LEDs

STATUS LED

The red/green/blue Status LED is located at the top of the

module and provides information regarding the state of the

module. This includes indication of the various stages of the start-

up routine (power-up), as well as any errors that may occur.

LED COLOR(S) MEANING

Flashing Blue Module is booting.

Flashing Green Module is switching to configuration.

Green Module is performing normally.

Flashing Green/Purple Module is performing auto calibration.

Flashing Blue/Yellow Module is being flash upgraded by Crimson.

Flashing Red Error: general error with module.

Flashing Red/Green Error: module is controlling properly, but has lost

communication with the Host.

Flashing Yellow Error: no bus frequency /module is not enumerated

Flashing Red/Green/Blue Error: module is running the Factory Programming

Console.

CAUTION: Only UL listed wiring with temperature

ratings greater than 90 °C permitted for Class I, Division

2, Zone 2 and ATEX/IECex installations.

ATTENTION: Seul le câblage homologué UL avec des

températures nominales supérieures à 90°C est autorisé

pour les installations de classe I, Division 2 , zone 2 et

ATEX/IECex.

Terminals 17 to 24

Terminals 25 to 32

Terminals 9 to 16

Terminals 1 to 8

0-10V

4-20 mA

INPUT COM

TC/RTD+

RTD +EXC

01

02

03

06

04

05

08

07

14

09

11

10

13

12

16

15

20

17

19

18

21

22

24

23

29

28

26

25

27

32

31

30

N/C

N/C

6

5

4

2

1

3

0-10V

4-20 mA

INPUT COM

TC/RTD+

RTD +EXC

0-10V

4-20 mA

INPUT COM

TC/RTD+

RTD +EXC

0-10V

4-20 mA

INPUT COM

TC/RTD+

RTD +EXC

0-10V

4-20 mA

INPUT COM

TC/RTD+

RTD +EXC

0-10V

4-20 mA

INPUT COM

TC/RTD+

RTD +EXC

ISOLATEDISOLATEDISOLATEDISOLATEDISOLATEDISOLATED

0-10V

4-20 mA

INPUT COM

TC/RTD+

RTD +EXC

+

0-10V

4-20 mA

INPUT COM

TC/RTD+

RTD +EXC

VDC-

VDC+

0-10V

4-20 mA

INPUT COM

TC/RTD+

RTD +EXC

LOAD

POWER

+

+

_

0-10V

4-20 mA

INPUT COM

TC/RTD+

RTD +EXC

5

Revised 03 2020 Drawing No. LP1122

AL1 : AL6 – Alarm LEDs

The red Alarm LEDs indicate the presence of an alarm.

Whenever one of the alarms is active, the LED turns on.

FIRMWARE UPGRADE

The module’s firmware is stored in flash memory so that

software/ hardware conflicts are avoided, and so features can be

added in the future.

During a download, Crimson compares its own library of

firmware files with those stored in the module. If they do not

match, Crimson will download the necessary firmware.

RED LION CONTROLS TECHNICAL SUPPORT

If for any reason you have trouble operating, connecting, or

simply have questions concerning your new DA Module, contact

Red Lion’s technical support.

Support: support.redlion.net

Website: www.redlion.net

Inside US: +1 (877) 432-9908

Outside US: +1 (717) 767-6511

Red Lion Controls, Inc.

20 Willow Springs Circle York, PA 17406

ORDERING INFORMATION

DESCRIPTION PART NUMBER

DA 6 Universal Isolated Input Module DA M00I0 UIN6I 0000

Spaces in listed part numbers are shown to improve readability,

do not include when searching for or ordering these parts.

A listing of the entire DA Series family of products and accessories

can be found at www.redlion.net.

6

Drawing No. LP1122 Revised 03 2020

This page intentionally left blank.

7

Revised 03 2020 Drawing No. LP1122

This page intentionally left blank.

8

LIMITED WARRANTY

(a) Red Lion Controls Inc. (the “Company”) warrants that all Products shall be free from defects in material and

workmanship under normal use for the period of me provided in “Statement of Warranty Periods” (available at

www.redlion.net) current at the me of shipment of the Products (the “Warranty Period”). EXCEPT FOR THE

ABOVE-STATED WARRANTY, COMPANY MAKES NO WARRANTY WHATSOEVER WITH RESPECT TO THE

PRODUCTS, INCLUDING ANY (A) WARRANTY OF MERCHANTABILITY; (B) WARRANTY OF FITNESS FOR

A PARTICULAR PURPOSE; OR (C) WARRANTY AGAINST INFRINGEMENT OF INTELLECTUAL PROPERTY

RIGHTS OF A THIRD PARTY; WHETHER EXPRESS OR IMPLIED BY LAW, COURSE OF DEALING, COURSE

OF PERFORMANCE, USAGE OF TRADE OR OTHERWISE. Customer shall be responsible for determining that a

Product is suitable for Customer’s use and that such use complies with any applicable local, state or federal law.

(b) The Company shall not be liable for a breach of the warranty set forth in paragraph (a) if (i) the defect is a

result of Customer’s failure to store, install, commission or maintain the Product according to specicaons; (ii)

Customer alters or repairs such Product without the prior wrien consent of Company.

(c) Subject to paragraph (b), with respect to any such Product during the Warranty Period, Company shall, in its

sole discreon, either (i) repair or replace the Product; or (ii) credit or refund the price of Product provided that,

if Company so requests, Customer shall, at Company’s expense, return such Product to Company.

(d) THE REMEDIES SET FORTH IN PARAGRAPH (c) SHALL BE THE CUSTOMER’S SOLE AND EXCLUSIVE

REMEDY AND COMPANY’S ENTIRE LIABILITY FOR ANY BREACH OF THE LIMITED WARRANTY SET

FORTH IN PARAGRAPH (a).

COPYRIGHT

©2020 Red Lion Controls, Inc. All rights reserved. Red Lion and the Red Lion logo are trademarks of Red Lion Controls, Inc. All other

company and product names are trademarks of their respective owners.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

red lion DA 6UIN Module Manuel utilisateur

- Taper

- Manuel utilisateur

dans d''autres langues

- English: red lion DA 6UIN Module User manual

Documents connexes

-

red lion DA 8AO Module Manuel utilisateur

-

red lion DA 8DI Guide d'installation

-

red lion DA 8DI/8RO Module Guide d'installation

-

red lion DA 8 Relay Output Module Manuel utilisateur

-

red lion DA 8DI/8DO Module Manuel utilisateur

-

red lion DA 4UI and 2UI MIX I/O Modules Manuel utilisateur

-

red lion E3 Guide de démarrage rapide

-

red lion DA PID Module Manuel utilisateur

-

red lion 700_7000 Managed Industrial Ethernet Switches Hardware , Vol I & II Manuel utilisateur

-

red lion E3 Guide de démarrage rapide

Autres documents

-

Spectrum Controls 1756sc-IC32 Quick Start

-

Crimson AV M631 Guide d'installation

Crimson AV M631 Guide d'installation

-

Crimson VW4600 Manuel utilisateur

-

Dwyer Series TTE Manuel utilisateur

-

PR 2204V104-UK Manuel utilisateur

-

Allen-Bradley FLEX I/O 1794-IR8 Installation Instructions Manual

Allen-Bradley FLEX I/O 1794-IR8 Installation Instructions Manual

-

Christie Crimson HD31 Manuel utilisateur

-

ARDETEM TPIs 2A User Handbook Manual

ARDETEM TPIs 2A User Handbook Manual