Manual No.: 15317001

Date of Release 15.11.2005

Unitom-50

Instruction Manual

Unitom-50

Instruction Manual

Table of Contents Page

User’s Guide ..............................................................1

Reference Guide.......................................................19

Quick Reference Card .............................................41

A

lways state Serial No and Voltage/frequency if you have technical questions or when ordering spare parts.

You will find the Serial No. and Voltage on the type plate of the machine itself. We may also need the Date

and Article No of the manual. This information is found on the front cover.

The following restrictions should be observed, as violation of the restrictions may cause cancellation of

Struers legal obligations:

Instruction Manuals: Struers Instruction Manual may only be used in connection with Struers equipment

covered by the Instruction Manual.

Service Manuals: Struers Service Manual may only be used by a trained technician authorised by Struers.

The Service Manual may only be used in connection with Struers equipment covered by the Service Manual.

Struers assumes no responsibility for errors in the manual text/illustrations. The information in this manual is

subject to changes without notice. The manual may mention accessories or parts not included in the present

version of the equipment.

The contents of this manual is the property of Struers. Reproduction of any part of this manual without the

written permission of Struers is not allowed.

A

ll rights reserved. © Struers 2005.

Struers A/S

Pederstrupvej 84

DK-2750 Ballerup

Denmark

Telephone +45 44 600 800

Fax +45 44 600 801

Unitom-50

Instruction Manual

Unitom-50

Safety Precaution Sheet

To be read carefully

before use

1. The operator(s) should be fully instructed in the use of the machine and its cut-

off wheels according to the Instruction Manual and the instructions for the cut-

off wheels.

2. The machine must be placed on a safe and stable support table. All safety

functions and guards of the machine must be in working order.

3. The unit must be installed in compliance with local safety regulations

4. Use only intact cut-off wheels. The cut-off wheels must be approved for min. 50

m/s.

5. Observe the current safety regulations for handling, mixing, filling, emptying and

disposal of the additive for cooling fluid.

6. The workpiece must be securely fixed in the quick-clamping device or the like.

Large or sharp workpieces must be handled in a safe way.

7. Do not touch anything inside the cutting chamber while positioning the cut-off

wheel with the position button.

8. Struers recommends the use of an exhaust system as the materials to be cut

may emit harmful gasses or dust.

9. The machine emits only moderate noise. However, the cutting process itself

may emit noise, depending on the nature of the workpiece. In such cases, use

of hearing protection is recommended.

10. The machine must be disconnected from the mains prior to any service.

11. Use of working gloves is recommended as workpieces may be both very hot

and produce sharp edges.

If optional rubber curtains are needed in order to cut long, protruding workpieces:

1. Check with your local authorities whether rubber curtains are approved as

protection in your country.

2. Do not put hands through the rubber curtain during operation of the machine.

3. Protruding workpieces should be shielded or marked.

The equipment is designed for use with consumables supplied by Struers. If subjected to misuse, improper

installation, alteration, neglect, accident or improper repair, Struers will accept no responsibility for

damage(s) to the user or the equipment.

Dismantling of any part of the equipment, during service or repair, should always be performed by a qualified

technician (electromechanical, electronic, mechanical, pneumatic, etc.).

Unitom-50

Instruction Manual

1

User’s Guide

Table of Contents Page

1. Getting Started

Checking the Contents of Packing................................................... 2

Recirculation Cooling Unit...................................................... 2

Placing Unitom-50 ............................................................................ 2

Getting Acquainted with Unitom-50 ............................................... 3

Noise Level........................................................................................4

Supplying Power............................................................................... 4

Direction of the Cut-off Wheel ................................................ 4

Connecting the Recirculation Unit .................................................. 5

Software Settings.............................................................................. 6

Configuration Menu ................................................................ 6

Setting the Language .............................................................. 7

2. Basic Operations

Using the Controls............................................................................ 8

Front Panel Controls of Unitom-50 ........................................ 8

Groups of Keys......................................................................... 8

Acoustic Signals....................................................................... 8

Front Panel Controls ........................................................................9

Cooling Valve Positions......................................................... 10

Reading the Display ....................................................................... 11

Reading the Display during the Cutting Process ................ 11

Sleep Mode.............................................................................11

Changing/Editing Values ............................................................... 12

Numeric Values .....................................................................12

Alphanumeric Values............................................................ 13

Changing the Cut-off Wheel........................................................... 14

Clamping the Workpiece ................................................................ 14

Positioning the Cut-off Wheel ........................................................ 14

Setting the Feed Rate before Cutting............................................ 15

Selecting Cutting Mode before Cutting ......................................... 15

Starting the Cutting ....................................................................... 16

Fast down............................................................................... 16

Setting the Feed Rate during Cutting........................................... 16

Stopping the Cutting ...................................................................... 17

AutoStop ................................................................................ 17

Stop Position.......................................................................... 17

STOP o Key ......................................................................... 17

Flushing the Cutting Chamber...................................................... 18

Unitom-50

Instruction Manual

2

1. Getting Started

In the packing box you should find the following parts:

1 Fork spanner 30 mm, for changing the cut-off wheel

1 Grease gun, for lubrication of tilting frame bearings and

oscillating table.

2 Cover plugs for threads for cutting tables

1 Set of Instruction Manuals

1 PVC hose 1/2", 2 m

1 Outlet hose, 2 m

1 Drain elbow pipe, 15°

5 Hose clamps

The kit also contains the below parts exclusively for Unitom-2/-5

1 38 mm drain hose

1 87° elbow drain fitting

1 32-50 mm hose clamp

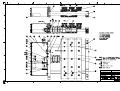

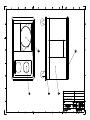

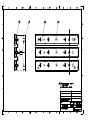

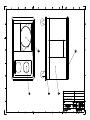

Unitom-50 should be placed on the optional Struers table

(LABUL), or a table that is able to carry a weight of min. 200 kg.

Adjust the table height using the screws in the table legs. It is

important that both the table and Unitom-50 are level. Place

Unitom-50 on the table. If the machine is not level, adjust the

height for each corner, as follows:

Loosen the upper 13 mm nut under the corner screw.

Adjust the lower 8 mm nut with a spanner.

Re-fasten the upper 13 mm nut again.

Repeat the adjustment for each of the other three corners until

Unitom-50 is levelled.

A 65 mm hole must be drilled in the base of the table for

attachment of the outlet hose.

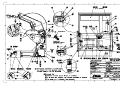

(see drawing 15317049 in the Spare Parts manual).

Checking the Contents

of Packing

Recirculation Cooling Unit

Placing Unitom-50

Placing Unitom-50 on a table

other than LABUL

Unitom-50

Instruction Manual

3

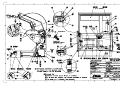

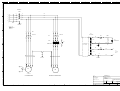

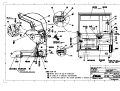

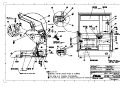

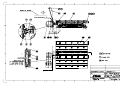

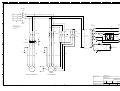

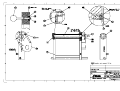

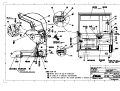

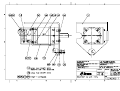

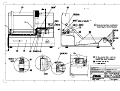

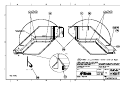

Take a moment to familiarise yourself with the location and

names of the Unitom-50 components.

c Front panel controls

d Cutting Table

e Quick-clamping device

f Table LABUL (optional)

g Recirculation cooling unit

h Removable plate. Can be replaced by a rubber curtain

(optional)

i Main switch

j Protection guard with window

1 Cooling valve

Getting Acquainted with

Unitom-50

Unitom-50

Instruction Manual

4

Approx. 73 dB (A) measured at idle running, at a distance of

1.0 m/39.4” from the machine.

Unitom-50 is factory mounted with an electric cable. Mount a

plug on the cable according to the following:

50 hz 60 hz

Phase Black and brown

Earth Yellow/green

L1 Black

L2 Red

L3 Orange

Earth Green

Check that the cut-off wheel rotates in the direction indicated on

the label attached to the guard of Unitom-50. If the direction of

rotation is incorrect:

50 hz 60 hz

Switch two of the phases Switch phases L1 and L2

Noise Level

Supplying Power IMPORTANT

Check that the mains voltage corresponds to the voltage

stated on the type plate on the side of the machine.

Direction of the Cut-off Wheel

Unitom-50

Instruction Manual

5

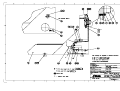

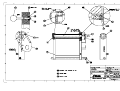

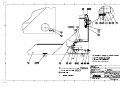

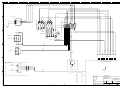

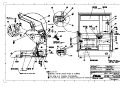

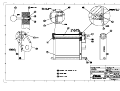

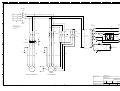

The cooling pump is delivered wrapped in corrugated cardboard

and placed inside the cutting chamber. The pump is connected as

follows:

Remove the cooling pump from its wrapping.

Mount the inlet hose on the pump using a hose clamp.

Mount the other end of the inlet hose on the back of Unitom-50

using a hose clamp.

Lead the pump through the opening in the back of the table.

Mount the drain elbow pipe on the water outlet tube in the

hose box at the bottom of Unitom-50.

Mount the outlet hose with the hose clamp on the drain elbow

pipe. Adjust the length of the hose, so as to direct the water

into the recirculation tank.

Place the tank on the trolley.

Place a disposable plastic insert (EXOSP, ordered separately)

in the tank and fold it over the edge.

Fill the tank with 63 l of water and 2 l Struers Additive for

cooling fluid. The water level should be 8-10 cm below the

upper edge of the tank.

Connecting the

Recirculation Unit

IMPORTANT

A too high level of coolant in the tank might damage the pump. To avoid

this: place the disposable insert so that the pre-punched hole is in front of

the overflow aperture in the tank.

Always maintain the correct concentration of Struers Additive in the cooling

water (percentage stated on the container of the Additive). Remember to

add Struers Additive for cooling fluid each time you refill with water.

Unitom-50

Instruction Manual

6

Switch on the power at the main switch. The following display

will appear briefly:

Afterwards, the display will change to the screen for cutting.

ESC Press ESC to come to the MAIN MENU.

D

The MAIN MENU is the highest level in the menu structure.

From here you can go to cutting or to the configuration menu.

mN Press MENU DOWN mN to select CONFIGURATION.

D

e Press ENTER e to activate the CONFIGURATION

menu.

D

Software Settings

Configuration Menu

Unitom-50

Instruction Manual

7

mO

mN

Press MENU UP/DOWN mON to select Language.

D

e Press ENTER e to activate the

Language pop-up menu.

D

mO

mN

Press MENU UP/DOWN mON to

select the language you prefer.

D

e Press ENTER e to accept the

language.

The CONFIGURATION Menu now appears in the

language you have chosen.

Setting the Language

Unitom-50

Instruction Manual

8

2. Basic Operations

A START

s/STOP o of Unitom-50

B Position of the cut-off wheel

C Programming and monitoring functions

A short beep when a key is pressed indicates that the

command has been accepted.

A long beep indicates that the key is inactive at the moment.

Three long beeps indicate that the cutting process is finished.

Using the Controls

Front Panel Controls of Unitom-50

Groups of Keys

A

coustic Signals

Location of the Main Switch

Please Note...

The contents of the program memory are not lost

when the main switch is turned off.

Unitom-50

Instruction Manual

9

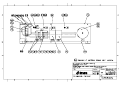

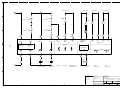

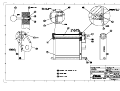

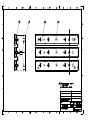

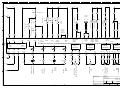

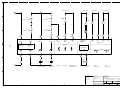

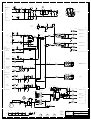

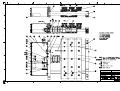

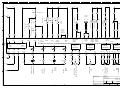

Name Key Function Name Key Function

c

MAIN

SWITCH

The main switch is located to the

right hand side of Unitom-50.

Turn clockwise to switch on the

power.

j

ESC

Esc

Leaves the present menu or

aborts functions/changes.

d

POWER

Power

Lights when main power is

switched on. k

ENTER

e

Accepts a marked parameter

value or chooses a menu.

e

START

s Starts the cutting process. l

FUNCTION

KEY

F1 Controls for various purposes.

See the bottom of the individual

screens.

f

STOP

o Stops the cutting process. l

FUNCTION

KEY

F2 Controls for various purposes.

See the bottom of the individual

screens.

gh

POSITION

v/V Moves the cut-off wheel up or

down.

Keep the key pressed to move

the cut-off wheel.

l

FUNCTION

KEY

F3 Controls for various purposes.

See the bottom of the individual

screens.

i

MENU UP

mO

Moves the cursor up or

increases the parameter value. l

FUNCTION

KEY

F4 Controls for various purposes.

See the bottom of the individual

screens.

i

MENU

DOWN

mN

Moves the cursor down or

decreases the parameter value. 2

EMERGENCY

STOP

- Push the red button to stop.

- Pull the red button to release.

Front Panel Controls

1 COOLING VALVE: See next page!

Unitom-50

Instruction Manual

10

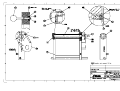

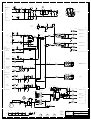

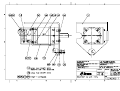

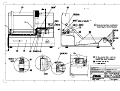

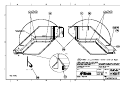

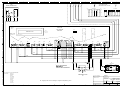

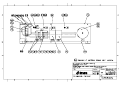

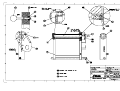

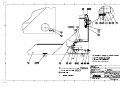

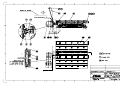

Cooling Valve Positions 1

COOLING

VALVE

The cooling valve for

cooling/cleaning is located

in the back of the cutting

chamber to the left.

Turn the knob counter-

clockwise to vertical position

for cooling of cut-off wheel.

Turn the knob to regulate the

flow while flushing the

cutting chamber.

Turn the knob clockwise to

vertical position for flushing

the cutting chamber with

maximum flow.

Location of Cooling Valve

for cooling/cleaning

Unitom-50

Instruction Manual

11

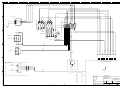

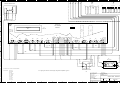

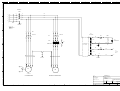

The display can show various kinds of information, for example

parameters for an ongoing process. During the cutting process the

screen could look as the following example:

A Heading.

B Inverted text: cursor position.

C Function key options.

Feed The feed rate of the cut-off wheel pre-set before

starting the cutting.

Load Load indicator of the cutting motor. The moving black

column shows the status of the cutting motor:

Inside the white area: The cutting motor can be loaded

continuously.

In the grey overload area: The cutting motor can only

be intermittently loaded. The built-in thermo fuse

might shut off the cutting motor.

Wheel Position. The actual position of the cut-off wheel measured

from the top position of the cut-off wheel.

Stop Position The pre-set stop position counted from the top

position of the cut-off wheel.

To increase the lifetime of the display, the backlight is

automatically switched off if Unitom-50 has not been used for 15

min. Press any key to re-activate the backlight.

Reading the Display

Reading the Display during the

Cutting Process

Sleep Mode

B

A

C

Unitom-50

Instruction Manual

12

Depending on the type of value, there are two different ways of

editing.

e Press ENTER e, to edit the value.

D Two square brackets [ ] appear around the value.

mO

mN Press MENU UP/DOWN mON to increase or decrease

the numeric value.

D

e Press ENTER e, to accept the new value.

Pressing Esc, aborts the changes, preserving the

original value.

Changing/Editing Values

Numeric Values

Unitom-50

Instruction Manual

13

mO

mN Press MENU UP/DOWN mON to select the

alphanumeric value you want to change

D

e Press ENTER e, to edit the value.

D A pop-up menu appears.

D

mO

mN Press MENU UP/DOWN mON to select the correct

value.

D

e Press ENTER e, to accept the new value and to return

to the previous screen.

Pressing Esc, preserves the original value, returning to

the previous screen.

A

lphanumeric Values

Unitom-50

Instruction Manual

14

Open the protection guard and swing the right cooling tube to

the right.

Press the black locking knob on the left-hand side of the cut-off

wheel, turning the cut-off wheel until the spindle lock clicks.

Remove the nut with a fork spanner. Remove the flange and

the old cut-off wheel.

Mount the new cut-off wheel.

Mount the flange and the nut. Tighten carefully.

Swing the right cooling tube back into position.

Place the workpiece between the clamp and the back stop at

the right hand cutting table.

Push the clamp towards the workpiece and lock the quick-

clamping device with the locking handle.

After clamping, you may lower the cut-off wheel to a position at

least 1 mm above the workpiece, to test the correct position of

the cut on the workpiece.

Press POSITION DOWN V to lower the cut-off wheel.

The cut-off wheel stops when you stop pressing the key.

You can follow the position of the cut-off wheel in the display:

Leave the cut-off wheel in position before you press START s.

Changing the Cut-off Wheel

IMPORTANT

The spindle in Unitom-50 is right-hand threaded.

IMPORTANT

Conventional cut-off wheels based on Al2O3/SiC abrasives should be placed

between two cardboard washers, to protect the cut-off wheel.

For maximum precision with diamond or CBN cut-off wheels, do not use

cardboard washers.

Clamping the Workpiece

Positioning the Cut-off Wheel

Unitom-50

Instruction Manual

15

e Press ENTER e, to edit the value.

D

Two square brackets [ ] appear around the value.

mO

mN Press MENU UP/DOWN mON to increase or decrease

the numeric value.

D

e Press ENTER e, to accept the new value.

Pressing Esc, aborts the changes, preserving the

ori

g

inal value.

mO

mN

Press MENU UP/DOWN mON to

select MODE in the CUTTING MENU.

D

e Press ENTER e, to activate the

MODE pop-up menu.

D

mO

mN Press MENU UP/DOWN mON to select CUTTING

MODE (Direct cut or ExciCut).

D

e Press ENTER e, to accept the selected

mode.

Pressing Esc, aborts the changes, preserving the

ori

g

inal settin

g

.

Setting the Feed Rate before

Cutting

Selecting Cutting Mode before

Cutting

Unitom-50

Instruction Manual

16

Before starting, lower the cut-off wheel into the correct position

above the workpiece.

Close the protecting guard.

Press START s. The cut-off wheel starts rotating and the

cooling water starts running. The cut-off wheel moves down at

the pre-set feed rate.

You may increase the feed rate to twice the pre-set value between

pressing start and the cut-off wheel physically touching the

workpiece.

Press the function key F1. The cut-off wheel quickly moves

down until it touches the workpiece. Unitom-50 will then

automatically change the feed rate back to the pre set value.

e Press ENTER e, to edit the value.

D Two square brackets [ ] appear around the value.

mO

mN Press MENU UP/DOWN mON to increase or decrease

the numeric value.

D

e Press ENTER e, to accept the new value.

Pressing Esc, aborts the changes, preserving the

original value.

Starting the Cutting

Fast down

Setting the Feed Rate during

Cutting

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

-

157

157

-

158

158

-

159

159

-

160

160

-

161

161

-

162

162

-

163

163

-

164

164

-

165

165

-

166

166

-

167

167

-

168

168

-

169

169

-

170

170

-

171

171

-

172

172

-

173

173

-

174

174

-

175

175

-

176

176

-

177

177

-

178

178

-

179

179

-

180

180

-

181

181

-

182

182

-

183

183

-

184

184

-

185

185

-

186

186

-

187

187

-

188

188

-

189

189

-

190

190

-

191

191

-

192

192

-

193

193

-

194

194

-

195

195

-

196

196

-

197

197

-

198

198

-

199

199

-

200

200

-

201

201

-

202

202

-

203

203

-

204

204

-

205

205

-

206

206

-

207

207

-

208

208

-

209

209

-

210

210

-

211

211

-

212

212

-

213

213

-

214

214

-

215

215

-

216

216

-

217

217

-

218

218

-

219

219

-

220

220

-

221

221

-

222

222

-

223

223

-

224

224

-

225

225

dans d''autres langues

- English: Struers Unitom-50 User manual

- Deutsch: Struers Unitom-50 Benutzerhandbuch

Documents connexes

-

Struers Discotom-50 Manuel utilisateur

Struers Discotom-50 Manuel utilisateur

-

Struers Labotom-3 Manuel utilisateur

Struers Labotom-3 Manuel utilisateur

-

Struers Accutom-50 Manuel utilisateur

Struers Accutom-50 Manuel utilisateur

-

Struers ProntoPress-10 Manuel utilisateur

Struers ProntoPress-10 Manuel utilisateur

-

Struers RotoPol-21 Manuel utilisateur

Struers RotoPol-21 Manuel utilisateur

-

Struers Transpol-2 Manuel utilisateur

Struers Transpol-2 Manuel utilisateur

-

Struers RotoPol-11 Manuel utilisateur

Struers RotoPol-11 Manuel utilisateur

-

Struers LaboForce-3 Manuel utilisateur

Struers LaboForce-3 Manuel utilisateur

-

Struers VersoCit-2 Manuel utilisateur

Struers VersoCit-2 Manuel utilisateur

-

Struers Abramin Manuel utilisateur

Struers Abramin Manuel utilisateur