Red Rock 9015918 Le manuel du propriétaire

- Catégorie

- Fendeuses de bûches

- Taper

- Le manuel du propriétaire

27 TON LOG SPLITTER

Owner’s Manual

ASSEMBLY AND OPERATING INSTRUCTIONS

This safety alert symbol identifies important safety messages in

this manual. Failure to understand and follow safety, assembly and

operating instructions could result in serious injury or death.

REV050321 LSP2700

- 2 -

Table of Contents

Important Safety Information..................................................................................................... 3-6

Intended Use................................................................................................................3

Personal Protective Equipment........................................................................................ 3

Safety Decals.................................................................................................................3-4

General Safety.................................................................................................................. 5

Work Area.......................................................................................................................... 5

Preparing Logs for the Splitter............................................................................................ 5

Operation of the Log Splitter............................................................................................... 5

General Repair............................................................................................... 5

Maintenance Safety......................................................................................... 6

Fire Prevention.................................................................................................................... 6

Towing Safety..................................................................................................................... 6

Assembly Instructions................................................................................................................. 7-13

Controls and Features Identification…………………………………………………………………….14

Operating Instructions............................................................................................................. 15-17

Engine Oil Recommendations......................................................................................... 15

Starting Instructions......................................................................................................... 15

Operation................................................................................................................... 15-16

Towing............................................................................................................................. 16

Maintenance............................................................................................................... 16

Splitter Positions…………………………………………………………………………….…. 17

Troubleshooting…………................................................................................................................18

Specifications................................................................................................................................ 19

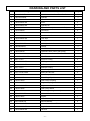

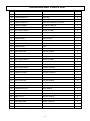

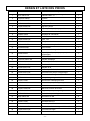

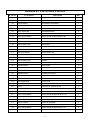

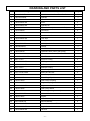

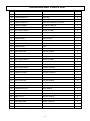

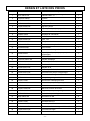

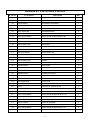

Drawing and Parts List.............................................................................................................. 20-23

Limited Warranty………….............................................................................................................. 24

- 3 -

WARNING: Read and understand all instructions and safety information in this manual and on safety

decals before assembling or operating the log splitter. Failure to understand and follow all

instructions and safety information may result in serious injury or death. Persons who have not read

the manual should never operate the log splitter. A log splitter can be dangerous when assembled

and/or used improperly. Do not operate the log splitter if you have any questions concerning safe

operation. Please call the technical support department at 1-888-723-6534 for answers to any

questions.

WARNING: This product can expose you to chemicals including lead and lead compounds which are

known to the State of California to cause cancer and birth defects or other reproductive harm. For more

information, go to www.P65Warnings.ca.gov.

INTENDED USE

NEVER use the log splitter for any purposes other than splitting wood. The log splitter is designed only for splitting

wood. Using the log splitter for any other purpose can result in serious injury or death and may void the warranty.

PERSONAL PROTECTIVE EQUIPMENT

BEFORE operating the log splitter always be sure to put on appropriate safety gear, including eye protection

(goggles), steel-toed shoes and tight-fitting gloves (without loose cuffs or draw strings). Also, the use of proper hearing

protection (headphones) is required when operating the log splitter.

SAFETY DECALS

ALWAYS check all safety warning decals are in good condition and readable. Immediately replace any missing or

damaged decals. Please call 1-888-723-6534 to obtain replacement decals.

DANGER

WARNING

CAUTION

IMPORTANT SAFETY INFORMATION

DANGER indicates a hazardous situation which, if not

avoided, will result in serious injury or death.

WARNING indicates a hazardous situation which, if

not avoided, could result in serious injury or death.

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

NOTICE

- 4 -

IMPORTANT SAFETY INFORMATION

- 5 -

GENERAL SAFETY

• ALWAYS keep the operator’s manual in the canister for reference. Review the manual periodically and as questions

arise.

• ALWAYS keep all bystanders and pets a minimum of 10 feet away from your work area when operating this log

splitter. The operator alone should be near the log splitter during use.

• NEVER activate the control valve until all people are clear of the work area.

• NEVER wear loose clothing or jewelry when operating the log splitter. Keep clothing and hair away from all moving

parts when operating the log splitter.

• NEVER allow adults without proper instruction and operational knowledge to use the log splitter.

• NEVER operate the log splitter when under the influence of drugs, alcohol or medication or when otherwise not

alert enough to operate the log splitter.

WORK AREA

• NEVER operate the log splitter on wet, icy, slippery or unstable ground.

• NEVER operate the log splitter in an enclosed area. Exhaust fumes contain carbon monoxide which is deadly

poison.

• ONLY operate the log splitter with adequate lighting.

• ONLY operate the log splitter on level ground. Operating on a slope may cause the log splitter to move and/or logs to

fall off the log splitter.

• ALWAYS keep the work area free of debris. Remove any split wood around the log splitter immediately to avoid

tripping.

PREPARING LOGS FOR THE SPLITTER

Log ends should be cut as squarely as possible before placing logs on the log splitter. The square shape of the log

helps prevent the logs from moving during splitter operation. The maximum log length is 26 inches.

OPERATION OF THE LOG SPLITTER

ONLY operate the log splitter from the operator zone as shown in the diagram. Operating the log splitter outside the

operator zone can result in serious injury or death.

• ALWAYS chock the wheels to prevent movement of the log splitter while in

operation.

• KNOW how to stop the log splitter and disengage the controls before

operating it.

• NEVER try to split a log against the grain.

• NEVER try to split two logs at the same time.

• NEVER step over the log splitter during operation.

• NEVER reach or bend over the log splitter to pick up a log.

• NEVER attempt to load the log splitter when the wedge is in motion.

• NEVER place hands or feet between the log and splitting wedge during forward or

reverse stroke as this could result in serious injury or death.

• NEVER use your foot, a rope or any extension device to operate the control lever

on the valve. Only use hands to operate control levers.

• NEVER touch the muffler and other hot areas of the engine. Allow

time for the engine to cool down before touching.

• NEVER move the log splitter while the engine is running. Turn off the engine

before leaving the log splitter.

• NEVER leave the log splitter running unattended, even for a short period of time.

GENERAL REPAIR

• NEVER operate the log splitter if it is in poor mechanical condition or in need of repairs.

• NEVER alter/modify the log splitter in any way. Any alterations/modifications may make the log splitter unsafe and

voids the warranty.

• NEVER perform any service or repair on the log splitter without first removing the spark plug wire.

• NEVER tamper with the engine settings. The maximum engine speed is preset by the manufacturer and is within

safety limits. Refer to the engine owner’s manual for the particular log splitter.

• ALWAYS perform all recommended maintenance procedures before using the log splitter.

• ALWAYS check the level of hydraulic oil and engine oil before operating the log splitter.

• NEVER use hands to remove a stuck log while the log splitter is running.

• ALWAYS replace all damaged or worn parts immediately.

IMPORTANT SAFETY INFORMATION

- 6 -

• ALWAYS check regularly that all nuts, bolts, screws, hydraulic fittings and hose clamps are tight.

• ALWAYS be sure any and all replacement parts meet the manufacturer’s specifications.

MAINTENANCE AND SAFETY

• The mechanical and hydraulic systems of the log splitter require careful inspection. Be sure to replace damaged

hydraulic hoses and components.

• NEVER check for leaks of hydraulic fluid by using your hands. Leaking hydraulic fluid under pressure can potentially

penetrate the skin causing SERIOUS INJURY or even DEATH. Leaks can be safely detected by holding a piece of

cardboard over the suspected leak and looking for discoloration.

• NEVER remove the cap from the hydraulic tank while the log splitter is running. The tank contains hot oil under

pressure which could cause serious injury if released from the tank.

• NEVER adjust the relief valve setting. The pressure relief valve on the log splitter is preset at the factory. Only a

qualified service technician should perform any adjustments.

• ALWAYS immediately seek medical attention if injured by escaping hydraulic fluid. Serious infections or reactions

can develop if proper medical treatment is not administered immediately.

• ALWAYS check the system is not under any pressure by shutting off the engine and moving the valve control handle

back and forth. Check for pressure before loosening or removing any hydraulic fitting.

FIRE PREVENTION

• ONLY refuel the log splitter in clear areas with no gas fumes and no spilled gas.

• NEVER operate the log splitter near flames, sparks or smoke. Hydraulic oil and gasoline are flammable and

potentially explosive.

• NEVER add fuel while the engine is hot or running. Allow the engine to cool completely before refueling.

• If gasoline spills, move the log splitter away from the area of the spill and avoid creating any source of ignition.

• ALWAYS securely replace the gas cap.

• ALWAYS clean wood debris from the muffler area of the engine.

• ALWAYS store gasoline in an appropriate, tightly sealed container. Store the gas container in a cool, dry place and

away from any heat sources.

IMPORTANT NOTE RE: SPEAK ARRESTER-REGULATION:

As a precautionary measure against possible flying sparks, always have a Class B fire extinguisher on hand when

operating the log splitter in dry areas. The log splitter is equipped with an internal combustion engine that generates

heat and potential flying sparks. Only use the log splitter on or near any unimproved, forest-covered, brush-covered or

grass-covered land if the engine’s exhaust system is equipped with a spark arrester in compliance with any applicable

local or state laws. Spark arresters should be effectively maintained and serviced. In the state of California, a spark

arrester is required by law and other states have similar laws. Federal laws will apply when operating the log splitter

on federal land. Always research and comply with applicable state, local and federal laws and regulations. A spark

arrester muffler is optional and available as an accessory at your nearest engine dealer.

TOWING SAFETY

• NEVER carry cargo or wood on the log splitter.

• NEVER allow anyone to sit or ride on the log splitter.

• NEVER move the log splitter over hilly or uneven terrain without a tow vehicle and/or adequate help.

• NEVER exceed weight capacity of ball or load limits of coupler.

• NEVER exceed speeds of 45 mph when towing the log splitter. Towing the log splitter at speeds higher than 45 mph

could result in loss of control, damage to the equipment, and/or serious injury or death. Adjust towing speeds for the

terrain and conditions. Utilize extra caution when towing over rough terrain. Avoid sharp turns and steep angles when

towing the log splitter.

• ALWAYS attach safety chains when towing the log splitter.

• ALWAYS confirm coupler tightness every time before towing and after towing 50 miles.

• ALWAYS use caution when backing up with the log splitter in tow as it could jackknife.

• ALWAYS accommodate for the added length of the log splitter when turning, parking, crossing intersections and

always when driving while towing the log splitter.

• ALWAYS disconnect the log splitter from the towing vehicle before operating.

• ALWAYS know and comply with all local and state regulations governing towing, licensing, and lights before towing

the log splitter.

• ALWAYS check before towing that the log splitter is correctly and securely attached to the towing vehicle and that

the safety chains are secured to the hitch or bumper of the vehicle with enough slack to allow for turning. Always use

a Class I or above; 2” ball for connecting to the log splitter.

• ALWAYS replace damaged ball couplers.

• ALWAYS turn the fuel shut off valve on the engine to the “OFF” position before towing the log splitter. Failure to turn

off the engine before towing may flood the engine and damage engine oil.

IMPORTANT SAFETY INFORMATION

- 7 -

TOOLS REQUIRED

• Screw Driver

• Hammer

• Band Cutter

• 17mm and 19mm Wrenches

• Large Adjustable Wrench

STEP 1: Unpack Unit

1.1 Remove the wrapping film.

1.2 Remove log cradle, engine oil jug and wheel assembly and set aside.

STEP 2: Connect Clear Hose

2.1 Remove the cable tie and protective bag on the clear hose and gear pump. Remove the red plug from the gear

pump connector.

2.2 Connect the clear hose to the end of the gear pump connector by tightening with the clamp (the clamp comes

attached to the clear hose).

ASSEMBLY INSTRUCTIONS

- 8 -

STEP 3: Attach the Wheel

3.1 Remove the nuts (73) and bolts (58) from the wheel axle.

3.2 Insert the wheel into the wheel axle of the hydraulic reservoir, secure with the previously removed nuts and bolts

using two 17mm wrenches.

STEP 4: Attach Hydraulic Reservoir and Tow Bar Assembly

4.1 Remove the two lock pins attached to the tank assembly and steel stand.

4.2 Pull out the safety pin on the support leg then rotate the support leg to the down position.

4.3 Grasp the top of the tongue assembly, then rotate the tongue and tank assembly down until wheels sit on the

floor.

4.4 Position the tank assembly in front of the beam.

4.5 Pull out the hitch pin and R-pin that come attached to the mounting rack. Attach the mounting rack and tank by

reinserting the hitch pin.

4.6 Hang the red strap on the hitch tongue, allowing the assembler/operator to step on the strap.

- 9 -

STEP 5: Remove the Plates Securing Beam to Stand and Secure the Beam to Tank.

5.1 Remove the bolts, nuts and the beam that hold down the plates using two 17mm wrenches.

5.2 Remove the hitch pin (17) and R-Clip-pin (20) from the beam.

STEP 6: Rotate and Secure the Beam

6.1 Lower the beam to the horizontal position. (NOTE: Step on the strap with one foot to avoid the tongue moving up

when lowering the beam.)

6.2 Connect the beam and the hydraulic reservoir using the large hitch pin (17) and the R-Clip-pin (20).

CAUTION: Moving the beam from vertical to horizontal positions can cause the tongue to rise up. Step on the

strap to hold down the tongue or have a second person assist and hold down the ball coupler.

- 10 -

STEP 7: Remove the Mounting Rack and Discard

7.1 Remove the two R-Clip pins under the beam, then pull out the hitch pin and remove the mounting rack and

assembly pins.

7.2 Discard the removed pins and the mounting rack.

STEP 8: Install Metal Plug/Dipstick

8.1 Retrieve the metal plug/dipstick (25) from the manual canister and use it to replace the temporary plastic one

from the hydraulic reservoir. The temporary plastic plug may be discarded.

NOTE: Remove the temporary plastic plug slowly as there may be pressure in the tank.

- 11 -

STEP 9: Attach Hydraulic Hose

9.1 Remove the connector and the hose plugs. Both plugs may be discarded.

9.2 Attach the hydraulic hoses (6 and 15) to the filter assembly and the pump.

The hydraulic hose (6) with a 90°degree fitting attaches to the filter assembly.

The Ø11x2.5 O-Ring (18) and Ø17x2.5 O-Ring (69) are preassembled in the connector.

Keep O-Rings in place during assembly.

A small amount of oil may come out of the hoses when the caps are removed. To prevent oil dripping on

the ground, use a small pail to catch any oil.

Each connection requires only one O-Ring. Both the hose and the fitting sides have O-Rings so remove

one O-Ring before installing the hoses. Save the extra O-Ring for possible future use/repair.

STEP 10: Attach Axle Cap and Control Lever

10.1 Use a black plastic bushing to fix the axle cap (39). Cover the black bushing on the axle cap, then use a

rubber/wooden hammer to knock the end of the plastic bushing and attach the axle cap onto the wheel.

10.2 Remove the spring cotter pin and the retaining pin from the control valve. Rotate the control lever to the vertical

position and secure with the retaining pin and the spring cotter pin.

- 12 -

STEP 11: Attach the Log Cradle

11.1 Attach the log cradle (59) to the beam with the Ø12 flat washer (63) and the M12 nylon lock nut (12) using a

19mm wrench.

STEP 12: Add Engine Oil

12.1 Make sure the log splitter is on a level surface.

12.2 Remove the oil fill cap/dipstick to check the oil level.

12.3 Refer to the separate owner’s engine manual to determine the necessary quantity of engine oil; add engine oil

to the proper level and replace the oil fill cap/dipstick.

12.4 Check the engine oil level daily and add oil as necessary to maintain the proper level.

NOTICE: During the break-in period check the engine oil level often. When initially using the log splitter the

operator should check the engine oil level frequently to ensure proper function.

DO NOT attempt to crank or start the engine before it has been properly filled with the recommended type and amount

of engine oil. Damage to the log splitter resulting from a failure to follow these instructions will void the warranty.

STEP 13: Add Gasoline to the Engine

13.1 Use only clean, fresh, regular unleaded fuel with a minimum 87 octane rating.

13.2 DO NOT mix oil with fuel.

13.3 Remove the fuel cap and slowly add fuel to the tank. DO NOT overfill and allow for approximately a ¼ inch of

space for fuel expansion.

13.4 Tightly screw on the fuel cap and clean/wipe away any spilled fuel.

- 13 -

DANGER

Log splitter engine exhaust contains carbon monoxide, a colorless, odorless, poison gas. Breathing carbon

monoxide may cause nausea, dizziness, fainting or death. If you start to feel dizzy or weak, immediately

cease operation and get to fresh air and seek medical attention.

Log splitters should be operated only outdoors and in well-ventilated areas.

DO NOT operate the log splitter inside any building, enclosure or compartment.

DO NOT allow exhaust fumes to enter a confined area through windows, doors, vents or other openings.

DANGER CARBON MONOXIDE, using a log splitter indoors CAN KILL YOU IN MINUTES.

CAUTION

Fuel and fuel vapors are highly flammable and extremely explosive.

Fire or explosion can cause severe burns or death.

Unintentional startup can result in entanglement, traumatic amputation or laceration.

Only use regular unleaded gasoline with a minimum 87 octane rating.

DO NOT mix oil and gasoline together.

Fill tank approximately ¼” below the top of the tank to allow for fuel expansion.

DO NOT fill fuel tank indoors or when the engine is running or hot.

DO NOT light cigarettes or smoke when filling the fuel tank.

STEP 14: Check Hydraulic Oil

14.1 The log splitter needs to be on a flat level surface before checking or adding the hydraulic oil.

14.2 The log splitter was prefilled with 3.1 gallons of AW32 hydraulic oil before shipping. AW46 and universal

hydraulic oil are other acceptable types of hydraulic oil to use with the log splitter

14.3 Start the engine and use the control lever to extend and retract the wedge several times to remove air from the

lines.

14.4 With the wedge retracted, check the hydraulic oil level again and fill if necessary.

14.5 To enhance engine start up, automatic transmission fluid can be used when operating in temperatures

below 32 degrees.

WARNING

DO NOT remove the hydraulic oil fill cap when the engine is running or hot. Hot oil can escape causing

severe burns. Always allow the log splitter to cool completely before removing the hydraulic oil cap.

High fluid pressure and temperatures are created inside hydraulic log splitters. Hydraulic fluid can escape

through a pin-size hole and can puncture skin and cause severe blood poisoning.

Inspect hydraulic systems regularly for possible leaks. Never check for leaks with your hand while the

system is pressurized. Seek medical attention immediately if injured by leaking fluid.

Make sure all fittings are

tight and secure before applying pressure. Relieve system pressure before

servicing.

Make sure the hydraulic hoses do not touch any hot surfaces or cutting areas.

Hoses need to be positioned away from the engine and cutting wedge. To avoid serious bodily injury always

inspect the hoses before operating the log splitter.

- 14 -

The diagram below identifies the major components and features of the log splitter described in this manual.

1) 2” Ball Coupler

2) Hydraulic Cylinder

3) Control Valve

4) 8” Wedge

5) External Filter

6) Beam

7) Engine

8) Tire / Wheel Assembly

9) Gear Pump

10) Support Leg

11) Safety Chains

12) Manual Canister

13) Log Cradle

CONTROLS AND FEATURES IDENTIFICATION

- 15 -

WARNING: Read and understand all instructions and safety information in this manual and on safety

decals before assembling or operating the log splitter. Failure to understand instructions and safety

information could result in serious injury or death. Do not allow anyone to operate the log splitter

who has not read this manual. A log splitter can be dangerous if assembled or used improperly. Do

not operate this log splitter if you have any questions concerning safe operation. Call our technical

support department at 1-888-723-6534 for answers to any questions.

CAUTION: DO NOT START/ RUN THE ENGINE BEFORE CHECKING THE OIL IN THE HYDRAULIC

RESERVOIR AND THE OIL IN THE ENGINE.

ENGINE OIL RECOMMENDATIONS

The engine comes with 10W-30 oil. Refer to the engine owner’s manual for information regarding proper oil

temperature ranges and grades to use. Engine oil capacity is 20.3 ounces.

After the hydraulic reservoir and the engine crankcase are filled with oil, start the engine. The hydraulic pump should

prime itself. With the engine running, move the control valve lever toward the foot plate. This will cause the cylinder to

extend and expel air. When the cylinder is fully extended, retract it. Repeat this procedure several times. After this

procedure check oil level again. If the tank is overfilled it tends to expel oil from the breather cap when the cylinder is

retracted. Cycle the cylinder again until it maintains a constant speed which indicates all the air has been expelled from

the cylinder.

STARTING INSTRUCTIONS

Refer to the Ducar Owner’s manual for complete information on starting, maintenance and specifications.

212cc Ducar Engine

a) Check that “ON”/“OFF” switch is in the “ON” position.

b) Move the throttle lever to “FAST”. Always operate the engine with throttle lever in the “FAST” position.

c) Move choke control lever to “CHOKE” position.

d) Grasp rope handle and pull slowly to the point of resistance. Once resistance is felt pull rapidly to start the engine

and to avoid engine kickback.

e) After allowing the engine to warm up, move the choke control lever slowly toward “RUN”. In cold weather give the

engine extra time to warm up before slowly moving the choke lever toward “RUN”. Operate with the choke lever in the

“RUN” position.

f) To stop engine, move the “ON”/“OFF” switch to the “OFF” position.

CAUTION: TURN FUEL SHUT OFF VALVE TO THE “OFF” POSITION BEFORE TOWING.FAILURE

TO DO SO MAY RESULT IN FLOODING THE ENGINE AND DESTROYING ENGINE OIL.

NOTE: The engine maximum governed speed is preset at the factory at 3600 RPM load speed. When splitting

wood, the throttle should be set at the maximum speed in order to generate the horsepower required

for the pump.

OPERATION

WARNING: Review safety information related to operation of the log splitter on page 5 and 6 of this manual.

Make sure that you have the recommended personal protective equipment described on page 3.

1) Set up the log splitter in a clear, level area and chock the wheels.

2) For horizontal operation, place a log on the beam against the foot plate. Make sure the log is securely on the foot

plate and up against the beam. To split wood in the vertical position, release the pin on the beam latch located near

the front end of the beam. Tilt the beam up until the foot plate is sitting squarely on the ground and the log splitter is

stable. Place the log on the foot plate up against the beam. When the beam is returned to the horizontal position make

sure the beam latch pin is secure.

OPERATING INSTRUCTIONS

- 16 -

3) Move control valve handle so that the cylinder will drive the wedge into the log. Extend the cylinder until the log

splits or until it reaches the end of its stroke. If the log has not completely split after the cylinder has reached the end

of its extension, retract the cylinder.

IMPORTANT: Leaving the valve in the “actuate” position at the end of the stroke can accelerate wear on the hydraulic

component. Do not split logs with unsquared ends.

NOTE: For operation in wooded areas, obtain a spark arrestor for the exhaust system. Consult the engine operating

and maintenance manual and check with your authorized Kohler service center. Also see Fire Prevention on page 6 of

this manual.

TOWING

The log splitter is equipped with pneumatic tires, a Class I or above coupler (2 in. diameter ball required) and safety

chains. Before towing, the safety chains must be secured to the hitch or bumper of the vehicle. Local regulations

should be checked regarding licensing, lights, towing, etc. Before towing, turn the fuel shut off valve on the engine to

the “OFF” position. Failure to turn off the engine before towing may flood the engine. Do not exceed 45 mph when

towing the log splitter. Also see Towing Safety on page 6 of this manual.

MAINTENANCE

1) Consult the operating and maintenance instructions of the engine’s manufacturer for engine care and maintenance.

2) Always check the oil level of the hydraulic reservoir before operation. Operating the log splitter without an adequate

oil supply will cause severe damage to the pump.

3) Change the oil filter after the first 25 hours of operation. After the initial 25 hours, the oil filter should be changed

seasonally or every 100 hours.

4) To drain the hydraulic oil, remove the drain plug from the bottom of the tank. The drain plug is located just to the

right of the oil filter.

5) If the wedge needs to be sharpened, it can be removed and sharpened.

6) Clean the breather cap after every 25 hours of operation. When operating in dusty conditions the breather cap

should be cleaned more frequently. To clean, first remove the breather cap from the tank, then flush with solvent

and blow out the cap with air.

7) Also see General Repair and Maintenance Safety on page 5 and 6 of this manual.

8) All replacement parts must meet manufacturer’s specifications.

OPERATING INSTRUCTIONS

- 17 -

OPERATING INSTRUCTIONS

- 18 -

Problem Cause Solution

Engine will not start

Engine switch in “OFF” position Move switch to “ON” position

Fuel shut-off valve in “OFF” position Move valve to “ON” position

No fuel Add fuel

Faulty spark plug Replace the spark plug

Spark plug is disconnected Connect the spark plug

Unit is loaded during start up Move valve handle back and forth,

remove load

Engine shuts off during

operation

Out of fuel Fill the fuel tank

Low oil level

Fill the crankcase to the proper oil

level

Wedge movement is slow or

erratic

Air in the hydraulic oil system

Purge air by extending and retracting

the wedge several time until motion

is smooth

Debris lodged in beam guides Clear debris from beam

Low hydraulic oil Check oil level and add as needed

Wedge will not extend or

retract

Faulty control valve Contact customer service

Faulty hydraulic pump Contact customer service

Low hydraulic oil Check oil level and add as needed

Wedge does not auto-return

Low hydraulic oil Check oil level and add as needed

Faulty control valve Contact customer service

Excessive bouncing while

towing Under-inflated tires Inflate tires to proper pressure level

For further technical support please contact:

YTL International Inc.

17517 Fabrica Way Suite H

Cerritos, CA 90703

Phone: (888) 723-6534

Phone: (562) 404-8016

Fax: (562) 404-8013

Email: parts@ytlinternational.com

Website: www.ytlinternational.com

For service, please contact:

Warranty & Customer Support Questions

Toll Free: (888) 723-6534

TROUBLESHOOTING

- 19 -

Maximum Splitting Force ............................................................................ 27 Tons

Cycle Time ............................................................................................ 14 Seconds

(Note: Cycle time may vary given mechanical and environmental factors; the

published cycle time is for ideal conditions)

Wedge Height ............................................................................. 8” Hardened Steel

Gear Pump .................................................................................. 14 GPM, 2-Stage

Hydraulic Oil ........................................... AW32, AW46 and Universal Hydraulic Oil

Hydraulic Capacity ................................................................................ 6.5 Gallons

Maximum Log Length ......................................................................................... 26”

Hydraulic Cylinder ................................................................................ 43/8” x 241/2”

Maximum Pressure ................................................................................... 3712PSI

Wheel Size ................................ 4.8-8 wheel with 16” outside diameter D.O.T tires

Hitch Type ....................................................................................... 2” Ball Coupler

Maximum Towing Speed ............................................................................ 45 MPH

Manual Start Engine ...................................................................................... 212cc

NOTE: For Engine Details Refer to the Engine Owner’s Manual.

SPECIFICATIONS

- 20 -

DRAWING AND PARTS LIST

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

Red Rock 9015918 Le manuel du propriétaire

- Catégorie

- Fendeuses de bûches

- Taper

- Le manuel du propriétaire

dans d''autres langues

- English: Red Rock 9015918 Owner's manual

Documents connexes

Autres documents

-

Swisher LS722A Le manuel du propriétaire

-

Southland SLS20825 Mode d'emploi

-

Toro 9 hp Log Splitter Manuel utilisateur

-

Texas Power Split 2100V Manuel utilisateur

-

Texas Power Split 2100V Manuel utilisateur

-

Detail K2 9204520 Le manuel du propriétaire

-

Woods KLS Manuel utilisateur

-

Woods 605000 Manuel utilisateur

-

Oregon 9217530 Le manuel du propriétaire

-

MTD 5DM Manuel utilisateur