D55170, D55180, D55390, D55395, D55570, D55575, D55580, D55585

Contractor’s Electric Wheeled Portable Air Compressor

Compresseur d’air électrique portatif sur roues de classe entrepreneur

Compresor de aire eléctrico portátil con ruedas para contratistas

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

2

English

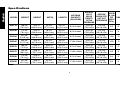

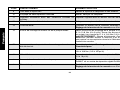

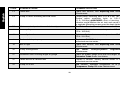

Air Compressor (Fig.1)

A. Pump Air Intake Filter

B. Pump Oil Drain Plug

C. On/Off Switch

D. Air Tank Pressure Gauge

E. Regulated Pressure Gauge

F. Pressure Regulator

G. Air Outlet

H. Pilot Valve

I. Safety Valve

J. Air Tank Drain Valves

K. Pump Oil Dipstick/Oil Fill Plug

L. Dual Voltage Control

M. Pressure Switch

A

K

F

H

I

J

B

C

D55170, D55180

D

E

F

G

FIG. 1

D55390

B

H

J

L

F

A

K

M

D

E

F

G

C

I

M

D55570, D55580

B

H

J

L

F

A

K

M

D

E

F

G

C

I

M

3

English

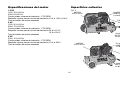

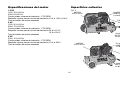

Pump Specifi cations

K PUMP

Inline, vertical twin cylinder

Single Stage

Oil Lubricated

Cast Iron crankcase cylinder, and head

Bore: 2.5" (63.5 mm)

Stroke: 2" (50.8 mm)

Weight: 47 lbs. ( 21.3 kg.)

Oil Capacity: 14 oz. (414 mL)

G PUMP

V - twin 4 cylinder

Single Stage

Oil Lubricated

Cast Iron crankcase cylinder, and head

Bore: 2.5" (63.5 mm)

Stroke: 2.375" (60.3 mm)

Weight: 69 lbs. (31.3 kg.)

Oil Capacity: 30 oz. (887 mL)

B

K

B

K

D55395

A

K

B

E

F

G

D

H

L

M

C

I

M

J

D55575, D55585

A

B

E

F

G

D

H

L

M

K

C

I

M

4

English

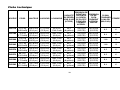

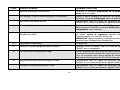

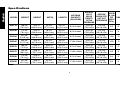

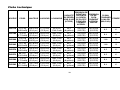

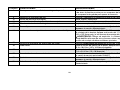

Specifi cations

MODEL WEIGHT HEIGHT WIDTH LENGTH

AIR TANK

CAPACITY

(GALLONS)

APPROX.

PILOT

VALVE

RESET/

CUT-IN

PRESSURE

APPROX.

BLOW OFF/

CUT-OUT

PRESSURE

SCFM

@ 100

PSI

(689.5

kPa)

PUMP MOTOR

D55170 168 lbs.

(76.2 kg.)

33.0 in.

(838.2 mm)

22.5 in.

(571.5 mm)

45.0 in.

(1143.0 mm)

8 (30.3 liters)

105 PSI

(723.9 kPa)

125 PSI

(861.8 kPa)

6.5 K 1.5 HP

D55180 172 lbs.

(78.0 kg.)

23.5 in.

(596.9 mm)

18.3 in.

(463.6 mm)

43.0 in.

(1092.2 mm)

8 (30.3 liters)

105 PSI

(723.9 kPa)

125 PSI

(861.8 kPa)

8.4 K 2 HP

D55390

231 lbs.

(104.8 kg.)

26.3

(666.8 mm)

18.3 in.

(463.6 mm)

43.0 in.

(1092.2 mm)

8 (30.3 liters)

105 PSI

(723.9 kPa)

125 PSI

(861.8 kPa)

13.8 G 3 HP

D55395

254 lbs.

(115.2 kg.)

32.0 in.

(812.8 mm)

20.3 in.

(514.4 mm)

43.0 in.

(1092.2 mm)

17 (64.4 liters)

105 PSI

(723.9 kPa)

125 PSI

(861.8 kPa)

13.8 G 3 HP

D55570

168 lbs.

(76.2 kg.

23.5 in.

(596.9 mm)

18.25 in.

(463.6 mm)

43.0 in.

(1092.2 mm)

8 (30.3 liters)

105 PSI

(723.9 kPa)

125 PSI

(861.8 kPa)

6.5 K 1.5 HP

D55575

194 lbs.

(88.0 kg.)

29.8 in.

(755.7 mm)

20.3 in.

(514.4 mm)

43.0 in.

(1092.2 mm)

17 (64.4 liters)

105 PSI

(723.9 kPa)

125 PSI

(861.8 kPa)

6.5 K 1.5 HP

D55580

175 lbs.

(79.4 kg.)

23.5 in.

(596.9 mm)

18.3 in.

(463.6 mm)

43.0 in.

(1092.2 mm)

8 (30.3 liters)

105 PSI

(723.9 kPa)

125 PSI

(861.8 kPa)

8.4 K 2 HP

D55585

201 lbs.

(91.2 kg.)

29.8 in.

(755.7 mm)

20.3 in.

(514.4 mm)

43.0 in.

(1092.2 mm)

17 (64.4 liters)

105 PSI

(723.9 kPa)

125 PSI

(861.8 kPa)

8.4 K 2 HP

5

English

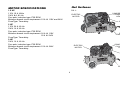

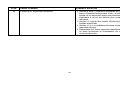

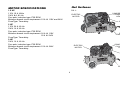

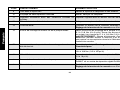

Hot Surfaces

COMPRESSOR

CYLINDER &

HEAD

OUTLET TUBE

PUMP

CRANKCASE

ELECTRIC

MOTOR

COMPRESSOR

CYLINDER &

HEAD

OUTLET TUBE

PUMP

CRANKCASE

ELECTRIC

MOTOR

FIG. 2

MOTOR SPECIFICATIONS

1.5 HP

115V, 15 A, 60Hz

230V, 8 A, 60 Hz

Four pole, induction type,1725 RPM

Minimum branch circuit requirement: 15 A @ 115V and 230V

Fuse Type: Time delay

2 HP

115V, 20 A, 60 Hz

230V, 10 A, 60 Hz

Four pole, induction type,1725 RPM

Minimum branch circuit requirement: 20 A @ 115V

15 A @ 230V

Fuse Type: Time delay

3 HP

230V, 10 A, 60 Hz

Four pole, induction type,1725 RPM

Minimum branch circuit requirement: 15 A @ 230V

Fuse Type: Time delay

6

English

Defi nitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and

pay attention to these symbols.

DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury.

WARNING: Indicates a potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

CAUTION: Indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury.

CAUTION: Used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT

THIS OR ANY D

E

WALT TOOL, CALL US TOLL FREE AT:

1-800-4-D

EWALT (1-800-433-9258)

Important Safety Instructions

Important Safety Instructions

WARNING: Do not operate this unit until you read and understand

this instruction manual for safety, operation and maintenance

instructions.

WARNING: Some dust created by power sanding, sawing, grind-

ing, drilling, and other construction activities contains chemicals

known (to the State of California) to cause cancer, birth defects or

other reproductive harm. Some example of these chemicals are:

• lead from lead-based paints

• crystalline silica from bricks and cement and other masonry

products

• arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these chemi-

cals: work in a well ventilated area, and work with approved safety

equipment, al ways wear OSHA/MSHA/NIOSH approved, properly

fit ting face mask or res pi ra tor when us ing such tools.

When using air tools, basic safety precautions should always be fol-

lowed to reduce the risk of of personal injury.

WARNING: This product contains chemicals, including lead,

known to the State of California to cause cancer, and birth

defects or other reproductive harm. Wash hands after handling.

SAVE THESE INSTRUCTION

DANGER: RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

• It is normal for electrical

contacts within the motor

and pressure switch to

spark.

• Always operate the compres-

sor in a well ventilated area

free of combustible materials,

gasoline, or solvent vapors.

7

English

DANGER: RISK TO BREATHING (ASPHYXIATION)

WHAT CAN HAPPEN HOW TO PREVENT IT

• The compressed air directly

from your compressor is not

safe for breathing. The air

stream may contain carbon

monoxide, toxic vapors

or solid particles from the

air tank. Breathing these

contaminant's can cause

serious injury or death.

• Air obtained directly from the

compressor should never

be used to supply air for

human consumption. In order

to use air produced by this

compressor for breathing,

suitable filters and in-line

safety equipment must be

properly installed. In-line

filters and safety equipment

used in conjunction with the

compressor must be capable

of treating air to all applicable

local and federal codes prior to

human consumption.

• Sprayed materials such as

paint, paint solvents, paint

remover, insecticides and

weed killers, may contain

harmful vapors and poisons.

• Work in an area with good

cross ventilation. Read and

follow the safety instructions

provided on the label or safety

data sheets for the materials

you are spraying. Always use

certified safety equipment:

OSHA/MSHA/NIOSH

respiratory protection designed

for use with your specific

application.

• If electrical sparks from

compressor come into con-

tact with flammable vapors,

they may ignite, causing fire

or explosion.

• If spraying flammable mate-

rials, locate compressor

at least 20' (6.1 m) away

from spray area. An addi-

tional length of hose may be

required.

• Store flammable materials in

a secure location away from

compressor.

• Restricting any of the com-

pressor ventilation openings

will cause serious overheat-

ing and could cause fire.

• Never place objects against

or on top of compressor.

• Operate compressor in

an open area at least 12"

(30.5 cm) away from any

wall or obstruction that would

restrict the flow of fresh air to

the ventilation openings.

• Operate compressor in a

clean, dry well ventilated area.

Do not operate unit indoors or

in any confined area.

• Unattended operation of

this product could result in

personal injury or property

damage. To reduce the risk

of fire, do not allow the

compressor to operate unat-

tended.

• Always remain in attendance

with the product when it is

operating.

• Always turn off and unplug

unit when not in use.

8

English

DANGER: RISK OF INJURY OR PROP ER TY DAMAGE WHEN

TRANSPORTING OR STORING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Oil can leak or spill and could

result in fire or breathing

hazard; serious injury or

death can result. Oil leaks will

damage carpet, paint or other

surfaces in vehicles or trailers.

• Always place compressor

on a protective mat when

transporting to protect against

damage to vehicle from leaks.

Remove compressor from

vehicle immediately upon arrival

at your destination. Always keep

compressor level and never lie

on its side.

WARNING: RISK OF BURSTING

Air Tank: The air tank on your Air Compressor is designed and may

be UM coded (for units with air tanks greater than 6 inch diameter)

according to ASME Section VIII, Div. 1 rules. All pressure vessels

should be inspected once every two years. To find your state pressure

vessels inspector, look under the Division of Labor and Industries in

the government section of a phone book or call 1-800-4-D

EWALT for

assistance.

The following conditions could lead to a weakening of the air tank and

result in a violent air tank explosion:

WHAT CAN HAPPEN HOW TO PREVENT IT

• Failure to properly drain

condensed water from

air tank, causing rust and

thinning of the steel air tank.

• Drain air tank daily or after

each use. If air tank develops

a leak, replace it immediately

with a new air tank or replace

the entire compressor.

• Modifications or attempted

repairs to the air tank.

• Never drill into, weld, or make

any modifications to the air

tank or its attachments. Never

attempt to repair a damaged or

leaking air tank. Replace with a

new air tank.

• Unauthorized modifications

to the, pilot valve, safety valve

or any other components

which control air tank

pressure.

• The air tank is designed

to withstand specific

operating pressures. Never

make adjustments or parts

substitutions to alter the factory

set operating pressures.

Attachments & accessories:

• Exceeding the pressure

rating of air tools, spray guns,

air operated accessories,

tires and other inflatables can

cause them to explode or

fly apart, and could result in

serious injury.

• Follow the equipment

manufacturers

recommendation and never

exceed the maximum

allowable pressure rating

of attachments. Never use

compressor to inflate small

low pressure objects such

as children’s toys, footballs,

basketballs, etc.

9

English

Tires:

• Over inflation of tires could

result in serious injury and

property damage.

• Use a tire pressure gauge to

check the tires pressure before

each use and while inflating

tires; see the tire sidewall for

the correct tire pressure.

NOTE: Air tanks, compressors and

similar equipment used to inflate

tires can fill small tires similar to

these very rapidly. Adjust pressure

regulator on air supply to no more

than the rating of the tire pressure.

Add air in small increments and

frequently use the tire gauge to

prevent over inflation.

WARNING: RISK OF ELECTRICAL SHOCK

WHAT CAN HAPPEN HOW TO PREVENT IT

• This air compressor is

powered by electricity.

Like any other electrically

powered device, If it is not

used properly it may cause

electric shock.

• Never operate the

compressor outdoors when it

is raining or in wet conditions.

• Never operate compressor

with protective covers

removed or damaged.

• Repairs attempted by

unqualified personnel can

result in serious injury or

death by electrocution.

• Any electrical wiring or

repairs required on this

product should be performed

by a D

EWALT factory

service center or a D

EWALT

authorized service center in

accordance with national and

local electrical codes.

• Electrical Grounding:

Failure to provide adequate

grounding to this product

could result in serious injury

or death from electrocution.

See Grounding

Instructions under

Installation.

• Make sure the electrical circuit

to which the compressor is

connected provides proper

electrical grounding, correct

voltage and adequate fuse

protection.

WARNING: RISK FROM FLYING OBJECTS

WHAT CAN HAPPEN HOW TO PREVENT IT

• The compressed air stream

can cause soft tissue

damage to exposed skin and

can propel dirt, chips, loose

particles and small objects

at high speed, resulting in

property damage or personal

injury.

• Always wear certified safety

equipment: ANSI Z87.1 eye

protection (CAN/CSA Z94.3)

with side shields when using

the compressor.

• Never point any nozzle or

sprayer toward any part of

the body or at other people or

animals.

10

English

• Always turn the compressor off

and bleed pressure from the

air hose and air tank before

attempting maintenance,

attaching tools or accessories.

WARNING: RISK OF HOT SURFACES

WHAT CAN HAPPEN HOW TO PREVENT IT

• Touching exposed metal

such as the compressor

head, engine head, engine

exhaust or outlet tubes, can

result in serious burns.

• Never touch any exposed

metal parts on compressor

during or immediately after

operation. Compressor will

remain hot for several minutes

after operation.

• Do not reach around

protective shrouds or attempt

maintenance until unit has

been allowed to cool.

WARNING: RISK FROM MOVING PARTS

WHAT CAN HAPPEN HOW TO PREVENT IT

• Moving parts such as the

pulley, flywheel and belt can

cause serious injury if they

come into contact with you or

your clothing.

• Never operate the compressor

with guards or covers which

are damaged or removed.

• Keep your hair, clothing and

gloves away from moving

parts. Loose clothes, jewelry

or long hair can be caught in

moving parts.

• Air vents may cover moving

parts and should be avoided

as well.

• Attempting to operate

compressor with damaged or

missing parts or attempting

to repair compressor with

protective shrouds removed

can expose you to moving

parts and can result in

serious injury.

• Any repairs required on this

product should be performed

by a D

EWALT factory

service center or a D

EWALT

authorized service center.

11

English

WARNING: RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

• Unsafe op er a tion of your air

compressor could lead to se ri-

ous in ju ry or death to you or

others.

• Review and understand all

instructions and warnings in

this manual.

• Be come fa mil iar with the

op eration and con trols of the

air compressor.

• Keep operating area clear of all

persons, pets and obstacles.

• Keep chil dren away from the

air compressor at all times.

• Do not operate the product

when fatigued or under the

influence of alcohol or drugs.

Stay alert at all times.

• Never defeat the safety fea-

tures of this prod uct.

• Equip area of operation with a

fire extinguisher.

• Do not op er ate machine with

missing, broken or un au tho-

rized parts.

• Never stand on the compressor.

WARNING: RISK OF

INJURY FROM LIFTING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Serious injury can result from

attempting to lift too heavy

an object.

• The compressor is too heavy

to be lifted by one person.

Obtain assistance from others

before lifting.

CAUTION: RISK FROM NOISE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Under some conditions and

duration of use, noise from

this product may contribute

to hearing loss.

• Always wear certified safety

equipment: ANSI S12.6

(S3.19) hearing protection.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

12

English

FEATURES (Fig. 1)

DUAL CONTROL

D55390, D55395, D55570, D55575, D55580, D55585

Dual control allows the compressor to operate in the constant

run or the stop/start mode of operation. The pilot valve (H) is

used to control the compressor when operating in the constant

run mode. The pressure switch is used to control the compressor

when operating in the stop/start mode. The mode of operation is

determined by the amount of time the compressor will be required to

supply air. If the demand for air is infrequent, then the unit should be

operated in the stop/start mode to minimize unnecessary run time

and to save energy. If there is a frequent or extended demand for

air, and/or the unit is located in a remote area where access to the

compressor is difficult, the unit should be operated in the constant

run mode to minimize the number of times the motor must start in

an hour to ensure good motor life.

DUAL VOLTAGE

D55570, D55575, D55580, D55585

The dual voltage (L) feature allows the

L

compressor to operate in 115 or 230 volt

operation. The advantage of running in the 230

volt operation is a lower current draw. Lower

current draw may be necessary in areas with a

poor power source. Lower current also reduces

operating costs. See 230 Volt Conversion

under Installation.

PILOT VALVE

D55390, D55395, D55570, D55575, D55580, D55585

When the maximum air tank pressure is obtained,

H

the pilot valve (H) will blow-off. This will cause the

compressor to exhaust the air though the the pump

head and not fill the tank.

Pilot Valve with Manual Lock (D55170, D55180):

The manual lock allows you to manually unload the

compressor with air pressure in the air tank.

To operate the manual lock:

Rotate the manual lock pilot valve lever to the

OPEN

H

CLOSED

H

open position to prevent air tank pressure

buildup. Rotate manual lock pilot valve lever to

the closed position after starting the motor to

allow air tank pressure to build. NOTE: Air will

not build in tank when manual lock pilot valve

lever is in the open position.

PRESSURE SWITCH

D55390, D55395, D55570, D55575, D55580, D55585

The pressure switch (M) automatically starts the motor when the air

tank pressure drops below the factory set cut-in pressure. It stops

the motor when the air tank pressure reaches the factory set cut-out

pressure.

The pressure release valve located on the side of the pres-

sure switch, is designed to automatically release compressed air from

the compressor head and the outlet tube when the air compressor

reaches cut-out pressure or is shut off. The pressure release valve

allows the motor to restart freely. When the motor stops running, air will

be heard escaping from this valve for a few seconds. No air should be

heard leaking when the motor is running.

13

English

SAFETY VALVE

This valve (I) is designed to prevent system failures

I

by relieving pressure from the system when the

compressed air reaches a predeter mined level. The

valve is preset by the manu facturer and must not be

removed or modified in any way.

AIR INTAKE FILTER

The filter (A) is designed to clean air entering the pump.

A

To ensure the pump continually receives a clean, cool

and dry air supply the filter must always be clean and

the filter intake must be free from obstructions.

AIR TANK DRAIN VALVES

The drain valve (J) is used to remove

J

moisture from the air tank after the air

compressor is shut off.

AIR TANK PRESSURE GAUGE

The air tank pressure gauge (D) indicates air

D

E

F

pressure in the air tank.

REGULATED PRESSURE GAUGE

The regulated pressure gauge (E) indicates

the air pressure available at the outlet side of

the regulator. This pressure is controlled by the

regulator and is always less or equal to the air

tank pressure.

REGULATOR

The regulator knob (F) controls the air pressure coming from the air

tank.

To Adjust Regulator:

1. Pull regulator knob (F) out.

2. Turn knob clockwise to increase regulated pressure and

counterclockwise to decrease regulated pressure.

3. When desired pressure is shown on the regulated pressure

gauge push knob in to lock.

INSTALLATION

Assembly (Fig. 1)

INSTALLING HOSES

WARNING: Risk of unsafe operation. Firmly grasp hose in hand

when installing or disconnecting to prevent hose whip.

1. Ensure regulated pressure gauge reads 0 PSI (0 kPa).

2. Apply sealant tape to hose threads.

3. Assemble hose to air outlet (G). IMPORTANT: Do not assemble

splitters directly to the air outlet (G).

NOTE: Assembling quick connect bodies to air outlet (G) and quick

connect plugs to hose ends make connecting and disconnecting

hoses simple and easy. Quick connect bodies and plugs are

available for purchase from your local dealer or authorized service

center.

DISCONNECTING HOSES

WARNING: Risk of unsafe operation. Firmly grasp hose in hand

when installing or disconnecting to prevent hose whip.

1. Ensure regulated pressure gauge reads 0 PSI (0 kPa).

2. Remove hose(s) from air outlet(s) (G).

Lubrication and Oil

AIR COMPRESSOR

The air compressor pump was filled WITH oil at the manufacturer.

Check air compressor pump oil level before operating unit. See

Compressor Pump Oil under Maintenance.

14

English

230 Volt Conversion

D55570, D55575, D55580, D55585

To operate the compressor at 230 volts replace the

115 volt plug supplied on the motor cord with a

UL/ CSA listed plug suitable for 230 volts and the

rated amps of the compressor, see Motor

Specifications at the beginning of this manual. A 230

volt plug as shown in the diagram may be purchased

at a local hardware or electrical supply store.

1. Follow the plug manu facturer installation procedures, contact

a qualified electrician, a D

E

WALT service center or call

1-800-4-D

E

WALT for assistance. IMPORTANT: The compressor

must comply with all local and national electrical codes after the

230 volt plug is installed.

WARNING: Ensure the 230 volt cord plug end is properly

connected before operating in 230 volt mode.

2. Remove the pin on the 115/230 dual voltage

L

control switch.

3. Move the 115/230 dual voltage control

switch (L) to the 230 volt position.

4. Replace the pin.

CAUTION: Once the unit has been converted

to 230 volts the 115/230 dual control switch

can not be placed in the 115 volt position until

the cord plug is replaced with a UL/CSA listed cord plug suitable

for 115 volts and the rated amps of the compressor, See Motor

Specifications.

WARNING: Do not operate this unit until you read and understand

this instruction manual for safety, operation and maintenance

instructions.

D55170, D55180

WARNING: Risk of electrical shock. Ensure motor is discon-

nected from the power source before rewiring motor leads.

The motor supplied with this compressor is a dual voltage, 115 / 230

volts motor. It is wired for 115 volt but can be converted to 230

volt operation. Instructions for connecting the motor for operation

at 230 volt can be found printed on the label attached to the side

of the motor. After converting to 230 volt operation, the attached

three-prong 115 volt motor cord assembly must be replaced with

a three-prong 230 volt motor cord assembly. The 230 motor cord

assembly may be purchased at your local hardware or electrical

supply store. Follow the motor cord manu facturer installation proce-

dures, contact a qualified electrician, a D

E

WALT service center or

call 1-800-4-D

E

WALT for assistance. IMPORTANT: The compressor

must comply with all local and national electrical codes after the 230

volt motor cord is installed.

WARNING: Do not operate this unit until you read and understand

this instruction manual for safety, operation and maintenance

instructions.

D55390, D55395

The motor supplied with this compressor is 230 volt.

Grounding Instructions

WARNING: Risk of electrical shock. In the event of a short

circuit, grounding reduces the risk of shock by providing an escape

wire for the electric current. This air compressor must be properly

grounded.

The portable air compressor is equipped with a cord having a

grounding wire with an appropriate grounding plug.

15

English

1. The cord set and plug (N) with this unit

O

P

115V

N

contains a grounding pin (O). This plug

MUST be used with a grounded outlet

(P).

IMPORTANT: The outlet being used must

be installed and grounded in accordance

with all local codes and ordinances.

2. Ensure the outlet being used has the

230V

P

N

O

same configuration as the grounded

plug. DO NOT USE AN ADAPTER.

3. Inspect the plug and cord before each

use. Do not use if there are signs of

damage.

4. If these grounding instructions are

not completely understood, or if in doubt as to whether the

compressor is properly grounded, have the installation checked

by a qualified electrician.

DANGER: Risk of electrical shock. IMPROPER GROUNDING

CAN RESULT IN ELECTRICAL SHOCK.

•

Do not modify the plug provided. If it does not fit the available

outlet, a correct outlet should be installed by a qualified electri-

cian.

• Repairs to the cord set or plug MUST be made by a qualified

electrician.

Extension Cords

Using extension cords is not recommended. The use of extension

cords will cause voltage to drop resulting in power loss to the motor

and overheating.

Instead of using an extension cord, increase the working reach of

the air hose by attaching another length of hose to its end. Attach

additional lengths of hose as needed.

If an extension cord must be used, be sure it is:

• a 3-wire extension cord that has a 3-blade grounding plug, and

a 3-slot receptacle that will accept the plug on the product

• in good condition

• no longer than 50 feet (15.2 m)

• 12 gauge (AWG) or larger. (Wire size increases as gauge num-

ber decreases. 10 AWG and 8 AWG may also be used. DO NOT

USE 14 OR 16 AWG.)

Voltage and Circuit Protection

Refer to Voltage and Minimum Branch Circuit Requirements

under Motor Specifications.

CAUTION: Certain air compressors can be operated on a

15 amp circuit if the following conditions are met.

• Voltage supply to circuit must comply with the National Electrical

Code.

• Circuit is not used to supply any other electrical needs.

• Extension cords comply with specifications.

• Circuit is equipped with a sufficient size circuit breaker or time

delay fuse for the motor set up, see Motor Specifications. NOTE:

If compressor is connected to a circuit protected by fuses, use

only time delay fuses. Time delay fuses should be marked “D” in

Canada and “T” in the US.

If any of the above conditions cannot be met, or if operation of the

compressor repeatedly causes interruption of the power, it may be

necessary to operate it from a circuit capable of providing a larger

amount of current, see Motor Specifications. It is not necessary to

change the cord set.

16

English

Compatibility

Air tools and accessories that are run off the compressor must be

compatible with petroleum based products. If you suspect that a

material is not compatible with petroleum products, an air line filter

for removal of moisture and oil vapor in compressed air is required.

NOTE: Always use an air line filter to remove moisture and oil vapor

when spraying paint.

Location

CAUTION: Risk of personal injury. In order to avoid damaging

the air compressor, do not allow the unit to be tilted more than 10º

when operating.

Place air compressor at least 12" (30.5 cm) away from obstacles that

may prevent proper ventilation. Keep unit away from areas that have

dirt, vapor and volatile fumes in the atmosphere which may clog and

gum up the intake filter and valves, causing inefficient operation.

HUMID AREAS

In frequently humid areas, moisture may form in the pump and

produce sludge in the oil, causing running parts to wear out

prematurely. Excessive moisture is especially likely to occur if the unit

is located in an unheated area that is subject to large temperature

changes. Two signs of excessive humidity are external condensation

on the pump when it cools down and a “milky” appearance in

compressor oil. You may be able to prevent moisture from forming in

the pump by increasing ventilation or operating for longer intervals.

NOISE CONSIDERATIONS

Consult local officials for information regarding acceptable noise

levels in your area. To reduce excessive noise, use vibration mounts

or silencers, relocate the unit or construct total enclosures or baffle

walls. Contact a D

E

WALT service center or call 1-800-4-D

E

WALT for

assistance.

ELECTRICAL

Refer to all safety instructions before using unit. Observe extension

cord safety instructions if necessary. Always move the On/Off switch

to the OFF position before removing the plug from the outlet.

TRANSPORTING

WARNING: Risk of injury from lifting. Unit weighs more than 160

lbs. (72.6 kg) Do not move or lift without assistance.

CAUTION: Risk of personal injury. The wheels and handle do not

provide adequate clearance, stability or support for pulling the unit

up and down stairs or steps. The unit must be lifted or pushed up

a ramp.

When transporting the com-

Q,R

S

Q,R

Q

pressor in a vehicle, trailer,

etc. ensure that the air tank is

drained and the unit is secured

and placed on a flat horizontal

surface. NOTE: Use

recommended tie down points

(Q) when transporting. Use

care when driving so to avoid

Q,R

S

Q,R

Q

tipping the unit over in the

vehicle. Damage can occur to

the unit or surrounding items

if unit is tipped. Use a ramp if

loading or unloading the unit

from a height of more than

12" (30.5 cm).

LIFTING

Always use two people when lifting and lift from the recommended

lift points (R).

17

English

WARNING: Risk of injury from lifting. Unit weighs more than 160

lbs. (72.6 kg) Do not move or lift without assistance.

MOVING

1. Grasp handle (S) of compressor and lift compressor high

enough so unit can be rolled on the front tire(s).

WARNING: Risk of unsafe operation. Ensure proper footing and

use caution when rolling compressor so that unit does not tip or

cause loss of balance.

2. When location is reached slowly lower rear of compressor to

ground. Always store compressor in a horizontal position.

PREPARATION FOR USE

Pre-Start Checklist (Fig. 1)

1.

Ensure the On/Off switch (C) is in the OFF position.

2.

Plug the power cord into the correct branch circuit receptacle.

See Voltage and Circuit Protection under Installation.

3. Ensure air tank is drained, see Draining Air Tank under

Maintenance.

4. Ensure the drain valve (J) is closed.

5. Ensure safety valve (I) is functioning properly, see Checking

Safety Valve under Maintenance.

6. Check pump oil level, see Compressor Pump Oil under

Maintenance.

CAUTION:

Risk of property damage. Do not operate without oil or

with inadequate oil.

D

E

WALT

is not responsible for compressor failure

caused by inadequate oil.

7. Turn regulator knob (F) counterclockwise until fully closed. Ensure

regulated pressure gauge reads 0 PSI (0 kPa).

8. Visually inspect drive belt. Replace belt if frayed, cracked, or worn.

NOTE: Outer belt cover must be removed to inspect drive belt.

9. Visually inspect air hose, replace if needed.

10. Attach hose and accessories.

WARNING: Risk of unsafe operation. Firmly grasp hose in hand

when installing or disconnecting to prevent hose whip.

WARNING: Risk of Bursting. Too much air pressure causes a

hazardous risk of bursting. Check the manufacturer’s maximum

pressure rating for air tools and accessories. The regulator outlet

pressure must never exceed the maximum pressure rating.

11. Ensure all covers and labels are in place, legible (for labels) and

securely mounted. Do not use compressor until all items have

been verified.

Initial Set-up

(Fig. 1)

WARNING: Do not operate this unit until you read and understand

this instruction manual for safety, operation and maintenance

instructions.

BREAK-IN PROCEDURE

WARNING: Serious damage may result if the following break-in

instructions are not closely followed.

This procedure is required before the air compressor is put into

service for the first time and when the check valve or a compressor

pump/motor has been replaced.

1. Ensure the On/Off switch (C) is in the OFF position.

2.

Plug the power cord into the correct branch circuit receptacle.

See Voltage and Circuit Protection under Installation.

3. Open the drain valve (counterclockwise) fully to permit air to

escape and prevent air pressure build up in the air tank during

the break-in period.

4. (

D55170, D55180) Rotate the manual lock pilot valve lever to the

open position to assist with start up.

18

English

5. Move the On/Off switch to the ON position. The compressor will

start.

6. Run the compressor for 20 minutes.

7. After 20 minutes, close the drain valve by turning clockwise s

o

the air tank pressure can build

.

(D55170, D55180) NOTE: R

otate the manual lock on the pilot

valve into the closed position.

NOTE: After the compressor

reaches blow-off pressure the unit will continue to run but will

not build additional tank pressure until the air is used and the

pilot valve reset pressure is reached. A slight air noise may be

heard while the air is being unloaded through the pump head.

8. Compressed air will be available until it is used or bled off.

OPERATING PROCEDURES

Start-up (Fig. 1)

1. Follow Pre-Start Checklist under Preparation for Use.

2.

(

D55170, D55180) Rotate the manual lock pilot valve lever to the

open position to assist with start up.

3. Move the On/Off switch to the ON position. The compressor will

start.

4.

(

D55170, D55180) Rotate manual lock pilot valve lever to the

closed position to allow air tank pressure to build.

5. Allow compressor to pump up to blow-off/cut-off pressure.

(

D55170, D55180) NOTE: After the compressor reaches blow-

off pressure the unit will continue to run but will not build

additional tank pressure until the air is used and the pilot valve

reset pressure is reached. A slight air noise may be heard while

the air is being unloaded through the pump head.

NOTE: If any unusual noise or vibration is noticed, stop the compressor

and refer to the troubleshooting section.

6. Attach hose and accessory.

CAUTION: Risk of unsafe operation. Compressed air from the unit

may contain wa ter condensation and oil mist. Do not spray un fil tered

air at an item that could be damaged by moisture. Some air op er ated

tools or de vic es may require filtered air. Read the in struc tions for the

air tool or device.

7. Adjust regulator (F) to desired setting. See Regulator under

Features.

Dual Control Operation (Fig. 1)

D55395, D55570, D55575, D55580, D55585

NOTE: Compressor must be running when performing the following

operation

WARNING: Hot surfaces. Risk of burn. Aftercooler, pump head,

and surrounding parts are very hot, do not touch (see the Hot

Surfaces identified in Fig. 2). Allow compressor to cool prior to

servicing.

WARNING: Risk of moving parts. Keep your hair, clothing, and

gloves away from moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts. Air vents may cover moving parts and

should be avoided as well.

STOP START MODE

1. Ensure the On/Off switch (C) is in the OFF position.

2.

Plug the power cord into the correct branch circuit receptacle.

See Voltage and Circuit Protection under Installation.

3. Open the drain valve (counter-clockwise).

4. Move the On/Off switch to the ON position. The compressor will

start.

5. Turn knob on top of pilot valve (H) clockwise until fully closed.

6. Close drain valve (clockwise).

19

English

WARNING: Risk of property damage. Over tightening the Pilot Valve

knob can cause damage to the pilot valve.

7. Allow compressor to reach cut-out pressure. If compressor does

not stop, contact a D

E

WALT service center or call 1-800-4-D

E

WALT

for assistance.

IMPORTANT: Always turn pilot valve knob counter-clockwise until it

stops before moving the On/Off switch (C) to the OFF position

CONSTANT RUN MODE

1. Ensure the On/Off switch (C) is in the OFF position.

2.

Plug the power cord into the correct branch circuit receptacle.

See

Voltage and Circuit Protection under Installation.

3. Open the drain valve (counter-clockwise).

4. Move the On/Off switch to the ON position. The compressor will

start.

5. Turn knob on top of pilot valve (H) fully counter-clockwise until fully

open.

6. Close drain valve (clockwise).

WARNING: Risk of property damage. Over loosening the pilot valve

knob can cause damage to the pilot valve.

7. The compressor is now in constant run mode. If compressor shuts

off, contact a D

E

WALT service center or call 1-800-4-D

E

WALT for

assistance.

NOTE: For proper operation the pilot valve blow-off pressure must be

below the pressure switch cut out pressure.

Shut-down

1 Move On/Off switch (C) to the OFF position. NOTE: If finished

using compressor, follow Steps 2 - 6. IMPORTANT: (D55390,

D55395, D55570, D55575, D55580, D55585) Always turn pilot

valve knob clockwise until it stops before moving the On/Off switch

(C) to the OFF position when unit is in the constant run mode.

2. Turn regulator knob (F) counterclockwise until fully closed. Ensure

regulated pressure gauge reads 0 PSI (0 kPa).

3. Remove hose and accessory.

4. Drain the air tank,

see Draining Air Tank under Maintenance

.

Ensure air tank pressure gauge reads 0 PSI (0 kPa).

WARNING: Risk of bursting. Water will condense in air tank. If not

drained, water will corrode and weaken the air tank causing a risk of

air tank rupture.

5. Allow the compressor to cool down.

6. Wipe air compressor clean and store in a safe, non-freezing area.

MAINTENANCE

The following procedures must be followed when maintenance or

service is performed on the air compressor.

1. Ensure On/Off switch is in the OFF position.

2. Remove air compressor plug from outlet.

3. Drain air tank.

4. Allow air compressor to cool down before starting service.

NOTE: All compressed air systems contain maintenance parts (e.g.,

oil, filters, separators) that are periodically replaced. These used parts

may contain substances that are regulated and must be disposed of in

accordance with local, state, and federal laws and regulations.

NOTE: Take note of the positions and locations of parts during

disassembly to make reassembly easier.

NOTE: Any service operations not included in this section should be

performed by a D

EWALT factory service center or a DEWALT autho-

rized service center.

20

English

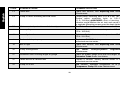

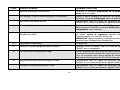

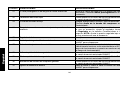

Maintenance Chart

Procedure Daily Weekly Monthly 1 year or

200 Hours

Check safety valve

X

Inspect air filter

+

X

Drain air tank***

X

Check pump oil level

X

Change pump oil**

+

X

Oil leak inspection

X

Inspect drive belt

X

Check drive belt tension

X

Check pulley/flywheel

alignment

X

Check for unusual noise/

vibration

X

Check for air leaks*

X

Clean compressor exterior

X

* To check for air leaks apply a solution of soapy water around joints.

While compressor is pumping to pressure and after pressure cuts out,

look for air bubbles to form.

** The pump oil must be changed after the first 20 hours or operation.

Thereafter, when using

DEWALT

synthetic compressor oil, change oil

every 200 hours of operation or once a year, whichever comes first.

*** Drain tanks daily or after four hours of use.

+ Perform more frequent in dusty or humid conditions.

Checking Safety Valve (Fig. 1)

WARNING: Hot surfaces. Risk of burn. Aftercooler, pump head, and

surrounding parts are very hot, do not touch (see the Hot Surfaces

identified in Fig. 2). Allow compressor to cool prior to servicing.

WARNING: Risk of bursting. If the safety valve does not work

properly, over-pressurization may occur, causing air tank rupture or

an explosion.

Before starting compressor, pull the ring on the safety valve to

make sure that the safety valve operates freely. If the valve is stuck

or does not operate smoothly, it must be replaced with the same

type of valve.

Checking Air Filter Element (Fig. 1)

WARNING: Hot surfaces. Risk of burn. Aftercooler, pump head, and

surrounding parts are very hot, do not touch (see the Hot Surfaces

identified in Fig. 2). Allow compressor to cool prior to servicing.

1. Ensure On/Off switch is in the OFF position.

2. Allow unit to cool.

3. Remove filter (A) top from filter base by turning filter counter-

clockwise about 5 degrees.

4. Separate filter top from base.

5. Remove element from filter base.

6. If element needs cleaning, blow out with air. Replace if needed.

Purchase replacement parts from your local dealer or authorized

service center. Always use identical replacement parts.

7. Place element back in filter base.

8. Reconnect filter top to filter base. While pushing in, rotate clock-

wise 5 degrees.

CAUTION: Risk of unsafe operation. Do not operate without air

inlet filter.

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

DeWalt D55570 Manuel utilisateur

- Catégorie

- Compresseurs d'air

- Taper

- Manuel utilisateur

dans d''autres langues

- English: DeWalt D55570 User manual

- español: DeWalt D55570 Manual de usuario

Documents connexes

-

DeWalt D55371 Manuel utilisateur

-

DeWalt D55570 Manuel utilisateur

-

DeWalt D55394 Manuel utilisateur

-

DeWalt Emglo D55153 Manuel utilisateur

-

DeWalt D55154 Manuel utilisateur

-

DeWalt D55154 Manuel utilisateur

-

DeWalt D55143 Manuel utilisateur

-

DeWalt D55390 Manuel utilisateur

-

DeWalt D55570 Manuel utilisateur

-

DeWalt D55276 Manuel utilisateur