KHM 190 HS

Instruction manual

Bedienungs- und Wartungsanleitung

Emploi et entyretien

Gebruiks- en onderhoudshandleiding

2 0794 999 900 06/11 Valid for serial No. 647 – XXX – XXXX

'(&/$5$7,212)&21)250,7<

ESAB Welding Equipment AB, S--695 81 Laxå, Sweden, gives its unreserved guarantee that the engine driven

welder KHM 190 HS with the code number 0794000880/1/4 complies with the Community Directives and related

modifications 98/37/CE - 73/23/CE - 89/336/CE and, in order to check the conformity, the following harmonized

standards EN 292-1 - EN 292-2 - EN 60974-1 - EN 60204-1 - EN 50199 and other standards or directives like

84/535/CE - ISO 8528 have been consulted .

Laxå 2001

Joakim Cahlin

ESAB Welding Equipment AB

695 81 LAXÅ

SWEDEN Tel. + 46 58 481000 fax +46 584 411924

*%

10/10/01 DC 190 H

-GB

Dear Customer,

We wish to thank you for having bought this product.

Please take time to read this manual and familiarize yourself with the machine before attempting to use it.

If you should have questions or problems please contact the nearest authorized Service Center. They have the experience

and original spare parts. The use of non-original spare parts will void the warranty.

TABLE OF CONTENTS

DESCRIPTION PAGE

GENERAL INFORMATION

INFORMATION ABOUT THIS MANUAL M 2

DESCRIPTION - SYMBOLS M 2.1

PRECAUTIONS - GENERAL M 2.5

PRECAUTIONS - ENGINE DRIVEN WELDERS M 2.5.1

TRANSPORT M 4.1

ASSEMBLY OF TROLLEY M 6

INSTALLATION INFORMATION M 2.6.1, M 2.7

OPERATION

UNPACKING M 3

PREPARING THE UNIT M 25

STARTING THE ENGINE M 26

STOPPING THE ENGINE M 27

CONTROLS M 31

USE AS A WELDER M 34

USE AS A GENERATOR M 37

MAINTENANCE M 43.1

STORAGE M 45.1

TECHNICAL DATA AND MACHINE DESCRIPTION M 51

SCHEMATICS AND SPARE PARTS

ORDERING SPARE PARTS R 1,

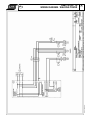

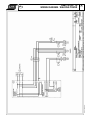

WIRING DIAGRAM – WELDING POWER M 61.2

WIRING DIAGRAM – AUXILIARY M 61.3

WIRING DIAGRAM – WELDING POWER M 61.4

DESCRIPTION - ELECTRICAL SYSTEM M 60

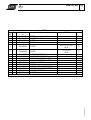

SPARE PARTS CG 4, CG 4.1,

SPARE PARTS CG 5, CG 5.1,

SPARE PARTS CG 6, CG6.1

KIT DECAL

TROLLEY KA 4

28/11/06 27252M1GB

TABLE OF CONTENTS

KHM 190 HS

M

1

GB

ü

'$1*(5286

ü

:$51,1*

ü

&$87,21

ü

,03257$17

ü

127(

ü

$77(17,21

86($1'0$,17(1$1&(

,1)250$7,21$%2877+,60$18$/

*(1(5$/,1)250$7,21

- In the envelope where you found this manual you will

also find an Owner’s manual for the engine, and ac-

cessories (if required).

This product has been designed for welding and genera-

tion of electrical power for tools and other electrical devices

used in construction; ANY OTHER USE, is not permitted

and we cannot be held responsible for injuries or damages

resulting from such incorrect use.

Our products are made in conformity with the safety norms

in force in order to avoid injury to persons or damage to the

machine or other things.

+ :DUUDQW\ LV QRW YDOLG LI QRW FDUULHG RXW E\

(6$%DXWKRUL]HGVHUYLFHDJHQW

Making modifications to the machine without our written

authorization will void the warranty and release us from

any liability.

$%2877+,60$18$/

Before using the machine please read this manual atten-

tively and follow the instructions contained in it. This will

help avoid problems, possible injury and damage to the

machine.

The manual is written for experienced, qualified personnel,

who are familiar with health and safety laws and related

regulations.

This manual is an integral part of the product and should be

kept in a safe place so that it will be available for consulta-

tion during the life of the product. If the machine is sold the

manual should be transferred to the new owner.

Some figures contained in this manual are designed to help

identify certain parts and may not correspond to the ma-

chine in your possession.

+ 1RWLFHWKHPDQXIDFWXUHUPD\PDNHLPSURYHPHQWVRU

PRGLILFDWLRQVWRWKHSURGXFWRULWVDFFHVVRULHVDVGH

VFULEHGLQWKLVPDQXDOZLWKRXWXSGDWLQJWKHPDQXDO

+($',1*686(',17+,60$18$/

The headings used in this manual are designed to call your

attention to potential hazards and important aspects of the

operation of the machine…

lndìcates a strong possíbility of severe personal injury or

death ìf ínstructions are not followed.

lndìcates a possibìlìty of personal ínjury or equipment dam-

age if ìnstructions are not followed

lndícates that equipment or property damage can result if

instructions are not followed.

These headings give helpful information about the prepara-

tion, operation and care of the machine.

0

2

11/9/00 ESABM2GB

*%

*(1(5$/6<0%2/6

6723²Read with great attention

Read with attention

:5(1&+Use the correct tools for the type of

work being done

:$51,1*6<0%2/6

$77(17,21 If this advice is not followed peo-

ple or things can be hurt or damaged.

+,*+92/7$*( Do not touch – risk of injury

or death.

),5( Risk of fire.

+($7 Hot surfaces.

(;3/26,9(Explosive material or danger of

explosion, in general.

12:$7(5'RQRWXVHZater as it can cause

shortcircuits or other damage.

12602.,1*&igarettes, matches or lighters

can start a fire or explosion.

$&,'6Danger of corrosion or burns.

6$)(7<6<0%2/6

8VHWKHFRUUHFWSURWHFWLYHGHYLFHVIRUWKHW\SHRIZHOG

LQJEHLQJGRQH

Use protective clothing, etc. specifically

designed for the type of welding being done.

3URWHFW\RXUVHOIZKHQGRLQJPDLQWHQDQFHRQWKHPD

FKLQH

It is advisable to protect yourself when carrying

out maintenance, such as filling the battery, refu-

elling, etc.

3D\DWWHQWLRQWRVDIHW\SUHFDXWLRQVZKHQPRYLQJWKH

PDFKLQH

Refer to the instructions before moving the ma-

chine

:HDULQGLFDWHGVDIHW\FORWKLQJ

It is compulsory to wear the personal pro-

tection items shown when using the equip-

ment.

8VHUHTXLUHGVDIHW\GHYLFHV

Safety devices suitable for the type of welding

and the location of the job must be used.

'RQRWXVHZDWHURQHOHFWULFDOILUHV

It is prohibited to use water to put our fires in

electrical equipment.

'RQRWWRXFKZLWKRXWKDYLQJGLVFRQQHFWHGWKH

HOHFWULFLW\

It is prohibited to work on the machine until the

electricity has been turned off.

:HOGLQJSURKLELWHG

It is forbidden to weld in areas containing explo-

sive gases.

06/03/00 ESABM2-1GB

86($1'0$,17(1$1&(

'(6&5,37,216<0%2/6

0

2.1

*%

ü ,03257$17

+ Read and understand these instructions.

+

Before installing, operating or servicing this equipment, read

the operating manuals of the welder and of the engine

.

+

Not observing the information in the manuals can result in

personal injury and/or damage to the equipment and other

property.

+

Respect all safety regulations and laws when operting this

equipment.

ü:$51,1*

'RQRWUHPRYHRUGLVDEOHSURWHFWLYHGHYLFHV

Removing or disabling protective devices on the ma-

chine is prohibited.

'RQRWXVHWKHPDFKLQHLILWLVQRWLQJRRGWHFKQLFDOFRQ

GLWLRQ

The machine must be in good working order before be-

ing used. Defects, especially those which. regard the

safety of the machine, must be repaired before using

the machine.

(1*,1()8(//,1*

⇒ Stop engine when fuelling.

⇒ Do not smoke, avoid open flames and sparks, and

do not use electric tools when fueling.

⇒ Unscrew the fuel cap slowly to let out the fuel va-

pours.

⇒ Do not over-fill the tank.

⇒ Avoid spilling fuel on hot engine.

⇒ Wipe up spilled fuel before starting engine.

⇒ Shut off fuel cock, if present, or remove fuel from

tank before moving machine

)25%$77(5<(48,33('81,7621/<

⇒ Sparks may cause the explosion of battery vapours

:$7(5&22/('(1*,1(621/<

⇒ Slowly unscrew the cooling liquid cap of a hot en-

gine to allow vapours to escape.

⇒ Hot vapor and heated cooling liquid under pressure

can burn face, eyes, skin.

F),567$,' In case the operator shold be sprayed by accident, from corrosive liquids a/o hot toxic gas or what-

ever event which may cause serious injuries or death, predispose the first aid in accordance with the ruling labour

accident standards or of local instructions.

Skin contact Wash with water and soap

Eyes contact Irrigate with plenty of water, if the irritation persists contact a specialist

Ingestion Do not induce vomit as to avoid the intake of vomit into the lungs, send for a doctor

Suction of liquids from lungs If you suppose that vomit has entered the lungs ( as in case of spontaneous vomit ) take the

subject to the hospital with the utmost urgency

Inhalation In case of exposure to high concentration of vapours take immediately to a non polluted zone

the person involved

F),5(35(9(17,21 In case the working zone,for whatsoever cause goes on fire with flames liable to cause se-

vere wounds or death, follow the first aid as described by the ruling norms or local ones.

(;7,1&7,210($16

Appropriated Carbonate anhydride (or carbon dioxyde) powder, foam, nebulized water

Not to be used Avoid the use of water jets

Other indications Cover eventual shedding not on fire with foam or sand, use water jets to cool off the surfaces

close to the fire

Particular protection Wear an autorespiratory mask when heavy smoke is present

Useful warnings Avoid, by appropriate means to have oil sprays over metallic hot surfaces or over electric

contacts (switches,plugs,etc.). In case of oil sprinkling from pressure circuits, keep in mind

that the inflamability point is very low.

06/03/00 ESABM2-5GB

7+(0$&+,1(0867127%(86(',1$5($6:,7+(;

3/26,9($70263+(5(

:$51,1*

ü

&$87,21

ü

:$51,1*

86($1'0$,17(1$1&(

35(&$87,216*(1(5$/

0

2.5

*%

35(&$87,216

The operator of the welder is responsible for the security of the people who work with the welder and for those in the vi-

cinity.

The security measures must satisfy the rules and regulations for engine driven welders.

The information given below is in addition to the local security norms.

⇒ Make sure that the area is safe before starting any

welding operation.

⇒ Do not touch any bare wires, leads or contacts as they

may be live and there is danger of electric shock which can

cause death or serious burns. The electrode and welding

cables, etc. are live when the unit is operating.

⇒ Do not touch any electrical parts or the electrode while

standing in water or with wet hands, feet or clothes.

⇒ Insulate yourself from the work surface while welding.

Use carpets or other insulating materials to avoid physical

contact with the work surface and the floor.

⇒ Always wear dry, insulating gloves, without holes, and

body protection.

⇒ Do not wind cables around the body.

⇒ Use ear protections if the noise level is high.

⇒ Keep flamable material away from the welding area.

⇒ Do not weld on containers which contain flamable ma-

terial.

⇒ Do not weld near refuellng areas.

⇒ Do not weld on easily flamable surfaces.

⇒ Do not use the welder to defrost (thaw) pipes.

⇒ Remove the electrode from the electrode holder, when

not welding.

⇒ Avoid inhaling fumes by providing a ventilation system

or, if not possible, use an approved air breather.

⇒ Do not work in closed areas where there is no fresh air

flow.

⇒ Protect face and eyes (protective mask with suitable

dark lens and side screens), ears and body (non-flamable

protective clothes).

86($1'0$,17(1$1&(

35(&$87,216(1*,1('5,9(1:(/'(5

0

2.5.1

19/6/00 ESABM2-5-1GB

$77(17,21

*%

ü127(

86($1'0$,17(1$1&(

75$163257

0

4.1

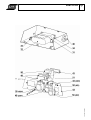

In case you have to move or transport the machine, follow the instructions as shown in the

figures.

Ship the machine ZLWKRXWpetrol in the tank, ZLWKRXW oil in the engine and ZLWKRXW

electrolyte

in the battery. Be sure that the transportation devices are adequate for the size and weight of

the machine.

'2127

75$163257$&&(6625,(62527+(5,7(06:+,&+&28/',1&5($6(

7+(:(,*+7$1'25&+$1*(7+(&(17(52)*5$9,7<2)7+(0$&+,1(

'2127

'5$*7+( 0$&+,1(2572:,72138%/,&52$'6 81/(66,7,602817('

21$+202/2*$7('75$,/(5

Not following these instructions could cause injury or damage to the machine.

20/6/00 ESABM4-1GB

:HLJKWPD[SHUSHUVRQNJ

7RWDOPD[ZHLJKWNJ

*%

ü

$77(17,21

The accessory cannot be removed from the machine

and used separately (actioned manually) for the

transport of loads or anyway for used different from

the machine movements.

E

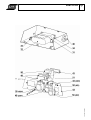

1RWH For assembling the generating set on the

trolley please keep to following instructions:

1) -

Lift the generating set (by means of suitable hook).

.+0+6

.+0<6

3%

ü $77(17,21

Do not substitute the original tires with other types

86($1'0$,17(1$1&(

$66(0%/<2)752//(<.+0+6<6

0

6

*%

22/1/01 ESABM6GB

,167$//$7,21,1)250$7,21

GASOLINE ENGINES

•

Use in open space with fresh air flow or vent exhaust

gases, which contain the deadly carbon-monoxide,

away from the work area.

POSITIONING THE MACHINE

Place the machine on a level surface at a distance of at

least 1,5 m from buildings or other structures.

If the surface is not level be sure that the angle of the ma-

chine does not exceed the values shown in the drawings

below.

+ Assure that the hot air and/or exhaust gas from the

machine are vented and are not recirculated in the ma-

chine. Hot air and/or exhaust gas which is recirculated wll

cause overheating of the machine and poor combustion

in the engine.

+ Make sure that the machine does not move during

operation.

Protect the machine from rain and do not put

it in a location where there is danger of flood-

ing.

:DWHULQILOWUDWLRQFDQFDXVHVKRUWFLUFXLWVZKLFKFDQ

EH GDQJHURXV IRU SHUVRQV DQG FDQ GDPDJH WKH PD

FKLQH

The degree of protection, of the machine is written the

rating plate and in this manual at the "Technical Data"

page.

MOVING THE MACHINE

Before moving the machine turn off the engine and dis-

connect all cables, which could impede the move.

86($1'0$,17(1$1&(

,167$//$7,21,1)250$7,21

0

2.6.1

20/6/00 ESABM2-6GB

*%

28/11/06 27252M2-7

M

2.7

KHM 190 HS - INSTALLAZIONE - INSTALLATION -

A

UFSTELLUNG -

INSTALACIÓN - INSTALLATIONEN - ASENNUS - ΕΓΚΑΤΑΣΤΑΣΗ – INSTALLASJON -

INSTALLATIE - INSTALAÇÃO - INSTALACJA

ü*(1(5$/3$&.,1*,1)250$7,21

813$&.,1*7+(0$&+,1(

1) Take the machine (C) out of the carton.

Locate the User’s Manual (B), which is

packed together with the engine

manual and accessories in a plastic

envelope (A). This envelope may be

under or inside the machine.

2) Check the rating plate on the machine

and confirm that the serial number and

model are the same as shown on the

packing note/invoice.

1% For further information on preparing

the unit for use refer to the related parts of

this manual.

02/03/00 ESABM3G

Upon receipt of the goods make sure that the product

has not been damaged during transport.

In case of damage or missing items you must inform

your freight forwarder immediately.

Packing materials must be disposed of

according to local regulations.

86($1'0$,17(1$1&(

813$&.,1*

0

3

*%

20/6/00 ESABM25GBH

86($1'0$,17(1$1&(

35(3$5,1*7+(81,7*$62/,1((1*,1(6

0

25

ü

:$51,1*

Gasoline is highly flammable. Refuel in well venti-

lated area with the engine stopped. Do not fuel in

the presence of open flames. Be careful not to spill

fuel. Spilled fuel or vapor may ignite. If any fuel is

spilled be sure the area is dry before starting the en-

gine.

/8%5,&$17

The engine is shipped without oil. Use a 4-stroke, high de-

tergent, premium quality motor oil certified to meet or ex-

ceed U.S. automobile manufacturer’s requirements for

service classification SG, SF. Motor oils classified SG, SF

wíll show this designation on the container. Refer to the

engine manual for recommended viscosities.

SAE lOW-30 is recommended for general, all temperature

use. lf single viscosity oil is used, select the appropriate

víscosity for the average temperature in your area.

To check the oil level:

1. Remove the oil filler cap and wipe the dipstíck clean.

2. Insert the dipstick into the oíl filler neck, but do not screw

it in.

3. If the level is low, fill to the top of the oil filler neck wíth

the recommended oil.

(1*,1(:,7+2,/$/(57'(9,&(

The Oil Alert System is designed to prevent engine damage

caused by an insufficient amount of oil in the crankcase.

Before the oil level in the crankcase can fall below a safe

limit, the Oil Alart System will automatically stop the engine

(the engine switch wili remain in the ON position).

If the engine stops and will not restart, check the engine oil

level.

$,5),/7(5

Check that the dry air filter is correctly installed and that

there is no air leakage around the filter which could let unfil-

tered air into the engine.

)8(/

Fill the tank with automotive gasoline (unleaded or lowlead

is preferred to minimize combustion chamber deposits).

*5281'&211(&7,21

A good ground is obligatory

for all models with GFI (ground

fault interrupter). This protective device will not

protect the

operator unless there is a good ground.

+ Use a good quality ground cable and connect it to the

grounding point of the machine. Follow all local rules

and/or regulations.

Once the above operations have been completed, the ma-

chine can be used.

*%

ü

127(

'RQRWDOWHUWKHIDFWRU\DGMXVWPHQWRIWKHHQJLQHDQG

GRQRWWRXFKDQ\VHDOHGSDUWV

28/5/01 ESABM26GB

86($1'0$,17(1$1&(

67$57,1*7+(*$62/,1((1*,1(

0

26

&KHFNGDLO\

$//

1. Turn the fuel valve to the ON position.

2. Move the choke lever to the CLOSE position.

127(: Do not use the choke if the engine is warm or the air

temperature is high.

3. The regulation is made by means of the knob for weldind

current control placed on the front panel.

4. Start the engine:

•

5(&2,/67$57

Turn the engine switch to the ON position.

Pull the starter grip lightly until resistance is felt, then pull

briskIy.

+ :$51,1*

'RQRWDOORZWKHVWDUWHUJUtSWRVQDSEDFNDJDLQVWWKH

HQJLQH

5HWXUQLWJHQWO\WRSUHYHQWGDPDJHWRWKHVWDUWHU

*%

+Before stopping the engine LWLVFRPSXOVRU\ to:

- disconnect or shut off any loads connected to the unit’s

auxiliary output.

- stop welding.

7RVWRSWKHHQJLQH

To stop the engine in an emergency, turn the engine switch

to the OFF position. Under normal conditions, use the

folfowing procedure:

1. Turn the welding current regulator knob in anti-clockwise

direction.

2. Turn the engine switch to the OFF position.

3. Turn the fuel valve to the OFF position.

28/5/01 ESABM27GB

86($1'0$,17(1$1&(

67233,1*7+(*$62/,1((1*,1(

0

27

*%

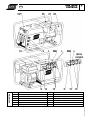

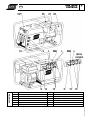

9 Welding socket ( + ) 27 Muffler

10 Welding socket ( - ) 59B Aux current circuit breaker

12 Earth terminal D Ground fault interrupter ( 30 mA )

15 A.C. socket L A.C. output indicator

16 Accelerator levelr T Welding current regulator

22 Engine air filter

'(6&5,37,21

26 Fuel tank cap

0

31

28/5/01 27252M31GB

.+0+6

&21752/6

.+0+6

&21752/6

*%

&211(&7:(/',1*&$%/(6

For direct current electrode positive, connect work cable to

negative (-) terminal and electrode holder to positive (+)

terminal. For direct current electrode negative, reverse ca-

ble connections. Turn them clockwise to lock them in posi-

tion. Loose plugs will result in poor welding and damage to

both plug and socket.

+ Make sure that the ground clamp makes a good connec-

tion and is near the welding posítion.

:(/',1*&855(175(*8/$7,21

Once the welding current range has

been chosen by attaching the elec-

trode holder lead to the corresponding

socket, the welding current is adjusted

by turning the knob on the front panel.

The knob regulates the rpm of the en-

gine.

ü

$77(17,21

To reduce the risk of electromagnetic interference, ke-

ep the welding cable length short and keep them on or

near the ground. Ensure that the machine is

grounded. If possible, welding operations should not

be done near sensitive electronic devices.

386+$1'

7:,67

ü

$77(17,21

When the machine is running the auxiliary power sock-

ets and the welding sockets are live.

ü

$77(17,21

Be sure that the machine is grounded before using it.

Without a ground the GFI (ground fault interrupter) will

not

function.

20/6/00 ESABM34GB

86($1'0$,17(1$1&(

86($6$:(/'(5

0

34

*%

(1*,1(63((')25&255(&792/7$*($1'

)5(48(1&<

Turn the welding current regulating knob fully clockwise to

put the engine at its maximum rpm. If the engine is not at

full rpm the voltage and the frequency of the auxiliary power

will not be correct. At no load the voltage can be 10%

above nominal and at full load the voltage can be 10% be-

low nominal.

3/8*6$1'&$%/(6

Before connecting a load to the socket check that the cables

are in good condition and that the plug is wired correctly.

32:(521/,*+7

The light (L), located above each socket, lights up when

there is power available from the socket.

+ If the warning light does not light, check that the en-

gine is at maximum rpm, that the GFI (ground fault in-

terrupter) is inserted and that the circuit breaker is

functioning.

When drawing power from more than one socket at the

same time, the power available is that indicated for each

socket but the total cannot exceed the maximum shown on

the rating plate.

*5281' )$8/7 ,17(55837(5 &,5&8,7

%5($.(5*),DOVRFDOOHG($57+/($.$*(

&,5&8,7%5($.(5(/&%

Turn on the GFI (ground fault

interrupter) (D) by pushing the

lever upwards.

The GFI (ground fault interrupter) is a safety device, which

protects the operator in the event of a malfunction. The GFI

(ground fault interrupter) shuts off the power to the three

and single-phase sockets there is a leakage current of more

than 30mA.

&,5&8,7%5($.(56)2562&.(76

If you overload the socket the circuit breaker will automati-

cally switch off the power.

To reset the circuit breaker, disconnect the load, wait a few

seconds for the circuit breaket to cool down and then push

the button. The button should stay depressed. If the circuit

breaker button does not stay in, let it cool down and try

again. If it still will not stay in call the service.

Before reconnecting the load check that the power required

is within the rating of the socket. A load which is too large

for the socket will cause the circuit breaker to intervene. If,

after reconnecting the load, the circuit breaker opens again,

check the connections, wires, etc. of the load to find the

fault.

03/03/00 ESABM37GB

ü

:$51,1*

When the machine is running the auxiliary power sock-

ets and the welding sockets are live.

ü

&$87,21

The auxiliary output should never be connected to

the mains or to any other source of electric power

35(6672

5(6(7

ü

:$51,1*

Be sure that the machine is grounded before using it.

Without a ground the GFI (ground fault interrupter) will

not

function.

86($1'0$,17(1$1&(

86($6$*(1(5$725

0

37

*%

0$,17(1$1&(2)7+(0$&+,1(

Maintenance refers to all operations regarding the control

and replacement of mechanical and electrical parts subject

to wear. In addition it refers to the control and topping up or

replacement of fluids such as fuel, oil and the regular clean-

ing of the machine.

Repairs refers to the substitution of worn or damaged parts

and repairs should be carried out by Authorized Service

Centers.

Refer to the Engine Manufacturer’s Manual for the mainte-

nance instructions for the engine. Periodic maintenance

should be performed according to the schedule shown in

this manual.

On a regular basis check that there are no obstructions in

the aspiration/exhaust ducts of the alternator, the engine or

the housing which could restrict the flow of cooling air.

'5<$,5),/7(5

Replace the air filter cartridge every 200 hours under normal

conditions and every 100 hours in dusty environents.

$6<1&+521286$/7(51$725

No maintenance is necessary, as the alternator has no

brushes or slip rings, and there are no devices for regulation

of the output.

:$51,1*/$%(/6$1''(&$/6

Check warning labels and decals once a year and UHSODFHG

if missing or unreadable.

&$%/(6$1'&211(&7,216

Periodically check the condition of the cables and tighten

the connections.

86($1'0$,17(1$1&(

0$,17(1$1&(

0

43.1

ü

,03257$17

When carrying out maintenance operations be

careful to avoid polluting the environment with

the materials used during maintenance. Follow

all local health and safety regulations.

ü

:$51,1*

• Maintenance and repair work should only be done by TXDOLILHG personnel.

• Stop the engine before doing any work on the machine. If for any reason the

machine must be operated while working on it, EHFDUHIXOQRWWRWRXFK

rotating

parts, hot surfaces, live wires, etc. which may be unprotected.

• Remove protective guards only when necessary to perform maintenance and re-

place them immediately after the maintenance is completed.

• Use suitable tools and wear suitable clothes.

• Do not modify the machine without prior authorization.

+27VXUIDFH

FDQ

KXUW\RX

029,1*

3$576

FDQLQMXUH

*%

20/6/00 ESABM43-1GB

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

dans d''autres langues

- English: ESAB KHM 190 HS User manual

- Deutsch: ESAB KHM 190 HS Benutzerhandbuch

- Nederlands: ESAB KHM 190 HS Handleiding

Documents connexes

-

ESAB KHM 190 YS Manuel utilisateur

-

ESAB KHM 190 HS Manuel utilisateur

-

ESAB KHM 300 YS - CC/CV Manuel utilisateur

-

ESAB KHM 300 YS - CC/CV Manuel utilisateur

-

ESAB KHM 350 YS - CC/CV Manuel utilisateur

-

ESAB KHM 350 YS - CC/CV Manuel utilisateur

-

ESAB KHM 500 PS - CC/CV Manuel utilisateur

-

ESAB KHM 351 YS Manuel utilisateur

-

ESAB KHM 405 YS Manuel utilisateur

-

ESAB KHM 525 PS Manuel utilisateur