Genie GCL Fire Door Operator / Installation Manual

- Catégorie

- Porte de garage

- Taper

- Operator / Installation Manual

03/2018112606.503918

This Installation Manual provides the information required to install,

troubleshoot and maintain a OPGSX Series Fire Door Operator.

FIRE DOOR OPERATOR

NOT FOR RESIDENTIAL USE

For use on Rolling Steel Fire Doors Only

GCL

PROPER APPLICATIONS:

Door Type(s) Operator Type(s) HP/MAX. Door Weight

Rolling Steel Hoist Model Only 1/2HP = 998lbs.

Fire Door Only FOH mount only 3/4HP = 1220lbs.

1HP = 1440lbs.

Table of Contents

Section 1:

How to use this manual ........................................1.1

Section 2:

Safety Information & Instructions ..............2.1-2.2

Section 3:

Critical Installation Information ..................3.1-3.3

Section 4:

Installation:

Rolling Steel Front of Hood ..........................4.1-4.2

Manual Handwheel/Release Cord .................... 4.3

Fusible Link ................................................................ 4.4

Clutch Adjustment ................................................. 4.5

Auxiliary Board Installation (optional) ............. 4.5

Section 5:

Wiring:

Safety Information .................................................. 5.1

External Wire Diagram ...........................................5.2

Line Voltage .............................................................. 5.3

Low Voltage .............................................................. 5.4

Wall Control Wiring .................................................5.5

Interlock Switches .................................................. 5.6

Wired Sensing Edge............................................... 5.7

Wireless Sensing Edge .......................................... 5.8

External Radio ........................................................... 5.9

FDO Control Board Information .........................5.9

FDO Control Board Wiring Diagram ...............5.10

Smoke Detector Wiring .............................5.11-5.12

Notication Appliance Wiring...........................5.13

Remote Test Plate ..................................................5.13

Fire Alarm Relay Input/Battery Wiring ...........5.14

Alarm/Trouble Indication Outputs ..................5.15

Motor Connection ................................................. 5.15

Section 6:

Operator Conguration:

Control Panel Information .................................... 6.1

Calibration Mode Information ............................6.2

Close Direction ......................................................... 6.3

Braking Rate .............................................................. 6.4

Setting Limits ........................................................... 6.5

Limit Overrun ........................................................... 6.6

Monitored Reversing Devices .............................6.7

Momentary and Constant Contact .................. 6.8

FDO Module Conguration:

Fire Alarm Delay/Safety Timer ........................... 6.9

Obstruction Cycles/Behavior ............................6.10

Auto Open/Alarm Loss of Power .....................6.11

Alarm at Down Limit ............................................6.12

Section 7:

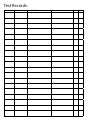

Test Procedures:

General Information ............................................... 7.1

Mechanical Drop Test ............................................. 7.2

Standard & Automatic Test ...........................7.3-7.4

Section 8:

Optional Setup Procedures and General

Information:

Transmitter Programming .................................... 8.1

Mid-Stop -DO NOT USE ......................................... 8.2

Max Run Timer .......................................................... 8.3

Timer to Close ...........................................................8.4

Cycle Count................................................................8.4

GDO Version/Firmware ..........................................8.5

GDO Type ................................................................... 8.5

Section 9:

Troubleshooting:

Troubleshooting Example .................................... 9.1

Run Codes ...........................................................9.2-9.3

Error Codes ......................................................... 9.4.9.7

FDO Module Trouble Codes ................................9.8

Section 10:

Service & Maintenance ....................................... 10.1

Section 11:

Parts Breakdown: ........................................ 11.1-11.3

Section 12:

General Information:

Device Compatibility Identier ........................12.1

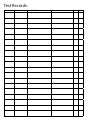

Test Recording Sheet .................................12.2-12.3

Warranty Information ..........................................12.4

1.1

Section 1: How to use this manual

Section 2

Provides important dening information related to safety terminology used throughout this manual, as well

as safety related instructions which must be followed at all times while doing any steps/tasks/instructions

detailed in this manual.

The 12 sections of this Installation Manual provide the information required to install, troubleshoot

and maintain a Fire Door Commercial/Industrial door operator.

Section 3

Details pre-installation concerns/issues/decisions that are recommended to be considered and/or resolved

prior to beginning any commercial door operator installation.

Sections 4-6

Provides step by step installation and set-up instructions for the re door commercial operator.

Each section is written such that it must be followed in a step by step order to complete a successful

installation.

Section 7-8

Details important test features and troubleshooting information for typical installation and normal

operations that may occur.

Sections 9-12

Provides related information on troubleshooting, service and maintenance items, operator drawings for use

in troubleshooting and service activities, test recording, along with important warranty and returned goods

policy information.

WARNING: Failure to correctly perform all steps in sections 4-6 can result in serious

injury or death.

AVERTISSEMENT: Ne pas eectuer correctement toutes les étapes dans les sections

4-6 peut entraîner des blessures graves voire la mort.

!

!

2.1

Section 2: Safety Information & Instructions

WARNING

!

Overhead Doors are large, heavy objects that move with the help of springs under high tension

and electric motors. Since moving objects, springs under tension, and electric motors can cause

injury, your safety and the safety of others depend on you reading the information in this manual. If

you have any questions or do not understand the information presented, call your nearest service

representative. For the number of your local Genie® Dealer, call 800-OK-GENIE, and for Genie® Factory

Technical Advice, call 800-843-4084.

In this manual the words Danger, Warning, and Caution are used to stress important safety

information. The word:

DANGER indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates potentially hazardous situation which, if not avoided, may result in injury

or property damage.

The word NOTE, is used to indicate important steps to be followed or important considerations.

!

!

!

POTENTIAL HAZARD EFFECT PREVENTION

MOVING DOOR

WARNING

Could result in Serious

Injury of Death

Do Not operate unless the doorway is in sight and free of

obstructions. Keep people clear of opening while door is moving.

Do Not allow children to play with the door operator.

Do Not change operator control to momentary contact unless and

external reversing means is installed.

Do Not operate a door that jambs or one that has a broken spring.

ELECTRICAL SHOCK

WARNING

Could cause Serious

Injury or Death

Turn o electrical poser before removing operator cover.

When replacing the cover, make sure wires are not pinched or near

moving parts.

Operator must be electrically grounded.

HIGH SPRING TENSION

WARNING

Could cause Serious

Injury or Death

Do Not try to remove, repair or adjust springs or anything to which

door spring parts are fastened, such as wood block, steel bracket,

cable or any other structure or like item.

Repairs and adjustments must be made by trained service

representative using proper tools and instructions.

!

!

!

IMPORTANT

READ PRIOR TO ANY DOOR OPERATION

1. Read manual and warnings carefully.

2. Keep the door in good working condition. Periodically lubricate all moving parts of door.

3. If door has a sensing edge, check operations monthly. Make any necessary repairs to keep it functional.

4. AT LEAST twice a year, manually operate the door by disconnecting it from the operator. The Door

should open and close freely. If it does not, the door must be taken out of service and a trained service

representative must correct the condition causing the malfunction.

5. The Operator Motor is protected against overheating by an internal thermal protector. If the motor

protector is tripped, a trained service technical may be needed to correct the condition which caused the

overheating. When the motor has cooled, thermal protector will automatically reset and normal operation

can be resumed.

6. In case of power failure, the door can be operated manually by pulling the release cable to disconnect the

operator drive system.

7. Keep instructions in a prominent location near the pushbutton.

2.2

Les portes basculantes sont de gros objets lourds qui fonctionnent à l’aide de ressorts soumis à une

haute tension et de moteurs électriques. Dans la mesure où les objets en mouvement, les ressorts

sous tension et les moteurs électriques peuvent entraîner des blessures, votre sécurité et celle des

autres exigent que vous preniez connaissance des informations stipulées dans ce manuel. Si vous

avez des questions ou si vous ne comprenez pas les informations ci-incluses, veuillez contacter le

représentant de service le plus près. Pour obtenir le numéro du revendeur Genie® local, appelez le +1

(800)-OK-GENIE, et pour obtenir des conseils techniques de l’usine Genie®, appelez le +1 (800)-843-

4084.

Dans ce manuel, les mots Danger, Avertissement, et Attention sont utilisés pour faire ressortir

d’importantes informations relatives à la sécurité. Le mot :

DANGER signale une situation dangereuse imminente qui si elle n’est pas évitée, risque d’entraîner

des blessures graves, voire mortelles.

AVERTISSEMENT signale une situation potentiellement dangereuse qui, si elle n’est pas évitée, risque

d’entraîner la mort ou des blessures graves.

ATTENTION signale une situation potentiellement dangereuse qui, si elle n’est pas évitée, risque

d’entraîner des blessures ou des dommages matériels.

Le terme REMARQUE est utilisé pour signaler les étapes importantes à suivre ou d’importants éléments

à prendre en considération.

AVERTISSEMENT

!

!

!

!

DANGER POTENTIEL EFFET PRÉVENTION

PORTE EN MOUVEMENT

AVERTISSEMENT

Pourrait entraîner des

blessures graves voire la mort

Utiliser uniquement si la porte est en vue et libre de tout obstacle.

Ne laisser personne se tenir dans l’ouverture de la porte pendant

qu’elle est en mouvement.

Ne pas permettre aux enfants de jouer avec l’opérateur de la porte.

Ne pas modier la commande de l’opérateur à contact momentané

à moins qu’un moyen d’inversion externe soit installé.

Ne pas faire fonctionner une porte qui bloque ou dont le ressort

est cassé.

CHOC ÉLECTRIQUE

AVERTISSEMENT

Pourrait entraîner des

blessures graves voire la mort

Couper le courant avant d’enlever le couvercle de l’opérateur.

Lorsque le couvercle doit être remplacé, s’assurer que les ls ne sont

ni coincés ni près des pièces mobiles.

L’opérateur doit être correctement mis à la terre.

TENSION ÉLEVÉE RESSORT

AVERTISSEMENT

Pourrait entraîner des

blessures graves voire la mort

Ne pas essayer d’enlever, réparer ni ajuster les ressorts ou

toute autre pièce à laquelle le ressort de la porte est attaché, y

compris blocs de bois, supports en acier, câbles ou autres articles

semblables.

Les réparations et les réglages doivent être eectués par

technicien qualié qui se sert d’outils appropriés et qui respecte les

instructions.

!

!

!

Section 2: Safety Information & Instructions

3.1

Section 3: Critical Installation Information

Job Site Issues to Consider/Concerns

The following list of items should be considered prior to selecting an operator for a given job

site.

1. Available power supply.

2. Type of door.

3. Potential operator mounting obstructions. Items to consider include, but are not limited to: side

room, room above door shaft, room below door shaft, available mounting surface integrity,

power supply location, and convenient chain hoist and release cable positioning.

4. Size of door for appropriate operator torque and door travel speed selection.

5. Operator mounting environment. Items to consider include operator location, dampness of

location, dustiness of the location and corrosiveness of the location.

6. Door activation needs/requirements. Examples include 3 button control stations, 1 button control

stations, radio controls, pull cords, loop detectors, photoelectric controls, key switches, etc. See

“Entrapment Protection” section below.

7. Interlock switches are required under certain conditions for doors with pass doors and door locks.

See Section 5.6.

8. Accessory equipment. Examples include reversing edges which are required for doors set to

operate as momentary contact, auxiliary control relays, warning lights, etc. See “Entrapment

Protection” section below.

WARNING: DO NOT apply line voltage until instructed to do so.

AVERTISSEMENT: NE PAS mettre sous tension tant que

l’instruction n’est pas donnée de le faire.

!

!

ENTRAPMENT PROTECTION

The installation of a fail safe external reversing device (such as a monitored reversing edge.) is

required on all momentary contact electronically operated commercial doors. If such a reversing

device is not installed, the operator will revert to a constant contact control switch for operation

(Closing only).

The Reversing Devices currently UL Approved are:

1). MillerEdge ME and MT series monitored edge sensors used in combination with Timer-Close

Module P/N OPABTCX.S

2). MillerEdge ME and MT series monitored edge sensors used in combination with MillerEdge

Interface Module OPAKMEIX.S. (Direct connect through STB inputs.)

3). MillerEdge Wireless monitored edge sensor OPAKMMWE.S.

These Monitored Sensing Edges are available in any door width.

NOTE: DO NOT use take up reels in conjunction with the Monitored Sensing Edge system. Use Coil Cords

Only.

3.2

The following information will help the installer and electrician fully understand all aspects of this

installation.

Technical Data

Section 3: Critical Installation Information

This unit contains the following parts:

Operator assembly.

Owners manual and warning/caution placards.

Hardware box.

3-button control station.

Drive Chain. #50

• Output Shaft Speed: 46 RPM

• Motor is continuous duty type

• Control wiring: Maximum of 1000 feet of 22-24 ga. stranded wire

run.

1 Phase 1/2HP Operators: 3 Phase 1/2HP Operators:

115VAC - 60Hz - 5 FLA 208VAC - 60Hz - 3 FLA

208VAC - 60Hz - 5 FLA 230VAC - 60Hz - 3 FLA

230VAC - 60Hz - 5 FLA 460VAC - 60Hz - 3 FLA

575VAC - 60Hz - 2 FLA

1 Phase 3/4HP Operators:

115VAC - 60Hz - 10 FLA 3 Phase 3/4HP Operators:

208VAC - 60Hz - 5 FLA 208VAC - 60Hz - 3 FLA

230VAC - 60Hz - 6 FLA 230VAC - 60Hz - 3 FLA

460VAC - 60Hz - 4 FLA

1 Phase 1HP Operators: 575VAC - 60Hz - 2 FLA

115VAC - 60Hz - 12 FLA

208VAC - 60Hz - 5 FLA 3 Phase 1HP Operators:

230VAC - 60Hz - 6 FLA 208VAC - 60Hz - 3 FLA

230VAC - 60Hz - 4 FLA

460VAC - 60Hz - 4 FLA

575VAC - 60Hz - 2 FLA

Electrical Load Information:

Amperage draw in Full Load Amps (FLA)

3.3

Section 3: Critical Installation Information

IMPORTANT

INSTALLATION INSTRUCTIONS

WARNING

To reduce the risk of severe

injury or death:

1. READ AND FOLLOW ALL INSTALLATION

INSTRUCTIONS.

2. Install only on a properly operating and balanced

door. A door that is operating improperly could

cause severe injury. Have qualied service personnel

make repairs to cables, spring assemblies and other

hardware before installing the operator.

3. Remove all pull ropes and remove, or make

inoperative, all locks (unless mechanically and/or

electronically interlocked to the power unit) that are

connected to the door before installing the operator.

4. Install the door operator at least 8 feet above the

oor if the operator has exposed moving parts.

5. Do not connect the door operator to the power

source until instructed to do so.

6. Locate the control station: (a) within sight of the door,

(b) a minimum of 5 feet above the oor so that small

children cannot reach it, and (c) away from all moving

parts of the door.

7. Install the Entrapment Warning Placard next to the

control station and in a prominent location.

8. For products having a manual release, instruct the

end user on the operation of the manual release.

!

!

CAUTION: Check working condition of door before installing the operator. Door must be free from sticking and

binding. If equipped, deactivate any door locking device(s). Door repairs and adjustments, including cables and spring

assemblies MUST be made by a trained service representative using proper tools and instructions.

ATTENTION: Vériez l’état de fonctionnement de la porte avant d’installer l’opérateur. La porte doit pouvoir

bouger librement et ne pas coincer. Désactivez tous les dispositifs de verrouillage de la porte (si équipés). Les

réparations et les réglages de porte, plus particulièrement pour les câbles et les ressorts DOIVENT être eectués par un

technicien qualié qui se sert d’outils appropriés et qui respecte les instructions.

AVERTISSEMENT

Pour réduire les risques de

blessures graves ou de mort :

1. LIRE ET RESPECTER TOUTES LES INSTRUCTIONS

D’INSTALLATION.

2. Installez uniquement sur une porte fonctionnant

correctement et bien équilibrée. Une porte qui

fonctionne mal peut provoquer des blessures graves.

Demandez à un technicien qualié d’eectuer les

réparations des câbles, des ressorts et de toute autre

quincaillerie avant de procéder à l’installation de

l’opérateur.

3. Retirez toutes les cordes de traction ainsi que tous

les verrous ou rendez-les inopérants (à moins qu’ils

ne soient mécaniquement et/ou électroniquement

interverrouillés à l’unité motrices) qui sont connectés à

la porte avant de procéderà l’installation de l’opérateur.

4. Installez l’opérateur de la porte à 2,4 m minimum au-

dessus du sol lorsque des pièces mobiles de l’opérateur

sont exposées.

5. Ne pas raccorder l’opérateur de la porte à la source

d’alimentation avant que l’instruction ne soit donnée de

le faire.

6. Installez la station de commande : (a) en vue de la porte,

(b) à 1,5 m minimum au-dessus du sol pour que les

jeunes enfants ne puissent pas l’atteindre, et (c) à l’écart

de toutes les pièces mobiles de la porte.

7. Installez le poster d’avertissement de pincement à côté

de la station de commande à un endroit bien en vue.

8. Pour les produits ayant un déclenchement manuel,

indiquez à l’utilisateur comment déclencher

manuellement.

IMPORTANT

INSTRUCTIONS

D’INSTALLATION

4.1

Front of Hood Mount

The Fire Door Operator can be assembled for right-hand or left-hand mounting Front of Hood Fig. 1.

Right hand view is shown, left hand mount is mirror image.

1) Determine operator mounting location, including desired hoist release cable routing.

2) Install two attachment brackets to operator using the six 5/16”-18 x 3/4” carriage bolts and nuts

provided. The attachment brackets must be turned inward. Fig 1.

3) Attach operator to main mounting bracket using the four 5/16”- 18 X 1-1/4” carriage bolts and ange

nuts using option 1 or option 2.

Section 4: Installation

NOTE: The operator output shaft extends

3-7/8” on each side of the operator frame.

It can be adjusted side to side, to increase/

decrease the eective shaft length. Adjust

by loosening the set screws in the shaft set

collars and sprocket, moving the shaft and re-

tightening the set screws. Be sure the bearings

are fully seated in the side frames before re-

tightening the set screws.

Mounting Option 1

Mounting Option 2

Figure 1

4.2

Front of Hood Mount (Continued)

4) Attach operator assembly to head plate using hardware provided. Note the position of bracket slots for

proper bracket orientation. Fig. 2.

Attach Operator to Door.

1) Attach 12 tooth sprocket to operator output shaft.

2) Align keyways and insert key into sprocket and output shaft keyway. Do not tighten set screw at this

time.

3) Attach door sprocket to door shaft. Do not tighten at this time.

4) Assemble chain using chain master link.

5) Place assembled chain over door shaft sprocket and around the 12 tooth sprocket.

6) Raise or lower operator to remove slack from the chain. Be certain operator output shaft is parallel with

door shaft.

7) Tighten operator mounting bracket nuts.

8) Tighten 12 tooth sprocket set screws.

9) Insert door sprocket key and tighten set screws.

Section 4: Installation

NOTE: Hand tighten bracket with head plate nuts. Adjusting the mounting plate position to tension the drive chain will be required later

in the installation process.

Figure 2

NOTES:

1. VERIFY VOLTAGE, PHASE & MOUNTING.

2. ALL OPTIONS ARE AN ADDED COST.

3. A CLEARANCE OF 6" SHOULD BE ALLOWED FOR ACCESS TO ELECTRIC BOX.

4. CONTROL VOLTAGE IS A NEC CLASS 2 CIRCUIT.

5. IT IS RECOMMENDED THAT THE OPERATOR BE BRACED TO THE WALL

FOR STABILIZING AND A SAFETY CABLE ATTACHED.

22 3/8"

(OPERATOR HEIGHT)

3 1/2"

14 1/8"

15 3/16"

14 3/16"

5 1/8"

6 13/16"

MOUNTING

OPTION 1

#347372

POWER SUPPORT

BRACKET

16"

(OUTPUT SHAFT LENGTH)

16 13/16"

(OPERATOR WIDTH)

4 11/16"

(OPERATOR

SIDE ROOM)

STANDARD FUSE LINK SWITCH

LOCATION (SEE MANUAL

FOR INSTALLATION OF

SASH CHAIN)

OPTIONAL

FUSE LINK

SWITCH

LOCATION

8 9/16"

MOUNTING

OPTION 2

#347372

POWER SUPPORT

BRACKET

* Mount Sprockets as close to the operator frame as possible.

NOTE: It is highly recommended to apply thread locking compound to sprocket set screws.

4.3

Hand Chain and Keeper

1) Route the hand chain through the chain guide, around the pocket wheel and back through the chain

guide. Fig.3.

2) Connect the hand chain ends together as shown in Fig 4. by twisting open the last link on one end of the

chain, and slipping the last link on the opposite end onto the open link.

3) Twist open link closed again.

4) Mount chain keeper to wall in line with chain approximately 4 feet from oor.

5) Loop chain around keeper as shown. Fig. 5. Optional Padlock not provided.

6) Install hoist cable.

• With operator installed motor DOWN, attach hoist cable to cam arm hole closest to mounting plate. Fig. 6.

• With operator installed motor UP, attach hoist cable to cam arm hole closest to electric box. Fig. 6.

Section 4: Installation

NOTE: To insure smooth operation, make sure there is no twist in the hand chain before connecting the link ends

together.

MOUNTED

MOTOR UP

MOUNTED

MOTOR DOWN

ATTACH

HOIST

CABLE

HERE

ATTACH

HOIST

CABLE

HERE

Figure 3 Figure 4 Figure 5

Figure 6

4.4

1) Move Fusible Link Switch from top of Electric Box to Side if necessary depending on installation of

operator direction or side. FIG. 1.

2) Remove E-Ring to remove switch assembly.

3) Remove plug and insert into hole where fuse link switch was removed.

4) Install fuse link switch assembly into desired connection point and install E-Ring.

5) Follow all recommendations for release chain installation per NFPA 80. Note direction of pull on switch.

FIG. 3.

6) Remove fuse link switch pin to tension chain. Ensure switch holds tension on chain and does not contact

internal switch. FIG. 3.

The Fire Door Operator provides a connection for the Fusible Link from the Fire Door. If tension is lost from chain,

operator will release its clutch and door will drop.

Fusible Link Switch

Section 4: Installation

E-Ring

Plug

Fuse Link

Switch

Assembly

Fuse Link

Switch Pin

Switch Mount

Top

Switch Mount

Either Side

Tensional Direction

FIG. 1

FIG. 2

Wall Mount Bracket

Fusible Link

Turnbuckle

Sash

Chain

Example

Remove

Pin

FIG. 3

NOTE: If operator and headplate sway during door operation, bracing is necessary. Using

structural angle, diagonally brace from operator mounting bracket or from front portion of

headplate back to wall.

4.5

Clutch Adjustment

To Adjust the Clutch

1) Decrease the compression on the clutch until the operator will

not lift the door.

• Turning the adjustment castle nut counter-clockwise will

decrease compression and clockwise will increase compression.

2) Gradually increase compression until the operator will perform a

complete open and close cycle without clutch slippage.

3) Insert a cotter pin through the adjustment castle nut and bend a

leg of the cotter pin to hold it in place.

Section 4: Installation

NOTE: The clutch is intended to provide protection for the door, the operator and

associated equipment. It is not intended for entrapment protection.

NOTE: Periodically check the system for proper clutch action. If clutch starts to slip

after working properly for some time , check manual operation of door BEFORE

adjusting clutch. The door may not be operating freely or the counterbalance spring

may need adjusting. Repairs and adjustments must be performed by a trained service

representative using proper tools and instructions.

CLUTCH PULLEY

WASHER

COTTER PIN

ADJUSTING NUT

CLUTCH

PAD

CLUTCH

PLATE

SPRING

1) Unplug FDO module ribbon harness from main

control board plug connector.

2) Remove the two screws mounting the FDO

module to plate.

3) Use the two screws included with the auxiliary

board and mount to plate where FDO module

was.

4) Plug auxiliary board ribbon harness into plug

connector on main control board.

5) Reinstall FDO module onto plate just above

the auxiliary board.

6) Plug FDO module ribbon harness into

connector on auxiliary board.

Only one auxiliary board can be used with this opener.

Optional Auxiliary Board (AOM or TCM)

FDO Module

AUX Board

Ribbon

Harness

Plug

NOTE: Additional menu items will appear during programming. See the instructions included with the Auxiliary

board to see changes.

5.1

Section 5: Wiring

WARNING

• DO NOT apply power to operator until instructed to do

so.

• It is strongly recommended, and may be required

by law in some areas, that line voltage wiring be

performed by a qualied electrician.

• Be sure that electrical power has been disconnected

from the input power wires being connected to the

operator prior to handling these wires. An appropriate

lock-out/tag-out procedure is recommended.

• Line voltage wiring must meet all local building codes.

• Make sure operator voltage, phase and frequency

nameplate ratings are identical to the job site line

voltage ratings.

• Input power wiring must be properly sized for the

operators amperage rating located on the nameplate.

• To reduce the risk of electric shock, make sure the

chassis of this unit is properly grounded.

!

• NE PAS mettre sous tension tant que l’instruction n’est

pas donnée de le faire.

• Il est fortement recommandé voire même exigé par la

loi dans certaines régions, de contacter un électricien

qualié pour l’acheminement du l électrique.

• Assurez-vous que l’alimentation électrique a été

déconnectée des câbles d’alimentation d’entrée

connectés à l’opérateur avant de manipuler ces câbles.

Une procédure de verrouillage/étiquetage appropriée

est recommandée.

• Le câblage au secteur doit satisfaire à tous les codes de

construction locaux.

• Assurez-vous que les valeurs nominales de la plaque

signalétique pour tension, phase et fréquence de

l’opérateur correspondent à celles des tensions de

l’alimentation sur site.

• La capacité d’entrée doit correspondre à la valeur

nominale de l’ampérage des opérateurs indiquée sur la

plaque signalétique.

• Pour réduire le risque de choc électrique, assurez-vous

que le châssis de l’unité est correctement mis à la terre.

AVERTISSEMENT

!

Installation of all wiring and connections, including Power

Limited Class 1 and Class 2 circuits, shall be performed in

accordance with, but not limited to, the latest NFPA, UL, and

N.E.C. standards and codes.

In addition, all installations subject to Canadian standards

shall be performed in accordance with the Canadian Electrical

Code, Part 1, with respect to wiring material type, wiring

gauge related to power capacity requirements, circuit length

and wiring methods.

5.2

External Wire Diagram

Section 5: Wiring

OPEN CLOSE

N-O

REVERSE

N-O

REVERSE

ODC

STB

ODC

STB

EXT

INTLK

EXT

INTLK

OPEN

CLOSE

STOP

1-BTN

STATION

KEY

SWITCH

STATION

CARD

READER

O/C

PULL

SWITCH

RELAY

GND

NOM

+ 24VDC

N/O

N/O

N/O

N/O

3-BUTTON

STATION

MONITORED SENSING EDGEINTERFACE MODULE

(OPAKMEIX.S)

RADIO

REMOVE JUMPER

WHEN INSTALLING

EXTERNAL INTERLOCK

CONTROL SIGNAL TERMINAL STRIP

MULTIPLE 3-BUTTON

STATION INSTALLATIONS

REQUIRE THE STOP

BUTTON TO BE WIRED

IN SERIES

REMOVE JUMPER

IF STOP BUTTON

IS USED

EXT

RADIO

CONNECTOR

PIGTAIL

LINE IN

POWER CONNECTIONS

L1/ L1

N/ L2

GND

120V

208/230V

LINE

(HOT)

NEUTRAL

LINE 1

LINE 2

L1/ L1

L1/ L2

GND

L3/ L3

(HOT)

(HOT)

(HOT)

SINGLE

PHASE

3

PHASE

STOP GND 1-BTN

Blue

Orange

Yellow

Chassis

208/230

460

575

Special Application

External Radio Terminal

0-40 VDC

250mA. Max Current

Power-Limited Class 2 Supply 0-40VDC

External Radio connections

are Non-Power-Limited.

All connections are to be

made within 20ft. (6.1M),

enclosed in conduit and in

the same room.

OPEN, CLOSE, STOP and 1-BTN terminals are 40VDC,

20mA MAX. ODC STB Terminals are 40VDC, 150mA MAX.

N/O Reverse Terminals are 40VDC, 10mA MAX.

EXT INTLK Terminals are 40VDC, 2.5mA MAX.

EXT INTLK connections

are Non-Powered-Limited.

All connections are to be

made within 20 ft. (6.1M)

and enclosed in conduit

and in the same room.

5.3

1) Remove LINE VOLTAGE INPUT PLUG and install proper ttings and 1/2”conduit.

2) Route proper LINE VOLTAGE wires into operator.

3) Locate LINE INPUT terminals on circuit board. Using correct connectors, attach wires to LINE INPUTS, and

GROUND terminal.

• Keep low voltage and line voltage wires separate.

• Route all line voltage wires as shown.

• Plug all unused conduit holes.

Line Voltage Wiring

Section 5: Wiring

1 Phase Line Voltage Wiring 3 Phase Line Voltage Wiring

Route Line Voltage wires in shaded areas

L1/L1

N/L2

GND

POWER CONNECTIONS

LINE

(HOT)

NEUTRAL

LINE 1

LINE 2

115V

208V

230V

1 Phase

LINE IN

3 Phase

LINE IN

POWER CONNECTIONS

L1

L2

GND

LINE 1

LINE 2 LINE 3

L3

5.4

1) Connect all LOW VOLTAGE control circuit wires using 1/2” conduit or exible convoluted tubing.

• Keep low voltage and line voltage wires separate.

• Route all low voltage control wiring as shown. This includes all control circuit wires such as wall

controls, timers and single button input devices as well as safety circuit wiring.

• Route FDO Control Board wires through opposite side of unit.

• Plug all unused conduit holes.

Low Voltage Control Wiring

Section 5: Wiring

Route Low Voltage Control & FDO Board wires in shaded areas.

Keep FDO Board and Control Wires separated.

FDO

BOARD

Low Voltage

Power Limited

Circuit Wiring

Fire Door

Module

Non-Power

limited

Circuit Wiring

5.5

1) For a single 3 - button installation, make connections as shown in Fig. 3.

2) For single button accessory controls, make connections as shown in Fig. 4.

3) For a multiple 3 - button installations, make connections as shown in Fig. 5.

Wall Controls

Section 5: Wiring

OPEN

CLOSE

STOP

CONTROL SIGNAL TERMINAL STRIP

NOTE

JUMPER BETWEEN

STOP AND GND

TERMINALS MUST

BE REMOVED

OPEN CLOSE STOP GND

3-BTN

Station

Entrapment Warning

Placard

CONTROL SIGNAL TERMINAL STRIP

1-BTN

Station

Key

Switch

Station

Card

Reader

Open/Close

Pull Switch

STOP GND 1-BTN

ODC

STB

CONTROL SIGNAL TERMINAL STRIP

OPEN

CLOSE

STOP

OPEN

CLOSE

STOP

OPEN CLOSE STOP GND

NOTE: JUMPER

BETWEEN STOP

AND GND TERMINALS

MUST BE REMOVED

3-BTN

STATION

3-BTN

STATION

NOTE: If an External STOP button is NOT being installed,

a jumper wire must be installed between the “STOP” and

“GND” terminals as shown.

NOTE: Low voltage wiring can be run a maximum of

1000 feet. DO NOT use long distance wiring kits on this

operator.

WARNING:

Single button input will reverse the door to the up limit. A timer will resume downward travel if set. Single button input will NOT

stop the door. Use of an emergency stop button is strongly recommended for single button input applications.

!

AVERTISSEMENT:

Une entrée à bouton unique inversera la porte vers la limite supérieure. Une minuterie reprendra le parcours vers le bas, si réglé.

Une entrée à bouton unique N’ARRÊTERA PAS la porte. L’utilisation d’un bouton d’arrêt d’urgence est fortement recommandée

pour les applications d’entrée à bouton unique.

!

!

!

WARNING:

AVERTISSEMENT:

Before momentary contact control can be used on the CLOSE button, a monitored external reversing device such as a sensing

edge switch must be used. See pages 5.7-5.8 for installation of entrapment protection devices.

Avant d’utiliser la commande à contact momentané sur le bouton FERMETURE, un dispositif d’inversion externe surveillée tel

qu’un système de un commutateur de détection de bord doit être utilisé. Voir l’installation des dispositifs de protection contre

le coincement en pages 5.7-5.8.

WARNING:

!

AVERTISSEMENT:

!

• Wall Control(s) must be located so that the door is within sight of the user and is far enough from the door, or positioned

such that the user is prevented from coming in contact with the door while operating controls.

• Attach the Warning placard adjacent to the Wall Control. Fig. 3A.

• La ou les commandes murales doivent être situées de telle sorte que l’utilisateur puisse voir la porte et positionnées de

telle sorte que l’utilisateur ne puisse pas entrer en contact avec la porte lorsqu’il se sert des commandes.

• Fixez le poster d’avertissement à côté de la commande murale. Fig. 3A.

5.6

Interlock Switches

Section 5: Wiring

INSTALLING EXTERNAL

INTERLOCK

CONTROL SIGNAL TERMINAL STRIP

* REMOVE JUMPER WHEN

*

NOTE: If External Interlock is used, THE

JUMPER WIRE BETWEEN THE EXT INTLK

TERMINALS MUST BE REMOVED.

STANDARD

SLIDELOCK

TRACK

SWITCH

(N.C.)

Switches must

be set in

the field.

Side lock interlock:

Should be open when door is locked.

Closed when door is unlocked.

A

ODC

STB

ODC

STB

N-O

REVERSE

N-O

REVERSE

EXT

INTLK

EXT

INTLK

1) Optional external interlock switches are required with some Rolling Steel Doors to prevent the door

from operating under certain conditions including the following:

• If the door is equipped with a functioning door lock, an interlock switch (A) must be installed to

prevent electric operation when the lock is engaged.

• If the door is equipped with a pedestrian pass-through door, an interlock switch (B) must be installed

at the pass-through door in order to prevent electrical operation when the pass-through door is open.

2) The switches must be set in the eld.

5.7

1/2 Door Height

+ 12in.

COIL

CORD

Monitored

Safety Edge

Red Wires

MillerEdge®

Interface Module

Install

Black

White

Control Wire

Terminals

ODC

STB

ODC

STB

Junction

Box

1) Mount junction box to wall One half the door height plus 12 inches from oor.

2) Install Hard-wiring from operator and coil cord to junction box and secure with conduit clamps.

3) Connect hard-wiring from operator to coil cord with wire nuts and install junction box cover plate. These

are not polarity sensitive.

4) Install hard-wires to ODC STB terminals in operator.

5) Attach coil cord to Monitored Edge Interface Module junction box and secure with conduit clamps.

6) Install wires to Monitored Interface Module as shown.

7) Install cover plate.

Right hand installation shown, Left hand installation mirrored

MillerEdge® Wired Monitored Sensing Edge

Monitored Sensing Edge Installation

Section 5: Wiring

WARNING: Actuating the operator using constant contact on the CLOSE button will override non-functioning

external reversing devices, including sensing edges.

AVERTISSEMENT: L’activation de l’opérateur avec un contact constant sur le bouton FERMER annulera les

dispositifs de renversement externes non fonctionnels, y compris les systèmes de détection des bords.

!

!

NOTE: DO NOT use take up reels with Monitored Edge systems

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

Genie GCL Fire Door Operator / Installation Manual

- Catégorie

- Porte de garage

- Taper

- Operator / Installation Manual

dans d''autres langues

- English: Genie GCL Fire Door

Documents connexes

-

Genie TCM Manuel utilisateur

-

Genie GCL-LJ Manuel utilisateur

-

Genie GCL-GH Operator / Installation Manual

-

Genie GCL-MJ / GCL-MH Operator / Installation Manual

-

Genie GCL-J&H 1HP Guide d'installation

-

Genie GCL-GT Operator / Installation Manual

-

Genie G3BT-P Manuel utilisateur

-

Genie GCL-MT Manuel utilisateur

-

Genie GCL-T Operator / Installation Manual

-

Genie AOM Manuel utilisateur

Autres documents

-

LiftMaster LMWEKITU Manuel utilisateur

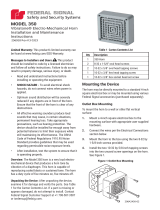

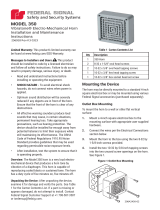

-

Federal Signal 350 Vibratone® Horn Manuel utilisateur

Federal Signal 350 Vibratone® Horn Manuel utilisateur

-

Grizzly G8696 Le manuel du propriétaire

-

LiftMaster LC36M Manuel utilisateur

-

Nice HySecurity SlideSmart CNX Slide Gate Operator Guide d'installation

Nice HySecurity SlideSmart CNX Slide Gate Operator Guide d'installation

-

Honeywell Modutrol IV M6294F1009-F Information produit

-

Blodgett MT2136E/AB Mode d'emploi

-

Dormakaba LA GARD 700 Series Mode d'emploi

-

Gentex WGESA24 Series Manuel utilisateur

-

BEA UL LISTED MAGLOCKS Mode d'emploi