Manual No.: 15137001

Date of Release 26.07.2006

Discotom-50

Instruction Manual

Discotom-50

Instruction Manual

Table of Contents Page

User’s Guide ..............................................................1

Reference Guide.......................................................21

Quick Reference Guide............................................33

A

lways state Serial No and Voltage/frequency if you have technical questions or when ordering spare parts.

You will find the Serial No. and Voltage on the type plate of the machine itself. We may also need the Date

and Article No of the manual. This information is found on the front cover.

The following restrictions should be observed, as violation of the restrictions may cause cancellation of

Struers legal obligations:

Instruction Manuals: Struers Instruction Manuals may only be used in connection with Struers equipment

covered by the Instruction Manual.

Service Manuals: Struers Service Manuals may only be used by a trained technician authorised by Struers.

The Service Manual may only be used in connection with Struers equipment covered by the Service Manual.

Struers assumes no responsibility for errors in the manual text/illustrations. The information in this manual is

subject to change without notice. The manual may mention accessories or parts not included in the present

version of the equipment.

The contents of this manual are the property of Struers. Reproduction of any part of this manual without the

written permission of Struers is not allowed.

A

ll rights reserved. © Struers 2006.

Struers A/S

Pederstrupvej 84

DK-2750 Ballerup

Denmark

Telephone +45 44 600 800

Fax +45 44 600 801

Discotom-50

Instruction Manual

Discotom-50

Safety Precaution Sheet

To be read carefully

before use

1. The operator(s) should be fully instructed in the use of the machine and

its cut-off wheels according to the Instruction Manual and the

instructions for the cut-off wheels.

2. The machine must be placed on a safe and stable support table. All

safety functions and guards of the machine must be in working order.

3. The unit must be installed in compliance with local safety regulations.

4. Use only intact cut-off wheels. The cut-off wheels must be approved for

min. 50 m/s.

5. The machine is not for use with saw-blade type cut-off wheels.

6. Observe the current safety regulations for handling, mixing, filling,

emptying and disposal of the additive for cooling fluid.

7. The workpiece must be securely fixed in the quick-clamping device or

similar. Large or sharp workpieces must be handled in a safe way.

8. Do not work on or around cutting table when the table is repositioned

using the forwards/backwards key (v V).

9. To achieve maximum safety and lifetime of the machine, use only

original Struers consumables.

10. The cutting handle should be lowered slowly and carefully, in order to

avoid breaking the cut-off wheel.

11. Struers recommends the use of an exhaust system as the materials

being cut may emit harmful gasses or dust.

12. The machine emits only moderate noise. However, the cutting process

itself may emit noise, depending on the nature of the workpiece. In

such cases, the use of hearing protection is recommended.

13. The machine must be disconnected from the mains prior to any service.

Discotom-50

Instruction Manual

14. Do not put your hand through the rubber curtain during operation of the

machine.

15. Use of working gloves is recommended as workpieces may be both

very hot and produce sharp edges.

The equipment is designed for use with consumables supplied by Struers. If subjected to misuse, improper

installation, alteration, neglect, accident or improper repair, Struers will accept no responsibility for

damage(s) to the user or the equipment.

Dismantling of any part of the equipment, during service or repair, should always be performed by a qualified

technician (electromechanical, electronic, mechanical, pneumatic, etc.)

Discotom-50

Instruction Manual

1

User’s Guide

Table of Contents Page

1. Getting Started

Checking the Contents of the Packing Box ..................................... 2

Unpacking Discotom-50.................................................................... 2

Placing Discotom-50 ......................................................................... 2

Getting Acquainted with Discotom-50............................................. 3

Front View ............................................................................... 3

Rear View................................................................................. 4

Noise Level........................................................................................ 4

Power Supply .................................................................................... 4

Connecting the Recirculation Cooling Unit (optional).................... 5

2. Basic Operation

Using the Controls............................................................................ 6

Front Panel Controls of Discotom-50 ..................................... 6

Front Panel Controls ........................................................................7

Cooling Valve Positions....................................................................8

Cutting position....................................................................... 8

Cleaning positions ................................................................... 8

Flush Hose ........................................................................................ 9

Cleaning of Flush Hose Nozzle ........................................................ 9

Light Diode and Beep Signals........................................................ 10

Using the Load Bar......................................................................... 11

Overload Protection ........................................................................ 11

Fitting or Changing the Cut-off Wheel.......................................... 12

Clamping the Workpiece ................................................................ 12

Positioning the Cutting Table........................................................ 12

Starting/Stopping the Cutting Process.......................................... 13

Automatic Cutting (AUTO mode)......................................... 13

Manual Cutting ..................................................................... 14

Combining Manual and Automatic Operation..................... 14

Programmable Stop............................................................... 15

Variable Rotational Speed ....................................................16

Feed Speed............................................................................. 17

Material-specific Cut-off Wheels ..........................................18

Using CBN or Diamond Cut-off wheels ...............................19

Cleaning .......................................................................................... 20

Flushing the Cutting Chamber............................................. 20

Discotom-50

Instruction Manual

1. Getting Started

In the packing box you should find the following parts:

Checking the Contents

of the Packing Box

1 Spanner (24 mm) for cut-off wheel

1 Spanner (13 mm) for transport bolts

1 Connector pipe for water outlet

1 Filter for drain

1 Set of Service Documentation for

Siemens frequency converter

1 Set of Instruction Manuals

Remove the screws underneath the pallet to release the

Discotom-50.

Unpacking Discotom-50

Discotom-50 should be placed on a table capable of carrying min.

150 kg.

Placing Discotom-50

2

Discotom-50

Instruction Manual

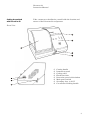

Take a moment to familiarise yourself with the location and

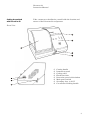

names of the Discotom-50 components.

Getting Acquainted

with Discotom-50

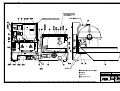

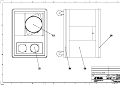

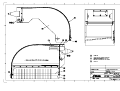

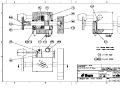

Front View

c Cutting handle

d Instrument panel

e Cooling valve

f Flush hose inlet

g Protection guard, with window

h Main power switch

i Secondary fuse, 3.15AT

j Cut-off wheel locking handle

3

Discotom-50

Instruction Manual

4

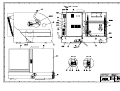

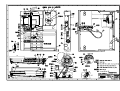

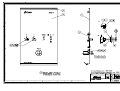

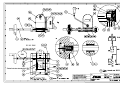

Rear View

c Upper back plate

d Reset button for recirculation pump

e Cable inlet for recirculation pump

f Electrical cable for power supply

g Cut-off wheel locking handle

h Overflow drain

i Water inlet

j Exhaust hose

k Water outlet

Approx. 67 dB (A) measured at idle running, at a distance of

1.0 m/39.4” from the machine.

Noise Level

First check that the mains voltage corresponds to the voltage

stated on the type plate on the side of the machine.

Power Supply

Discotom-50 is factory mounted with an electric cable. Mount a

plug on the cable:

Black and brown = phase

Yellow/green = earth

Important

Residual Current Circuit-Breaker must be min. 20 mA.

Discotom-50

Instruction Manual

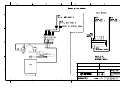

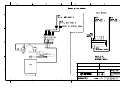

Connect the Recirculation Cooling Unit (optional), product code

TRECA as follows:

Connecting the Recirculation

Cooling Unit (optional)

To connect the electric cable for the recirculation pump, remove

the upper back plate on Discotom-50 and follow the

instructions on the wiring diagram found on the inside of the

back plate.

Check that when the power is turned on, the pump rotates in

the direction indicated by an arrow on the top of the pump. If

not, switch two of the phases to the pump motor and re-check.

Replace the back plate.

Clamp the inlet hose to the pump and attach the other end to

the water inlet on Discotom-50 i.

Attach the connector pipe to the water outlet k, mount the

large outlet hose and secure with the large hose clamp.

Place the tank on the trolley.

Place a disposable plastic insert (EXOSP) in the tank and fold

it over the rim.

Fill the tank with 63 l water and 2 l Struers Additive. The

water level should be 8-10 cm below the upper rim of the tank.

Fit the tank lid and sieve.

Roll the trolley into its proper position and place the outlet and

overflow drain hoses k & h inside the cooling water tank.

Adjust the hose lengths if necessary.

IMPORTANT

c Too high a level of coolant in the tank might damage the pump. To avoid

this, place the disposable insert so that the pre-punched hole is in front of

the overflow aperture in the tank.

d Always maintain the correct concentration of Struers Additive in the

cooling water (percentage stated on the Additive container).

Remember to top up with Struers Additive each time you refill with water.

If the recirculation pump is overloaded or blocked, a thermal cut-

out will switch the pump off. This safety cut-out must be reset by

pushing the red button on the back of the Discotom-50 d before

the machine can be restarted.

Re-set button

5

Discotom-50

Instruction Manual

2. Basic Operation

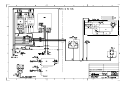

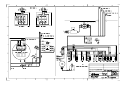

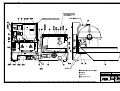

Using the Controls

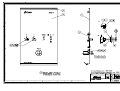

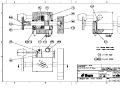

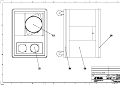

Front Panel Controls

of Discotom-50

c

Control name Symbol

c Main power switch ...........................................................

d Power indicator light .........................................................Power

e Start key .............................................................................s

f Stop key .............................................................................o

g Auto key ..........................................................................Auto

h Auto mode indicator light..................................................Auto

i Forwards key.......................................................................v

j Backwards key ....................................................................V

k Feed Speed knob.............................................................

l Feed Speed Reduced indicator light.................................

1 Rotational speed knob...................................................

2 Load bar.....................................................................

3 Emergency stop................................................................

4 Emergency stop/overload indicator light...........................o

6

Discotom-50

Instruction Manual

Front Panel Controls

Name Key Function Name Key Function

c

MAIN

SWITCH

The main power switch is

located on the right hand

side of Discotom-50. Turn

clockwise to switch on the

power.

i

FORWARDS v Moves cutting table

forwards.

d

POWER

INDICATOR

Power Lights when main power is

switched on. j

BACKWARDS V Moves cutting table

backwards.

e

START s Starts the machine. The cut-

off wheel starts rotating and

the cooling water is turned

on.

k

FEED SPEED

Regulates the feed speed of

the cutting table. The speed

can be set from 0.1-2.5

mm/sec.

f

STOP o Stops the machine. The cut-

off wheel stops rotating and

the cooling water is turned

off.

l

FEED SPEED

REDUCED

Lights when the feed speed

has been set too high and is

reduced by the machine.

g

AUTO

Auto Select or deselect automatic

cutting mode 1

ROTATIONAL

SPEED

Regulates the rotational

speed of the cut-off

wheel. The speed can be

set from 1000-3000 rpm.

h

AUTO

INDICATOR

Auto Lights when automatic

cutting mode selected. 2

Reflects the present motor load status.

LOAD BAR

3

EMERGENCY

STOP

Push the red button to stop.

Pull the red button to release.

4

EMERG. STOP

OVERLOAD

oLights when emergency stop

has been pressed or the

cutting motor is overloaded.

7

Discotom-50

Instruction Manual

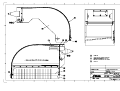

The flush hose, and a valve for cooling and cleaning, are located

on the front of the machine.

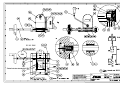

Cooling Valve Positions

During cutting, the valve is placed in the vertical position to cool

the cut-off wheel. During cleaning the valve is turned clockwise to

regulate the water flow of the hose.

8

For cut-off wheel cooling,

position the knob

vertically with dot

upwards.

Cutting position

Flush hose and

Cooling valve Turn the knob clockwise

to activate flushing

mode. Adjust flow while

flushing the cutting

chamber.

Cleaning positions

Turn the knob clockwise

to vertical position for

flushing the cutting

chamber with maximum

flow.

Please Note

After cleaning, turn cooling valve back to vertical position. START s can

not be activated unless the cooling valve is in the cutting position.

Discotom-50

Instruction Manual

The nozzle of the flush hose is adjustable for additional control of

coolant flow. Turn the nozzle clockwise/counter-clockwise as

appropriate.

Flush Hose

IMPORTANT

Do not move the cooling valve to the cleaning position

until the flush hose is pointing inside the cutting chamber.

Cleaning of Flush Hose Nozzle

The flush hose nozzle may collect swarf, inhibiting flow. To clean,

unscrew nozzle head as shown, and rinse both parts under clean

water.

9

Discotom-50

Instruction Manual

Discotom-50 is provided with various light diodes indicating the

status of the machine. Beep signals will sound if a key is pressed

when the function cannot be activated.

Light Diode and Beep Signals

Status Explanation Comments

Green POWER indicator on The main power switch has been

turned on.

Green AUTO indicator on AUTO mode is active.

Beep signal You pressed AUTO, START s,

FORWARDS v or BACKWARDS V

while the motor was running.

You pressed START s while the

protection guard was open. Turn cooling valve to cutting position.

You pressed START s for cutting

while cooling valve isn’t in cutting

position.

Red STOP o indicator on The emergency stop has been

pressed. Release the emergency stop to shut off

the STOP o indicator.

Red STOP o indicator on

and beep signal The emergency stop has been

pressed and you tried to press

another key.

In AUTO mode: the feed speed is

too high.

10

The machine automatically turns the feed

speed down.

Yellow FEED SPEED

REDUCED indicator on An AUTO cut has finished. Feed

speed reduced. Reduce feed speed or press any key.

Yellow FEED SPEED

REDUCED and

Red STOP o indicator lights

come on

Cutting motor overloaded due to

heavy use:

Material is too hard

Feed speed setting too high

Rotational speed setting too high

Cutting table is jammed

Press any key to stop the indicators.

Solve the problem causing the machine

to stop, for example, by reducing the feed

speed, or using a different cut-off wheel,

then release the emergency stop.

Red STOP o indicator and

LOAD BAR in red area Process halted.

Main motor or frequency inverter

overloaded or overheated.

Red STOP o indicator and

LOAD BAR in red area and

beep signal

START was pressed before re-

setting the warning indicator.

Press the STOP key o to re-set the

warning indicator and wait until the motor

or frequency inverter had cooled down.

Discotom-50

Instruction Manual

Discotom-50 is equipped with an LED load bar, indicating the

load on the cutting motor. The bar is divided into three areas; a

green area showing that the load on the cutting motor is OK, a

yellow area indicating that the load is near maximum and a red

area indicating overload of the motor.

Using the Load Bar

In automatic cutting mode, the feed speed is automatically

reduced on overload, i.e. if the red area is reached.

When cutting manually, the load bar serves as an indicator of

how much force is applied on the sample.

The machine may cut with the load bar in the yellow area for a

period of time depending on how hot the motor is when cutting is

started:

Starting with a hot motor, cutting will be stopped after a few

minutes.

Starting with a cold motor, cutting will be stopped after up to 20

minutes.

For continuous load, the feed speed should be reduced to a green

load level.

Discotom-50 is equipped with an overload protection to prevent

damage to the cutting motor and the recirculation pump motor.

Overload Protection

If the cutting motor has been overloaded, a thermal cut-out will

stop the motor.

Cutting Motor

Open the protection hood and allow the motor to cool down

before resuming cutting.

If the recirculation pump has been overloaded, a thermal cut-out

will stop the motor.

Recirculation Pump

To reset the pump, press the red re-set button on the rear of

the machine. Allow the motor to cool down, before resuming

cutting.

11

Discotom-50

Instruction Manual

Fitting or Changing the

Cut-off Wheel IMPORTANT

The spindle of Discotom-50 is left-hand threaded.

If Discotom-50 has been used for manual cutting, secure the

cut-off wheel with the locking handle on the right hand side of

the machine before changing the cut-off wheel.

Press and hold down the black locking knob on the right-hand

side of the cut-off wheel, turning the cut-off wheel until the

spindle lock clicks.

Remove the nut with a fork spanner. Remove the flange,

cardboard washers and the old cut-off wheel.

Mount the new cut-off wheel.

IMPORTANT

Conventional cut-off wheels based on Al2O3/SiC abrasives should be placed

between two cardboard washers, to protect the cut-off wheel.

For maximum precision with diamond or CBN cut-off wheels, do not use

cardboard washers.

Mount the flange and the nut. Tighten carefully and release

the locking knob.

Clamp the workpiece with the clamping device of your choice

e.g. a quick clamping device. Place the workpiece between the

clamp and the back stop.

Clamping the Workpiece

Push the clamp towards the workpiece and lock the clamp on

the quick-clamping device.

Generally, it is recommended to clamp the workpiece as far back

in the cutting chamber as possible.

IMPORTANT

Prior to cutting, ensure that the workpiece is held firmly in place by a

clamping device.

Prior to cutting, the cutting table is positioned using the

FORWARDS v and BACKWARDS V keys.

Positioning the Cutting Table

12

Discotom-50

Instruction Manual

When the machine is used in AUTO mode the cut-off wheel is

stationary and the cutting table moves. In MANUAL mode the

cutting table is stationary and the operator moves the cut-off

wheel.

Starting/Stopping

the Cutting Process

Clamp the workpiece.

A

utomatic Cutting

(AUTO mode) Loosen the cut-off wheel locking handle situated on the right-

hand side of the cutting chamber.

Lower the cut-off wheel by pulling the cutting handle

downwards until the cut-off wheel is positioned ready to cut

the workpiece. Re-fasten the locking handle.

Press v FORWARDS to position the cutting table and the

workpiece just in front of the cut-off wheel.

Close the protection guard.

Set the desired feed speed and rotational speed.

Select AUTO mode by pressing the AUTO mode key.

Press START s; the cut-off wheel starts rotating and the

cooling water starts to flow. The cutting table moves forward

towards the cut-off wheel at the preset feed speed.

When the cutting table reaches the back of the cutting

chamber, the cut-off wheel automatically stops and the cutting

table returns to its start position.

If the machine is stopped with the STOP o key, the cutting

table will stay at the present position. To return the cutting

table to its start position, wait for the double beep and press

BACKWARDS V once.

If the protection guard has been opened, press and hold the

BACKWARDS key V to move the cutting table to its start

position.

Please Note

The cutting table will only move when AUTO mode is switched on.

13

Discotom-50

Instruction Manual

Manual cutting may be the preferred cutting mode for simple

cutting tasks.

Manual Cutting

For cutting of extremely hard materials (>1000 HV), manual

cutting is recommended.

Clamp the workpiece.

Loosen the locking handle on the right side of the cutting

chamber. The cutting handle is now easily moved up and down.

Position the cutting table and the workpiece under the cut-off

wheel with the FORWARDS v and BACKWARDS V keys.

Close the protection guard.

Ensure that AUTO mode is de-selected.

Press START s to start the machine. The cut-off wheel starts

rotating and the cooling water is turned on.

Pull down the cutting handle and let the cut-off wheel work

itself into the workpiece. Increase the pressure and begin

cutting.

When the cut-off wheel has almost cut through the workpiece

reduce the pressure.

When the cut-off wheel has cut through the workpiece push the

cutting handle back to its top position.

Press the STOP o key to stop the machine.

Combining Manual and

A

utomatic Operation

IMPORTANT

When cutting manually, the motor load bar should be used

to monitor the force on the workpiece.

Try to keep the motor load in the green or the beginning of the yellow area.

Manual and Automatic cutting modes may be used in

combination. You may start in manual mode and cut into the

workpiece.

Secure the locking handle in this position, press AUTO and

continue in automatic mode; the workpiece will move towards the

cut-off wheel.

14

Discotom-50

Instruction Manual

Discotom-50 is supplied with an automatic feature, allowing you

to pre-program a specific stop position.

Programmable Stop

Position the cutting table at the desired stop position using the

FORWARDS v and BACKWARDS V keys.

Set the stop position by pressing the STOP o key and holding

it down whilst activating the FORWARDS v key.

Use BACKWARDS V to move the cutting table clear of the cut-

off wheel. Place and clamp the workpiece and press START s.

The cutting table stops when it reaches the pre-set stop

position and the cutting table moves to the position from where

cutting was started.

Cancelling the Programmable

Stop

Cancel the stop position by pressing the STOP o key and

holding it down whilst activating the BACKWARDS V key.

Note

The stop position will also be cancelled when the machine is switched off.

15

Discotom-50

Instruction Manual

Discotom-50 is fitted with a variable rotational speed feature.

This allows you to optimise cutting quality and cut many different

materials using the same cut-off wheel. Thus materials as

different as aluminium and hardened steel can be cut using the

same cut-off wheel.

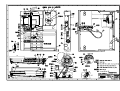

Variable Rotational Speed

The table below is a guide to recommended rotational speed

settings for popular materials using a single cut-off wheel

(Struers 53UNI).

Recommended Settings, Rota-

tional Speed

16

Rotational Speed Settings using 53UNI cut-off wheel

What happens when the

rotational speed changes?

Ordinary cut-off wheels, based on

bakelite-bonded siliciumcarbide

(SiC) or aluminiumoxide (Al2O3),

change their properties with the

rotational speed.

The higher the speed, the ‘harder’

the properties of the wheel, and

vice versa. The benefit of a higher

speed is that the wheel wears at a

slower rate. At the same time, the

workpiece becomes more prone to

heat damage, which is countered

by reducing the feed speed.

Using a slower rotational speed,

the same wheel becomes softer,

and capable of cutting through

harder materials, with less risk of

workpiece damage. The downside

is increased wheel wear.

Struers have optimised both

rotational and feed speed, as per

the table and graph shown.

Metalog Guide

Description Material

Tested Hardness

(HV) Speed

(RPM)

Non ferrous

soft metal Aluminium 50-110 3000

Very ductile metal Stainless steel 220 2200

Medium soft ferrous

metal UHB IMPAX

Cold work tool steel 300 2200

Medium hard metal UHB IMPAX

Cold work tool steel 480 2000

Hard ferrous metal UHB ARNE

Cold work tool steel 750 1750

Please note that the above settings are based on lab tests of the

specific materials listed above. Any deviation in material will

require a different setting. Interpolate the Vickers hardness to

approximate the corresponding rotational speed.

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

dans d''autres langues

- English: Struers Discotom-50 User manual

- Deutsch: Struers Discotom-50 Benutzerhandbuch

Documents connexes

-

Struers Unitom-5 Manuel utilisateur

Struers Unitom-5 Manuel utilisateur

-

Struers Unitom-50 Manuel utilisateur

Struers Unitom-50 Manuel utilisateur

-

Struers Labotom-3 Manuel utilisateur

Struers Labotom-3 Manuel utilisateur

-

Struers Accutom-50 Manuel utilisateur

Struers Accutom-50 Manuel utilisateur

-

Struers Abramin Manuel utilisateur

Struers Abramin Manuel utilisateur

-

Struers Prepamatic-2 Manuel utilisateur

Struers Prepamatic-2 Manuel utilisateur

-

Struers Transpol-2 Manuel utilisateur

Struers Transpol-2 Manuel utilisateur

-

Struers Accutom-2 Manuel utilisateur

Struers Accutom-2 Manuel utilisateur

-

Struers Tenupol-3 Manuel utilisateur

Struers Tenupol-3 Manuel utilisateur

-

Struers RotoPol-11 Manuel utilisateur

Struers RotoPol-11 Manuel utilisateur